Prima additive

Videos

Loading the player ...

- Offer Profile

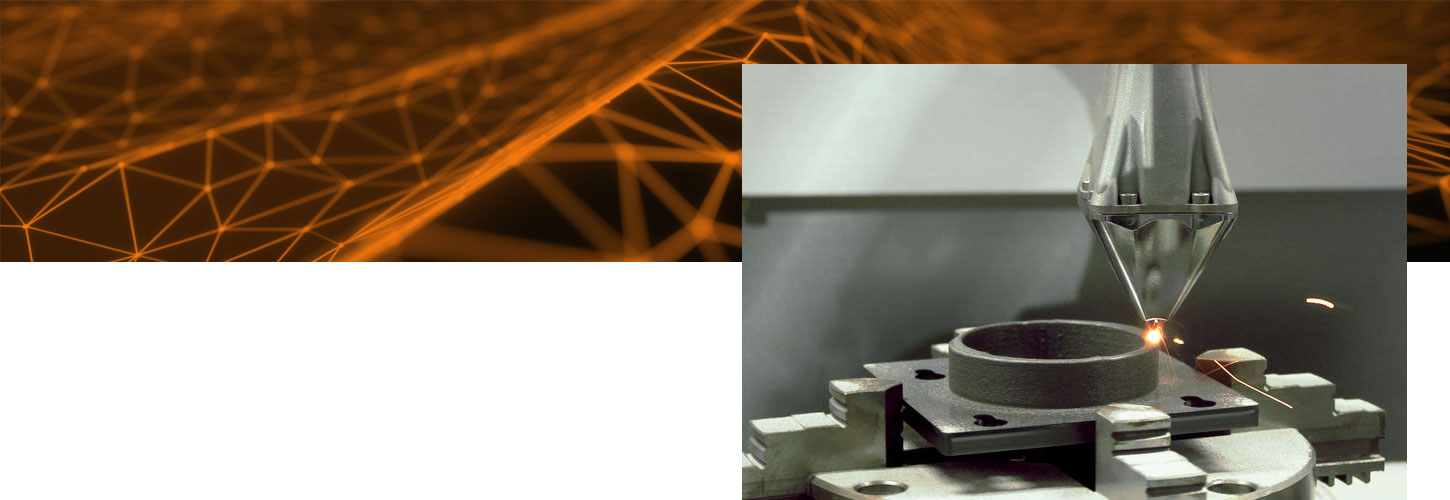

- Prima Additive is one of the few manufacturers and distributors in the world to offer the best laser technology for additive manufacturing: Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

Prima Additive’s product portfolio includes the two largest laser technologies on the market for metal 3D printing applications and aspires to become one of the leading manufacturers in the additive manufacturing market through both strategic partnerships and innovative solutions.

Product Portfolio

Additive Manufacturing

Manufacturing is changing radically!

Prima Additive specialises in the design and manufacture of machines that take advantage of the latestlaser technology and applies it tometal 3D printing.

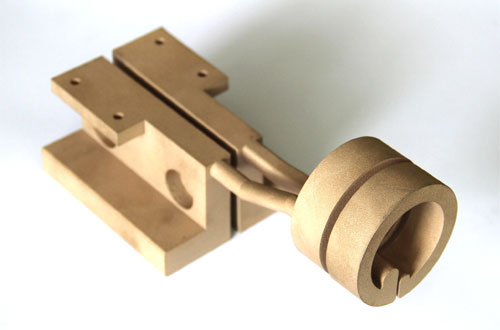

The result? Manufacturing of three-dimensional parts with complex geometries created layer by layer from metal powder melted by an extremely accurate laser source, but also the option of repairing metal parts with high added value.What is additive manufacturing?

Design like you have never designed before.

Metal Additive Manufacturing, also known as Metal 3D Printing, is technology used to produce three-dimensional parts formed layer by layer by using a metal powder that is melted with a laser source .

Or, more simply, with this technology you can produce metal objects with complex geometries that you otherwise could not achieve with other traditional technologies.

The benefits are considerable, starting with a business model that is truly tailored to your needs and ultimately offers previously unexplored production opportunities.

In fact, with Additive Manufacturing, you can completely turn the production paradigm on its head, moving from a model requiring large warehouses to on-demand production, or from standard to customised production, making components lighter and more functional in their use.

The two main processes of Additive Manufacturing

- Complex geometries or targeted repairs, all tailor-made.

Prima Additive develops and offers innovative laser systems for both major metal additive manufacturing processes: Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

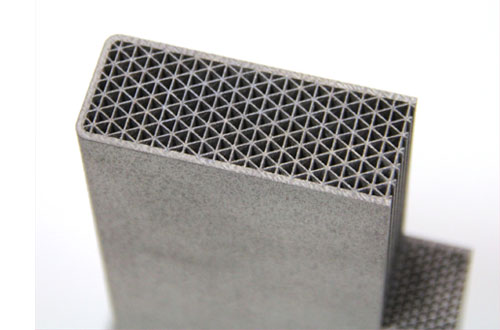

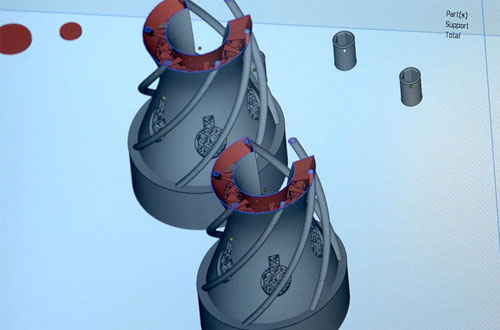

With Powder Bed Fusion technology, you can make objects having very complex geometries, with internal channels or very small parts, thus giving the finished piece a truly functional design.

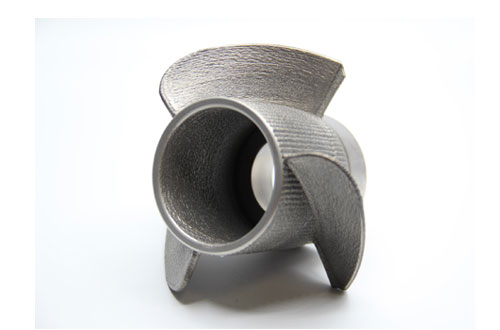

With Direct Energy Deposition technology, also known as Laser Metal Deposition, you can choose to deposit metal powder exactly where it is needed. In this way, you can repair, customise or coat parts with high added value, reducing waste and embracing the Circular Economy model.

But technology alone is not enough, however: Prima Additive also provides you with all the application support you need to reap the best possible benefits from the additive manufacturing process. Thanks to our experience, you can learn how to redesign your components to take full advantage of this technology: in so doing, you can produce more functional, lighter parts or integrate several components into one thanks to the freedom that additive technology brings.

Advantages

Discover how Additive Manufacturing can revolutionise your business.

Design freedom

- Thanks to its layer-by-layer creation process first and foremost, metal additive manufacturing provides freedom of design that is unthinkable with traditional metalworking technologies. By 3D printing a component rather than machining it, you can produce complex geometries with unmatched accuracy and detail.

In this way, you can redesign components with a shape that is functional to their use rather than a shape that suits the production technology. What's more, you can consolidate multiple parts into one piece, resulting in a better-performing design while eliminating assembly time and related issues.

With additive manufacturing, you can also make parts with very complex internal channels, which ensure optimal cooling of the components.

Lighter parts

- Since component design is optimised according to its actual use, you can create

lighter parts by emptying full parts into lattice structures, creating

organic, fluid shapes where previously there were square, solid parts.

Think of the advantages that lighter parts can bring to sectors such as aerospace or motorsport: greater competitiveness, better performance in cars, reduced fuel consumption in aircraft, etc.

Finest mechanical characteristics

- The mechanical characteristics in terms of porosity of the material, high-temperature resistance, and resistance to stress and fracture are comparable to, if not better than, parts produced with traditional or cast technologies.

Rapid prototyping

- An object can be designed, printed, and tested much more quickly and accurately, eliminating several steps in the product development process, with a

drastic reduction in errors, thanks to a system that controls the whole production process layer by layer.

In this way, the lead time from idea to the final product is shortened, prototyping time is reduced and this allows you to go to market faster, as well as to test more variants and customisations. This offers your customers better and more reliable parts, improving the whole product development process.

Repair and customisation of components

- Not just building parts from scratch: Prima Additive’s Direct Energy Deposition solutions also allow you to repair metal parts, as well as coat them with other metal or add customised parts to existing parts. In this way, instead of creating new components, you can reuse what you have, making your business “greener” and more sustainable and, above all, save money.

Reducing waste

- With the layer-by-layer powder fusion process, only the material needed to produce the object is used. The metal powder used in the production process and that is not melted can be recycled and used later. This drastically reduces production waste, which is a major issue with traditional machining technologies.

More product control

- The infinite possibilities offered by additive manufacturing allow you to make any part that can fit within the working area of the machine. In so doing you can produce

parts that were previously made by different suppliers, or make third-party parts for the most varied of sectors.

