- Offer Profile

-

FINALLY, ADDITIVE MANUFACTURING WITHOUT COMPROMISE

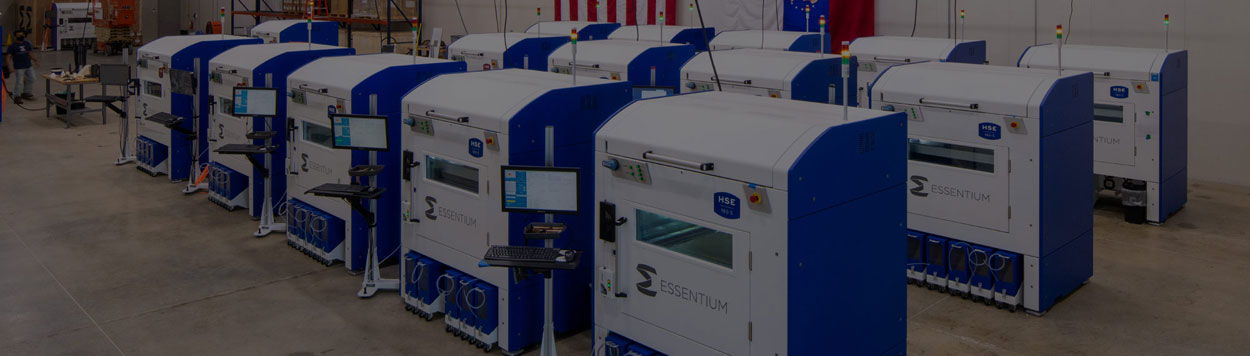

In the past, deploying additive manufacturing at scale was not feasible due to cost, durability, and speed requirements. Essentium has overcome the limitations of previous additive systems and has unlocked the promise of large-scale additive manufacturing.

With High Speed Extrusion technology, Essentium has become a category creator in the additive manufacturing industry. The Essentium HSE 3D Printing Platforms are transforming traditional manufacturing, giving customers an industrial-scale additive manufacturing solution that allows them to generate production floor-ready parts at scale quickly and cost-effectively.

Fueling these outcomes even further is a robust end-to-end additive manufacturing ecosystem that includes the industry’s broadest range of engineering-grade materials and leading-edge technology.

Essentium: Innovating the Future of Manufacturing

- Essentium is leading the way with next-generation additive manufacturing solutions that challenge the status quo, empower customers, and fuel the future of manufacturing.

Finally, Additive Manufacturing without Compromise

In the past, deploying additive manufacturing at scale was not feasible due to cost, durability, and speed requirements. Essentium has overcome the limitations of previous additive systems and has unlocked the promise of large-scale additive manufacturing.

With High Speed Extrusion technology, Essentium has become a category creator in the additive manufacturing industry. The Essentium HSE 3D Printing Platforms are transforming traditional manufacturing, giving customers an industrial-scale additive manufacturing solution that allows them to generate production floor-ready parts at scale quickly and cost-effectively.

Fueling these outcomes even further is a robust end-to-end additive manufacturing ecosystem that includes the industry’s broadest range of engineering-grade materials and leading-edge technology. ESSENTIUM 3D PRINTERS

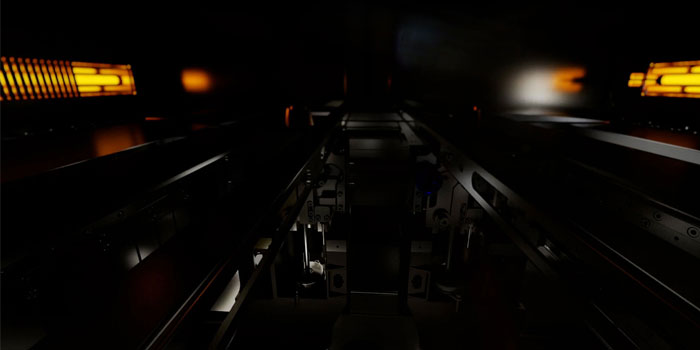

ESSENTIUM HSE 280I HT 3D PRINTER

- Designed exclusively for production environments seeking to scale through additive manufacturing, the new Essentium HSE 280i HT 3D Printing Platform is the first industrial 3D printer featuring independent dual extruders (IDEX) in which each head is fully independent on both the X and Y axis. It’s like getting two 3D printers for the price of one, making it ideal for high-volume applications.

ESSENTIUM HSE 180 3D PRINTING PLATFORM

- At five to 15x faster than the competition, Essentium's High Speed Extrusion (HSE) 180 3D Printing Platform is built to transform the factory floor. Using an X-Y stage with all linear servo motors, the HSE 180 3D Printer solves strength, speed, and scale issues that have historically limited additive manufacturing.

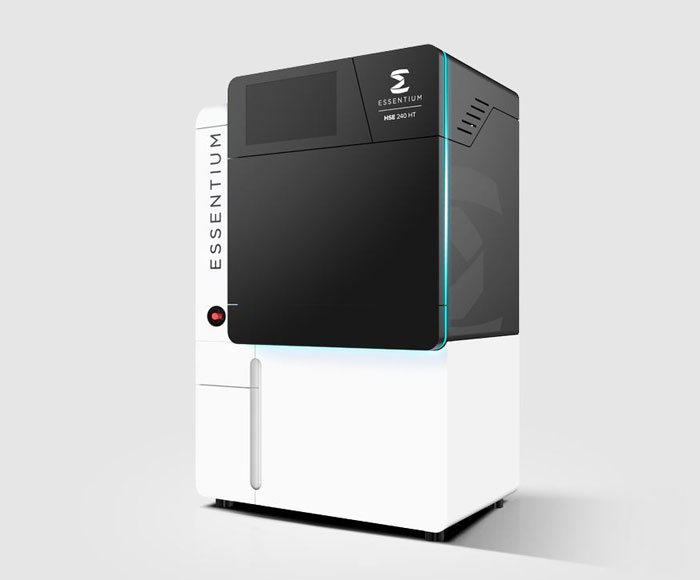

ESSENTIUM HSE 240 HT DUAL EXTRUDER 3D PRINTER

- The High Speed Extrusion (HSE) 240 HT Dual Extruder 3D Printer is the newest addition to Essentium’s line of 3D printers. The world-class industrial design of the HSE 240 HT 3D Printer enables seamless user interaction and effective usage of space, allowing customers to print complex geometries and realize ROI quickly.

