- Offer Profile

-

STATE-OF-THE-ART AGITATION TECHNOLOGY

The VISCO JET® agitators are cone-shaped and inherently dynamic slow-speed mixers.MIX AND HOMOGENIZE

Key to success in mixing and homogenizing is not speed, but technology.A QUANTUM LEAP IN LABORATORY AGITATORS

The excellence lies in the special geometry of their cone-shaped agitator elements.

VISCO JET® AGITATORS

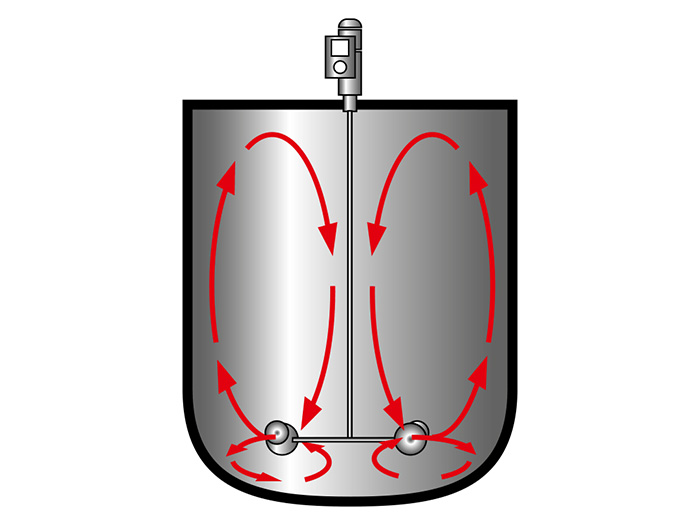

- The VISCO JET® agitation system proves beyond doubt that success in mixing and homogenizing is not about speed but rather about techniques.

LABORATORY AND PILOT PLANT AGITATORS

- For science and research – small, strong, efficient

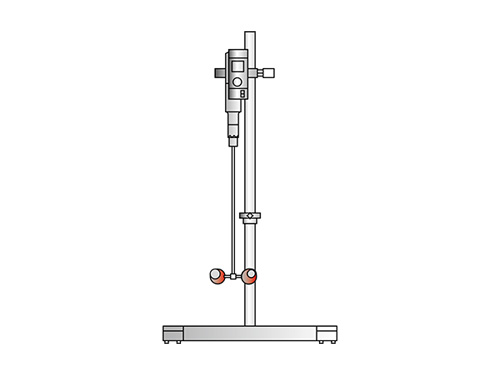

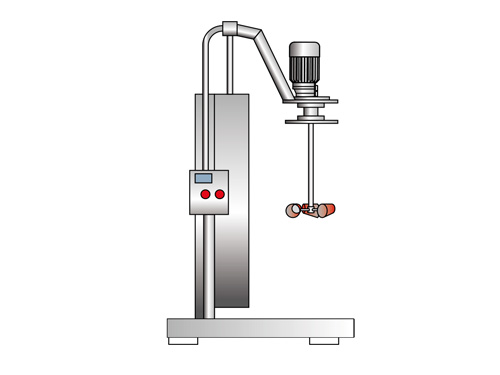

VISCO JET® VJ100

-

for container size up to 10 Liters

FOR SCIENCE AND RESEARCH

- High-torque drive with continuously variable speed control

- Height-adjustable coated stand in H-form base

- Different VISCO JET ® mixing elements for low, medium and high-viscosity media in plastic and stainless steel

- Drive fixed by an agitator damp on the guide column

Upgrade options

- Agitator shaft d = 10 mm, Lw = 500 mm with M8 threaded connector in stainless steel

