- Offer Profile

-

Your Partner for High Precision

in Positioning and Metrology.SmarAct develops high-performance solutions for handling and positioning in the micro- and nanometer range. The broad product portfolio – from single positioners to complex parallel kinematics, miniaturized robots and easy-to-use control systems – is completed by sophisticated measuring equipment based on powerful laser interferometers.

Automation

Automation Technologies

- Our flexibility in developing both partially and fully automated systems to exactly your needs is rooted in the strict modularity of our approach in hardware and software.

Automation Platform

-

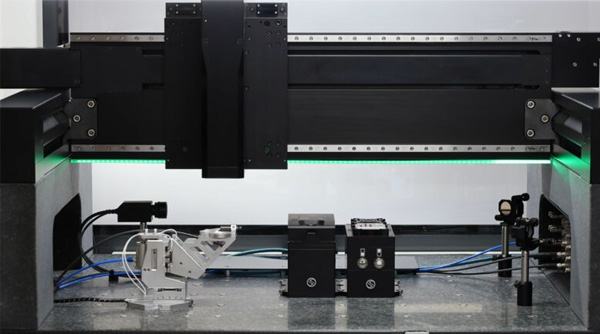

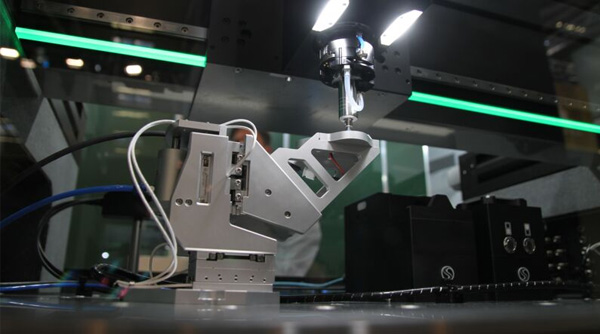

The microassembly platform P50 provides for the fundamental infrastructure. This includes central control systems and a common network and media supply. It extends to a motion system for large and quick movements for component feeding and withdrawal of assembled products. It also establishes a boundary separating delicate processes from the surroundings on the production floor.

A fan filter unit (FFU) can be integrated in order to maintain air cleanliness inside the main chamber. Mechanical interfaces exist for integration of feeding systems.

Processes are implemented by adding generic or process specific modular tools and made available to the production floor through the control software.

Modular Tooling

-

Modular tools are introduced specific to the needs of your particular process. This ranges from generic handling and vision modules to supports for components and dispensing equipment for adhesives, to name a few. Dedicated modules exist for very special functionality.

All modules share a common interface - system bus, power supplies, pressurized air and vacuum supplies - either on the working space's base or at gantry system. A module's functions are mirrored in software modules that are integrated to a powerful control software.

Modular Software

-

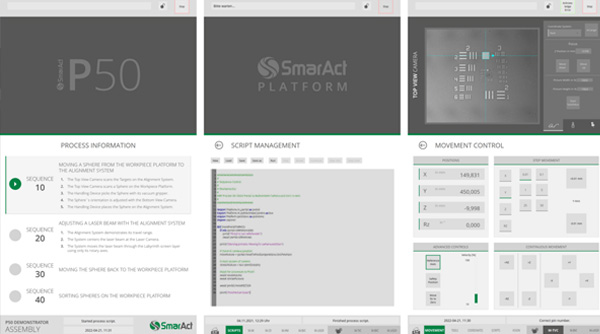

Modularity does not stop at hardware. Hardware tools are mirrored in software modules that are readily integrated into the control application according to the configuration of the microassembly station.

The controls software offers an intuitive user guidance concept which adapts perfectly to the user’s role. Interface options range from a basic operator GUI, guiding the user through processes with short and engaging video tutorials, to a fully featured developer interface.

Process control is achieved through our scripting framework. This includes programming movement sequences and triggering alignment routines. Each script is user editable that makes it possible to adjust processes on the fly.

For prototyping the process every function of the platform itself and of all its integrated modules are operated through touch-optimized interfaces.

Dedicated Modules

-

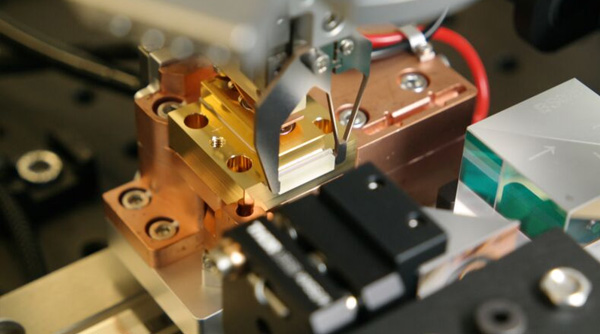

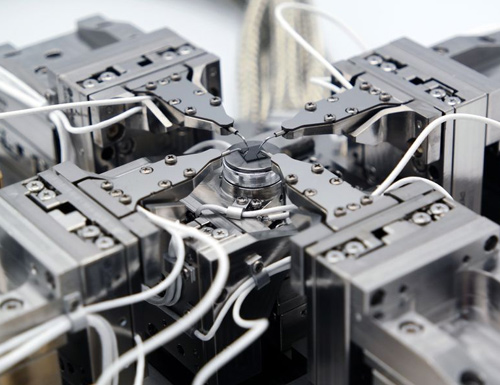

Some modules are very specific to a particular process. Common interfaces and a decentralized approach minimize the effort of integration. An example is the process of aligning lenses for shaping the beam of high power laser diodes.

We have integrated our experience with fast axis and slow axis collimation into our LensAlignmentModule. The hardware integrates several sensors for beam profiling and power measurement as well as filter adaption to incoming laser powers. Based on the analysis of available sensor data the corresponding software module controls the active alignment of the FAC and SAC lenses

Nanopositioning and Microgripping Technology

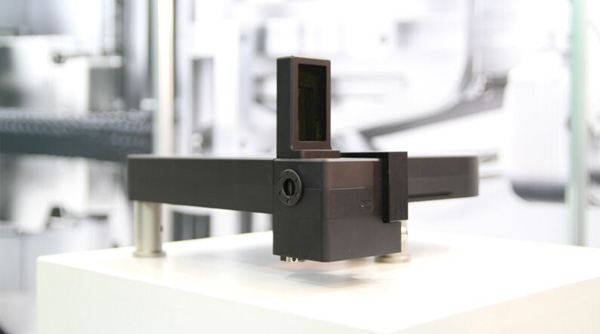

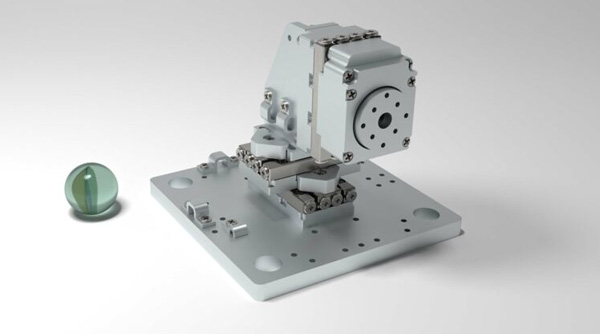

- The most advanced products from the entire SmarAct Group are used and combined with further state-of-the-art technology to provide precise, fast and reliable solutions. The best-selling positioning systems such as the hexapod-like SmarPods and XYZ positioning systems from SmarAct can be expanded with versatile microgrippers and are then integrated as highly precise robotic modules.

Automation Products

- From process developement and contract manufacturing to modular automation systems and service agreements.

