- Offer Profile

-

PLASTIC RECYCLING SOLUTIONS

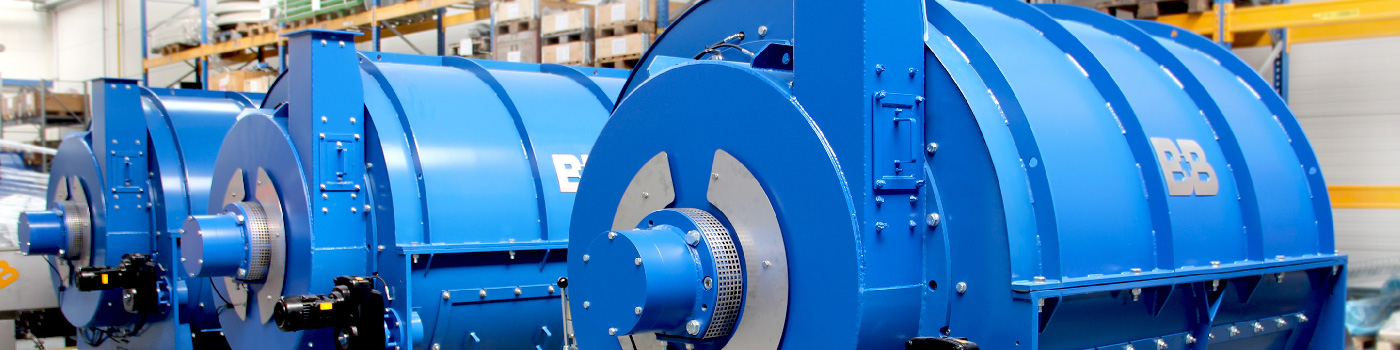

B+B DESIGN, SUPPLY, INSTALL AND MAINTAIN RECYCLING MACHINERYThe growing part of waste management is plastic recycling solutions. Quality of sorting, washing and separation machinery is becoming increasingly important.

For recycling plants worldwide, we design, supply, install, and maintain plastic recycling machinery and complete washing lines for nearly all kinds of plastic.

PLASTIC RECYCLING MACHINERY

-

At B+B, we have been designing, developing, and delivering various machines to wash, separate, dry, and pack plastic flakes, granules, and pellets for over 30 years. We deliver plastic recycling machinery with high experience and knowledge.

The general awareness for a circular economy and specifically regarding the need to recycle plastics, for instance from packing we discard, grows every day. Statistics show that within the European Union, for instance, only a small amount of recyclable plastics is converted to cleaned reusable materials.

However, the knowledge and experience to build recycling installations and design machines to generate high-quality renewable plastics are available.

By combining forces with other Heilig companies such as Bezner for pre-selection machines and Beemster for electrical solutions we can design complete and high-tech plastic recycling installations.

SEPARATION MACHINERY

-

SEPARATION MACHINERY FOR PLASTIC WASHING LINES

An important part of recycling plastics is the dewatering process and subsequent drying process. Our drying systems consist of mechanical dryers, thermal dryers, and step dryers for the following steps in the process, e.g., extrusion.

SINK FLOAT TANK

-

APPLYING GRAVITY SEPARATION

Applying a sink float tank is one of the most valuable separation techniques in recycling systems. We also see descriptions in the industry such as separation tank or float sink separator. The tank is filled with water and, depending on the materials to be separated, additives to alter the fluid’s density.

The mixed plastic stream is dosed into the tank where high-density materials will sink, and low-density materials will float. The separated particles will be recovered and conveyed for further processing.

EXAMPLES OF COST-EFFECTIVE GRAVITY SEPARATION

The separation tank is ideal for PET bottle recycling. The PET flakes, for instance, will sink to the bottom. Other materials such as plastic wrappers and bottle cap flakes will float, as they are manufactured from different kinds of plastics, mainly from PP and PE.

Another application is mixed plastics streams. For example rigid PP/PE or film. This has a lower density making the plastics float while contaminant particles such as metals, glass, soil, and sand will sink to the bottom to be discarded.