HSE™ 280i HT 3D PRINTER

Transforming the Manufacturing Floor

At five to 15x faster than the competition, Essentium’s High Speed Extrusion (HSE) 3D Printing Platform is built to transform manufacturing floors and solve the issues of speed, strength, and scale. You can finally harness the flexibility of 3D printing with the productivity of traditional manufacturing.Fully Independent

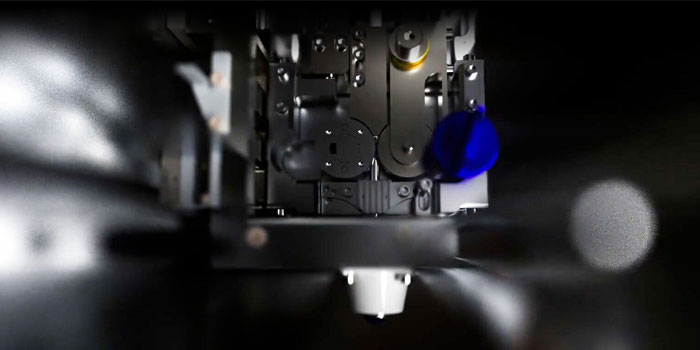

The HSE 280i HT 3D Printer is the industry’s first 3D printer equipped with true independent dual extruders (IDEX), meaning each head is fully independent on both the X and Y-axis.Speed and Reliability

By utilizing a non-slip, high torque extrusion system with all linear servo motors, the HSE 280i HT 3D Printer offers a no compromise solution, offering the speed and reliability to 3D print at scale.Open Ecosystem

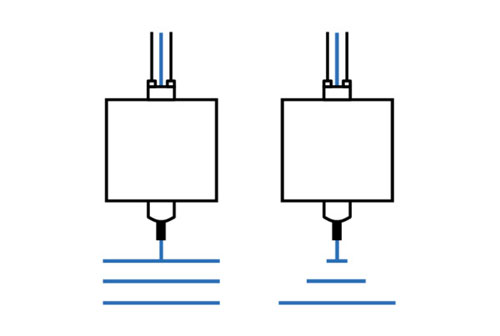

According to recently commissioned 3rd party study, 96% of manufacturers are demanding open ecosystems to give them more control. With limitless material option, the HSE 280i HT 3D Printer gives users that control.Five Print Modes

The Essentium HSE 280i HT 3D Printer features five print modes. The true independence of the print heads in both the X and Y-axis gives users the flexibility to print parts at scale.- Single Head Mode

Single Head Mode uses one head to print five to 15x faster than competitors, equipping manufacturers to print at the speed of relevance.

- Copy Mode

Double productivity with Copy Mode. This mode unlocks the ability to print two identical parts simultaneously, ideal for AM at scale.

- Independent Mode

Get two machines for the price of one with Independent Mode. This mode allows users to print two unique parts concurrently, ideal for low volume, high mix manufacturing.

- Multi-Process Model

Multi-Process Mode allows users to print with two materials or nozzle sizes ideal for parts with both flexible and rigid features.

- Support Mode

Support Mode makes it possible to print support for parts in progress using soluble or breakaway material, ideal for printing complex geometries.

- Single Head Mode

Printer Specifications

-

- Print Heads: Two

- Print Speed: 500 mm/s

- Build Volume (Single Head Mode): 695 x 500 x 600 mm

- Build Volume (Support Mode): 595 x 500 x 600 mm

- Build Volume (Multi-Process Mode): 595 x 500 x 600 mm

- Build Volume (Copy Mode): (395 x 500 x 600 mm) x2

- Build Volume (Independent Mode): Coming Winter 2021

- Printer Dimension: 1590 x 1350 x 2490 mm

- Nozzle: Gen 5 Hozzle™ Heated Nozzle

- Nozzle Temperature: Up to 550ºC

- Nozzle Diameters: 0.4, 0.8 mm

- Filament Diameter: 1.75 mm

- Electrical Requirements: 200–240 VAC, 40A, single/dual phase

- Net Weight: 850 kg

- Additional Features: 1G acceleration, all linear servo motors – no belts or pulleys, fully digital

- Print Heads: Two

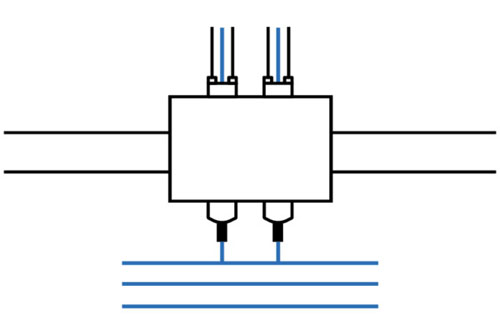

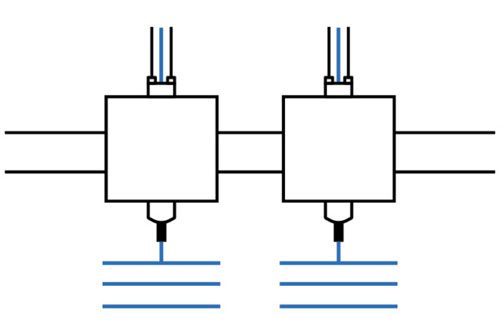

What is True IDEX?

- The Essentium HSE 280i HT 3D Printing Platform is the first industrial 3D printer that offers true IDEX. Other IDEX machines on the market feature print heads that are placed on the same X-axis gantry, preventing independent movement on the Y-axis. This limits these “semi-IDEX” machines to print modes that are synchronous on the Y-axis.

Conventional Dual Extruder

- One head, two nozzles

- Prints primary filament and support material

- Second nozzle may leave filament deposits

Semi-Independent Dual Extruder

- Two heads, independent movement in the X-axis

- Prints with two materials and two identical parts

- Fixed on the X-axis gantry, preventing independent movement on the Y-axis

True Independent Dual Extruder

- Two heads, fully independent

- Prints two materials, identical parts, or unique parts

- Independent movement in the X and Y-axis effectively gives users two machines for the price of one

HSE 180 3D PRINTING PLATFORM

Building a Full Stack Additive Manufacturing Ecosystem

At five to 15x faster than the competition, Essentium's High Speed Extrusion (HSE) 180 3D Printing Platform is built to transform the factory floor. Using an X-Y stage with all linear servo motors, the HSE 180 3D Printer solves strength, speed, and scale issues that have historically limited additive manufacturing (AM). With Essentium you can finally harness the power of 3D printing at scale without sacrificing accuracy or speed.- Unmatched Speed

Print at speeds of up to 500 mm/sec with all linear servo motors, 1G acceleration, and 1 m/sec travel speed.