Process Development for Microassembly Challenges

-

Developing the assembly of your products into automated processes

In order to develop the most efficient, economic and reliable assembly or processing concepts we have established our own application laboratory. Here we can build first mock up systems to understand your product and develop the (assembly) processes directly on one of our production platforms that is available for process development at all times.

Our team of mechanical, electrical and software engineers has access to a vast variety of tools including machining equipment to ensure short learning cycles for identifying the most suitable concept for your product.

With a proven concept at hand, we can continue development to provide either a desktop or a fully automated manufacturing platform to you. Alternatively, we can use our in house production capabilities to manufacture parts for you by means of contract manufacturing. This will not exclude the possibility to develop and deliver an according manufacturing platform at a later stage of your product's life cycle.

Desktop Solutions for Microassembly Projects

-

Easily transferable desktop solutions for the beginning of your product's life cycle

For microassembly projects with an emphasis on product development desktop solutions are there to speed up the feedback cycles. Highly precise nanopostioning and microgripping technology is extended with supportive functions and modules such as the Lens Alignment Module.

Case Study: Automated FAC Alignment StationThe FAC Alignment Station automates the assembly of Fast Axis Collimation (FAC) lenses to laser diodes. The process starts with contacting laser modules and completes with the final measurements of beam collimation after adhesive curing. The alignment of the lens in front of a multi-emitter laser diode bar is achieved in less than 25 seconds.

Automation Stations for Microassembly Production

-

Fully automated production stations based on the microassembly platform P50

Our P50 manufacturing platform acts as a reliable basis into which your process can be integrated to offer you the most suitable system without the necessity to develop the entire production environment from scratch.

Its modular structure offers fully automated manufacturing capabilities in combination with easy accessibility for set-up, maintenance and service to - keep downtimes low and to adapt to changes in the product's life cycle.

For production the control interface offers one-touch operation. At the same time you have full control over the process and even the option to make changes to certain scripts directly in the HMI, depending on the operator’s administration rights.

The platform life cycle can be extended well beyond the initial process by constantly adapting, revising and adding new modules to fit new variants or even entirely new products. Every P50 is delivered as a turn-key solution that can be set up by our professional team of technicians to ensure a seamless start of production within your facility.

Contract Manufacturing for Engineering and Series

-

Production of engineering samples and small series when a fully automated microassembly station is not an option yet

Whether your product is still early in its life cycle or you just need a small number of engineering samples, your own desktop station or microassembly platform may not be an option (yet). In addition to process development our application laboratory offers the possibility for assembling engineering samples - and contract manufacturing your products in small to medium series is an option as well.

Once your production demand increases and you decide to produce inhouse, the process is transferred to your own automated production station. Your advantage - the process is already validated and process know-how needs only to be shared and generated once.

Service Agreements

-

If you have decided to use one of our assembly systems in your production or prototyping environment, it is of course also important to clarify how possible maintenance cycles can be scheduled or how quickly even unlikely machine down times will be remedied to enable the greatest possible availability of your production capabilities.

Just like our automation systems, our service agreements are also based on a modular approach and define the framework for our joint business relationship to cover your requirements in terms of quality, response times, maintenance intervals and much more.

To this end, we offer the options of customer-based and multi-level service agreements. In either case, you have the option to completely customize these service agreements to your needs.

Are you interested in more information about our service agreements? Simply contact us so that we can also put together a customized package for you and your application.

s

Positioning Systems

-

Most applications in academia and industry require more than one degree of freedom when it comes to the precise positioning of samples, tools or equipment.

SmarAct Modular System

-

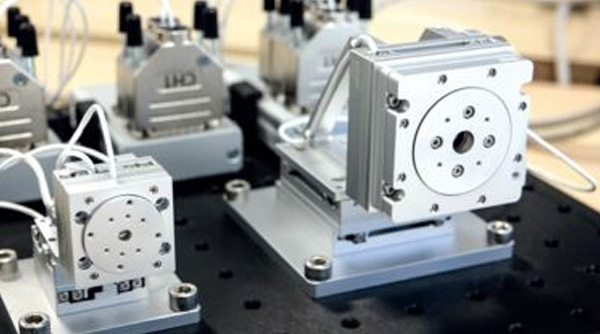

Change is a constant in academic research as well as in industrial manufacturing. Equipment needs to be adaptable in order to address new requirements and to keep investments manageable.

SmarAct's modular system is a product concept which allows customers to adapt, modify and reconfigure even complex multi-axis positioning systems in the field, based on stringent modularity and intercompatibility between linear, rotation and goniometer stages. It allows the combination of compatible actuators of the CLS, SLC, CGO, DLS, MLS and SR product series to form complex and reconfigurable positioning setups. Standardized angle brackets, adapters and accessories provide the flexibility needed to combine SmarActÂs single-axis stages into convertible instruments while guaranteeing the highest precision and quality of the positioning solution thus created. Due to the high modularity and large number of components and accessories, the SmarAct modular system offers almost endless possibilities to build your very own setup. The positioning systems presented in the following serve as examples to show the possibilities and onsite reconfigurability of SmarActÂs modular system.

Pre-Defined Positioning Systems

-

Within the scope of SmarActÂs modular system, fully pre-built and pre-configured positioning systems are available. These pre-defined positioning systems are customer inspired and represent the systems and platforms most commonly requested by our customers. The systems are very versatile and can be used for a wide range of positioning tasks. In the following, the systems are displayed including a breadboard adapter. All systems are also available without the breadboard adapter if a direct mounting method is preferred. On the basis of these pre-defined systems, and in combination with customized connection elements and customized stages, very complex serial positioning systems can be realized. Some of them are presented on the following pages. If your application requires a special configuration that is not shown in the following, please do not hesitate to contact our application specialists to discuss your applicationÂs requirements.

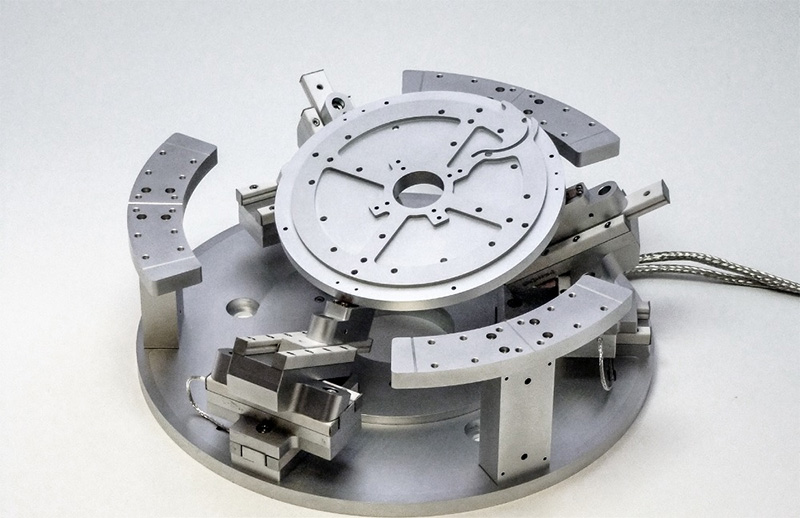

SMARPOD - A Hexapod-like Positioning System

-

The SMARPOD offers the same degrees of freedom as classical hexapod systems while guaranteeing high resolution and repeatability. Compared to serial kinematic systems with six degrees of freedom SMARPODs exhibit a higher stiffness and a higher rigidity. A user friendly software package allows easy integration into your own control environment assuring a very short setup time. SMARPODs, like all other SmarAct products, is highly customizable and can be integrated into completely customized setups. Regardless if your application requires only a modified base or top plate or a completely different configuration do not hesitate to contact us to discuss your requirements and the best-suited solution. Let us assist you in bringing your idea to life.