B+B SINK-FLOAT TANK IS LOW IN ENERGY CONSUMPTION

An innovative float-sink tank installation built by B+B offers advantages including:

- applicable for multiple types of plastics, e.g. PET, PP/PE, and PS/ABS

- high selectivity through basic principle of gravity separation

- automatic level adjustment via pressure gauging

- cost-effective thanks to low operational costs (low maintenance and wear) and low energy consumption

ZIG ZAG AIR CLASSIFIER

-

A zig zag air classifier divides a mixed material stream into two homogeneous streams. The upward vacuum extraction ensures the lighter micronized materials blow up to exit the sorting chamber separately, leaving the heavier materials to exit at the bottom.

For higher quality performance, B+B builds classifiers by placing multiple units in a circular arrangement. The material is evenly distributed via a plate ensuring a higher throughput.

ZIG ZAG AIR SEPARATOR APPLICATION

B+B builds and supplies customized zig-zag air separators for two main points in the recycling process. First, for the separation of films or paper after dry cleaner and second, for the separation of fines and dust from the ‘end product’.

The zig-zag air classifier is commonly applied in the PET recycling process, when contaminants, such as labels, paper, and plastic wrappers are removed from the PET flakes.

WITH A ZIG-ZAG AIR CLASSIFIER, YOUR PROCESS BENEFITS FROM:

- crossflow sifting of granules and small-sized plastic particles

- multi-chamber system for high-quality separation

- compact design

- practically maintenance-free enabling continuous operation

DRY CLEANER RECYCLING

-

SERVES AS PRE CLEANER AND CENTRIFUGE

A dry cleaner recycling is a machine designed by B+B that serves the purpose to pre-clean plastics from sand, stones, glass, paper, etc. This method is very sustainable because it requires no addition of water and is low in energy consumption.

Practice shows that a combination of the dry cleaner followed by the zig-zag air classifier {LINK to zig-zag air classifier} results in a 90 – 95% separation of contaminants, without the plastics coming in contact with water or cleaning solution.

ADVANTAGES OF DRY CLEANER AS PRE-CLEANER

- no water consumption, no water waste

- low waste disposal costs because this is dry material only

- save on operating costs as the machine stays dry at all times

B+B builds and supplies a custom-made dry cleaner according to your requirements for the plastic recycling process. For wet material streams, we design stainless steel machines.

DRYING MACHINERY

-

DRYERS FOR PLASTIC WASHING LINES

An important part of recycling plastics is a dewatering process and subsequent drying process. Our drying systems consist of mechanical dryers, thermal dryers, and step dryers for the following steps in the process, e.g., extrusion.