- Large Build Volume

Print large parts with speed and strength on a build plate large enough to fit 85% of the world’s jigs and fixtures.

- Open Ecosystem

Use filament from Essentium’s material portfolio or others for the optimal material for your application.

- Unmatched Speed

Printer Specifications

-

- Technology: High Speed Extrusion

- Print Heads: One

- Motion System Accuracy: XY < 30um, Z < 5um

- Build Area: 690 x 500 x 600 mm

- Nozzle: Hozzle™ heated nozzle

- Nozzle Diameters: 0.4, 0.8 mm

- Filament Diameter: 1.75 mm

- Electrical Requirement: 4 KVA, 220/240V 20A for LT machine and 40A for ST and HT machines, Single Phase 50/60 Hz

- Printer Dimension: 1590 x 1250 x 2490 mm

- Net Weight: 850 kg

- Additional Features: 1G acceleration, all direct-drive servo motors – no belts or pulleys, fully digital/p>

A Category Creator in Additive Manufacturing

- Historically, extrusion 3D printing processes like FFF and FDM have been painstakingly slow, taking hours to produce a relatively simple geometry and days to produce complex designs. Essentium’s HSE technology eliminates wasted movement with linear servo motors, 1G acceleration, and 1 m/sec movement speed, allowing manufacturers to print parts five to 15x faster than conventional FFF and FDM printers.

Essentium’s HSE technology paired with its best and broadest materials offering, allows manufacturers to scale 3D printing like subtractive manufacturing and set the stage for Industry 4.0.

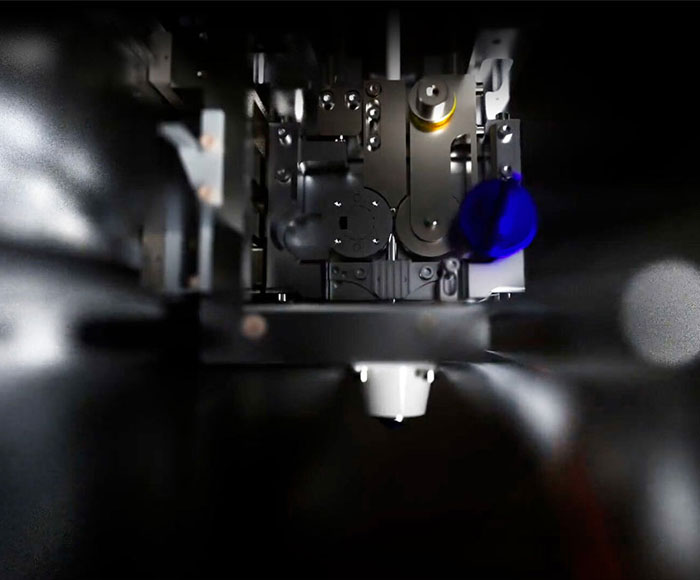

Essentium’s Hozzle™ Heated Nozzle

- Printing high-performance materials with high-speed extrusion is only possible with a world-class nozzle. The Hozzle — Essentium’s heated nozzle — is an integrated heating and temperature sensing unit that achieves unmatched performance with temperatures reaching up to 550°C. Complete with a sapphire tip, the Hozzle heated nozzle gives manufacturers the ability to extrude the highest performance materials on the market.

HSE 180 3D Printer Models

HSE 180 LT

- Low-Temperature Materials

Key Industries:- Biomedical Device

- Commercial Manufacturing

- Footwear and Apparel

- Architecture and Design

Key Applications:- Prosthetic Sockets

- Orthotic Devices

- Low-Temp Jigs and Fixtures

- Rapid Prototyping

- Castings

HSE 180 ST

- Standard Materials

Key Industries:- Automotive and Transportation

- Consumer Goods

- Electronic Manufacturing Services

Key Applications:- Low-Temp Jigs and Fixtures

- Low-Pressure Mold Tooling

- NPI and Bridge-to-Production

- Manufacturing Aids

HSE 180 HT

- High-Temperature Materials

Key Industries:- Aerospace and Defense

- Semiconductor Device Manufacturing

- Oil and Gas

Key Applications:- High-Pressure Mold Tooling

- High-Temp Jigs and Fixtures

- Connectors

- Functional Parts

HSE™ 240 HT DUAL EXTRUDER 3D PRINTER

High Speed Extrusion with a Smaller Footprinter

Building on the proven foundation of the Essentium High Speed Extrusion (HSE) 3D Printing technology, the HSE 240 HT Dual Extruder 3D Printing Platform speeds time to production of complex parts, while significantly reducing post-processing costs. Featuring a new industrial design including a single dual extrusion print head, the latest addition to the Essentium HSE 3D Printer portfolio is designed to maximize the performance, reliability, and efficiency of parts production — all within a small footprint.- Smallest Footprint

Harness the power of High Speed Extrusion even where space is limited.

- Lowest Price Point

The power of larger High Speed Extrusion 3D printers, at a lower entry price point increases ROI.

- Auto Spool Switching

Run longer print jobs to maximize print time and save on material costs.

- Smallest Footprint

Printer Specifications

-

- Technology: High Speed Extrusion

- Print Heads: One dual extrusion print head

- Motion System Accuracy(Single Head Mode): 0.081 mm @ 70 mm/s and 0.091 mm @ 300 mm/s

- Position Accuracy: XY < 30 μm, Z < 5 μm

- Part Accuracy: .15% or 0.25 mm (whichever is larger)

- Encoder Accuracy: 1 μm

- Part Speed: 375 mm/s

- Build Volume: 430 x 350 x 375 mm

- Nozzle: Hozzle™ heated nozzle

- Nozzle Diameters: 0.4, 0.8 mm

- Bed Plate Temperature: Up to 190°C

- Build Chamber Temperature: Up to 185°C

- Printer Dimensions: 1168 x 795 x 1687 mm

- Net Weight: 452 kg

- Additional Features: Non-slip, high-torque extrusion system, X-Y stage linear servo motors

Materials

ESSENTIUM 9085

- Essentium 9085 is a high-performance polyetherimide blend made with SABIC ULTEM™ 9085 resin. Essentium 9085 has excellent long term temperature performance and toughness. The base resin meets FAR 25.853 and OSU 65/65 for flammability, heat release, smoke density, and toxicity. Parts printed from Essentium 9085 are ideal for aerospace, automotive, and industrial components that must meet strict requirements for strength, temperature performance, and flammability.