TRIPOD - A Hexapod-like Positioning System

-

The TRIPOD product series consists of compact and modular multidimensional positioning systems that combine serial and parallel kinematics in a hybrid design. Compared to classic hexapods, which are limited in rotation around their Z-axis, SmarAct's TRIPODs offer continuous rotation and high stiffness over the entire working range.

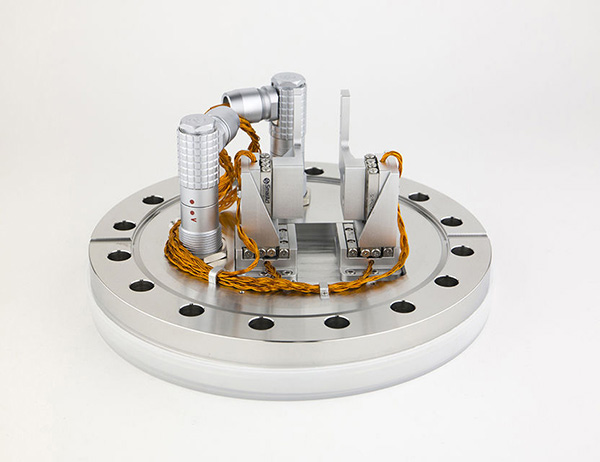

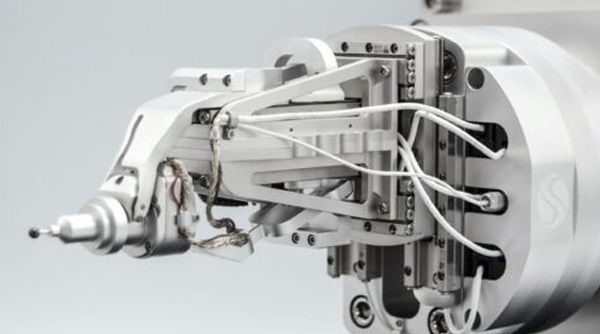

SMARGON - Microrobot

-

Highest precision, robustness and reliability are the top priority properties when selecting positioning equipment for the use in science and industry. SmarAct has designed a robotic positioning system with six degrees of freedom to be used for various positioning tasks in experiments or micro-assembly setups. Its compact design reduces results in a slim silhouette and allows large rotary angles even in confined spaces. With a smart automated calibration routine, it achieves a sphere of confusion in the single-digit micrometer range for all rotary axis.

The SMARGON is a positioning system with six degrees of freedom based on a combination of serial and parallel kinematics mounted to a heavy duty rotation stage, defining the ?-axis of the device. This rotation platform can either be a Direct-Drive or a piezo-driven stage. The sophisticated hybrid kinematic approach allows the end effector which can also be a component or another payload up to 50 grams to be positioned in X, Y and Z direction and to be rotated in ?-, ?- and ?-direction.

The SMARGON control system calculates the partially parallel kinematic transformation, which allows for direct positioning of the end effector which makes the teaching of poses an easy task. The compatibility with the MCS2 Modular Control System guarantees an easy integration into existing control environments and an intuitive way to command the positioning system.

Optical Microscopy

-

In life sciences, precise sample handling and manipulation is the most important part of day-to-day operations at a microscopy workstation; therefore, the equipment used must be extremely precise and reliable.

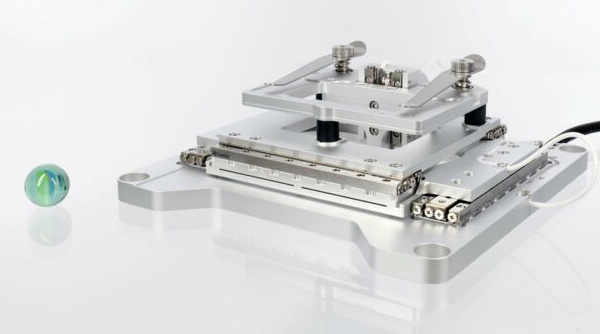

Microscope Stages and ManipulatorsTo meet these requirements, SmarAct has developed microscope stages that not only allow the specimen to be positioned in two dimensions, but also enable the mounting of micro-manipulation systems for in situ sample manipulation. The microscope stages themselves are based on compact linear stages and allow long travel ranges with nanometer precision and highest closed-loop repeatability.

In addition to the standard universal object slide holder, unified well plate holders and petri dish holders are available. For easy and fast exchange of slides and coverslips in high throughput experiments, a magnetic holder is also available. Micro-manipulation systems are very versatile devices when it comes to handle pipettes, micro-knives, micro-grippers, micro-injectors or other mechanical or electrical probes. Our portfolio includes several different manipulators with three and four degrees of freedom for the most common tasks.

Larger stages support not just one, but two or more micro-manipulators, providing even more degrees of freedom for specimen manipulation. All manipulators can be moved completely independently and can of course be equipped with different tools and axis configurations.

Opto-Mechanics

-

Because of their miniaturization and overall compactness as well as their modularity SmarAct positioning systems are the optimal solution for optical setups and experiments in the field of optics. In addition to multi-axes positioning systems we have also developed a large number of dedicated opto-mechanical components like motorized tip-tilt mirror mounts, iris diaphragms, filter wheels, rectangular apertures and beam shutters. Combined with positioning sensors, they enable closed-loop position control and are perfectly suited for automated or remotely controlled experimental setups.

To address the high demand of in-vacuum optical setups nearly all components are available as high vacuum variants. For setups where reflections have to be omitted Black anodized versions of the components are available. All presented opto-mechanical components and devices in this catalog section can be highly customized. Our applications scientists are eager to discuss customized solutions to exactly match your requirements.

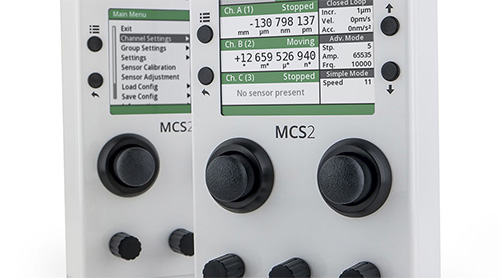

Control Systems and Software

-

Every successful positioning solution rests on at least two pillars. The first is defined by the mechanical part of the solution, the second by the electronics and software to control it. Our sophisticated and easy to use control systems together with our intuitive software solutions and software development kits (SDKs) are the basis for a fast and easy integration of our positioning technology into your application. SmarActÂs control system portfolio consists of a wide variety of components optimized for different applications and integration scenarios. From single channel hand held controllers up to rack mountable modules with up to 18 channels, we are able to equip you with the right tools.

Positioning Stages

-

Miniaturization in all fields of application increases the demand and requirements for compact and high-resolution positioning solutions.

Piezo Stick-Slip Stages: Linear Stages

-

SmarActÂs product portfolio includes several lines of linear positioning stages. Each line was developed with our customers requirements in mind. The full compatibility between the components of the different product lines allows to select stages with specific key features to combine them into sophisticated multi-axis systems.

SLC Series

-

Linear stages of the SLC series are based on linear slides with crossed roller bearing. SmarActÂs SLC stages are characterized by their compactness, high rigidity and straightness. They are ideally suited for positioning systems where stability and high accuracy are top priorities. Optionally, the stages are available in specialized versions for use in high and ultra-high vacuum or can be manufactured in different material combinations. SLC linear stages are available in two different series, which differ primarily in width and height.