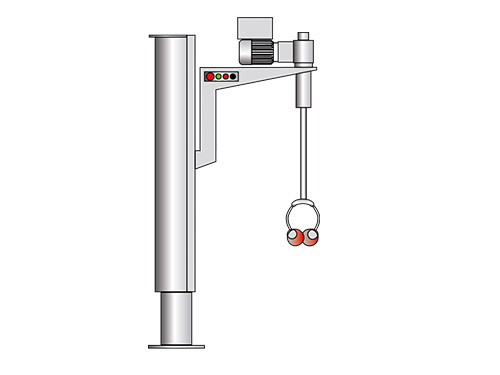

VISCO JET® VJ150

-

for container size up to 10 Liters

For laboratory and development

- For container heights up to 400 mm

- Max. Container diameter 400mm

- Manual lift height adjustment, infinitely variable lock

- Cover of the rear mounted lifting mechanism for best cleanability and safety

- Agitator stand in stainless steel design

- Drive with 0,25kW and frequency converter

- Different VISCO JET® agitators for low, medium and high viscosity media

- Agitator shaft with convenient quick-change coupling

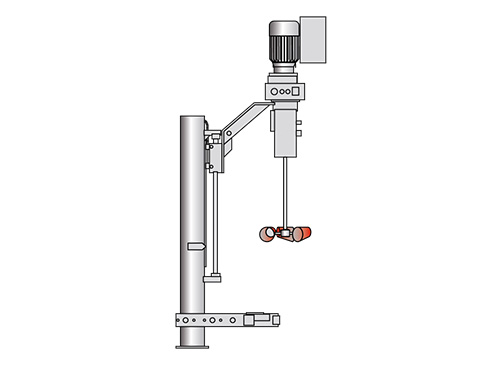

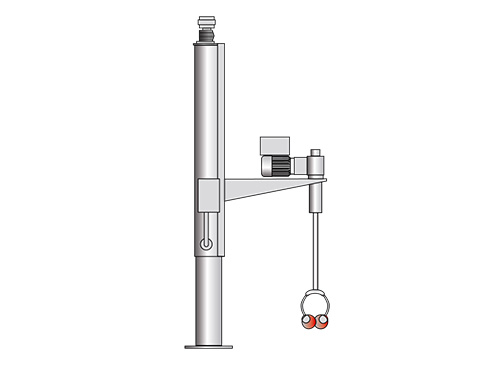

VISCO JET® VJ200

-

Support agitator for container height up to 500mm, manual lift

FOR RESEARCH AND PRODUCTION

- Can be used up to a container height of 500mm

- Maximum container diameter of 400mm

- Manual lift adjustment, infinitely variable lockable

- Different VISCO JET ® mixing elements for low, medium and high-viscosity media

- Various drive outputs available

Upgrade options

- Also available with ATEX certification ex-logo

- Container holder and base plate

- Individual control technology

- Agitator stand in stainless steel

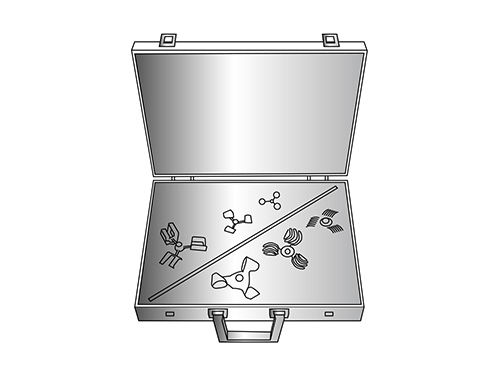

VISCO JET® VJ900

-

Laboratory suitcasewith variety of mixing elements

COMPLETE, VERSATILE, ROBUST

Everything at hand

- Aluminum laboratory case with foam padding, containing the following VISCO JET® mixing elements:

