Visevi Robotics

Videos

Loading the player ...

- Offer Profile

- RoVi was founded by three

engineers as a spin-off from Technical University of Munich (TUM). Our

common vision is to create robots that improve our daily lives. Robots that

are simple and low-cost yet smart enough to take over dull, dirty and

dangerous tasks.

Our vision is to make intelligent robots available to everyone – to help us in manufacturing, in the office and at home. Sensors are a key technology to bring robots “out of the cage”, but current sensor systems are complex and expensive.

Visevi Robotics offers the world's first completely camera-based sensor system for robot arms and grippers. Our patented solution relies on an image processing software and features rich sensory feedback.

Product Portfolio

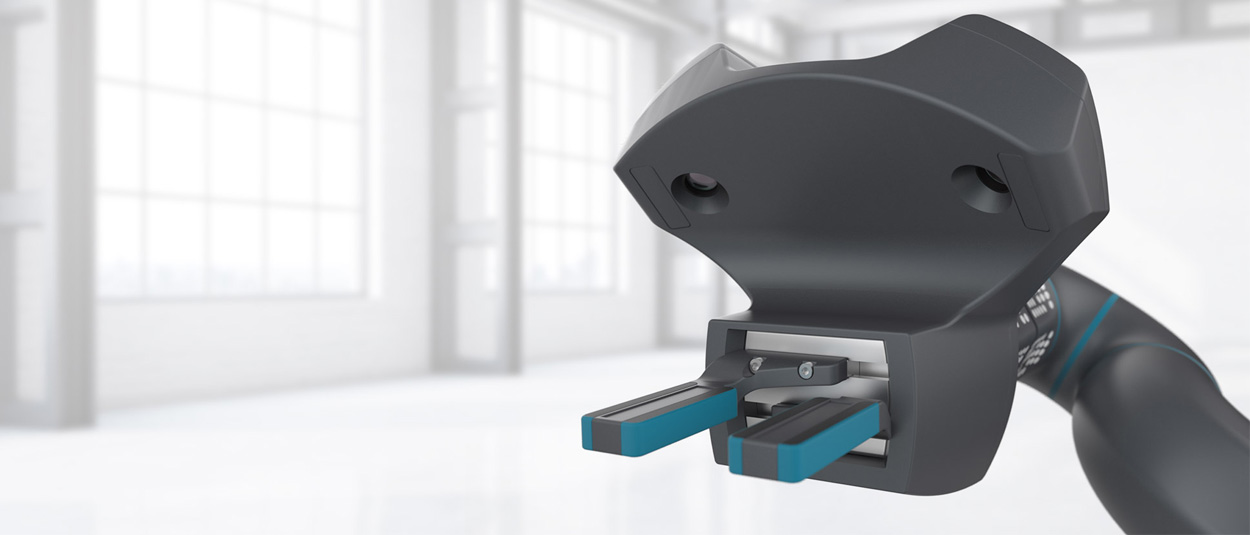

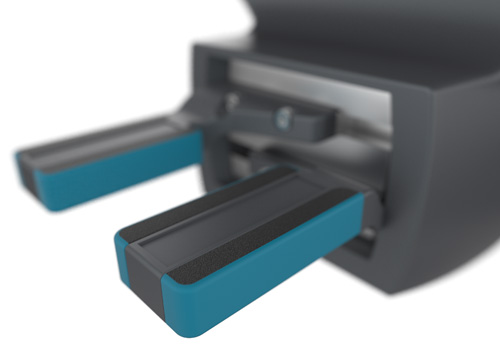

ViseGrip

See, detect and grasp: An intelligent gripping system for versatile and sensitive grasping.

Intelligent gripping system

- A gripping system providing the sense of touch

Our intelligent gripping system is a ready-to-use solution for flexible and sensitive grasping applications. It integrates an industrial gripper, a stereo vision system, as well as our camera-based sensors for tactile data and optionally force/torque.

Your benefits

- Versatile

Recognizes and grasps a large variety of different objects in unstructured environments

Cost Effective

Avoids complex, inflexible and expensive feeding systems

Ease of Use

Allows an easy setup due to a tight integration of the camera, software and gripper

Reliable Gripping

Monitors the gripping process to ensure an accurate, rapid and secure grip

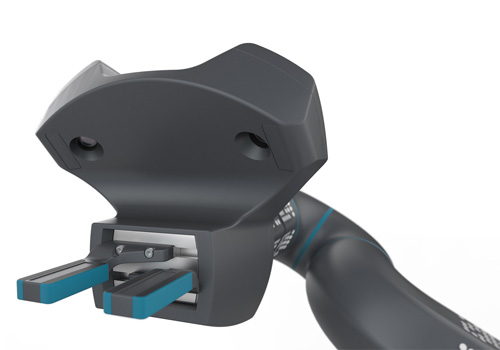

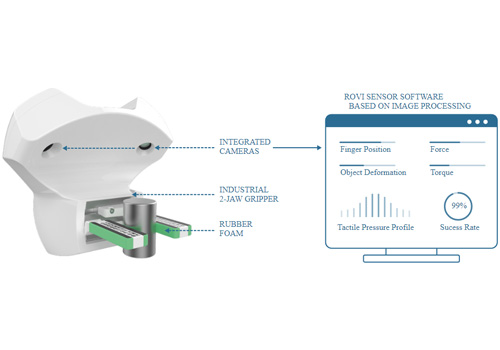

Our technical solution

- Our intelligent gripping solution integrates two

grayscale/color cameras, an industrial 2-jaw gripper, as well as universal

fingers in a compact package with a standard mount. The fingers are equipped

with a layer of rubber foam to support camera-based tactile sensing.