In addition, additive manufacturing revolutionises the supply chain: it is, therefore, possible to produce parts on-demand, preventing large stocks of spare parts being kept in a warehouse, but producing only what is needed, when it is needed, avoiding long waits and transport costs.

Our vision

We bring innovation to the future of your business.

Metal Additive Manufacturing is a profitable and reliable technology that relates to an innovative business model.

Thanks to our solutions, you can grow your company with greater efficiency and creativity, ensuring your projects are highly functional and optimised.

To do this, we apply three major pillars that are the basis of our way of working.Competitiveness

Today's production technologies are changing fast: companies need to react quickly. Timing is crucial, and Metal Additive Manufacturing can be the ideal solution to innovate your business. Even if everyone applies the same rules of play, in industry there will always be someone who manages to outperform the rest. This is because that business has a broad culture, a system of intelligent thinking that spans across production, sales and marketing of the product. This, together with time, is what makes the difference between a true market leader and a hamster running on its wheel.Sustainability

Sustainability is not just a word. It is a concrete strategy to improve your business: Additive Manufacturing can help you achieve significant innovative, sustainable and profitable goals, while reducing waste and costs.

Recycling and reducing emissions are an important step, but if we really want to shift the paradigm, we have to start at the beginning of the product's life, where we can really make a meaningful and lasting impact. For us, sustainability is not just a question of ethics, but a real desire to find a solution that is good for both the environment and profitability.Change

No one is really aware of the importance of change. Many times the innovation process is seen as a waste of time or money: the problem is not the innovation process itself – the problem is finding the right partner with whom to tackle innovation.

Constant change, combined with adaptability, is a vital requirement for every business. Only those who adapt quickest to market requirements survive and thrive. But to really understand change, we have to be ready to embrace it. Only a fluid and flexible solution can ensure our survival in a market that changes much faster than we do.Technologies

What are your needs?

Do you need to produce ultra-lightweight or geometrically complex components? Would you like a prototype quickly? Or do you need to repair or replace parts without having to wait for suppliers?

In all these cases, metal additive manufacturing comes to your aid. Thanks to our more than 40 years of experience in laser technologies, we have developed complete solutions based on Powder Bed Fusion and Direct Energy Deposition technologies.Powder Bed Fusion

Space for any shape

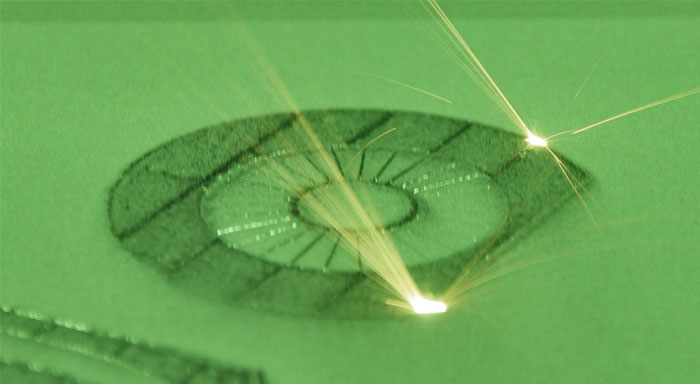

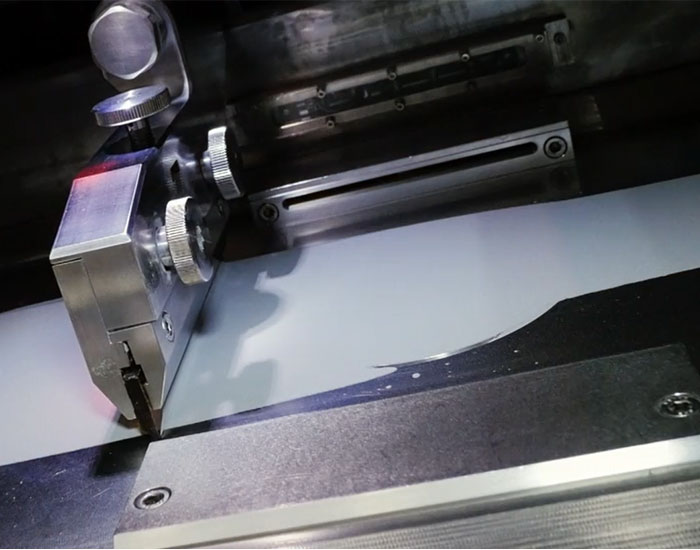

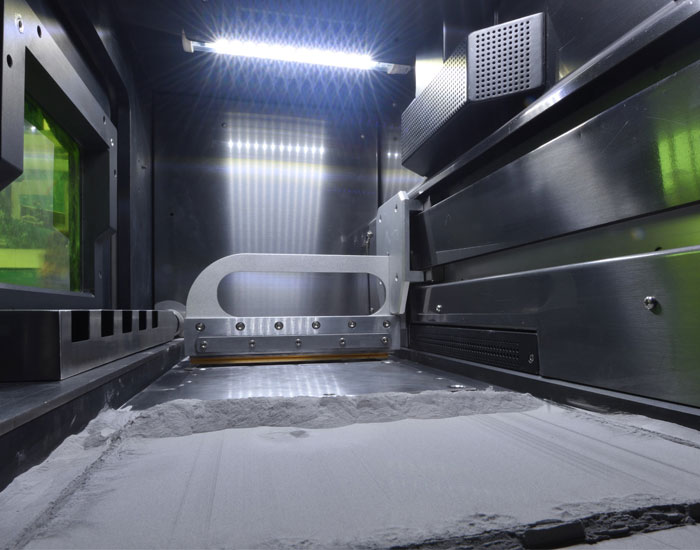

The Powder Bed Fusion process uses the thermal energy of the laser to fuse the section of an object to a layer of metallic powder.

Thermal energy generated by a fibre laser source melts the powder, which solidifies as it cools, thus creating the part layer by layer.

After melting a section, the platform lowers and the doctor blade deposits a new layer of powder. The process is repeated until the component is completely manufactured section by section.

Choose this technology if you need:- complex geometries

- small batch production

- prototypes

Print Sharp 150

- Designed for R&D applications, for processing steel, aluminium, nickel, titanium, and cobalt chrome alloys.

- Open Parameters

User-customisable for research and development of new materials - All Under Control

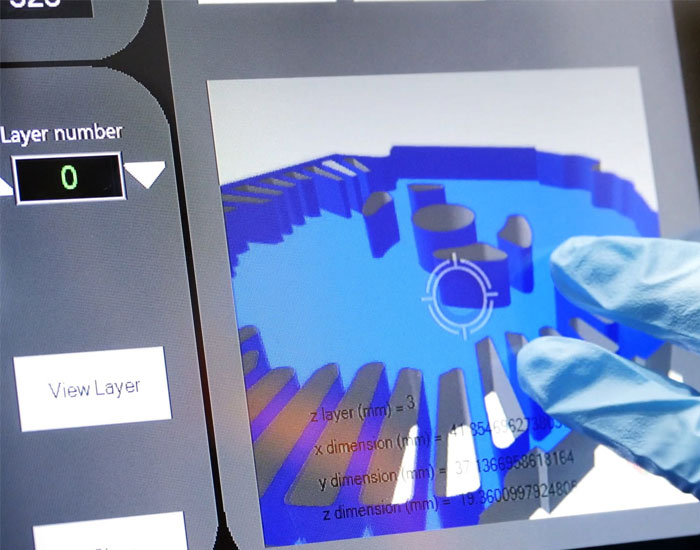

Control systems analyse any defects in the metal powder layer in real time.

Overview

The Print Sharp 150 Powder Bed Fusion machine is an innovative open-configuration powder bed additive system consisting of a cylindrical working area, a preheating system, real-time monitoring of process parameters and a laser spot. A compact additive manufacturing machine with a building volume of Ø150mm and H = 160mm for manufacturing small components.

The system has optimised gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components.

With the ability to customise process parameters, Print Sharp 150 is also ideal for those looking for a machine with which to research new materials.

Characteristics

Print Sharp 150 is equipped with a 300W single mode IR fibre laser source. The laser source is air-cooled, so no external unit cooler is required.

A single line width of 0.1mm and a minimum layer thickness of 0.02mm can be achieved for high precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy and export machine-readable files.

The system is equipped with a filter unit for recirculating gas within the working area. The filter unit maintains a high level of cleanliness and is easily adjustable thanks to the control installed on the interface. Gas flow within the chamber can be modified to optimise flow as required. - Open Parameters

Print Sharp 150 Technical Data

- Building volume: Ø 150mm; h=160mm

- Layer thickness: 0.02 – 0.12mm

- Laser: 1 x 300W IR fibre laser

- Laser spot diameter: 35 - 100μm (adjustable focus position)

- Heated platform: Up to 300°C

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Print Genius 150

- Great versatility thanks to multi-laser technology

- Double Laser

Equipped with two lasers working simultaneously or alternating to increase process versatility. - High Quality

Pre-heating both from the top and bottom of the powder bed to 300°C to ensure best melting performance.

Overview

The dual laser solution of the 150 family: Print Genius 150 is an innovative additive system based on Powder Bed Fusion technology, based on Prima Additive’s 150 platform, which features a cylindrical working volume of Ø150mm and H = 160mm.