KEY FEATURES:- Excellent temperature resistance

- Excellent toughness

- Great strength and stiffness

- Inherently flame retardant

- Environmental stress cracking resistance

APPLICATIONS INCLUDE:- Aerospace

- Defense

- Composite layup tooling

- Functional prototypes

ESSENTIUM ABS MG94

- Essentium ABS MG94 filament made with SABIC CYCOLACTM MG94 resin is a premium grade of ABS designed for high speed prints with excellent surface finish and balanced mechanical properties. Acrylonitrile butadiene styrene (ABS) is an amorphous terpolymer with outstanding impact resistance and toughness which makes it a good choice for cost-effective functional prototypes, equipment enclosures, general purpose jigs and fixtures, and automotive components.

KEY FEATURES:- General purpose material

- Best-in-class printability

- Good ductility

- Good electrical properties

- Good paintability and platability

APPLICATIONS INCLUDE:- Jigs and fixtures

- Prototypes

- Automotive ducting

- Project enclosures

ESSENTIUM HTN

- Essentium HTN (high-temperature nylon) is a polyamide-based chemistry that has improved mechanical and thermal properties compared to standard nylons. Additionally, it is an easy-to-print, low-warp material that boasts high toughness and wear resistance. This material is a drop-in replacement for Acetal (Delrin®) and has best-in-class slow moisture absorption.

KEY FEATURES:- Better heat deflection temperature and printability than ABS and standard nylons

- High toughness and high strength

- Improved chemical and solvent resistance

- Wear resistance

APPLICATIONS INCLUDE:- Jigs and fixtures

- Electrically insulating components

- Electrical housings

- Low-speed gears and moving parts

ESSENTIUM HTN – CF25

- Essentium HTN-CF25 (high-temperature nylon) is a polyamide-based chemistry with a 25% carbon fiber reinforced core. HTN-CF25 is the highest strength and stiffness material in the Essentium portfolio. This material also boasts easy processing and excellent thermal resistance. This material is designed for tooling applications, high-strength/stiffness jigs and fixtures, and as a replacement for light-duty aluminum parts.

KEY FEATURES:- High strength Solvent resistance Good temperature resistance Easy to print Solvent resistance

APPLICATIONS INCLUDE:- Tooling:

- Injection molds

- Thermoforming

- Blow molding

- High-stiffness jigs and fixtures

- High-strength and end-use parts

- Replacement for light-duty aluminum parts

ESSENTIUM HTN – Z

- Essentium HTN-Z (high-temperature nylon) is the ESD-safe version in our HTN line of materials. This material is designed for use in medium-duty electronics manufacturing. The HTN line has improved mechanical and thermal properties compared to standard nylons. Additionally, it is an easy-to-print, low-warp material that boasts high toughness and wear resistance. This material is a drop-in replacement for ESD-safe Acetal (Delrin®) and has best-in-class slow moisture absorption.

KEY FEATURES:- ESD safe Solvent resistance

- Good temperature resistance

- Higher strength than PCTG, ABS, and Nylons

APPLICATIONS INCLUDE:- Assembly aids for electronics

- ESD-safe fixtures

- Electrical housings

- Part trays for electronics manufacturing

ESSENTIUM PA (NYLON)

- Essentium PA (Nylon) provides exceptional strength and durability while retaining a surprising amount of stiffness. BASF formulated, Essentium produced.

KEY FEATURES:- Strong, tough, abrasion and cut resistant

- Nearly indestructible

- Resistant to fuels, solvents, and hydrocarbons

- Some inherent flex

- Strong price/performance ratio

- Made in the U.S.A.

APPLICATIONS INCLUDE:- Gears

- Mechanisms

- Low-friction bearings

- Thrust washers

- Automotive parts

ESSENTIUM PA-CF

- PA-CF provides strong, durable, and heat-resistant prints. BASF formulated, Essentium produced.

KEY FEATURES:- Exceptional strength

- Easy to print while boasting a variety of excellent mechanical properties

- Perfect for industrial-grade parts

- High impact resistance

- Can withstand temperatures upward of 150 degrees Celsius; HDT of 178 degrees Celsius

- Optimized for low moisture absorption and ease of printing

- Made in the U.S.A.

APPLICATIONS INCLUDE:- Handheld fixtures

- Automotive parts, brackets, covers

- Jigs and fixtures that need increased strength and stiffness

ESSENTIUM PCTG

- Essentium PCTG is an easy-to-use material with incredible surface finish, superior toughness, and chemical resistance — use it just like PETG.

KEY FEATURES:- Perfect starting point for fixtures Low cost

- Easy to print, machine, and finish Excellent surface finish Prints in open air Great filament for prosthetics and orthotics Unaffected by humidity Strong enough for lightly loaded fixtures Colors available for color coding Higher impact strength than PETG Made in the U.S.A.

APPLICATIONS INCLUDE:- Handheld tools

- Gauges

- Location fixtures

- General assembly fixtures

- Check sockets for prosthetics

ESSENTIUM PCTG – Z

- Essentium PCTG-Z is specially formulated to be ESD safe. It is an easy-to-print material with significantly increased impact strength when compared to PETG. Target Surface Resistance 10^4 to 10^9 Ohms. Our ESD materials are non-marring and are engineered to the highest quality standards.

KEY FEATURES:- Perfect starting point for electronic jigs and fixtures

- Low cost

- Easy to print, machine, and finish

- Excellent surface finish

- Prints in open air

- Unaffected by humidity

- Strong enough for lightly loaded fixtures

- Non-marring Made in the U.S.A.

APPLICATIONS INCLUDE:- Handheld tools

- General assembly fixtures for electronics

- Robotics and automation components

- Parts for explosion-proof environments

- ESD part trays

ESSENTIUM PEEK

- Essentium PEEK is the highest performance material in our broad material portfolio. In addition to best-in-class printability, it has excellent thermal and chemical resistance. Essentium PEEK boasts outstanding strength, stiffness, and impact properties and is inherently flame resistant.

KEY FEATURES:- Best-in-class PEEK printability

- Excellent thermal resistance

- Excellent chemical resistance

- Inherent flame resistance

APPLICATIONS INCLUDE:- Aerospace

- Oil & Gas

- Biomedical (non-implantable)

- Semiconductor processing

- Chemical processing

- Military

ESSENTIUM PEKK

- Essentium polyetherketoneketone (PEKK) filament shares most of the performance attributes of PEEK: strong chemical resistance, high dimensional stability, and high temperature resistance. PEKK maintains the flame smoke toxicity ratings for FAR compliance and offers excellent resistance to chemical attack.