The core of our sensing technology is an image processing software, which derives physical sensor signals from the observation of the rubber foam's deformation during contact. Hence, the sensor functionality is shifted from complex and dedicated hardware modules into our intelligent sensor software. This sensor software provides rich feedback about the grasping process, including tactile/pressure profile, grasping force, gripper opening, object position/count, object shape, object deformation and detailed grasping statistics. Using this data, our multi-goal grasp controller enables intelligent and flexible grasping of varying objects.

Our patented sensor principle allows you to simply replace or adapt the gripper's fingers. This is due to the fact that no wiring is needed in the fingers, since the rubber foam is completely passive and without any integrated electronics.

VisePick

Camera-based pick and place solution for the reliable handling of objects in unstructured environments.

Camera-based pick and place solution

- Reliable picking in unstructured environments

Our camera-based pick and place solution for low cost robot arms employs a stereo depth camera system to locate objects in the workspace. It enables the reliable handling of a wide range of objects from unstructured positions without time-extensive programming and teaching.

Please get in touch for an evaluation of your use case.

Your benefits

- Versatile object recognition

Recognises a large variety of different objects even in unstructured environments.

Low cost solution

Employs a stereo depth camera system and avoids expensive feeding systems.

Reliable gripping

Monitors the gripping process to ensure an accurate and secure grip.

Easy plug and play

Allows an easy setup due to a tight integration of the camera, software and gripper.

Features

- Hardware General

Payload Depending on your robot model (e.g. for Igus Robolink-D: 300-2500g)

Gripper Exchangeable suction cup

Flange Available for various robot models

Hardware Camera

Depth Technology Active IR Stereo (Global Shutter)

Depth Field of View (FOV) 85.2° x 58° x 94° (+/- 3°) (Horizontal × Vertical × Diagonal)

Depth Stream Output Resolution Up to 1280 x 720

ViseTac

Feeling by seeing! Camera-based tactile sensors providing the sense of touch.

Your benefits

Tactile Profile

Pressure profile, e.g. to be used as touch feedback for gripper fingers

Passive Element

No electronics/wiring

Remote Sensing

External camera (“eye-in-hand” on the gripper), or nearby

Virtual sensor Tactile signal from image processing

Development kit

Our kit contains everything you need to get started quickly with tactile sensing. Contact us for options and availablity.- Sensitive element (rubber foam bar), with mounts for common grippers

- USB3 camera

- Sensor software with ROS integration

- Bootable USB stick

- Web-based interface

Camera-based tactile sensor

- Tactile sensors provide a pressure or contact profile, similar to touch we feel on our skin. They offer rich feedback about the grasping process and are thus essential for adaptive and sensitive grasping processes. Our camera-based solution requires only a passive and deformable material, which deforms on pressure. Our image processing software derives a tactile signal from the observed deformation.

Exemplary application: gripper fingers

- Our camera-based tactile sensors are easily attachable to gripper fingers, since they do not require any wiring.

Different shapes and sizes

- Since the sensing element is passive and deformable, it can be adapted to any shape and size.

Technology

- Visevi Robotics offers the world's first completely camera-based sensor system for robot arms and grippers. Our patented solution relies on an image processing software and features rich sensory feedback.

- Low-cost passive elements substitute electronic sensors for joint positions, force/torque and tactile data. Positions are determined using visual markers, while force sensing relies on deformable elements, such as rubber foam. A camera obserses these elements remotely. The physical measurements are calculated from the image by our software.

- Visevi’s sensor software greatly simplifies the mechanics, hardware design and wiring of robot arms – and thus enables their use in low-cost automation, service robotics and consumer applications. The robot is continuously auto-calibrated, enabling the use of low-cost structural parts even for precise manipulation tasks.

Use Cases

- The following shows some exemplary use cases and applications for robots using our sensing system. Do not hesitate to tell us about your application! We will provide a quick evaluation of what our technology can do to solve your automation problem!

Desktop robot arm

- Our camera-based sensing technology enables lightweight, low-cost and mobile robot arms. They fit on any desk or workbench to assist a human worker. With integrated computer vision, they are easily adaptable and can detect objects.

Versatile sensitive grasping

- Take your grasping applications to the next level! Handle objects of different shapes, rigidities and materials with a single versatile and self-adapting gripper. With our tactile sensor, you get rich feedback about the grasped object and the grasping state.

Order picking

- Commission small parts such as screws, fittings or

plastic part in exact quanities for packagaing or for subsequent worksteps.

The robot can do this step even right on the workbench using our versatile

grasping system, or any another manipulator.

Process monitoring

- Monitor the status of your automation systems by adding our software-based sensors. Data and statistics are processed on-site or in the cloud and presented on any web browser.

Flexible packaging

- Package parts or components provided by a machine or a human worker. Our camera-based system flexibly localizes new parts, picks them and places them to a free spot.