In its standard version the machine features a laser configuration with two 300W infrared lasers that operate simultaneously on the same work area, thus reducing part build times.

The system has optimised gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components.

Like the other machines in the 150 Series, it is equipped with a system for adjusting the focal point of the laser beam as required, so that parameters are always optimised to suit the application. It also has a dual pre-heating system that allows the surface of the powder bed to be heated both from above and below via a heated plate, thus allowing the powder bed to reach a temperature of up to 300°C.

The high-speed coaxial pyrometer monitors the temperature in real time and 2 cameras monitor the process and the powder bed. The system has open parameters, suitable for process and material research and development.

Print Genius 150 Double Wavelength

Print Genius 150 is also available in a “Double Wavelength” version. What makes this machine unique is the innovative configuration of the laser sources: Print Genius 150 Double Wavelength is equipped with a 300W infrared laser and a 200W green laser, which can operate alternately on the same work area. This makes it possible to process both alloys that can conventionally be processed using infrared lasers (steel alloys, aluminium, titanium nickel, cobalt chrome), as well as pure copper or other highly reflective materials with the green laser. - Double Laser

Print Genius 150 Characteristics

- Laser configuration:

- Standard version: 2x single mode IR fibre lasers with 300W power and 100% overlap area.

- Double Wavelength version: 1x single mode fibre laser in IR with 300W power + 1x green fibre laser with 200W power

A single line width of 0.1mm and minimum layer thickness of 0.02mm can be achieved for high precision. A reliable and compact 3-axis optical scanning system, offering high processing speeds and various scanning strategies.

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy and export machine-readable files.

The system is equipped with a filter unit for recirculating gas within the working area. The filter unit maintains a high level of cleanliness and is easily adjustable thanks to the control installed on the interface. Gas flow within the chamber can be modified to optimise flow as required.

Technical Data- Building volume: Ø 150mm; h=160mm

- Layer thickness: 0.02 – 0.12mm

- Laser: 2 x 300W IR or 1x 300W IR + 1x 200W Green fibre laser

- Laser spot diameter: 45 - 100μm (adjustable focus position)

- Heated platform: Up to 300°C

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy, pure copper.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Print Green 150

- Equipped with a green laser for processing pure copper, copper alloys and highly reflective materials.

- Green Laser

Thanks to the green laser, you can process highly reflective materials such as pure copper or precious metals: the ideal solution for the electronics and industrial components sector. - Always the Right Spot

An optical system equipped with a beam expander to adjust the size of the laser beam according to requirements, combined with automatic variation of the laser’s focal spot on the platform, performed by software for an optimal result.

Overview

Print Green 150 is Prima Additive's Powder Bed Fusion solution with a green laser for processing highly reflective materials such as pure copper.

It has a cylindrical building volume of Ø150mm and H = 160mm and a configuration with open parameters.

Like the other machines in the 150 Series, it is equipped with a system for adjusting the focal point of the laser beam as required, so that parameters are always optimised to suit the application. It also has a dual pre-heating system that allows the surface of the powder bed to be heated both from above and below via a heated plate, thus allowing the powder bed to reach a temperature of up to 300°C.

The high-speed coaxial pyrometer monitors the temperature in real time and 2 cameras monitor the process and the powder bed. The system has open parameters, suitable for process and material research and development.

The system has optimised gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components.

Characteristics

The Print Green 150 is equipped with a 200W single mode green fibre laser. A chiller unit is included to cool the green laser source.

A single line width of 0.1mm and a minimum layer thickness of 0.02mm can be achieved for high precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy and export machine-readable files.

The system is equipped with a filter unit for recirculating gas within the working area. The filter unit maintains a high level of cleanliness and is easily adjustable thanks to the control installed on the interface. Gas flow within the chamber can be modified to optimise flow as required. - Green Laser

Print Green 150 Technical Data

- Building volume: Ø 150mm; h=160mm

- Layer thickness: 0.02 – 0.12mm

- Laser: 1 x 200W Green fibre laser

- Laser spot diameter: 30μm (adjustable focus position)

- Heated platform: Up to 300°C

Materials- aluminium alloys,

- copper alloys,

- pure copper.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Print Sharp 250

- Great flexibility for any application in terms of size, materials, and complexity of parts that can be printed.

- Flexible

Suitable for a wide range of materials, including reflective metals. An “open” system for configuring process and machine parameters. - Reliable

Capable of working continuously for up to 200 consecutive hours ensuring process repeatability and quality. - Convenient

Excellent value for money together with an extensive network of suppliers of materials and consumables. - Easy to Use

Simple operating process, intuitive software interface, easy maintenance and configuration.

Overview

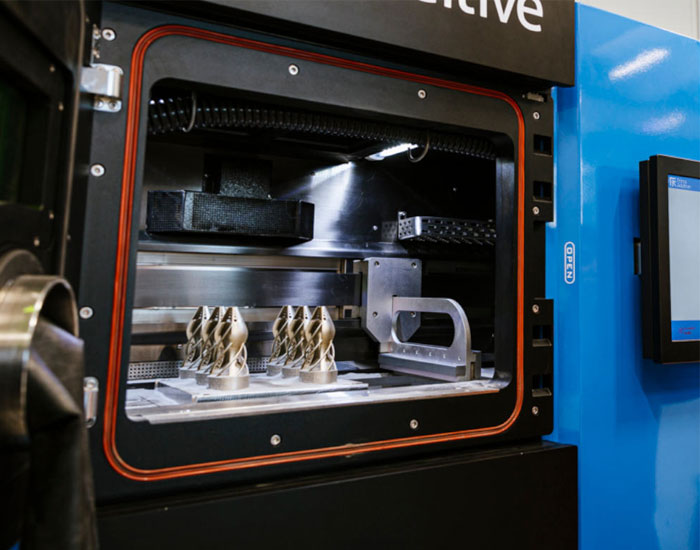

Print Sharp 250 is a medium-volume machine for Powder Bed Fusion applications, developed for industrial manufacturing of complex components. Suitable for both Additive Manufacturing companies and prototyping purposes, it offers high flexibility in terms of parts management and operational performance.

The competitive price of the entire system means that you can invest in Additive Manufacturing technology quickly and with little risk, intelligently achieving one of the most innovative manufacturing technologies available on the market.

Thanks to its modular configuration with easily removable components, a full material change can take place in less than 2 hours.

The machine comes with a “glove box” type access door to the working chamber, through which it is possible to move the powder inside the chamber while keeping the door closed during operations. The machine is also equipped with a socket for using an integrated vacuum cleaner directly inside the building chamber. This allows the operator to operate the machine safely, without coming into contact with the powder.

Print Sharp 250 includes intelligent control software designed to make operation easy and efficient, with an intuitive interface that makes setting up and operating the machine simple and hassle-free. The user can adjust parameters, modify printing conditions, change the building platform, material or powder collector. Intuitive operating procedures and simple maintenance operations increase the machine's utilisation rate and performance, helping you get the most out of your investment. - Flexible

Print Sharp 250 Characteristics

- The Print Sharp 250 comes with a 500W single mode IR fibre laser.

Print Sharp 250 comes with a range of suggested configurations for each available material. Nevertheless, depending on the desired objective (output or quality), different sets of customised process parameters can be created to suit different applications.

Print Sharp 250 produces components with high quality mechanical and surface characteristics, and offers post-processing solutions to meet the most demanding objectives.

It has a filter unit for gas recirculation within the working area. The filter unit maintains a high level of cleanliness, minimising the need to replace parts prone to wear and tear.

Technical Data- Building volume: 258x258x330

- Build rate: 12-30cm3/h (depending on material used and part geometry)

- Deposition layer height: 0.02 – 0.1mm

- Layer width: 0.1mm (single track width)

- Laser power: 500W single mode IR fibre laser

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Print Genius 250

- Optimised dual laser solution

- Production

The two lasers work simultaneously to improve production time. Ability to work with individual laser print modes. Small parts can be printed during the same job using just one laser. - Production

The two lasers work simultaneously to improve production time. Ability to work with individual laser print modes. Small parts can be printed during the same job using just one laser. - Efficient

Improved gas recirculation system reduces purge time to fill the chamber in 25 minutes and reduces gas consumption during the process. - Safe

Equipped with two lines of 1+1 filters that increase the service life of the filter, decrease frequency of cartridge changes and allow the filter to be changed during the process thanks to the removable cylinder.

Overview

Print Genius 250 is a metal additive manufacturing machine with a building volume of 258x258x350mm for producing medium-sized components.

This machine is the ideal solution for metal printing requiring high productivity, thanks to two 500W lasers, an intelligent control interface and software that allows for quick part orientation and functions setting.

Thanks to modular and easily removable components, it is possible to change material in less than 2 hours.

The machine comes with a “glove box” type access door to the working chamber, through which it is possible to move the powder inside the chamber while keeping the door closed during operations. The machine is also equipped with a socket for using an integrated vacuum cleaner directly inside the building chamber. This allows the operator to operate the machine safely, without coming into contact with dust.