MECHANICAL DRYER

-

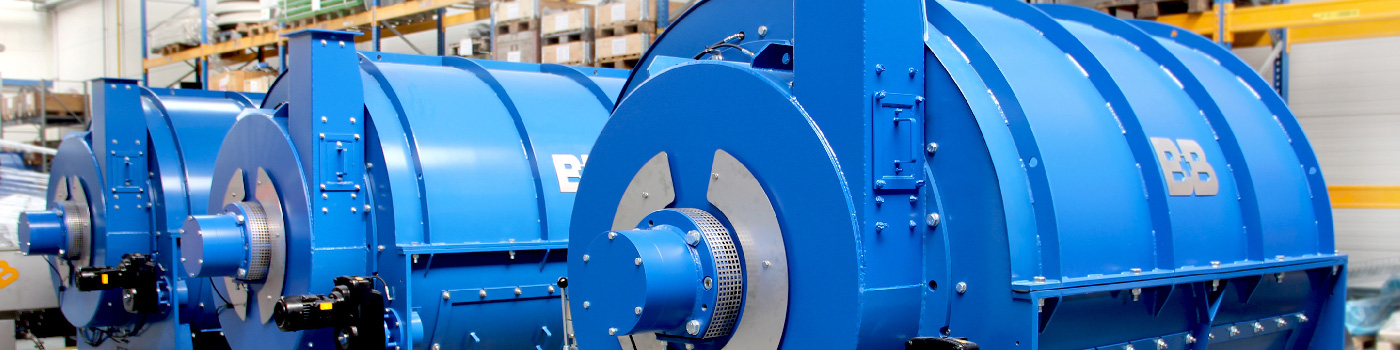

FOR MAXIMUM MOISTURE REDUCTION IN YOUR RECYCLING PROCESS WITH MECHANICAL DRYER

This efficient mechanical dryer machine obtains maximum moisture reduction from a plastic flake stream, for instance PET. A logical step between the washing and the drying process, because it reduces the overall effort of the thermal dryer resulting in reduced energy consumption.

B+B designs and builds dryers with a length of up to 5 meters by using the method of centrifugal force. Our machines reach a residual humidity of < 1% in the output stream of plastic pellets or flakes.

CENTRIFUGAL FORCE GENERATES FRICTION FOR ADDITIONAL CLEANING BENEFIT

The centrifugal force in the machine generates high friction. The stream of dried materials will therefore also be disposed of dust by the basket screens. During the process, the screens will be automatically cleaned.

Features of the B+B dryer or centrifugal washer include:

- designed for maximum moisture reduction

- practically maintenance-free

- low wear

THERMAL DRYER RECYCLING

-

THERMAL DRYER FOR RESIDUAL MOISTURE REDUCTION

Installing a thermal dryer is the logical subsequent step in the plastic recycling process which follows the mechanical drying stage. Thermal drying will reduce any residual moisture from the surface of plastic flakes (rigid or film) for the subsequent steps in the process, e.g. extrusion.

B+B builds and supplies thermal dryers, or air dryers, by implementing the heat conveying technique from our sister company Geurts Heat Exchangers. According to your requirements, we can design a thermal dryer fueled by oil or gas, thermal oil, or electrically operated or utilizing hot air from another part of your production process.

STEP DRYER

-

FOR DEWATERING AND DRYING

An important part of recycling plastic is the dewatering process and subsequent drying process. B+B designs and supplies a combination of innovative vertical dewatering equipment and a dry system named step dryer.

Residual moisture levels in the range of 0.4 – 0.06 wt% can be attained for thermoplastic granules in virgin production processes such as polycarbonate, polyethylene, polyamide, polypropylene, and polystyrene. Our engineers can aim for even lower numbers upon request.

REMOVING CLEANING WATER FROM PLASTIC GRANULES IN STEPS

Contrary to a regular dewatering machine, or plastic sludge dryer, the step dryer, designed by B+B, is fitted with both a step-shaped basket screen and rotor.

The material stream of plastic granules or flakes and water enters the lower part of the step dryer and is transported throughout the process by conveyor vanes. After the first step of separating the splash water, the granulated or flake material stream is accelerated by inertial forces resulting in an optimal separation of residual adherent water. In the last step, the static pressure of air in the upper part of the dryer prevents any excess water to exit with the dried material.

PLASTIC WASHING MACHINERY

- We build plastic washing machinery such as friction and hot washers for mixed plastics with high contamination or persistent dirt, for instance, PET and film flakes. According to your requirements, B+B builds and supplies a variety of plastic washing lines differing in throughput, driving power, and diameter. Check out our plastic washing lines.

FRICTION WASHER

-

REMOVES DIRT FROM CONTAMINATED PLASTICS

A friction washer or friction separator is a water high-speed cleaning machine for mixed plastics with high contamination or persistent dirt, for instance, PET and film flakes. Ideally, the friction washer follows both the hot washer as a rinsing unit in the plastic recycling process.

Also, B+B supplies customized friction separators for the paper and cardboard industry.

CLEANING PROCESS OF A HIGH-SPEED FRICTION WASHER

With a high-speed revolving rotor, the polluted ground material is conveyed through the housing. A cleaning solution that is constantly refreshed flows in the opposite direction and the rapid rotations allow the contaminants to rub off and break down into small particles. The inner screen tube functions as a dewatering device and filter for contaminants.