- VISCO JET® 2x d = 60 mm

- VISCO JET® 3x d = 80 mm

- VISCO JET® 3x spiral mixing element d = 80 mm

- VISCO JET® 3x spiral mixing element d = 120 mm

- ProJet colored mixing element 3x d = 120 mm

- Special plastic in red RAL 3000

- VISCO JET® mixing element 3x Crack II d2 = 120 mm

- Agitator shaft d = 10 x 500 mm with M8 thread

VAT AND CONTAINER AGITATORS

- Efficient mixing performance despite small container opening

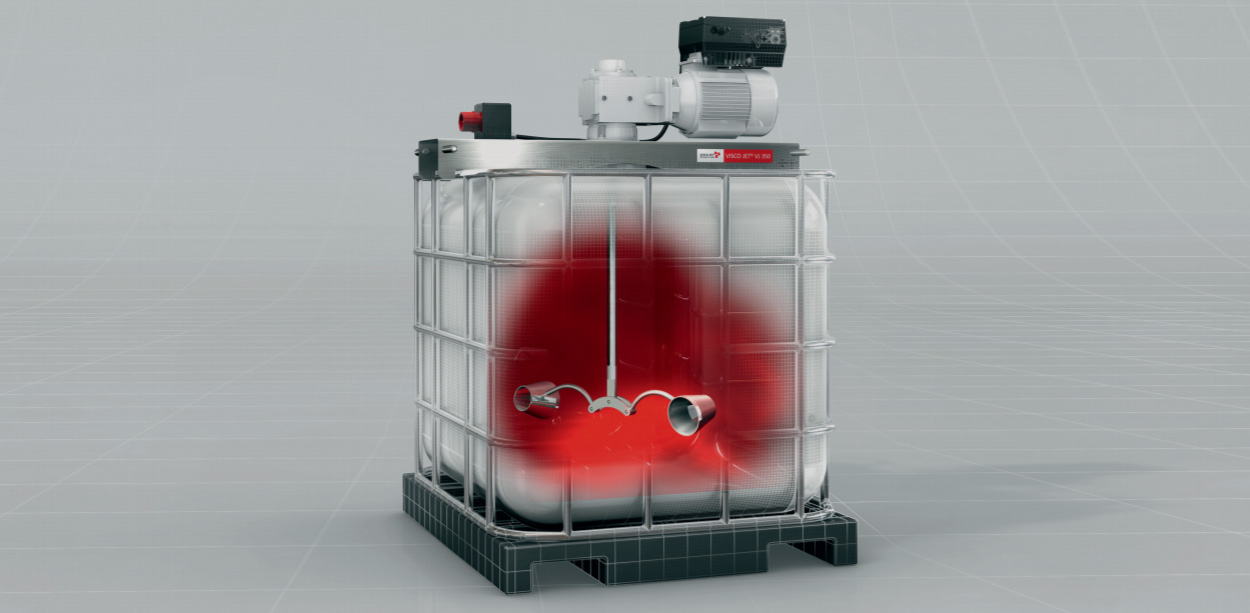

VISCO JET® VJ300

-

Tote tank (IBC) agitator directly mounted

CONTAINER SCREW-ON AGITATOR

- For direct screw mounting on IBC containers

- Special VISCO JET® „Expander“ mixing element with an effective diameter of 300 mm for mixing low-viscosity products

- Drive with 0.37 kW

- Version for foodstuffs also available

Upgrade options

- Available as ATEX-version ex-logo

VISCO JET® VJ350

-

Tote tank (IBC) agitator mounted with brackets

CONTAINER ATTACHMENT AGITATOR

The Bestseller

- For IBC containers with openings from 150 mm

- Special VISCO JET® „Tornado“ mixing element with an effective diameter of 650 mm

- With stainless steel cross beam and lift pockets or aluminium cross beam

- Drives with 1.1 / 1.5 / 2.2 / 3.0 kW available (380V, also 230V in some cases)

- Individual speed control for all mixing tasks

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

Upgrade options

- Available as ATEX-version with 1.85 kW drive

- Customised to suit your specific requirements

- Version for foodstuffs available

- Programming and readout unit

- Speed control based on fill level

- Lifting fixture

VISCO JET® VJ370

-

Agitator for closed drums (2 bunghole)

THE SPECIALISTS FOR DRUMS

- VJ370 for closed drums (2“ bung hole) with VISCO JET® „Mistral“ mixing element and angled stainless steel cross beam

- VJ380 for open drums with VISCO JET® mixing element and flat stainless steel cross beam

- Drive with 0.37 kW

Upgrade options

- Available as ATEX-version

- Lifting bracket for easy disassembly

VISCO JET® VJ380

-

Agitator for open drums

THE SPECIALISTS FOR DRUMS

- VJ370 for closed drums (2“ bung hole) with VISCO JET® „Mistral“ mixing element and angled stainless steel cross beam

- VJ380 for open drums with VISCO JET® mixing element and flat stainless steel cross beam