Key Features- High glass transition temperature

- Chemical resistance

- Flame retardant

Applications- Aerospace

- Industrial

- Oil & Gas

- Chemical processing

- Military

ESSENTIUM PET-CF

- Essentium PET-CF is a 15% carbon fiber reinforced polyester filament made with Luvocom® 3F resin from Lehvoss. Polyethylene terephthalate (PET) is a semicrystalline polyester commonly used in soda bottles and automotive parts when reinforced with a fiber-filler. This material is one of the easiest filaments in our portfolio to print and has an outstanding price-to-performance ratio. PET-CF has a good balance of stiffness and strength, and when annealed it has temperature resistance of over 155 ̊C, and good chemical resistance for common solvents.

KEY FEATURES:- Excellent price-to-performance ratio

- Good stiffness and strength Very low warping

- Very low moisture absorption

- Good

- Temperature, chemical and wear resistance

APPLICATIONS INCLUDE:- Jigs, fixtures, tooling

- Functional prototypes

- Brackets

- Automotive parts

- Component housings

ESSENTIUM PLA XTR

- Essentium PLA XTR is specifically designed to solve many of the common issues plaguing current PLA offerings. Colors are available upon request.

KEY FEATURES:- Engineering-grade performance with the convenience of PLA

- Low melting point

- Many colors

- Decreased brittleness

- Superior tensile strength

- Improved elastic modulus

- Better impact resistance

- Vastly increased thermal stability (2X vs regular PLA)

- Fewer nozzle jams

- Made in the U.S.A.

APPLICATIONS INCLUDE:- Mold work

- Lost foam casting

- Investment casting with molds

- Form and fit

ESSENTIUM PP-CF

- Essentium PP-CF is a 20% carbon fiber reinforced polypropylene filament made with Luvocom® 3F resin from Lehvoss. Polypropylene (PP) is a semicrystalline polymer commonly used in consumer goods and automotive parts when reinforced with a fiber filler. This material has excellent chemical resistance and low surface energy which makes it useful for silicone and urethane low pressure molding applications.

KEY FEATURES:- Low surface energy

- Excellent intrinsic mold release

- Excellent chemical resistance

- Low density

- Lower abrasion than glass filled PP

APPLICATIONS INCLUDE:- Low pressure resin casting molds

- Glue and adhesive bonding clamps

- Chemical processing parts

- Automotive part

ESSENTIUM PPS-CF

- Essentium PPS-CF is a 15% carbon fiber reinforced polyphenylene sulfide (PPS) filament made with LUVOCOM® 3F resin from LEHVOSS Group. PPS is a semicrystalline, high-performance polymer used in numerous challenging applications in various industries. This material has an outstanding price-to-performance ratio with exceptional strength, stiffness, temperature, chemical and wear resistance. PPS is suitable in many cases instead of higher priced super polymers as PAEKs (PEEK, PEKK).

KEY FEATURES:- High temperature resistance

- Excellent chemical and solvent resistance

- Lower cost compared to PEEK

- Inherently flame retardant

APPLICATIONS INCLUDE:- Injection mold tooling

- Expanded foam mold tooling

- Aerospace parts

- Railway parts

- Oil and gas

ESSENTIUM SUPPORT S10

- Essentium Support S10 is our entry-level water soluble support material that is compatible with our HTN, PA, TPU, and PLA material families. Support S10 allows users to print complex designs on our HSE IDEX printers, then wash away the supports in warm tap water. Users no longer have to worry about caustic water baths, detergent solutions, or the hassle of disposing hazardous waste.

ESSENTIUM TPU 58D-AS

- Essentium’s TPU 58D-AS is an industry-first ESD safe and anti-static 58D Shore hardness thermoplastic polyurethane filament that is available in a variety of colors. This cutting-edge material resulted from a close collaboration between Croda and Essentium to develop an exclusive anti-static filament line based on Croda IonphaseTM permanent anti- static additives. It has excellent impact strength, tear strength, and abrasion resistance and is safe for clean room and electronics manufacturing applications.

KEY FEATURES:- ESD safe in colors

- Clean room safe

- Non-marking

- Good abrasion and wear resistance

- Excellent chemical, solvent, oil and ozone resistance

APPLICATIONS INCLUDE:- ESD safe dust caps

- Abrasion resistant panel covers

- ESD safe jigs and fixtures

- No-fly parts

- Impact rated components

ESSENTIUM TPU 74D

- Essentium TPU 74D is the highest durometer filament in our broad flexible portfolio. It is a no-warp drop-in replacement for ABS. It has excellent impact strength, tear strength, and abrasion resistance.

KEY FEATURES:- Semi-rigid

- Best-in-class tear resistance

- Good tensile strength

- Good abrasion and wear resistance

- High impact

- Low temperature flexibility

- Excellent chemical, solvent, oil and ozone resistance

APPLICATIONS INCLUDE:- ABS replacement

- Abrasion-resistant covers

- Snap-fit connectors

- Heavy load vibration isolation

- Impact rated structural components

ESSENTIUM TPU 74D – Z

- Essentium TPU 74D-Z is a high durometer filament in Essentium’s electrostatically dissipative (ESD) portfolio. With non-marring surface properties, you don’t have to worry about latent failures in electronics. These materials are the only industrially proven, safe material for ESD-sensitive applications. Essentium TPU 74D-Z is a no-warp drop-in replacement for ABS. It has excellent impact strength, tear strength, and abrasion resistance.

KEY FEATURES:- ESD-safe

- Semi-rigid

- Best-in-class tear resistance

- Good tensile strength

- Good abrasion and wear resistance

- High impact

- Low temperature flexibility

- Excellent chemical, solvent, oil, and ozone resistance

- Outstanding tear resistance

APPLICATIONS INCLUDE:- ABS ESD replacement

- Electronics manufacturing

- ESD-safe jigs and fixtures

- Abrasion-resistant covers

- Snap-fit connectors Heavy load vibration isolation Impact rated structural components

ESSENTIUM TPU 80A – Z

- Essentium TPU 80A-Z is the lowest durometer filament in Essentium’s electrostatically dissipative (ESD) portfolio. With non-marring surface properties, you don’t have to worry about latent failures in electronics. These materials are the only industrially proven, safe material for ESD sensitive applications. Currently, Essentium TPU 80A-Z is the softest 3D printing material that can be printed on any open-source printer. It has excellent elongation at break and impact strength and has a low friction surface that allows for easier feeding while printing.