Print Genius 250 includes intelligent control software designed to make operation easy and efficient, with an intuitive interface that makes setting up and operating the machine easy and hassle-free. The user can adjust parameters, modify printing conditions, change the building platform, material or powder collector. Intuitive operating procedures and simple maintenance operations increase the machine's utilisation rate and performance, helping you get the most out of your investment. - Production

Print Genius 250 Characteristic

- The Print Genius 250 is equipped with a dual laser: two single mode IR fibre lasers with 500W power working simultaneously in the same working area.

A single line width of 0.1mm and a minimum layer thickness of 0.02mm can be achieved for maximum precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

Depending on the desired objective (output or quality), different sets of customised process parameters can be created to suit different applications.

It has a filter unit for gas recirculation within the working area. The filter unit maintains a high level of cleanliness, minimising the need to replace parts prone to wear and tear.

Print Genius 250 produces components with high quality mechanical and surface characteristics, and offers post-processing solutions to meet the most demanding objectives.

Technical Data- Building volume: 258 x 258 x 350 mm

- Build rate: 25 - 50cm3/h (depending on material used and part geometry)

- Layer thickness: 0.02 – 0.1mm

- Layer width: 0.1mm (single line width)

- Laser: 2x 500W single mode IR fibre laser

Materials

Stainless steel, maraging steel, high-temperature nickel alloy (Inconel), titanium alloy, cobalt chrome alloy, aluminium alloy, high strength steel, copper alloy.

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

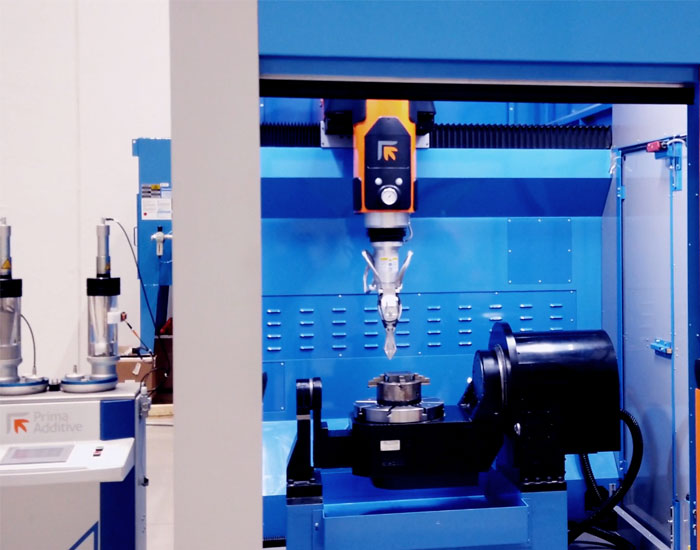

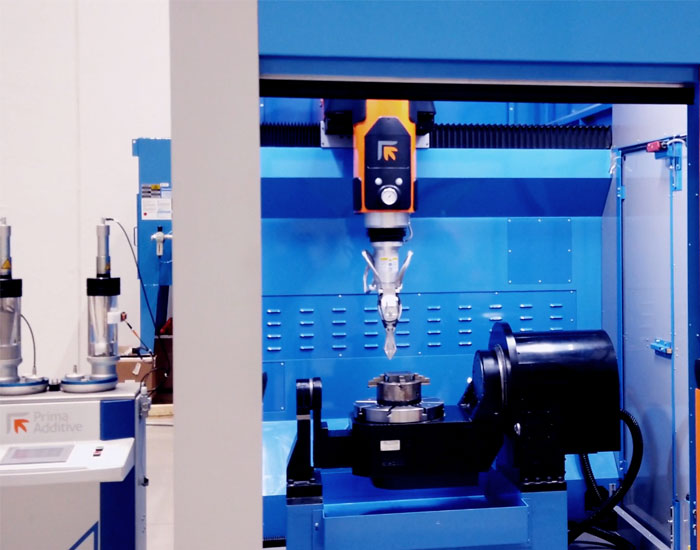

Direct Energy Deposition

Repair, coat and add with the power of laser

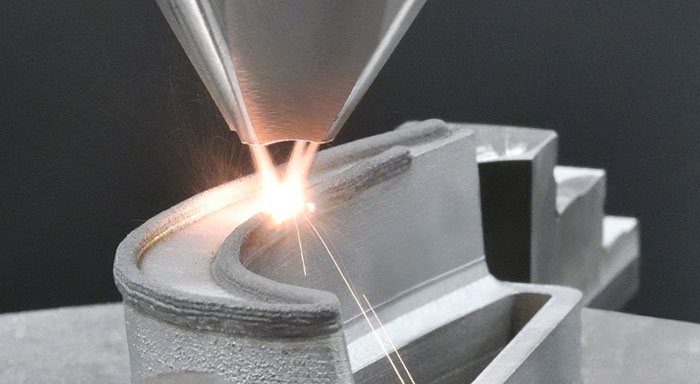

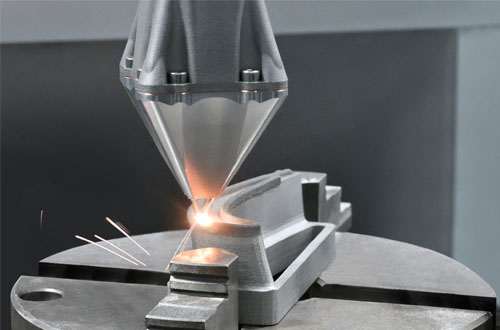

The Direct Energy Deposition process, also known as Laser Metal Deposition, uses focused thermal energy generated by a fibre laser source to melt sprayed metal powder at the point where the material is to be deposited.

In this way, the laser melts the powder, which is deposited on the component only where it is needed.

The laser is coaxial to the deposition head, which moves along 3 or 5 axes simultaneously. A rotary table can also be installed to keep the melt pool horizontal.

Choose this technology if you need to:- repair or coat metal parts

- add parts to existing objects

- produce large parts

LASERDYNE® 811

- The fastest solution for 3D manufacturing, repairs and coating with quality and precision.

- Reliable The machine embodies over 40 years of experience in engineering and industrial laser processing.

- Efficient

Increased overall equipment efficiency thanks to reduced downtime and maintenance. Fewer resources dedicated to machine maintenance. - Innovative

The machine can be equipped with the REAL_DED (Real-time Adaptive Laserbeam for Direct Energy Deposition) laser deposition head, developed and patented by Prima Additive to increase the performance and efficiency of the deposition - Inert Chamber

The machine can be equipped with an optional inert chamber to print reactive materials such as aluminium and titanium.

Overview

LASERDYNE® 811 with Direct Energy Deposition technology is a compact and precise laser platform for direct metal powder deposition. Thanks to its high build ratio, it is suitable for 3D manufacturing, component repair, research into new materials and the development of repair, rebuilding or coating applications.

This system provides precision and flexibility for a wide variety of components. The machine is equipped with one of the fastest laser processing systems in the industry. The controller supports 7 simultaneous motion axes and integrated automation to load and unload components and automation systems such as robotic and automated inputs, turntables or output platforms.

To facilitate the needs of different industries, the Prima Additive team supports customers at every stage until optimal process parameters are achieved and a repeatable result is guaranteed.

LASERDYNE® 811 Characteristics

- LASERDYNE® 811 DED is available with a 1000W (CF1000), 2000W (CF2000) or 3000W (CF3000) ytterbium fibre laser source. Convergent CF fibre lasers are the result of

Prima Industrie Group's experience in laser technology and have been developed for

industrial and research applications: it is a compact and efficient high-power laser, producing from 1000 up to 3000 watts respectively, with a wavelength of about 1070nm.

Rotary Table

The rotary table is the 6th and 7th control axis for manufacturing of DED parts, repairing of critical components or rebuilding of damaged tools. The rotary axis (6th axis) provides continuous rotation of N x 360° clockwise or anti-clockwise on the vertical axis. The tilting axis (7th axis) provides rotation from -150° to + 150° on the vertical axis. The rotating tilt can support 300kg and has T-slots for fitting equipment.

Technical Data- Working volume: 1100 x 800 x 600 mm

- Deposition rate: up to 70cm3/h (up to 100cm3/h with REAL_DED head)

- Laser: Yb Fibre Laser, CW multimode, 2000-3000W, IR 1070-1080nm

Materials

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

Laser Next 2141

- A large machine, available in various configurations, for repairing, coating, adding custom parts.

- Flexible The most versatile platform available today for direct deposition additive manufacturing. Allows for easy processing of even the most complex part geometries.

- Reliable Unique and proven reliability, thanks to the experience and installations of the Prima Industrie Group’s Laser Next platform.

- Efficient High efficiency (OEE) thanks to reduced downtime and maintenance. Fewer dedicated resources and simplified maintenance.

- High Capacity Very large working area combined with reduced floor area occupied

Overview

Laser Next 2141 with Direct Energy Deposition technology is based on a laser metal deposition process.

The system can handle both large and small parts and is suitable for repairs, reworking and coating.