CLS-Series

-

Linear stages of CLS series are the best choice for multi-axis setups in high availability applications, since they are equipped with exchangeable drive units to assure quick and easy on-site servicing.

Their stringent compatibility with the SmarAct modular system enables them to be easily integrated into multi-axis systems: Their mounting hole pattern is perfectly matched to the mounting of our rotation stages and goniometers.

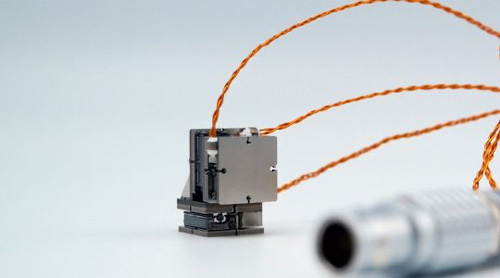

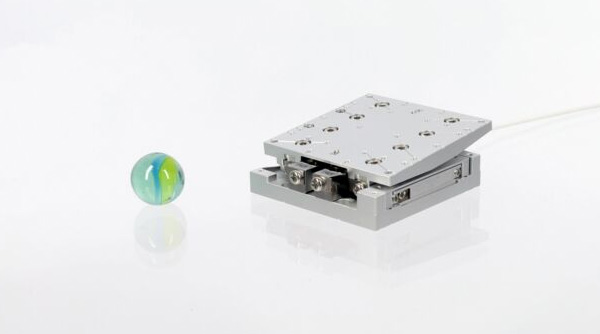

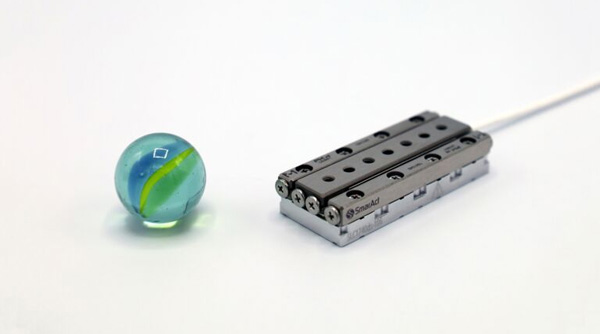

SL Series

- Linear stages of the SL series are ultra-compact and specifically designed for setups with space constraints or requirements for extreme miniaturization. While maintaining their miniature size, the stages offer comparatively long travel ranges and can be combined to build complex multi-axis systems. Stages of the SL series are 11 mm in width and 5.2 mm in hight

CLL Series

-

Linear stages of the CLL series are based on recirculating ball slides. Tey offer standard travel ranges of 99, 179, 259 and 379 mm. Since special lengths are of course available on request, these long travel stages are the optimal solution for precise positioning over long distances in limited spaces. CLL stages are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. CLL stages can be operated by any of our control systems for stick-slip drives.

It is also possible to place multiple slides on the same rail and move them independently. This allows for fully motorized optical bench setups.

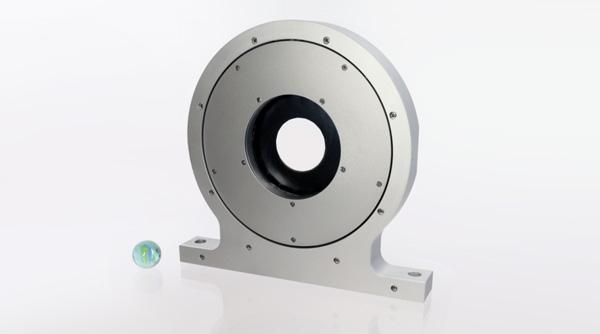

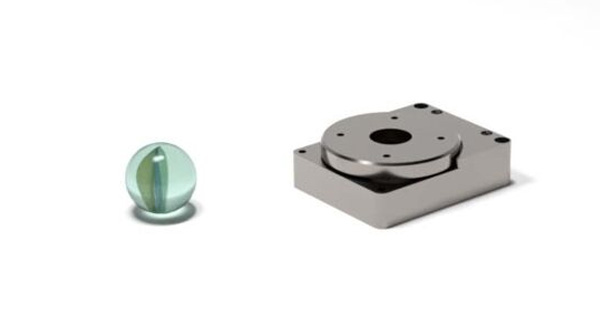

Piezo Stick-Slip Stages: Rotation Stages

-

Based on the SmarAct piezo drive technology rotation stages and platforms are available. They can be easily combined with each other or with our linear positioning stages to form more complex set- ups like gimbals, rotatable Eulerian cradles, multi-axes or multi-rotation positioning systems. SmarAct rotation stages allow for continuous and mechanically unlimited rotation. They differ by blocking force, velocity and outer dimensions as well as by the available options when it comes to integrated position sensors and vacuum compatibility.

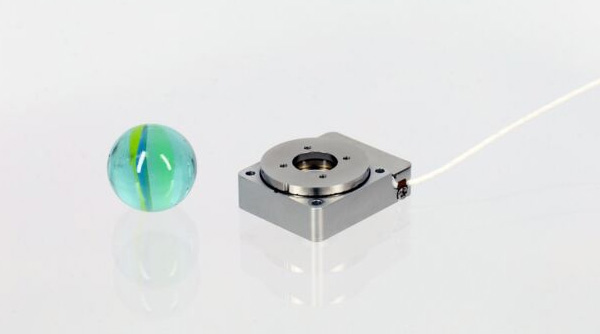

SR-1908 - Rotation Stage

-

The SR-1908 is our smallest standard rotation stage. The very robust stainless steel bearing together with an aperture of 7 mm enables a broad range of possible applications.

The SR-1908 is our most compact and cost efficient rotation stage. With its small outer dimensions the stage is a perfect solution for setups with space constraints.

SR-2013 - Rotation Stage

-

The SR-2013 is our lightest closed-loop rotation stage. An integrated ceramic precision bearing is the reason for the ultra-high accuracy as well as the extremely low radial run-out.

It is also available with different options like ultra-high vacuum compatibility or as a fully non-magnetic version.

SR-2812 - Rotation Stage

-

The SR-2812 is a small closed-loop rotation stage with an aperture opening of 9 mm.

A tailored, backlash-free ceramic bearing leads to a very high accuracy and an extremely low radial runout. This stage is available with different options like ultra-high vacuum compatibility or as a fully non-magnetic version.

SR-3211 - Rotation Stage

-

The SR-3211 rotation stage is designed to be easily mounted onto linear piezo stages of the CLS-32 or SLS-32 Series.

It is also available with different options like ultra-high vacuum compatibility or as a fully non-magnetic version.

SR-4011- Rotation Stage

-

Due to the high-load stainless steel bearing, the SR-4011 is very robust. Compared to the footprint, the height is relatively low, making this stage an excellent choice for integration into flat positioning systems.

The SR-4011 rotation stage has a square base and exhibits a free aperture opening of 9 mm in diameter. It is also available in a high vacuum compatible version.

SR-4513 - Rotation Stage

-

Due to the high-load stainless steel bearing, the SR-4513 is very robust. Compared to the footprint, the height is relatively low, making this stage an excellent choice for integration into flat positioning systems.

The SR-4513 rotation stage has a square base and exhibits a free aperture opening of 8 mm in diameter.

SR-5014 - Rotation Stage

-

The integration of a microsensor makes the rotation stage SR-5014 the most cost effective closed-loop rotary positioner in our product line.

The SR-5014 rotation stage was designed with the compatibility to SmarAct’s CLS and SLS Series in mind allowing them to be easily mounted to linear stages of this Series and to goniometer stages of the SGO Series.