- Drive with 0.37 kW

Upgrade options

- Available as ATEX-version

- Lifting bracket for easy disassembly

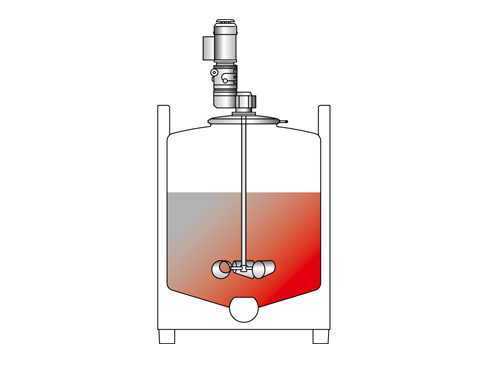

VISCO JET® VJ520

-

Agitator for stainless steel containers, mounted to cap

TANK AGITATOR FOR STAINLESS STEEL CONTAINERS

For transport containers – securely bolted and yet flexible

- Agitator for stainless steel transport containers with covers

- Agitator firmly bolted to the cover

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX version

- Lifting bracket for easy hoisting with lifting gear

STAND AGITATORS

Intelligent stand agitators for small and large containers

VISCO JET® VJ200

-

Support agitator for container height up to 500mm, manual lift

FOR RESEARCH AND PRODUCTION

- Can be used up to a container height of 500mm

- Maximum container diameter of 400mm

- Maximum container diameter of 400mm

- Manual lift adjustment, infinitely variable lockable

- Different VISCO JET ® mixing elements for low, medium and high-viscosity media

- Various drive outputs available

Upgrade options

- Also available with ATEX certification

- Container holder and base plate

- Individual control technology

- Agitator stand in stainless steel

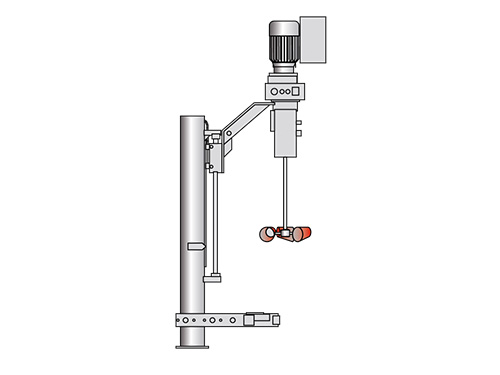

VISCO JET® VJ400

-

For pail or drum, manual lift, 500 or 900 mm

FOR BUCKETS OR CONTAINERS UP TO 200 L

The compact all-rounder

- Maximum container diameter of 600 mm

- Fully adjustable and lockable throughout height range

- Lift height to either 500 mm or 900 mm

- Available as wall or floor mounted stand

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Various drives available

Upgrade options

- Available as ATEX-version

- Agitator stand in stainless steel

- Individual control technology

VISCO JET® VJ421

-

Enclosed electric lift, 1.200, 1.400, or 1.600 mm, high-end stirrer for food and pharmaceuticals, easy to clean

THE HIGH-END STAND AGITATOR

For food and pharmaceuticals

- High-end stand agitator for all types of transport containers

- Electrical height adjustment to 1,000 mm, 1,200 mm, 1,400 mm or 1,600 mm

- Stand agitator made entirely of stainless steel

- Enclosed lifting mechanism for high standards of hygiene and easy cleaning

- Available as wall or floor mounted stand

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Several control variants available