The 5-axis platform is particularly suitable for all sectors that require movement flexibility and high precision.

Thanks to Prima Additive’s Direct Energy Deposition technology, the powder deposited on the component is melted where it is needed by a deposition head that moves along 3 to 5 axes simultaneously.

5-axis motion with CNC control and full CAM suite

5-axis CNC system with integrated multiple crash protection, easy access and loading position. The addition of a tilting rotary table increases the machine’s flexibility by providing the system with two additional axes for more complex applications. An integrated powder feeder with 1-4 hoppers (1.5 litres), Prima CNC control, and CAM software provide users with all the tools they need to set up the machine according to the requirements of the application.

Suitable for parts manufacturing and reworking in a wide range of materials

- Taking advantage of the workspace and easy installation, Prima Additive's largest Direct Energy Deposition machine can be used for complex repairs and reworking. To facilitate the needs of different industries, the Prima Additive team supports customers at every stage until optimal process parameters are achieved and a repeatable result is guaranteed.

Characteristics

Laser

Laser Next 2141 DED is available with a 1000W (CF1000), 2000W (CF2000) or 3000W (CF3000) ytterbium fibre laser source. Convergent CF fibre lasers are the result of Prima Industrie Group's experience in laser technology and have been developed for industrial and research applications: it is a compact and efficient high-power laser, producing from 1000 up to 3000 watts respectively, with a wavelength of about 1070nm.

Rotary table

The rotary table is the 6th and 7th control axis for manufacturing of DED parts, repairing of critical components or rebuilding of damaged tools. The rotary axis (6th axis) provides continuous rotation of N x 360° clockwise or anti-clockwise on the vertical axis. The tilting axis (7th axis) provides rotation from -150° to + 150° on the vertical axis. The rotating tilt can support 300kg and has T-slots for fitting equipment.

Technical Data- Working volume: 4140 x 2100 x 1020 mm

- Deposition rate: Max 50-70cm^3/h - typical 25-30cm^3/h (up to 100cm3/h with REAL_DED head)

- Laser: Fibre 1-6kW

Materials

Prima Additive helps you choose the right material for each application

Prima Additive recommends and offers a wide range of metallic powders, tested to ensure product quality and repeatable mechanical properties. The process parameters were fine-tuned to the specifications and behaviour of the powders during printing, enabling excellent (re)production of the components. Thanks to its portfolio of services, Prima Additive can provide support to customers to evaluate and select the most suitable powder for their applications and needs.

DED kit

- Unleash the power of direct energy deposition technology

An innovative and multi-purpose laser head, a highly efficient laser source, and a flexible and reliable powder feeder that can be integrated on your machine or on a robotic system.- Modular

Modular design allows the laser head to be mounted in different configurations (straight, 90 degrees, with or without monitoring system). Easy installation on any type of machinery and easy maintenance of all the components of the DED kit. - Flexible

The kit can be integrated with any laser machine and robotic system. Possibility to satisfy different requests related to laser power, laser head configuration, process monitoring system, type and capacity of the powder. - Efficient

The new nozzle design allows better powder use, while the fiber laser designed to offer high performance and efficiency guarantees low maintenance operations. - Profitable

Low cost of ownership along with a wide network of suppliers for materials and consumables.

Overview

The DED kit includes all the equipment needed for direct energy deposition applications: an innovative and multi-purpose laser head, a highly efficient laser source and a flexible and reliable powder feeder. Prima Additive can offer the main components together or separately, allowing the retrofit of any laser machine or the integration on any type of robotic arm and structure.

Kit Elements

Laser head

Modular and innovative laser head, designed to accommodate different laser processes and DED requirements. The laser head can be assembled in order to provide melt-pool monitoring (high-speed camera), pressurized optical path to avoid powder infiltration, and water-cooled additive-made nozzle for continuous additive depositions reducing powder adhesion risk during the process. Easy maintenance (cover glass and focal lens replacement), easy alignment of powder/laser spot and integration in any machinery and robotic systems.

Powder feeder

A powder feeding system developed to offer maximum flexibility and accommodate different materials. With the possibility of up to 4 powder hoppers and a capacity for up to 5.5 liters each, the system can be easily connected with any control system. Optional heating mats to keep the powder pre-heated, gas flow controller, and powder level sensors.

Laser source

The highly efficient and compact CF series high power fiber lasers, guarantees low maintenance operation, high reliability, and superior process performances. Convergent Photonics Fiber lasers are very easy to integrate into different machine configurations.

Other options

Along with the DED kit, Prima Additive can provide the rest auxiliaries for the DED process such as sieving system, vacuum cleaner as well as the AMXpress software plug-in (CAD / CAM) modified for any machinery. - Modular

Materials

Choose the metal that suits you.

Additive manufacturing is the innovative process of transforming metal into the component you need, even when it has to have very complex shapes or characteristics that are difficult or impossible to achieve with traditional industrial processes.

Yes, but what kind of metal?

Our 3D printing can work with different types of materials: aluminium, steel, copper, titanium, nickel, cobalt chrome. And we are here to advise you on the most suitable alloy for your production goals, depending on whether you choose Powder Bed Fusion or Direct Energy Deposition.Materials for Powder Bed Fusion

Discover the variety within Prima Additive’s offering

Yes, we can work on your material.

And, yes, if the material you want is not available, we can help you find the most suitable one.

And yes again, we can carry out tests to assess whether it is possible to print your material with our machines.

Prima Additive is at your side so you can always say "yes" to additive manufacturing with Powder Bed Fusion technology.

Are you curious to find out how our applications work and the properties of different materials?

Discover the list of materials available for your additive manufacturing needs. Prima Additive offers you a comprehensive selection of metal powders ranging from aluminum to nickel, from steel to titanium and copper and cobalt-chrome alloys.

In this way, materials, machines and production parameters are harmonised for excellent results.

Aluminium alloys for PBF

- All the lightness of working with aluminium.

Overview

Processing aluminum alloys with Prima Additive's Powder Bed Fusion machines gives you the following benefits for your finished parts:

high thermal conductivity, high mechanical properties(strength and hardness), high electrical conductivity, good post-process finish, excellent resistance to corrosion and low density.

The main advantage of aluminium is its lightness.

Aluminium alloys that can be processed with Prima Additive machines:- AlSi10Mg

Steel alloys for PBF

- For quality that’s hard as steel.

Overview

Processing steel alloys with Prima Additive's Powder Bed Fusion machines gives you the following benefits for your finished parts:

excellent resistance to high temperatures combined with high corrosion resistance, hardness as well as high ductility, high post-process finish and good thermal properties.

The main advantage of steel alloys is their superior hardness.

Steel alloys that can be processed with Prima Additive machines:- 316L

- Maraging M300

- 17-4PH

Titanium alloys for PBF

- Lightness and biocompatibility all in one material.

Overview

Processing titanium alloys with Prima Additive's Powder Bed Fusion machines gives you the following benefits for your finished parts:

low specific weight combined with low thermal conductivity, excellent mechanical properties, high biocompatibility and high resistance to corrosion.

The main advantages of titanium alloys are their lightness and biocompatibility.

Titanium alloys that can be processed with Prima Additive machines:- Ti-6Al-4V

Nickel alloys for PBF

- No stress and corrosion with nickel

Overview

Processing nickel alloys with Prima Additive's Powder Bed Fusion machines gives you the following benefits for your finished parts:

high yield, resistance to wear and friction, with excellent antioxidant and anticorrosion performance in aggressive environments, high resistance tocorrosion at high temperatures, high strength and good ductility.

These characteristics make nickel superalloys suitable for industrial applications at temperatures between 500°C and 1000°C.

The main advantage of nickel alloys: stress and corrosion resistant parts.

Nickel alloys that can be processed with Prima Additive machines:- Inconel 625

- Inconel 718

- Hastelloy X

Chrome-Cobalt alloys for PBF

- Biocompatible and resistant: discover the benefits of cobalt-chrome alloys.

Overview

Processing cobalt chrome alloys with Prima Additive's Powder Bed Fusion machines gives your finished parts the following benefits:

biocompatibility, exceptional strength and durability, and resistance to wear and corrosion. It is commonly used for applications such as medical and dental implants, gas turbines, engine and transmission parts, but also for jewellery thanks to its biocompatibility.

The main advantage of cobalt-chrome alloys is biocompatibility.

Cobalt chrome alloys that can be processed with Prima Additive machines:- CoCr

Copper alloys for PBF

- The best electrical conductivity at your service.

Overview

Processing copper alloys with Prima Additive's Powder Bed Fusion machines gives you the following benefits for your finished parts:

high resistance to corrosion combined with mechanical properties and both thermal and electrical conductivity.

The main advantage of copper alloys is their electrical conductivity.

Copper alloys that can be processed with Prima Additive machines:- CuSn10

- Cu

Materials for Direct Energy Deposition

Discover the variety within Prima Additive’s offering

Repairing or replacing small parts within your components with additive manufacturing becomes particularly cost-effective, fast and simple. But what materials can be used?

To select the most suitable ones, you can always count on our qualified support, who will provide you with all the technical information you need and with whom you can plan assessment tests before going into production.