SR-5714 - Rotation Stage

- Designed with an aperture of 25 mm, the very robust rotation stage SR-5714 can be used for a broad range of applications.

SR-5714C - Rotation Stage

-

This robust rotation stage can be used also for applications in harsh environments, down to ultra high vacuum environments.

The SR-5714C is equipped with a ceramic bearing while exhibiting the same aperture opening of the SR-5714 of 25 mm. It is available in an ultra-high vacuum compatible and non-magnetic version and is the right solution if robustness and the applicability in harsh environments is top priority.

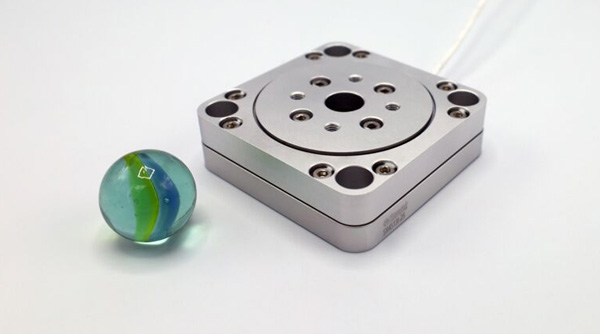

SR-7012 - Rotation Stage

-

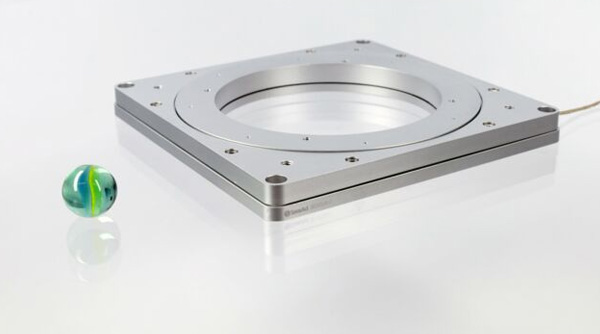

With its large platform and aperture opening the SR-7012 Rotation Stage is one of the most versatile rotation stages available

With its square base, its rotation platform diameter of 60 mm and a free aperture opening of 30 mm the rotation stage SR-7012 is very versatile. Because of its low height of only 12 mm and its overall ruggedness it can be used to carry bigger and heavier positioning setups.

SR-9219 - Rotation Stage

- The SR-9219 rotation stage was designed with the compatibility to other SmarAct Product Series in mind allowing it to be easily mounted to linear stages of the CLS-92, SLS-92 and MLS-92 Series

SR-9219C - Rotation Stage

-

The SR-9219C stage is equipped with a ceramic bearing offering full ultra-high vacuum compatibility

Beside the vacuum compatibility, versions made of non-magnetic materials are also possible. Its outer dimensions and its mounting hole pattern allows this rotation stage to be directly mounted onto CLS-92, SLS-92 and MLS-92 Series linear stages.

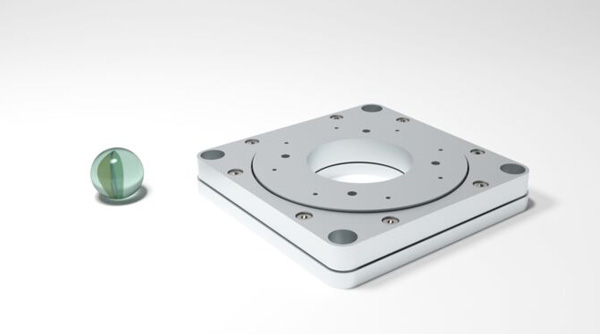

SR-12012 - Rotation Stage

-

The SR-12012 rotation stage offers a large aperture and is mostly chosen for applications where an aperture and highest precision is absolutely essential.

With its 120 x 120 mm footprint the SR-12012 rotation stage offers an aperture opening of 82 mm while maintaining a low profile with a height of only 12 mm.

Piezo Stick-Slip Stages: High Load Stages

-

Linear stages of the CHS and SHL series are specifically designed to handle heavy payloads. The mechanical design is based on an actuated wedge which guarantees highest resolution of the stages motion. A separate guideway assures a straight movement along the load direction and allows an integration of a position sensor for direct position feedback and closed-loop operation. Stages with one degree of freedom, intended for pure vertical lifting movement, can be equipped with an additional constant force spring (CFS) to increase the payload to even higher values. CHS stages are equipped with SmarActÂs exchangeable drive units for easy maintenance. CHS and SHL stages can also be combined to form multi-axis systems with high blocking forces in all three dimensions.

CHS-3232-1D-5 - High Load Stage

-

A very compact high load stage equipped with an exchangeable drive unit, offering a vertical travel range of 5 mm and the capability to handle payloads of up to 5 N.

The CHS-3232-1D-5 is SmarActÂs most compact high load stage. Due to itÂs mounting hole pattern, it can be mounted directly to the linear stages of the CLS32 series and the SR-3211 rotation stage. In case of service, the complete exchangeable drive unit can be removed from the stage while the device remains in the positioning setup. The exchangeable drive unit is easy to access from the side of the stage. Straight movement along the load direction is assured by a separate guideway. The integration of a position sensor provides direct feedback and closed-loop operation. Highest motion resolution is guaranteed by the mechanical design which is based on an actuated wedge. The CHS-3232-1D-5 is suitable for high availability applications in science and industry. The stages can be equipped with an additional constant force spring to handle payloads of 5 N.

CHS-5237-1D10N-10 - High Load Stage

-

A high load stage equipped with an exchangeable drive unit, offering 10 mm of vertical travel and the handling of payloads up to 10 N

This high load stage is suitable for high availability applications in science and industry. It is equipped with SmarAct's exchangeable drive unit, which allows the complete piezo drive to be removed from the stage when required for servicing. As the drive unit is accessible from the side of the stage, the device does not need to be removed from the positioning setup during servicing. The mechanical design is based on an actuated wedge which guarantees highest resolution of the stages' motion. A separate guideway assures a straight movement along the load direction and allows an integration of a position sensor for direct position feedback and closed-loop operation. The mountinghole pattern supports an easy screwing to the linear stages of the CLS52-Series and the SR-5014. Optionally, different constant force springs can be added to handle payloads up to 10 N.

CHS-9257-1D-15 - High Load Stage

-

A high load stage equipped with a long vertical travel range of 20 mm that handles payloads of up to 15 N

This long travel high load stage is equipped with SmarAct's exchangeable drive unit, which allows the complete piezo drive to be removed from the stage when required for servicing. Since the drive unit is accessible from the stage's side, the device does not need to be removed from the positioning setup during servicing. The mechanical design is based on an actuated wedge which guarantees highest resolution of the stages' motion. A separate guideway assures a straight movement along the load direction and allows an integration of a position sensor for direct position feedback and closed-loop operation. The mountinghole pattern supports an easy screwing to the linear stages of the CLS92-Series. Optionally, the maximum lift force can be increased upon request.This long travel high load stage is equipped with SmarAct's exchangeable drive unit, which allows the complete piezo drive to be removed from the stage when required for servicing. Since the drive unit is accessible from the stage's side, the device does not need to be removed from the positioning setup during servicing. The mechanical design is based on an actuated wedge which guarantees highest resolution of the stages' motion. A separate guideway assures a straight movement along the load direction and allows an integration of a position sensor for direct position feedback and closed-loop operation. The mountinghole pattern supports an easy screwing to the linear stages of the CLS92-Series. Optionally, the maximum lift force can be increased upon request.