- Various drives available

Upgrade options

- Available as ATEX version

- Individual control technology

VISCO JET® VJ450WH / VJ450BH

-

Manual lift, 1.200 mm, wall or floor mounted, entry-level stirrer

THE ENTRY-LEVEL MODEL

For all types of transport containers

- Manual height adjustment, safety switch

- Lift height 1,200 mm

- Available as wall or floor mounted stand

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Various drives available

Upgrade options

- Available as ATEX-version

- Agitator stand in stainless steel

- Individual control technology

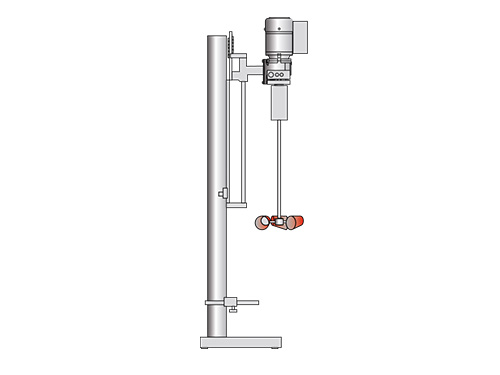

VISCO JET® VJ455WE / VJ455BE

-

Electric lift, 1.200 mm, optional to 1.400 mm, wall or floor mounted

THE MULTI-USE MIXER

- Stand agitator for all types of transport containers

- Electrical height adjustment to 1,200 mm, optional to 1,400 mm

- Available as wall or floor mounted stand

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Various drives available

Upgrade options

- Available as ATEX version

- Agitator stand in stainless steel

- Individual control technology

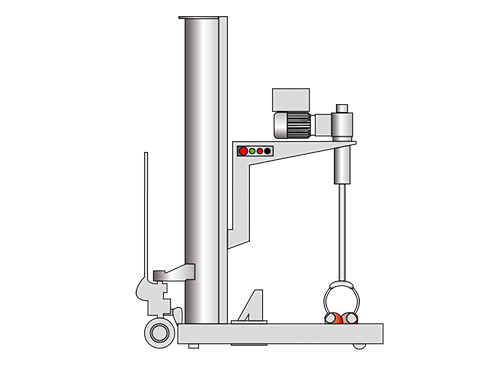

JET® VJ480 / VJ485

-

Manual lift, portable, 1.200 mm range

THE MOBILE COLUMN AGITATOR

- Mobile stand agitator for all types of transport containers

- Manual or electric height adjustment, lift height 1,200 mm

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Various drives available

Upgrade options

- Available as ATEX version

- Container holder available

- Agitator stand in stainless steel

- Program control technology

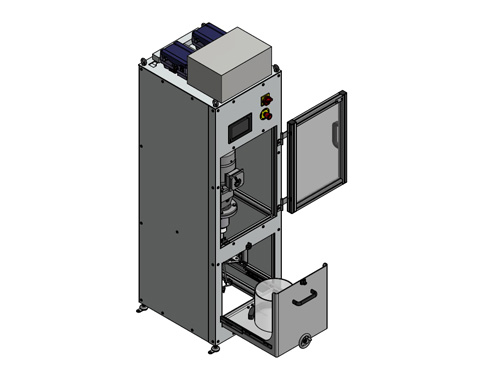

VISCO JET® VJ411

-

semi-automatic, for small casks ca. 5 – 30 liter

PROGRAMMABLE AGITATOR FOR SMALL CASKS

For all types of transport containers

- Semi-automatic column agitator for small vessel approx. 5 – 30 liter

- Fulfills the highest security/safety requirements for the operator

- Aluminium housing with working and maintenance access via secured door with window

- Very simple and safe handling

- VISCO JET pyramid mixing element for effective agitation of products from low to high viscosities

- Simple change of mixing elements using fast release coupling

- Digital control unit with programming via touch screen

- Secure vessel fixing using mechanical clamping system

- Drip tray prevents contamination of any parts

VISCO JET® VJ405

-

semi-automatic, ideally suited for agitation or tinting of

facade paints ca. 5 –50 literTHE SEMI-AUTOMATIC AGITATOR

for all types of transport containers

- Semi-automatic column agitator for the highest demands

- Ideally suited for agitation or tinting of facade paints and plasters in round, or oval, single vessels approx. 5-50 litre

- VISCOJET pyramid mixing element for effective agitation of products from low to high viscosities

- Simple change of mixing elements using fast release coupling

- Designed for professional use in continuous operation, up to hundreds of buckets a day

- Can be used in connection with automatic roller conveyor systems

- Digital control unit with programming via touch screen

- Secure vessel fixing using pneumatic clamping system with vacuum gripper

- Drip tray prevents contamination of any parts

- Complete covering of the agitator with an aluminium housing meets the highest security and safety requirements