Prima Additive will also guide you when you choose Direct Energy Deposition technology.

Find out now which materials are perfect for your production needs.

Prima Additive offers you a complete selection of metal powders ranging from steel to nickel, from cobalt chrome to copper and even titanium alloys; the latter can be processed thanks to the inert chamber option available on our machines.

Ready to achieve optimum standards in your production? Start matching the right metal to your Prima Additive machine now.

Steel alloys for DED

- Superior hardness.

Overview

With Prima Additive's Direct Energy Deposition machines you can work with steel alloys and obtain finished parts that are extraordinarily hard. Even when small parts need to be repaired.

Discover all the benefits of working with this metal:- excellent resistance to high temperatures

- high resistance to corrosion

- hardness

- high ductility

- high post-process finishing

- good thermal properties

Steel alloys that can be processed with Prima Additive machines:- 316L

- 304L

- H13

- FeCrV

- Maraging M300

- 17-4PH

Titanium alloys for DED

- The advantage of lightness and biocompatibility combined.

Overview

Thanks to the inert chamber option available on Prima Additive’s Direct Energy Deposition solutions, you can process highly reflective materials, including titanium alloys, with excellent results in terms of mechanical properties and surface quality.

Discover all the benefits of working with this metal:- low specific weight

- low thermal conductivity

- excellent mechanical properties

- high biocompatibility

- high resistance to corrosion

Titanium alloys that can be processed with Prima Additive machines:- Ti-6Al-4V

Nickel alloys for DED

- For stress and corrosion resistant parts.

Overview

Nickel superalloys are suitable for industrial applications at temperatures between 500°C and 1000°C and are perfect for processing on Prima Additive's Direct Energy Deposition machines.

Discover all the benefits of working with this metal:- high yield

- resistance to wear and rubbing

- excellent antioxidant and anticorrosive performance in aggressive environments

- high resistance to corrosion at high temperatures

- good ductility

Nickel alloys that can be processed with Prima Additive machines:- Inconel 625

- Inconel 718

- Hastelloy X

Chrome-Cobalt alloys for DED

- Our watchword: strength.

Overview

Processing cobalt chrome alloys with Prima Additive's Direct Energy Deposition machines means giving your finished parts extraordinary strength.

These alloys perform best in situations where they have to withstand extreme wear, making them the ideal solution for hard-surface valve components in the energy generation and oil & gas industries.

Discover all the benefits of working with this metal:- Excellent resistance to mechanical wear, especially at high temperatures

- excellent resistance to corrosion.

Cobalt chrome alloys that can be processed with Prima Additive machines:- Stellite™ 6

- Stellite™ 21

Copper alloys for DED

- Excellent for electrical conductivity.

Overview

With a Direct Energy Deposition machine from Prima Additive, working with copper alloys is a pleasure, obtaining finished parts that perfectly conduct both heat and electricity.

Discover all the benefits of working with this metal:- high resistance to corrosion

- mechanical properties

- both thermal and electrical conductivity

Copper alloys that can be processed with Prima Additive machines:- CuSn10

- Gr-Cop84

- Cu-Mn

Industries

Prima Additive opportunities for your industry.

How can additive manufacturing help you in your industry? There are many applications for metal 3D printing that can develop business in different areas: mechanics and machinery, universities and research, jewellery and design, naval, heat exchangers, electronics, injection moulding, energy and oil & gas, automotive, aerospace, medical and dental.

Find out what we can do for your specific needs.

Aerospace

- Additive manufacturing is not only part of the future, but also of the present in the

aerospace sector. The need to make lighter parts, with higher quality mechanical properties while using more efficient materials is a perfect match for additive technologies.

Find out what we do for the aerospace sector

The adoption of additive manufactured parts is not only advantageous in terms of aircraft functionality, but also means a real respect for the environment and sustainability within aerospace. Reducing the weight of an aircraft simultaneously reduces the aircraft's fuel consumption and, as a result, its CO2 emissions.

Similarly, in the space sector, reducing the weight of a satellite or its launch vehicle reduces the cost of launching, thus enabling barriers to entry to be lowered, opening up new opportunities for the space economy.

It is not only weight that is crucial when it comes to aerospace, but also mechanical characteristics, material performance and, above all, component reliability. Metal additive manufacturing enables both to produce parts with unrivalled mechanical properties and absolute dimensional accuracy, as well as identifying new materials that are more efficient and reliable.- Precision

With the additive process, we are able to produce components with any geometry, with absolute precision. - We listen

We advise you on the technology best suited to your actual needs. - Experience

Prima Additive is part of the Prima Industrie group, a leader in aerospace laser systems for over 40 years

Solutions

Find your ideal solution

In the aerospace sector, especially, it is very important to comply with stringent industry standards, above all NADCAP certification (National Aerospace and Defense Contractors Accreditation Program).

Prima Additive can support you through the entire certification process, including process verification, powder verification and finished product testing, to enable you to obtain certification and produce additive parts using a standardised, repeatable and qualified process.

We are at your service to help you take full advantage of the shape flexibility made possible through metal additive manufacturing.

Application Examples

Behind every innovation is a Prima Additive machine- Spare parts

- Combustion chambers

- Custom-designed spacecraft parts

- Precision

Automotive

- The automotive sector is changing. As thermal propulsion systems are being phased out, there is a growing need for car manufacturers to integrate

new types of engines and energy storage systems.

Another major change in the industry is the move towards ever lighter motor vehicles to improve their performance. This applies both to vehicles intended for the general public and especially in motorsport, where the shapes made possible by additive manufacturing offer a significant competitive advantage.

Find out what we do for the automotive sector

The constant evolution of the automotive sector offers ample scope for the use of metal 3D printing. On the one hand, greater focus can be placed on innovation, since prototypes are made quickly, without the need for moulds. On the other hand, additive manufacturing has the potential to revolutionise the supply chain, particularly with regard to spare parts, which can be made on demand only when needed.

More generally, given the constant renewal of car manufacturers' product ranges, additive manufacturing allows parts to be modified and customised to update models from year to year.

In addition, common parts such as brackets or fasteners can be redesigned or consolidated into a single part, reducing moving parts and eliminating the need for subsequent assembly.- Speed

Our machines quickly produce prototypes and finished components without the need for moulds. - Efficiency

Spare parts are produced immediately and on demand, without the need for holding stock. - We listen

We advise you on the technology best suited to your actual needs.

Solutions

Find your ideal solution

We will support you in the process of identifying components that can be made with additive manufacturing and their redesign, as well as in choosing the most suitable materials for your application. We are at your service to help you take full advantage of the shape flexibility made possible through metal additive manufacturing.

The speed and ease of use of our machines also means that you can move quickly from design to manufacture, allowing you to modify and customise your parts as required, giving you unmatched flexibility.

Application Examples

Behind every innovation is a Prima Additive machine- Supports with lattice structures

- Custom motorsport parts

- Custom-shaped exhaust pipes

- Brake caliper elements

- Speed

Electronics

- The current technological evolution is leading towards increasingly powerful electronics that use ever smaller yet more efficient components.

Additive manufacturing is an efficient solution for the electronics industry, both in terms of material utilisation and process flexibility, making it possible to produce electronic components of any size in a wide range of different alloys without wasting raw materials.

Find out what we do for the electronics sector

Even very small electronic circuits or components can be created quickly with Prima Additive's solutions.

Thanks to the option of processing copper alloys and pure copper offered by our green laser solutions, it is possible to produce parts with complex geometries and optimal electrical conductivity.

The competitive advantage offered by additive manufacturing in the electronics sector opens up new developments in technology thanks to the option of rapidly producing prototypes, small series or finished parts in a very short lead times.- Flexibility

Additive manufacturing brings flexibility to your production process, allowing you to produce prototypes, small series or finished parts in a short time. - Speed

From design to manufacture of small electronic components in no time at all. - Innovation

Every Prima Additive machine works to provide solutions that traditional industry cannot offer.

Solutions

Find your ideal solution

We are here to help you take advantage of all the benefits of additive manufacturing within the electronics industry.

The speed and ease of use of our machines also means that you can move quickly from design to manufacture, allowing you to modify and customise your parts as required, giving you unmatched flexibility.

We will support you in the process of redesigning your components and choosing the most suitable materials for your application.

Application Examples

Behind every innovation is a Prima Additive machine- Inductors

- Heat exchangers

- Sensors

- Flexibility

Energy, Oil & Gas

- The current evolution of the energy sector is moving towards

increasingly green and sustainable methods of energy generation. Nevertheless, the types of components used in this sector have always had the same characteristics: they are made in

very limited runs, are particularly complex and very expensive.

With metal additive manufacturing you will discover that there is a viable and innovative alternative that can cut costs and improve the efficiency of your products.

Discover what we do for the energy, oil & gas sector

More than anything else, downtime due to the need to change worn parts affects the costs of energy companies. Thanks to additive manufacturing, the required components can be produced on site, without having to wait for spare parts and thus minimising downtime.