SHL-1D80N-1 - High Load Stage

-

High load vertical stage that is able to lift 80 N over a travel range of 1 mm with nanometer precision.

Linear stages of the SHL series are specifically designed to handle heavy loads. The mechanical design is based on an actuated wedge which guarantees highest resolution of the stages motion. A separate guideway assures a straight movement along the load direction and allows an integration of a position sensor for direct position feedback and closed loop operation. Stages which are intended for pure vertical motion to lift components or equipment can be equipped with an additional constant force spring to offset the payload to even higher values. Accordingly, nano-encoded stages which can lift up to 10 kilogramms over several millimeter are possible as well as multi-axis systems based on linear stages of the SHL Series which offer high blocking forces in all three dimensions.

While offering high payloads, SmarAct SHL stages remain very compact and are suitable also for setups with space contraints

Piezo Stick-Slip Stages: Stages with Exchangeable Drive-Units

-

SmarActÂs exchangeable drive units (EDUs) are specifically designed for high availability applications in industry and science. The stick-slip piezo drive is housed in a robust drive unit that you can easily replace yourself. To do so, neither the payload has to be removed from the stage nor or the stage itself from the setup of the positioning system.

With SmarActÂs EDUs, service intervals of piezo actuators can be planned and downtime for piezo motor replacement is reduced to a few minutes. The unique and patented drive units are available for linear stages of the CLS series, CGO goniometer stages and for CHS high load stages. Complete positioning systems, from serial multi-axis systems up to highly complex parallel kinematics like the hexapod-like SMARPOD can also be equipped with SmarActÂs EDUs.

CLS-3232 - Linear Stage with EDU

-

The smallest of the CLS-32 linear stages offers a footprint of only 32 x 32 mm and a travel range of 21 mm. It is able to handle payloads of up to 30 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

CLS-3252 - Linear Stage with EDU

-

The middle size stage of the CLS-32 series offers a travel range of 31 mm while maintainig a footprint of only 32 x 52 mm. It is able to handle payloads of up to 30 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

CLS-3282 - Linear Stage with EDU

-

The longest stage of the CLS-32 series offers a travel range of 51 mm while maintainig a footprint of only 32 x 82 mm. It is able to handle payloads of up to 30 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

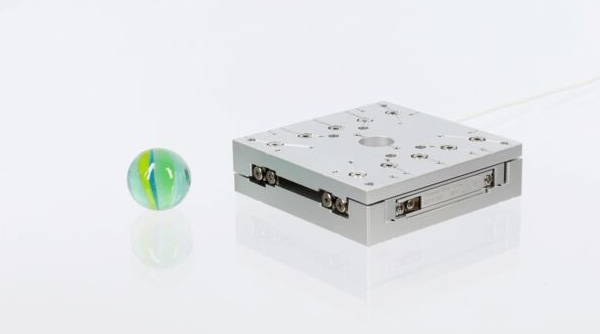

CLS-5252 - Linear Stage with EDU

-

The smallest one of the CLS-52 linear stages offers a footprint of 52 x 52 mm, a travel range of 31 mm and an aperture of 9 mm in diameter. Furthermore, it is able to handle payloads of up to 20 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

CLS-5282 - Linear Stage with EDU

-

The larger one of the CLS-52 linear stages offers a footprint of 52 x 82 mm, a travel range of 51 mm and an aperture of 9 mm in diameter. Furthermore it is able to handle payloads of up to 20 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

CLS-92152 - Linear Stage with EDU

-

The larger CLS-92 linear stage has a footprint of 92 x 152 mm and a travel range of 103 mm. Furthermore it is able to handle payloads of up to 20 N.

Linear stages of the CLS series have been specifically designed for high availability applications in science and industry. They are equipped with SmarActs Exchangeable Drive Units which guarantees an easy access to the stages core component, the piezo drive which makes servicing a simple task. The drive unit can be exchanged without the need to remove the complete device from the surrounding positioning setup. They are the perfect option whenever modularity and easy configuration are the top level requirements.

CLS-9292 - Linear Stage with EDU

-

The smaller one of the CLS-92 linear stages offers a footprint of 92 x 92 mm and a travel range of 63 mm. Furthermore it is able to handle payloads of up to 20 N.

Linear stages of the CLS series were consistently designed for high availability applications in science and industry. They are equipped with SmarActs exchangeable drive units which guarantees easy access to the stage's core component, the piezo-drive. That makes servicing a very simple task. The drive unit can be exchanged without removing the complete device from the surrounding positioning setup. Additionally, their mounting hole pattern is perfectly matched to mount our rotation stages and goniometers.

SMARPOD CLS-32 with Exchangeable Drive-Units

-

The SMARPOD CLS-32 is equipped with Exchangeable Drive Units and is perfectly suitable for all high availability applications

The SMARPOD CLS-32 is a mid-size hexapod-like positioning system. This unit is equipped with SmarAct's Exchangeable Drive Units (EDUs) guaranteeing an easy and fast exchange of the piezo drive without the necessity to fully disassemble the positioning setup and without losing calibration and position data.

Like other SmarAct SMARPOD's, the SMARPOD CLS-32 is also available in a high vacuum and ultra-high vacuum version or made out of fully non-magnetic materials.

Piezo Stick-Slip Stages: Goniometer Stages

-

All piezo-based goniometer stages are based on SmarActÂs piezo drive technology and are equipped with SmarAct's exchangeable drive units. Goniometer stages are available with different radii. In addition to their compactness, these stages are very rigid and therefore ideally suited for micro- or nanopositioning tasks.

Due to the usage of high precision crossed roller bearings their angular accuracy is very high. The goniometer stages offer highest resolution of motion over their whole working range of ±5 °.

SGO-60.5 - Goniometer Stage

-

The CGO-60.5 goniometer stage can be easily stacked on top of the CGO-77.5 stage to form an Eulerian cradle with a common center of rotation 60.5 mm above the working platform.

All piezoelectric goniometer stages are based on SmarAct piezo drive technology. Goniometer stages are available with different radii. In addition to their compactness, these stages are very rigid and therefore ideally suited for micro- or nanopositioning tasks. Due to the usage of high precision crossed roller bearings, their angular accuracy is very high. The goniometer stages offer highest resolution of motion and are directly stackable. By combining two stages with appropriate radii, it is possible to build a compact Euler goniometer with a common center of rotation. Their mechanical interface perfectly fits the CLS-52 series stages. Thus, allowing the creation of multi-axis systems by direct combination of linear, rotation and goniometer stages. SmarAct's goniometer stages can be operated by any of our control units and are also available with integrated positioning sensors. Furthermore, the CGO series goniometer stages are available for different environmental conditions, such as high vacuum and ultra-high vacuum environments.

Since the CGO-60.5 is equipped with an exchangeable drive unit, easy access to the stage's core component for servicing is guaranteed.

SGO-77.5 - Goniometer Stage

-

The precise and compact goniometer stage CGO-77.5 can be directly mounted on top of CLS-52 linear stages or act as a base for an Eulerian cradle when combined with a CGO-60.5 stage.

All piezoelectric goniometer stages are based on SmarAct's piezo drive technology. Goniometer stages are available with different radii. In addition to their compactness, these stages are very rigid and therefore ideally suited for micro- or nanopositioning tasks. Due to the usage of high precision crossed roller bearings, their angular accuracy is very high. The goniometer stages offer highest resolution of motion and are directly stackable. By combining two stages with appropriate radii it is possible to build a compact Euler goniometer with a common center of rotation. Their mechanical interface perfectly fits to the CLS-52 series stages. Thus, allowing the creation of multi-axis systems by direct combination of linear, rotation and goniometer stages. The SmarAct goniometer stages can be operated by any of our control units and are also available with integrated positioning sensors. Furthermore, the CGO series goniometer stages are available for different environmental conditions, such as high vacuum and ultra-high vacuum environments.