- Working and mantainance access via secured door with window

TANK AGITATORS

- Whether it‘s 1000 or 1,000,000 litres

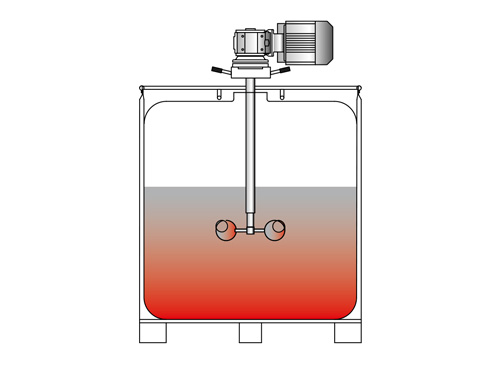

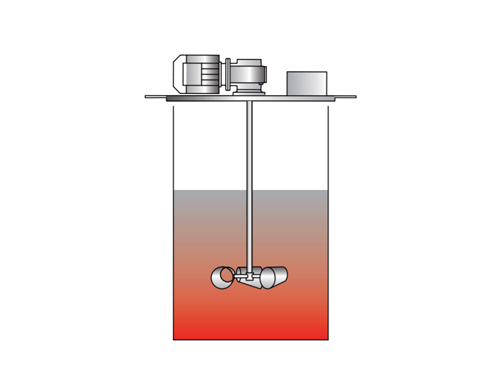

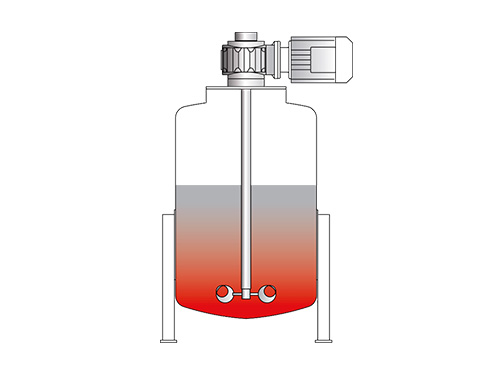

VISCO JET® VJ500

-

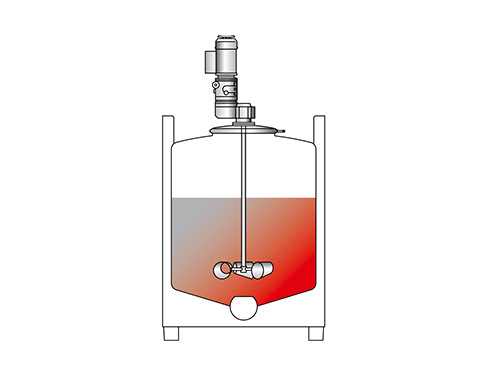

Tank agitator from 10 - 1.5 million litres, installation from above

FOR INSTALLATION FROM ABOVE

- For fixed, stationary storage or production tanks

- Volume from 10 litres to 1.5 million litres

- For installation from above

- Can be used with any container shape and base

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX-version

- Sealing: from simple sealing ring to mechanical sea

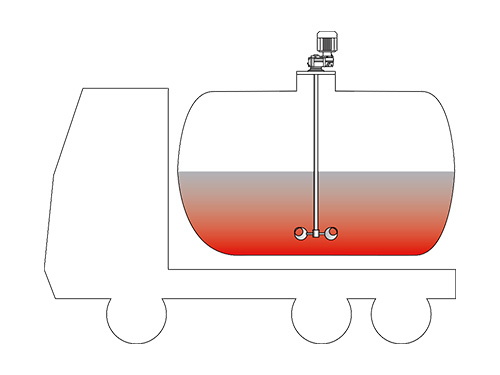

VISCO JET® VJ510

-

Agitator for horizontal tanks

FOR HORIZONTAL TANKS

- Tank agitator for fixed or movable horizontal storage or production tanks (on a truck or train)