Additive manufacturing, and in particular Prima Additive’s technology, meet the needs of this sector in two ways: with powder bed fusion technology to make parts only when they are needed, avoiding keeping expensive parts in stock for long periods, and with direct energy deposition technology for repairing components with high added value.

This allows for more sustainable and environmentally friendly manufacturing, using less material than machining technologies, and also allows worn components to be remanufactured and given a new lease on life without the need to buy new ones. All where it is needed, simplifying the supply chain.-

Sustainability

With additive manufacturing you reduce waste by using less material than with machining technologies. -

We listen

We advise you on the technology best suited to your actual needs. -

Efficiency

Since you can repair parts with Direct Energy Deposition technology, there is no need to fill your warehouse.

Solutions

Find your ideal solution

We are at your service to help you identify which of the components you currently produce are best suited to additive technology. We will support you in choosing the most suitable materials for your application and in determining the best printing strategy to create your parts.

Thanks to our solutions, you can reduce your spare parts procurement time, avoiding full warehouses or waiting for parts to arrive from far away. We will support you in the design, prototyping and production of the final parts, giving you the opportunity to experiment with new shapes and digitally customise each part according to its use.

Application Examples

Behind every innovation is a Prima Additive machine- Turbomachinery components

- Repair of turbine parts

- Impellers

-

Sustainability

Heat exchangers

- More efficient shapes for better heat dissipation. Thanks to the

complex geometries possible with metal additive manufacturing, heat exchangers can be more

functional, smaller, lighter and shaped as required.

Find out what we do for the heat exchanger sector

With Powder Bed Fusion technology, you go digitally from CAD to the finished product, achieving shapes that were previously unthinkable. In many sectors, such as motorsport, the need is for top performance combined with the lowest possible weight and a functional shape. All this is possible by 3D printing the component. Similarly, it is possible to consolidate several parts into one, resulting in exchangers with an internal sectional structure without the need for subsequent assembly.

Furthermore, thanks to the wide range of materials that can be used on Prima Additive machines, it is possible to improve one's own components and their mechanical characteristics also thanks to the choice of the most functional material that guarantees best thermal conductivity.- Adaptability

Our machines adapt to the chosen material to ensure best thermal conductivity. - Speed

With Powder Bed Fusion technology you go directly from CAD to the finished product. - Efficiency

You can get more functional heat exchangers that are smaller, lighter and shaped as required.

Solutions

Find your ideal solution

We are at your service to help you take full advantage of the shape flexibility made possible through metal additive manufacturing. We will support you in redesigning your heat exchangers and in the choice of materials.

Thanks to our solutions you can reduce the time between design, prototyping and production of the final part, giving you the opportunity to experiment with new shapes and digitally customise each part according to its use.

Application Examples

Behind every innovation is a Prima Additive machine- Lighter and better performing heat exchangers

- Improved thermal conductivity

- Option of making internal sectional shapes in one part

- Adaptability

Injection moulding

- Metal additive manufacturing is an excellent partner when it comes to

injection moulding and die casting. Digitisation and 3D printing enable the

design and manufacturing of moulds with complex conformal cooling channels. Thanks to this,

waste is reduced, the quality of the finished product is improved and cooling efficiency is increased.

Try to imagine a completely efficient, faster production process that leads to a higher quality result – impossible with traditional technologies.

Metal additive manufacturing is an excellent partner when it comes to injection moulding and die casting. Digitisation and 3D printing enable the design and manufacturing of moulds with complex conformal cooling channels. Thanks to this, waste is reduced, the quality of the finished product is improved and cooling efficiency is increased.

Try to imagine a completely efficient, faster production process that leads to a higher quality result – impossible with traditional technologies.

Find out what we do for the injection moulding sector

The value of additive manufacturing lies in function-oriented product design and in the manufacturing of products that cannot be produced with traditional technologies. This does not mean that traditional cooling channels are not adequate, but that channels made using additive manufacturing can bring more value to the finished product.

The main problems with moulds made using traditional technologies include low heat dissipation, possible localised deformation at high temperatures, high cost and slow production repeatability.

Additive manufacturing makes it possible to improve heat dissipation by creating conformal cooling channels. Thanks to this, production times are reduced, as are the costs of developing the finished product. A higher quality mould also means less scrap on finished parts and thus a more efficient production process.- Efficiency

With additive manufacturing you eliminate waste and achieve more efficient production quality - We listen

We advise you on the technology best suited to your actual needs. - Speed

With Prima Additive machines, you go quickly from design to the final result.

Solutions

Find your ideal solution

We are at your service to help you redesign your moulds to achieve the best possible benefits through the design of new conformal cooling channels. In addition, we will support you in choosing the most suitable materials for your application.

The speed and ease of use of our machines also means that you can move quickly from design to manufacture, allowing you to modify and customise your moulds as required, giving you unmatched flexibility.

Application Examples

Behind every innovation is a Prima Additive machine- Injection moulds with conformal channels

- Support in channel design and cooling flow analysis

- Prototype development and management

- Efficiency

Jewellery and design

- Until recently, making jewellery with complex shapes could involve long days of craftsmanship. The same process then had to be repeated for each individual part, thus multiplying the working hours. Today, thanks to

metal additive manufacturing, designers can indulge their imaginations and create shapes that were once unthinkable. They can

print beautiful objects in just a few hours, with the option of producing

several objects during the same work process.

Now is the time to unleash your creativity, safe in the knowledge that even your boldest projects can become a reality with Prima Additive’s technology and advice.

Find out what we do for the jewellery and design sector

Shapes that might once have been a dream can become a reality thanks to metal additive manufacturing.

Thanks to the wide range of materials that can be processed by Prima Additive's solutions, it is also possible to achieve aesthetic results worthy of a “wow!”.

For the jewellery sector, moreover, working with the right material and the geometry of the finished piece makes it possible to create jewellery that is not only visually striking, but also extremely light.

In addition, it is possible to design objects with moving or rotating parts in a single print, without the need for later assembly that would be required if similar parts were to be made using traditional technologies.- Precision

Complex products need extremely precise manufacturing processes: that's what additive manufacturing is about. - We listen

We advise you on the technology best suited to your actual needs. - Imagination

Unleash your imagination by freeing yourself from the constraints of traditional manufacturing

Solutions

Find your ideal solution

Are you ready to completely rethink the manufacturing process of your jewellery or design objects? We will support you in choosing the most suitable materials for your application and in assessing the best printing strategy to create your parts.

In addition, we will support you in the design, prototyping and production of the final parts, giving you the opportunity to experiment with new shapes and digitally customise each part to create visually striking objects.

Application Examples

Behind every innovation is a Prima Additive machine- Jewellery

- Watches and mechanical parts

- Design objects of all kinds

- Precision

Mechanics and machinery

- Absolute precision, flawless mechanical characteristics, reliability and

process repeatability are key features in mechanical engineering. And all this can be achieved by making parts using

additive manufacturing, with the advantage that the final shape of the parts can also be

improved to increase their performance.

To explore the innovative world of additive manufacturing, we support you during the design phase, assessing together with you the most suitable tools for your goal and recommending the most suitable technology and materials.

Absolute precision, flawless mechanical characteristics, reliability and process repeatability are key features in mechanical engineering. And all this can be achieved by making parts using additive manufacturing, with the advantage that the final shape of the parts can also be improved to increase their performance.

To explore the innovative world of additive manufacturing, we support you during the design phase, assessing together with you the most suitable tools for your goal and recommending the most suitable technology and materials.

Find out what we do for the mechanical engineering and machinery sector

In the field of mechanical engineering and industrial machinery, metal additive manufacturing is a very important enabling technology.

New frontiers are opening up thanks to the option of using metal alloys with ideal mechanical characteristics, as well as the option of optimising parts and redesigning them in a way that is functional to their use.

We in the Prima Industrie group, as manufacturers of industrial machinery, also use additive manufacturing to make parts for our machines. Our laser head for Direct Energy Deposition, for example, is made using Powder Bed Fusion technology and this has enabled us to improve its performance enormously, as well as reducing the number of components in our head and eliminating the need for storing parts.

The laser machines made by the Prima Power division also feature parts created with additive manufacturing, which allows the cutting machines to be ever more efficient.- Know-how

The Prima Industrie group is the first to use additive manufacturing for its machines: we know what we are talking about. - We listen

We advise you on the technology best suited to your actual needs. - Efficieny

Each Prima Additive machine works to guarantee precision, impeccable mechanical characteristics, reliability and process repeatability.

Solutions

Find your ideal solution

We are at your service to help you identify which of the components you currently produce are best suited to additive technology. We will support you in choosing the most suitable materials for your application and in determining the best printing strategy to create your parts.

We will support you in design, prototyping and production of the final parts, giving you the opportunity to experiment with new shapes and digitally customise each part according to its use.

Application Examples

Behind every innovation is a Prima Additive machine- Mechanical components

- Structural parts

- Know-how

Medical and Dental

- In a highly innovative field such as medicine, Prima Additive machines offer

freedom of design that was unthinkable just a few years ago, with results that from a quality perspective exceed the expectations of both medical personnel and patients.