KEY FEATURES:- ESD-safe

- Soft-touch

- Ultra-flexible

- Best-in-class elongation at break

- Excellent abrasion and wear resistance

- Excellent vibration damping

- Low temperature flexibility

- Excellent chemical, solvent, oil, and ozone resistance

APPLICATIONS INCLUDE:- Electronics manufacturing

- ESD-safe jigs and fixtures

- Non-marring grippers

- Print-in-place soft springs

- Bumpers, vibration absorbers, isolation mounts

- Seals, gaskets, suction cups, boots, plugs

- Parts catchers, shoe straps

ESSENTIUM TPU 80A LOW FRICTION

- Essentium TPU 80A-LF is the most flexible filament on the market and is able to print on any open platform. It is perfect for applications requiring toughness and flexibility. BASF formulated, Essentium produced.

KEY FEATURES:- Extremely flexible yet still tough, abrasion-resistant

- Good chemical resistance

- Made in the U.S.A.

APPLICATIONS INCLUDE:- Non-marring grippers

- Print-in-place soft springs, high grips

- Bumpers, vibration absorbers, isolation mounts

- Seals, gaskets, suction cups, boots, plugs

- Parts catchers, shoe straps, sheets

ESSENTIUM TPU 90A FLAME RETARDANT

- Essentium Flame Retardant TPU 90A has been engineered to have the perfect balance of elasticity and toughness. This filament exhibits excellent interlayer adhesion and high strain at break; the base resin is UL94 V0 certified for flame retardancy and printed samples pass FAA FAR 25.853(a) 12 and 60 second vertical flame tests for 1/16” and 1/4” thickness. Our TPU 90A FR filament is perfect for a print that needs inherent flame retardant properties with flexibility, grip, and abrasion resistance. Use this material to make flexible hinges, belts, plugs, gaskets, protective cases, overgrips, wheels, vibration dampeners, energy-absorbing lattices, and so much more.

ESSENTIUM TPU 95A – Z

- Essentium TPU 95A-Z is a medium durometer filament in Essentium’s electrostatically dissipative (ESD) portfolio. With non-marring surface properties, you don’t have to worry about latent failures in electronics. These materials are the only industrially proven, safe material for ESD-sensitive applications. Essentium TPU 95A-Z balances high elongation with impressive impact resistance and tensile strength. This filament has a low friction surface that allows for easier feeding while printing.

KEY FEATURES:- ESD safe

- Flexible

- Best-in-class tensile strength

- Exceptional elongation at break

- Excellent abrasion, tear and wear resistance

- High impact

- Excellent vibration damping

- Low temperature flexibility

- Excellent chemical, solvent, oil and ozone resistance

APPLICATIONS INCLUDE:- Electronics manufacturing

- ESD-safe jigs and fixtures

- Vibration damping feet

- Grommets

- Bushings

- Protective case inserts

- Automotive vibration isolation

- Overmolded soft grips

- Flexible hose and ducting

ESSENTIUM TPU 95A LOW FRICTION

- Essentium TPU 95A-LF is the medium durometer filament in our broad flexible portfolio. It balances high elongation with impressive impact resistance and tensile strength. This filament has a low friction surface that allows for easier feeding while printing lattices.

KEY FEATURES:- Flexible

- Exceptional elongation at break

- Excellent abrasion and wear resistance

- Outstanding tear resistance

- High impact

- Excellent vibration damping

- Low temperature flexibility

- Excellent chemical, solvent, oil, and ozone resistance

APPLICATIONS INCLUDE:- Vibration damping feet

- Grommets

- Bushings

- Protective case inserts

- Automotive vibration isolation

- Overmolded soft grips

- Flexible hose and ducting

- Sporting protective equipment

- Footwear

INDUSTRIES

WHY ESSENTIUM?

Implementing design changes can be costly and time-consuming – luxuries the defense and homeland response industry cannot afford – especially given the lag time in outsourced tooling while moving through multiple iterations of hundreds of parts. The Essentium HSE 3D Printer delivers the speed, size, and material versatility to handle the production of up to 85% of all the jigs and fixtures required to assemble a vehicle. This brings an incredible toolset to the warfighter, enabling innovation and increasing readiness. No other manufacturing option gives users the ability to design a part in the morning and have a prototype in the field by the afternoon. Designed for reliability at scale, the HSE 3D Printer reduces the turnaround time and cost of your next innovation.

Aerospace Solutions

- Equipping the Aerospace Industry to Achieve Innovative Design Breakthroughs

Essentium offers a full suite of chemically resistant, high-strength, and heat-resistant materials that are used by the world’s most demanding customers in the aerospace industry. With these high-performance materials and the speed and reliability of the Essentium High Speed Extrusion (HSE™) 3D Printing Platform, you can create critical parts for tomorrow's aerospace innovations faster, cheaper, and lighter than ever before.

Key Applications- Jigs and Fixtures

Print ground support equipment using high-strength and chemically resistant materials in a matter of hours.

- End-Use Parts

Use Essentium PEEK and other high-performance materials to create commercial-grade, functional aerospace components.

- Rapid Prototyping

Iterate design changes in hours instead of days and weeks to determine the proper form, fit and function of a part in the manufacturing process.

Essentium's HSE 3D Printing Platform in conjunction with the industry’s best and broadest materials offering is designed to move beyond the limitations of traditional machining methods in the aerospace industry. Using Essentium systems and materials capabilities, aerospace manufacturers can produce parts on-demand, enabling a more streamlined assembly line.

Additionally, Essentium’s certification-friendly practices ensure a choice of materials to match your application. Versatile enough for one-off, low-volume, or mass production runs of high-performance parts, the Essentium HSE 3D Printers are designed for reliability at scale. Essentium stands ready to transform your manufacturing processes without compromising strength or quality. - Jigs and Fixtures

Automotive

- Driving Automotive Manufacturing Forward With Increased Agility and Innovation

Traditional manufacturing processes and early additive manufacturing machines have come up short for the automotive industry. Essentium is building toward a full-factory solution that will streamline tooling and provide a quick-turn, in-house capability set to automotive manufacturers. As part of this full-stack solution, the Essentium High Speed Extrusion (HSE™) 3D Printing Platform is an on-demand manufacturing tool alternative to quickly produce jigs, fixtures, and tools right on the factory floor.

Key Applications- Jigs and Fixtures

Reduce operational expenses such as warehousing costs for outdated jigs and fixtures.

- Tooling

Design large, commercial-grade tools, that can go from concept to final part in a matter of days.

- Rapid Prototyping

Print prototypes using high-performance, end-use materials ready for functional testing.

Utilizing a non-slip, high-torque extrusion system and all linear servo motors, the HSE 3D Printing Platform can reach print speeds of up to 500 mm/s. In demanding environments like the automotive factory floor, Essentium systems give manufacturers the agility to design, prototype, and produce end-use parts in a matter of days.