Since the CGO-77.5 is equipped with an exchangeable drive unit, easy access to the stage's core component for servicing is guaranteed.

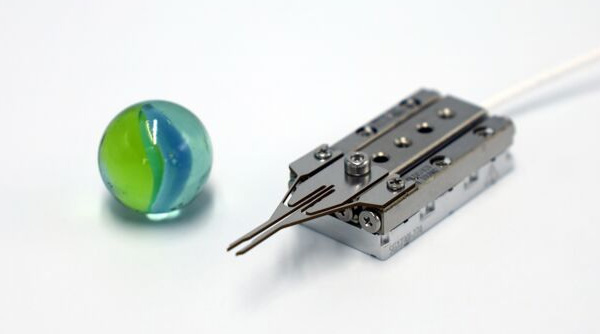

Piezo Stick-Slip Stages: Micro-Grippers

-

Precise handling of components, parts and tools at automated assembly lines and sample handling and manipulation in life science are most crucial positioning tasks. We have complemented our product portfolio with versatile gripping solutions to address the growing demand to precisely control tweezers, pincers and grippers. Modularity is one of the key features of SmarActÂs products. SmarActsÂs micro-grippers consist of linear piezo stages and a gripping jaws which can be easily exchanged and customized if required. Several different and specialized designs of gripper jaws are available.

When equipped with a position sensor the grippers allow full closed-loop control about the gripping process and the opening of the jaw. In addition, force sensors integrated into our parallel micro-gripper SGP-17F allow to control not only the jaw opening but also the gripping force when handling fragile or highly delicate objects. If your specific application requires a dedicated design, do not hesitate to contact our application specialist to discuss possible solutions or fully customized designs.

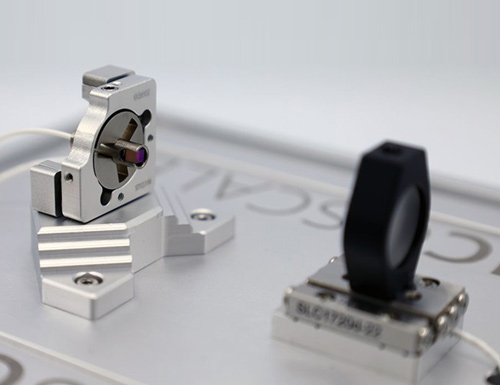

SGE-17 - Micro-Gripper

- SmarActÂs SGE-17 micro-gripper utilizes the most compact SLC-1720 stage offering a miniaturized and versatile tool for pick and place applications in optics and electronics. It can be equipped with different position sensors, allowing to control and monitor the gripping process precisely. The screwed gripper jaws can be easily exchanged on site. A wide variety of dedicated standard jaw geometries is available. In addition, customer-specific jaw geometries can be designed to meet your application. Vacuum-compatible variants extend the range of applications to pressure ranges down to ultra-high vacuum.

SGP-17F - Micro-Gripper

-

SmarActÂs SGP-17F micro-gripper is the perfect solution when it comes to applications in the field of optoelectronics such as active alignment of optics and sub-components or the parallel gripping of delicate objects with a constant force. Due to the integrated force sensors, it doubles as a sensitive force detection system that can be used in a variety of applications like the monitoring of UV-curing processes. The micro-gripper is equipped with one biaxial load cell per jaw, allowing to measure gripping force and orthogonal contact force individually. Gripping force orientation is constant and jaw movement is fully parallel over the whole gripping range. The jaws itself can be easily exchanged, adapted or fully customized to address the requirements of specific applications.

SGQ-17 - Micro-Gripper

- SmarActÂs SGQ-17 micro-gripper utilizes the SLC-1730 stage and is equipped with a magnetic quick-exchange system enabling a tool-free exchange of gripper jaws. It can be equipped with different position sensors, allowing to control and monitor the gripping process precisely. A wide variety of dedicated standard jaw geometries is available. In addition, customer-specific jaw geometries can be designed to meet your application. Vacuum-compatible variants extend the range of applications to pressure ranges down to ultra-high vacuum.

Environment Specific Stages and Systems: Cryogenic Piezo Stages and Systems

-

Many applications in industrial and medical research as well as in fundamental research require cryogenic temperatures. Additionally, in many cases it is not only necessary to cool the samples but also to mechanically manipulate them precisely within the cryostat. SmarAct has developed stick-slip piezo actuators with low-heat profiles and ultra-high vacuum compatibility, which allow sample manipulation in temperatures down to the mK regime. Resistive cabling (based on phosphor bronze) is optionally available to reduce the heat load on the positioning stages. Additionally, they can be used at temperatures of up to 330 K and are bakeable at temperatures of up to +150 °C. For the use in high magnetic fields at cryogenic temperatures, non-magnetic versions are available. For high precision positioning under cryogenic conditions, such as quantum computing, SmarAct has developed cryogenic positioning stages featuring unmatched closed-loop positioning performance.

SmarActÂs cryogenic actuators can be easily assembled into complete positioning systems including thermalization management and customization to your specific application.

Closed-Loop Cryogenic Stages

-

or cryogenic applications where highest precision and thermal stability are essential for successful operation, SmarAct has developed cryogenic positioning stages featuring unmatched closed-loop positioning performance with resolutions below 0.5 nm and unidirectional repeatabilities of 5 nm over a 1 mm travel range. This makes SmarAct's closed-loop cryogenic stages ideally suited, for example, in the field of fundamental research including 2D materials science or for cryogenic applications such as low-temperature quantum technologies. The high-performance stages are specifically designed to meet the most demanding requirements that world-changing technologies like quantum computing induce. The materials for SmarAct's closed-loop cryogenic positioning stages are selected to match the required thermal properties and prevent mechanical stress during cooling and heating cycles. This ensures long lifetime under cryogenic and ultra-high vacuum conditions. Fully non-magnetic versions are available for use in high magnetic fields.

For the closed-loop cryogenic actuators, SmarAct combines its stick-slip piezo drive stages with its high-performance PICOSCALE sensor heads, which are based on an all-optical Michelson interferometric design. SmarAct's closed-loop cryogenic stages are 28 mm in width and 14 mm in hight. They are available in lengths from 30 mm to 75 mm with travel ranges from 16 mm to 49 mm. To fulfill customers' individual requirements, completely customized setups are also possible.

Cryogenic Linear Stages

-

Cryogenic linear stages are specialized versions of SLC stages and completely retain the compact design of the room temperature versions. Therefore, they are ideally suited for limited spaces, typically found in heat shields of cryostats. Materials are selected to match the required thermal properties and prevent mechanical stress during cooling and heating cycles. This ensures long lifetime under cryogenic and ultra-high vacuum conditions.

The cryogenic option is available for many linear stages of the SLC product series. Please note that the following changes apply to the specifications given in the product specification tables.

- Cryo SLC stages are about 60 % heavier because of the use of titanium as a base material compared to the standard aluminum versions of an SLC stage.

- Cryo SLC stages have a lower blocking force value of 2 N and also a lower lift force value of 1 N compared to 3.5 N and 1.5 N of non-cryo versions of SLC stages.

- Due to an application optimized piezo drive the travel range of the cryo SLC-1720 is 6 mm.