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX-version

- Sealing: from simple sealing ring to mechanical seal

VISCO JET® VJ520

-

Agitator for stainless steel containers, mounted to cap

TANK AGITATOR FOR STAINLESS STEEL CONTAINERS

For transport containers – securely bolted and yet flexible

- Agitator for stainless steel transport containers with covers

- Agitator firmly bolted to the cover

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX version

- Lifting bracket for easy hoisting with lifting gear

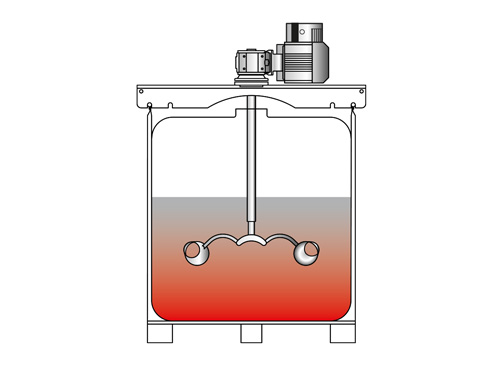

VISCO JET® VJ600

-

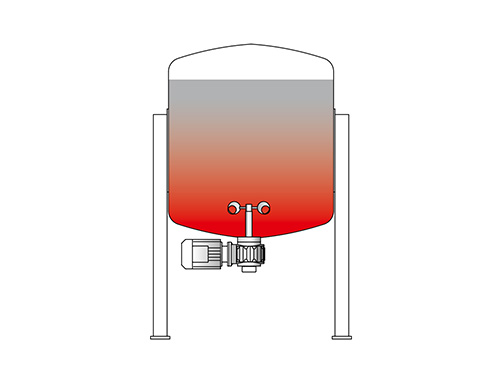

Tank agitator for 10 to 1,5 Mio Liter, bottom mounted

TANK AGITATOR FOR INSTALLATION FROM BELOW

- Tank agitator for fixed, stationary storage or production tanks

- Volume from 10 litres to 1.5 million litres

- For installation from below, including sealing

- Can be used with any container shape and base

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX-version

VISCOJET® VJ610

-

Sub-level agitator with magnetic technology

SUB-LEVEL AGITATOR WITH MAGNETIC TECHNOLOGY

- Tank agitator for fixed, stationary storage or production tanks

- Leak-free power transmission, drive technology with no product contact

- Volume-independent

- Can be used with any container shape and base

- Different VISCO JET® mixing elements for low, medium and high-viscosity media

- Customised to suit your specific requirements

- Various drives available

Upgrade options

- Available as ATEX version

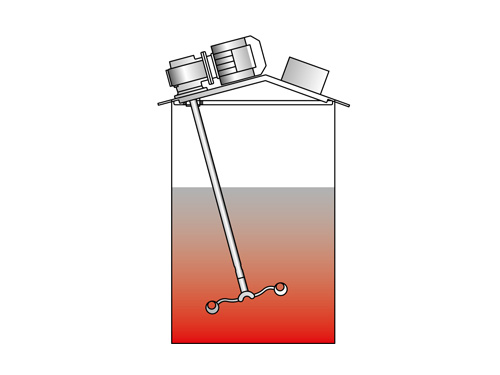

VISCOJET® VJ620

-

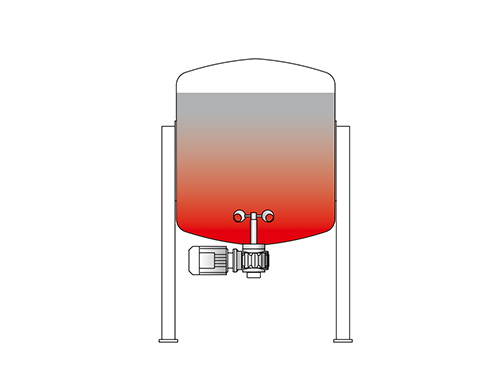

Tank agitator for lateral mounting

- Tank agitator for fi xed, stationary storage or production tanks

- Volume from 10 litres to 1.5 million litres

- Lateral mounting with sealiing technology

- Can be used with any tank shape and base

- Customised to suit your specifi c requirements

- Different VISCO JET® mixing elements for low,

medium and high-viscosity media - Various drives available

VISCO JET® AGITATOR TECHNOLOGY

-

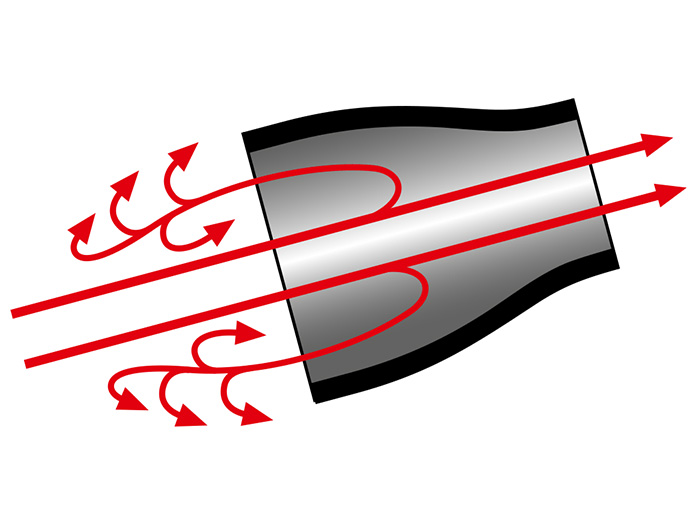

AGITATE SLOWLY – WITH FAST RESULTS

VISCO JET® proves beyond doubt that for successful agitation, mixing, homogenizing, suspending, or dispersing, it’s not the speed that’s decisive, but the technique. Its particular strength lies in the special geometry of its conical mixing elements. With its cleverly-designed spatial and angular relationship, the agitator ensures an optimum mixing process in a very short time even at low circumferential speeds.