Additionally, Essentium has the best and broadest materials portfolio in the industry that includes non-marring, ESD-safe, and nylon materials that are ideally suited for mold tooling, jigs and fixtures, end-use parts, and other important applications within the automotive industry. - Jigs and Fixtures

Biomedical

- Helping Healthcare Providers Improve Quality of Life

Using the Essentium High Speed Extrusion (HSE™) 3D Printing Platform for prosthetics and orthotic devices yields best-in-class results that provide better patient outcomes through more precise fit, faster turnaround, and reduced cost. Orthopedic labs and clinics can conduct patient scanning and provide a finished product in days instead of weeks.

Additionally, Essentium is proud to partner with Vorum, a leader in the development of prosthetics and orthotics CAD/CAM design technology, to replace traditional plaster-cast prosthetic molding with 3D printing. Essentium’s experience in this market can help improve your patients' quality of life through additive manufacturing.

Key Applications- Jigs and Fixtures

Design, iterate and produce unique tools and surgical devices for new procedures or individual patients.

- End-Use Parts

Create custom orthotic devices with unique specifications and characteristics.

- Rapid Prototyping

Fit braces and sockets to each patient's unique physiology for stability, durability, and comfort.

High Speed Extrusion for Biomedical Devices

Essentium's HSE 3D Printing Platform delivers unmatched freedom of design to create biomedical tools and orthoses with maximum precision and user comfort. Utilizing linear servo motors on an X-Y stage, 1G acceleration, and 1 m/sec movement speed, HSE 3D Printers eliminate wasted movement and allow clinicians and manufacturers to print faster and help more patients.

Additionally, Essentium offers a wide range of filament materials featuring exceptional strength and impact resistance to make the medical innovations of tomorrow a reality today. - Jigs and Fixtures

´Customer Goods

- Embrace Mass Customization With Additive Manufacturing

While traditional injection molding remains king for the mass production of consumer goods, an increase in demand for custom products has uncovered an urgent need for mass customization Essentium High Speed Extrusion (HSE™) 3D Printing Platform has the power to keep pace with traditional manufacturing methods while creating highly customized, commercial-grade parts without impacting quality, strength, or performance.

Key Applications- Casting

Ensure a perfect fit before approving final injection molds for mass production.

- End-Use Parts

Quickly print commercial-grade parts with precision and repeatability.

- Rapid Prototyping

Bring ideas to life using unique materials and various designs to test and present custom solutions.

High Speed Extrusion for Customer Goods

While traditional injection molding remains king for the mass production of consumer goods, an increase in demand for custom products has uncovered an urgent need for mass customization Essentium High Speed Extrusion (HSE™) 3D Printing Platform has the power to keep pace with traditional manufacturing methods while creating highly customized, commercial-grade parts without impacting quality, strength, or performance. - Casting

Contract Manifacturing

- Decreasing Time-to-Market With Additive Manufacturing

The Essentium High Speed Extrusion (HSE™) 3D Printing Platform is disrupting every aspect of the factory floor. It is the world’s most comprehensive full-stack advanced manufacturing system, offering high-performance machines and materials that allow you to scale, enhance QA processes, and reduce the need for finished good warehousing. The HSE 3D Printing Platform allows contract manufacturers to execute production runs on-demand with high-performance materials at the lowest possible cost.

Key Applications- Casting

Develop new and complex castings that fit seamlessly into existing workflows — and save on time and cost in the process.

- Jigs and Fixtures

Quickly produce parts to customer's specifications and keep them on hand without warehousing costs.

- Rapid Prototyping

Win new business by giving customers the flexibility to customize products and make changes at the last minute.

High Speed Extrusion for Customer Goods

While traditional injection molding remains king for the mass production of consumer goods, an increase in demand for custom products has uncovered an urgent need for mass customization Essentium High Speed Extrusion (HSE™) 3D Printing Platform has the power to keep pace with traditional manufacturing methods while creating highly customized, commercial-grade parts without impacting quality, strength, or performance. - Casting

Defense

- Unlock Warfighter Potential

Modern missions require independent logistical systems that enable the warfighter to quickly manufacture solutions on demand. Whether emergency replacement of critical parts, the manufacturing of unmanned platforms, or innovation at the frontlines, Essentium materials and High Speed Extrusion (HSE) technology gives commanders and end users the freedom of 3D printing with the required speed and scale that provides true advantage. The Essentium HSE 280i 3D Printing Platform is an open platform well-suited for the defense industry, creating the capability to quickly produce an assortment of parts, mounts, tooling, platforms, and accessories that increase force lethality and unit readiness. Additive manufacturing reduces reliance on traditional logistical systems that have proven to be slow and cumbersome and Essentium pushes the technology to the speed of relevance. Combined with the ingenuity and innovation of the modern warfighter, the applications are limitless.

Key Applications- End Use Parts

Create and manufacture customized mounts, accessories, platforms, or parts+ for an entire unit or team at a fraction of the time and cost.

- Jigs and Fixtures

Harness speed and scale. Spread frontline innovations and expeditionary systems faster and farther through secure mass production at the points of need.

- Tooling

Essentium’s open materials platform means it can support innovation across biomedical, automotive, aerospace, and electrical applications to provide optimal advantage through tooling applications.

- End Use Parts

Applications

Casting

- Reduce Lead Times and Costs for Molds With High Speed Extrusion

Avoid the high cost and long lead times of traditional tool creation and print molds on the Essentium High Speed Extrusion (HSE™) 3D Printing Platform. Manufacturers can create prototypes, iterate designs, and print the final part on the same platform and materials which saves time and increases quality.

Why High Speed Extrusion?

Decreased Time-to-Part

Faster print times allows manufacturers to reduce lead time and rapidly iterate through designs to get to a final product faster than with other FFF printers and traditional machining.

Reduce Costs

Instead of paying for excess material waste required in subtractive processes, only pay for the material needed for the printed part.

Print Unique Geometries

Creating parts with intricate geometries can be difficult to produce with traditional machining. Utilizing the capabilities that AM offers to produce more exotic shapes unlocks new potential in casting designs.

End-Use Parts

- Reduce Time-to-Market With High Speed Extrusion

To get a product to market, it can take months to design, prototype, iterate, manufacture, and ship, even with the best suppliers on the planet. When traditional manufacturing falls short, the Essentium High Speed Extrusion (HSE™) 3D Printing Platform can bridge the gap. More than just a prototyping tool, Essentium’s powerhouse 3D printers can print end-use parts with complex geometries to ensure that manufacturers get to market ahead of the competition.