B+B supplies friction washers with the following advantages:

- Intensive pre-cleaning of plastic flakes

- Thorough dissolution and separation of impurities

- Intensive rinsing through additional washing fluids

- Automatically cleaning of the screens through water injection

- Continuous recycling operation thanks to maintenance-free quality

PLASTIC FLAKES HOT WASHER

-

HOT WASHER FOR PET FLAKES

A plastic flakes hot wash machine, or also known as a PET hot washer, is an indispensable piece of equipment for any plastic recycling industry producing recyclables requiring food-grade or high-quality grades. Adding this machine to the washing line of plastics such as PET, HDPE, PP/PE, etc., removes contaminants such as adhesives, scrap label remnants, drink and food residues, odor, etc.

HIGH ENERGY EFFICIENCY AND CONTINUOUS OPERATION

Depending on your throughput requirements, B+B customizes the plastic hot washer with a number of washing chambers that are continuously filled and emptied in a revolving principle. Also, the machine is provided with a closed cleaning water circuit that automatically purifies the washing solution and passes it through a heat exchanger before reentering the washing chamber.

THE BENEFITS OF A B+B CUSTOM-MADE PLASTIC HOT WASHER MACHINE INCLUDE:

- Pre-cleaning for obtaining food grade recyclables

- High energy efficiency thanks to innovative recycling technology

- Precise dispensation of caustic soda or other additives

- Installable as a single machine to an existing recycling plant

- Washing water heated by commonly fueled heat exchangers (steam, gas, and electricity)

- Continuous operation

- Continuous cleaning water circuit

PACKING MACHINERY

BIG BAG FILLING STATION WITH VARIOUS OPTIONS

-

To complete the washing line, a big bag filling station is the last step in the plastic recycling process offering perfect material handling.

B+B supplies automatic filling stations for big bags with the following options:

- a choice of vibration or distribution mechanism

- filling level control

- fan to inflate the big bag

- double or single design

- dust extraction

- optional integrated weighing scale

PROCESS

-

THE PROCESS OF PLASTIC RECYCLING

At B+B, we build machines used in the process of plastic recycling plants. Our machines process various kinds of plastics, including PET, HDPE, LDPE, PP, PVC, PS, etc. As every kind of plastic has their specific properties and the output of the recyclable new ground materials need to meet different demands, the recycling requirements may vary. To illustrate the steps of the plastic recycling process, we will describe the recycling of plastic bottles (PET). Due to the feed-quality requirements, this type of recycling needs to meet stringent demands.

EXAMPLE WASHING LINE FOR PLASTIC RECYCLING

Shredded waste material enters the washing line as contaminated PET flakes and is first conveyed through a friction washer for cold water cleansing of light contaminants such as liquids and paper. After the first wash, the next step is drying the material stream and separating further contaminants, for example, dust and sand. This is done in a mechanical dryer. For highly contaminated material, e.g. to remove adhesives from labels, and to meet food grade standards, another washing stage may be required. In a continuous PET hot washer, the flakes are soaked in a mixture of hot water washing solution, followed by a friction washer where the material is rinsed. In a sink-float tank the PET flakes separation from the lighter plastics such as PE/PP from bottle caps will take place. Lastly, the mechanical dryer will dewater the PET flakes while the polyolefins are dried by a thermal dryer.

TESTING FACILITY

-

TESTING FACILITY TO VALIDATE YOUR CASE

Are you ready to stop wondering about recycling and start validating your needs?

If you are interested in recycling of your plastics, this can raise a lot of questions about the feasibility. Wouldnt it be nice to build in some certainty before making an important decision?

This is what we offer you! At our warehouse (shop) only 40 minutes away from Amsterdam, you can do a solid test and prove your business case to obtain your own plastic hot washer. Based on the results we realize an optimized plant for your needs with lowest operational costs.

With our installations you can do all kind of tests. Together we review the final results and we advise you about the next steps.