Cryogenic Rotation Stages

Many applications in industrial and medical research as well as in fundamental research require cryogenic temperatures often well below 10 Kelvin. Additionally, in many cases it is not only necessary to cool samples but also to mechanically manipulate them precisely within the cryostat.

SmarAct has developed stick-slip linear and rotation stages with low-heat profiles and ultra-high vacuum compatibility which allow sample manipulation in temperatures down to the millikelvin regime.

Resistive cabling (based on phosphor bronze) is optionally available to reduce the heat load on the positioning stages. They can also be used at temperatures of up to 330 K like our standard UHV stages. Furthermore, they are bakeable at temperatures of up to +150 °C. For the use in high magnetic fields at cryogenic temperatures, non-magnetic versions are available.

Cryogenic stages can be easily assembled into complete positioning systems including thermalization management and customization to your specific application

Cryogenic Positioning Systems

-

Many applications in science and industry require more than two degrees of freedom for positioning samples or components. Even at very low temperatures and in confined spaces, the payload must be moved with the highest precision. SmarActs' cryogenic positioning systems are modular, precise, customizable and thermally managed to keep your samples as cold as possible during positioning or scanning tasks.

The central component of any XYZ positioning system is a linear stage. In this example, an SLC-1720-CR. Three stages can be easily combined with holders and adapter plates to form compact multi-axis setups, which are usually connected to the cold finger of a cryostat in the customer setup.

When designing high-resolution positioning systems that need to operate accurately at cryogenic temperatures, it is important to ensure that the heat load from the stages is transferred to the cryostat as quickly as possible to reduce temperature creep of the positioning system due to thermal expansion of the stages and mounting components.

The most important task is to transfer the heat from the payload to the mounting base plate to ensure a constant and low temperature at the point of action.

Environment Specific Stages and Systems: Non-Magnetic Piezo Stages and Systems

Non-magnetic Piezo Stages and Systems

-

For applications, in magnetic fields or in other en-vironments where non-magnetic materials are required, SmarAct offers completely non-magnetic positioning stages and systems. Typical materials for these stages are copper beryllium, titanium, ceramics, and copper wires with Teflon® or Kapton® insulation.

Non-magnetic stages of the SLC-17 and SLC-24 series include ceramic guideways. We recommend that you also opt for the U-shaped base to increase the overall stiffness of the stage.

The U-shaped base has the usual mounting hole pattern, but is 6 mm wider than the standard stages. Therefore, the stages with U-shaped bases of the SLC-17 series are 23 mm wide and those of the SLC-24 series are 30 mm wide. Dispensing with the U-shaped base plate is only advisable if compactness is most important.

Environment Specific Stages and Systems: Ultra High Vacuum Piezo Stages

Ultra High Vacuum Piezo Stages

-

SmarActÂs stages and systems are not only perfectly suited for applications under atmo-spheric conditions, but in some cases also for more extreme environments like high vacuum (HV, 10-6 mbar) and ultra-high vacuum (UHV, 1E-11 mbar).

Most of the stages presented on this website are available in versions specially prepared for operation under vacuum conditions. UHV versions are bakeable at up to 150 °C and are available with two different cable types:

- The cost efficient version utilizes Teflon insulated wires.

- The Kapton® insulated version is a fluorine free solution.

Since SmarAct is a full solution provider, HV and UHV positioning systems are supplied with matching electrical feedthroughs. As standard, SmarAct uses:

- HV as bulkhead LEMO® feedthroughs which are O-ring sealed.

- UHV tightly welded designs for the use in UHV.

Electromagnetic Direct-Drives

-

SmarActÂs MLS product series offers electromagnetic linear motors for industrial applications, laboratory automation and compact positioning solutions where high speed, force and nanometer- precise motion must be paired with high duty cycle and durability. The stages are equipped with SmarActÂs non-contact and wear-free linear motors, opening up a field of applications where highly dynamic processes require high speed and nanometer accuracy at the same time. The electromagnetic drive enables speeds of up to 1 m/s. In addition, they are durable and virtually maintenance-free. Their compact size ensures seamless integration into existing systems.

MLS-3252 - Electromagnetic Direct-Drive

-

A miniaturized Electromagnetic Direct-Drive with 25 mm travel range.

The MLS-3252 is a miniaturized electromagnetic direct drive which is compatible to the CLS-32 modular system. It can be easily combined with CLS-32 linear and rotation stages. The stages can be powered by the reliable MCS2 controller series.

MLS-5282 - Electromagnetic Direct-Drive

-

An electromagnetic direct drive with 38 mm travel range.

The MLS-5282 is a mid size electromagnetic direct drive which is compatible to the CLS-52 modular system. It can be easily combined with CLS-52 linear, rotation and goniometer stages. The stages can be powered by the reliable MCS2 controller series.

MLS-92122 - Electromagnetic Direct-Drive

-

A large high performance electromagnetic direct drive with 65 mm travel range.

The MLS-92122 is a large size electromagnetic direct drive which is compatible to the CLS-92 modular system. It can be easily combined with CLS-92 linear, rotation and goniometer stages. The stages can be powered by the reliable MCS2 controller series.

Control Systems and Software

-

Every successful positioning solution rests on at least two pillars. The first is defined by the mechanical part of the solution, the second by the electronics and software to control it. Our sophisticated and easy to use control systems together with our intuitive software solutions and software development kits (SDKs) are the basis for a fast and easy integration of our positioning technology into your application. SmarActÂs control system portfolio consists of a wide variety of components optimized for different applications and integration scenarios. From single channel hand held controllers up to rack mountable modules with up to 18 channels, we are able to equip you with the right tools.

Control Systems

-

SmarAct offers several lines of control systems. From simple OEM board level controllers up to highly modular multi-axis controllers with intuitive user interfaces

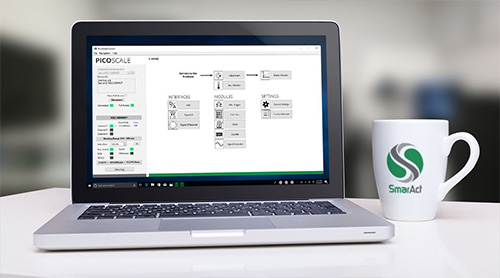

Software

-

SmarActÂs control systems come bundled with different software tools that supports you during setup, configuration and controlling your positioning systems.

Metrology

-

SmarAct offers a range of measurement solutions that are widely applied in industrial and academic settings.

Displacement Measurements

-

For high precision displacement measurements, SmarAct offers the PICOSCALE Interferometer, a powerful sensor with picometer resolution. Based on an extremely compact Michelson interferometer, non-invasive displacement measurements with low restrictions on the target reflectivity can be realized very efficiently.

Sensor heads are available for general purpose or optimized for specific tasks like angular or differential measurements. Furthermore, we provide sensor heads for use in vacuum, cryogenic or other harsh environments. Due to their compactness, they fit into almost every setup. Powerful firmware modules and versatile accessories complement the PICOSCALE portfolio to emphasize its use as a laboratory device for synchronization with other devices, signal generation, real-time calculation and many more applications.

Vibration Measurements

-

The PICOSCALE Vibrometer is a turnkey solution to measure vibrations of micromechanical structures with sizes that range from just a few µm to multiple cm. Applications include the testing of MEMS, sensors, miniature loudspeakers but also bearings and actuators. Because the instrument is equipped with an integrated microscope and can measure up to 1 million pixels, it is excellently suited to visualize vibrational modes at high spatial and temporal resolution.

Electrical Probing

-

Electrical characterization of semiconductor devices.