Find out what we do for the medical and dental sector

Once upon a time, there was milling. But also casting or forging. They still exist today, but have technical limitations that only additive manufacturing can overcome.

When it comes to prostheses and implants, anatomical models, dental crowns, bridges and partial dentures, it can be difficult to achieve the levels of lightness and customisation required.

New, complex geometries that make the produced parts unique and more precise are now a reality that is not only very practical to pursue, but also cost-effective.

More and more doctors, dentists and surgeons are demanding tools that help them to do their work more accurately and gently, with the aim of making their procedures less and less invasive. Our machines work towards the same goal, which is an advantage for patient satisfaction.

Particularly in the orthopaedic sector, given the constant increase in injuries due to the progressive ageing of the population and broader reach of various sporting activities, Additive Manufacturing is at its best, manufacturing plates, screws and other anatomical elements required to restore natural movement in the shortest possible time.

By adopting an operating model with a very high degree of customisation, we are able to guide each of your projects, advising you on how to achieve your goal in the most effective way possible.- Reliability

Our machines produce components that then meet the standards set out by regulations. - We listen

We advise you on the technology best suited to your actual needs. - Innovation

Every Prima Additive machine works to provide solutions that traditional industry cannot offer.

Solutions

Find your ideal solution

Metal 3D printing may be the key that opens the door to utmost patient satisfaction, especially in the orthopaedic and dental fields, while also reducing the number of trial appointments normally required.

How? Thanks to the high degree of customisation, it is possible, for example, to produce accurate prostheses. Very high precision in size and detail on all corners, spaces and edges is achieved thanks to a laser spot of only 50 microns. Maximum precision in small details and no problems with breakages. Or dental implants that are extremely adaptable to the individual case. Or again, it is possible to reconstruct anatomical parts with adaptability and flexibility that was previously unthinkable with traditional production techniques. Digital production also drastically reduces time between the design and manufacturing of dental implants. In just a few hours, you can go from a 3D digital scan of the patient’s mouth to the finished product.

The speed and ease of use of our machines also means that you can get the part you want without having to wait for the ordering and shipping lead times you are normally used to, managing the process yourself exactly as you designed it.

Application Examples

Behind every innovation is a Prima Additive machine- Prostheses and implants

- Medical instruments and models

- Dental crowns, partial dentures and dental bridges

- Reliability

Naval

- Additive manufacturing offers many advantages in the naval sector, both in creating finished parts and for repairing components subject to wear.

The sea is an environment requiring performance that can respond to natural laws that are sometimes very different to those on land. That is why we have researched the best additive technologies to offer you innovative solutions that traditional industry cannot.

Find out what we do for the naval sector

One of the advantages of metal 3D printing for the shipbuilding industry is the ability to produce spare parts over a short time.

Similarly, components used in the naval sector often have textures to improve grip of the part in situations of high humidity as well as giving the end user a better quality feel. Achieving this type of texture with additive manufacturing becomes incredibly simple and requires no additional effort.

Thanks to additive technology, it is also possible to reduce the weight of components to improve the performance of the vessel, as well as make parts subject to wear from high-performance materials to extend their service life as much as possible.

In addition, thanks to Direct Energy Deposition technology, it is possible to repair high-value metal parts typical of naval propulsion systems, such as propellers. New material can be added to damaged or worn propellers to restore them to their original shape.- Know-how

Whether you need to repair or create new parts, we offer you the ideal solution to maximise their performance. - We listen

We advise you on the technology best suited to your actual need - Innovation

Every Prima Additive machine works to provide solutions that traditional industry cannot offer.

Solutions

Find your ideal solution

Through our two main technologies, Powder Bed Fusion and Direct Energy Deposition, we are able to guide you towards the best possible solution to achieve your goal.

As a result, metal 3D printing can give a decisive boost to naval production.

How? Thanks to the high level of customisable options, complex geometries functional to their use can be produced while maintaining or even improving the mechanical performance of the part.

In addition, the option of repairing metal parts makes it possible to fit fully into the Circular Economy, saving resources, time and money by not having to produce new components, but regenerating what is already there.

The speed and ease of use of our machines also means that you can get the part you want without having to wait for the ordering and shipping lead times you are normally used to, managing the process yourself exactly as you designed it.

Application Examples

Behind every innovation is a Prima Additive machine- Spare parts

- Complex textures

- Repairing propellers and other metal part

- Know-how

Universities and research institutes

- There is a constant commitment to the advancement of metal additive manufacturing technology in

Prima Additive's DNA. We are not doing this alone, but have a large network of

universities, research institutes and competence centres with whom we have embarked on a

co-innovation process using an open innovation approach.

What we are interested in is improving the efficiency of production processes and making them environmentally sustainable.

Find out what we do for the university and research institute sector

We are an active participant in numerous research projects that focus on improving the additive process and its efficiency, design, work on topology optimisation, photonics, applications and much more.

Prima Additive's solutions are particularly suitable for research purposes, as parameters are completely open and allow full customisation of all process parameters, thus allowing the end user to freely carry out any research on new materials or process optimisation.- Experience

We are part of the Prima Industrie group, a leader in the laser processing sector for more than 40 years - Productivity

We are constantly striving to improve the quality of our products. - Open Innovation

Open parameters to innovate the process and study new applications

Solutions

Find your ideal solution

To further facilitate the research process on additive manufacturing with the Open Innovation approach, we have created the Prima Open Additive project: a network of companies, universities and research centres working with Prima Additive in developing additive manufacturing technology.

Our experts can help you identify the solution that best suits your research centre. Similarly, Prima Additive not only supplies machines and systems, but also provides its customers and the Prima Open Additive network with all the expertise we have gained to help you identify the best materials and printing methods for your research objective.

Application Examples

Behind every innovation is a Prima Additive machine- Research into new materials

- Process optimisation

- Design innovations

- Experience

Services

Path to profitable AM adoption

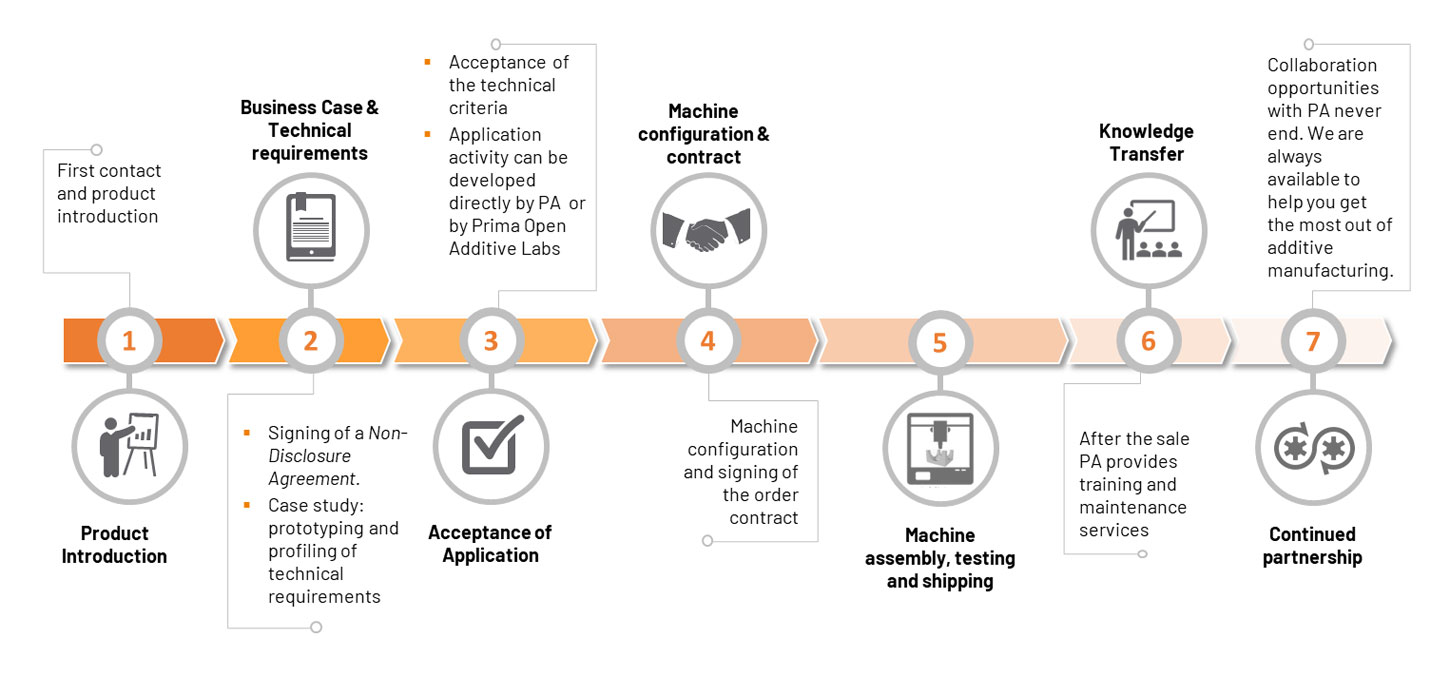

The Prima Additive 360° supportBeyond the machines, there is more.