We‘ve proven this technology in almost every industry. It is flexible, reduces costs, and guarantees high-quality results.

YOUR ADVANTAGE

- Product-friendly mixing with the classic VISCO JET®

- Effective breakup of agglomerates with VISCO JET® CRACK

- Short mixing times and low motor power requirements for maximum cost-effectiveness

- No air intake – no frothing

- Easy to clean

- Flexible for all types of mixing

CAUSE …

- Accelerated laminar flows at the cone exit and the reverse turbulence, created by dynamic pressure at the cone entrance, interact as the agitator rotates generating high-momentum mixing movements.

… AND EFFECT

- The extremely material-friendly and highly efficient agitator makes it possible to mix, agitate, homogenize, disperse, and suspend with very little energy expenditure. This applies particularly to tanks with very high volumes.

Industries

AGITATORS FOR THE MANUFACTURING OF PAINT AND LAQUER PRODUCTS

-

Visco Jet® Agitators are designed to mix a diverse range of materials used in the manufacturing of paint and laquer products.

- Resins

- Varnishes

- Laquers

- Dispersions

- Plasters

- Pigment Colors

- Distempers

- Color Suspensions

- Printing Inks

- Hardener

- Primers

- Water-based Paints

- Architectural Paints

- Thinner

AGITATORS FOR THE MANUFACTURING OF CERAMIC PRODUCTS

-

- Porcelain Slurry

- Porcelain Glaze

- Clay

- Ceramic Slurry

- Fireproof Material

- Aluminum oxide

- Electroplating and Galvanizing Material

- Zink dust

AGITATORS FOR THE PRODUCTIONS OF COSMETICS

-

- Toothpaste

- Shampoo

- Creams

- Lotions

- Fragrances

- Perfumes

AGITATORS FOR THE PRODUCTION OF FOOD AND BEVERAGES

-

BEVERAGES

- Cider and wine

- Beer and wort

- Beer-lemonade mixed drink

- Fruit juices

- yeast

- mash

- slop

- raising agents

- carbonated drinks

SAUCES AND SPREADS

- bouillon concentrates

- spread

- ketchups

- mustard

- spice mixtures

- jam

- salad dressing

- honey

- syrup

AGITATORS FOR THE MANUFACTURING OF MILK PRODUCTS

-

Visco Jet® Agitators are designed to mix a diverse range of milk products.

- Milk, Condensed Milk, and Buttermilk

- Sour Cream

- Quark

- Cheese Spread

- Whey and Whey Concentrate

- Cream

- Yoghurt (with and without fruit)

- Milk Drinks

- Milk Powder

AGITATORS FOR THE MANUFACTURING OF PHARMACEUTICAL AND CHEMICAL PRODUCTS

-

Visco Jet® Agitators are designed to mix a diverse range of materials used in the manufacturing of Pharmaceutical and Chemical products.

- Lecithin

- Blood Plasma

- Nitric acid

- Capillary products

- Paraffins

- Penicillin

AGITATORS FOR THE MANUFACTURING OF PAPER PRODUCTS

-

Visco Jet® Agitators are designed to mix a diverse range of materials used for manufacturing paper products.

- Cardboard And Paper Pulp

- Gluing Agents

- Dyes and Colorants

- Bleaches

- Cellulose Pulp

- China Clay Suspensions

AGITATORS FOR THE MANUFACTURING OF SOAP AND OIL PRODUCTS

-

Visco Jet® Agitators are designed to mix a diverse range of materials used in the manufacturing of soap and oil products.

- crude oils

- oils

- greases

- liquid soap

- soap pastes

AGITATORS FOR THE MANUFACTURING OF SWEETS AND CONFECTIONARY

-

Visco Jet® Agitators are designed to mix a diverse range of materials used in the manufacturing of sweets and confectionary.

- Biscuit Mixtures

- Chocolate and Cocoa Mixtures

- Caramel and Honey Masses

- Butter Mixtures

- Ice Cream

- Protein and Egg Yolk Mixtures

- Chewing Gum Mixtures

- Gelatin

- Baking Mixtures

- Fruit Mixtures

- Syrup Mixtures

- Melted Mixtures

- Juice Mixtures