Why High Speed Extrusion?

Make Material Changes Without Extending Lead Time

Using the HSE 3D Printing Platform, material changes can be executed quickly and without tool changes, allowing manufacturers to get parts to market faster and cheaper.

Impact Supply Chain at Scale

The HSE 3D Printing Platform gives manufacturers the agility to design, prototype, produce, and distribute end-use parts in a matter of weeks.

Experience Best-in-Class Repeatability

Desktop printers cause part-to-part variation issues that render them useless in end-use applications. The HSE 3D Printing Platform has all linear servo motors and log files, allowing users to have a statistically relevant manufacturing capacity.

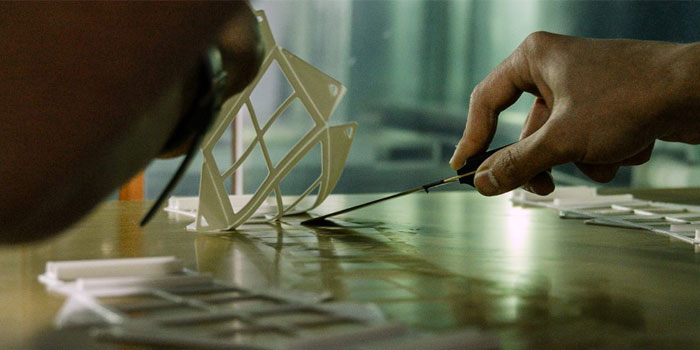

Jigs and Fixtures

- 3D Printed Jigs and Fixtures Unlock the Future of the Factory Floor

Building jigs and fixtures using additive manufacturing offers several advantages including time and cost savings for faster speed to part, as well as increased flexibility and agility in the design stages. Essentium’s unique High Speed Extrusion (HSE™) technology magnifies the power of additive manufacturing by enabling speed and strength, at scale, to meet the volume production needs that other 3D printers just cannot match.

Why High Speed Extrusion

Decrease Time-to-Part

Avoid lengthy lead times, and costly tool changes, and quickly iterate through designs using the end-use material, to land on the ideal final part.

Design for Complex Geometries

Manual fixturing, taping, and masking can cause bottlenecks and delays in production. Custom jigs and fixtures solve these challenges to save time and money.

Select Ideal Materials

Whether an application requires a material that is flexible, ESD-safe, or high-temperature or chemical resistant, Essentium HSE 3D Printing Printers allow users to utilize an open ecosystem of materials to use the best material for your application.

Masking

- Reduce Cost and Labor Hours With 3D Printed Masking Fixtures

To protect parts during various processes on the factory floor, manufacturers occasionally need to mask sensitive areas. This process typically requires manufacturers to manually tape over specific areas, which can be time-consuming, or use injection-molded boots, which speeds up the process but has unsustainable lead times and cost. Using the Essentium High Speed Extrusion (HSE™) 3D Printing Platform, users can eliminate these bottlenecks and print custom masks in hours.

Why High Speed Extrusion?

Increase Throughput

Printing custom masks using an HSE 3D Printing Platform eliminates masking bottlenecks in a matter of hours, reducing time-to-part so manufacturers can get the product to market before the competition.

Eliminate Single-Use Masking Products

Reusable 3D printed masks eliminate the need for manually applied, single-use masking products which saves money by reducing labor hours and unnecessary waste.

Produce Complex Geometries at Scale

Utilize Support Mode on the HSE 280i HT 3D Printer to print masks for the most complex applications.

Rapid Prototyping

- Reduce Prototype Iterations From Weeks to Hours

The benefits of using additive manufacturing for prototyping were some of the first to be realized. During that age of Additive 1.0, manufacturers learned that they could skip the lengthy lead times and costly tool changes during initial iterations and accepted it despite its limitations. Additive 2.0 introduced rapid prototyping where manufacturers can use technology like the Essentium High Speed Extrusion (HSE™) 3D Printer to reduce the time to prototype to a few hours instead of days and instead of iterating with ABS or PA, they can design with the end-use material.

Why High Speed Extrusion?

Reduce Time-to-Prototype

Instead of waiting overnight for prototypes to print, iterate through rounds of designs in a single day.

Access Broad Material Portfolio

Prevent late-stage design changes and use end-use materials to create prototypes that behave and look like the final part.

Receive Informed Feedback on Iterations

Gather real-time feedback on prints rather than blind designing on desktop printers.

Tooling

- Design and Print Tools and Molds at a Fraction of the Cost

Traditional manufacturing methods are driven by CNC machines and injection molding machines, both of which require tools to be made, iterated, manufactured, and shipped. This entire process can take months, even with the best suppliers on the planet. With the Essentium High Speed Extrusion (HSE™) 3D Printing Platform, skip over the lead time and tooling costs, and create highly accurate molds, that can be tweaked on the fly. These 3D-printed tools can be printed in a matter of days at a fraction of the cost of traditional tooling and casting methods.

Why High Speed Extrusion

Cut Print Time in Half

The HSE 280i HT 3D Printer features true independent dual extruders, allowing users to print two halves of a mold at once, cutting print time in half.

Skip Lead Time

Traditional tooling manufacturing can take months to arrive. Skip the lead time and design and print tools in a matter of hours.

Reduce Capital Expenses

CapEx costs such as tooling material storage, creation of the tool, and the storage of the tool increase with every product order. With AM manufacturers can directly produce parts on the fly.

Other Applications

End-Use Applications ESSENTIUM PPE

- With a fleet of 10 Essentium HSE 180•ST 3D Printers, Essentium produced more than 25,000 masks in 90 days.

Jigs and Fixtures Applications Tool Insulator Boots

- The anti-static properties of Essentium TPU 58D-AS prevent possible damage to electronic parts caused by electrostatic discharge. Parts printed with this material can be custom designed to protect parts from a variety of manufacturing tools, from handheld devices to installed tools and holders.

Tooling Application Bottle Blow Mold

- Discover the benefits and weaknesses of using additive manufactured molds within the blow molding process and the reasoning behind material selection.

EssentiumX

We are on a Mission

EssentiumX is a team dedicated to colliding experimentation and creativity into the future of advanced manufacturing. As partners of the United States government and Department of Defense, our goal is to introduce revolutionary materials and development of new technologies that can provide advantage in every domain. We operate on the edge to bring the next generation of 3D printers and materials to the world.

Rethink what is possible with driven problem solvers prepared to tackle your challenges, both known and unknown.Ready for Moonshots

From concept to project launch, we specialize in the impossible. Together, our team of scientists, strategists and engineers apply Essentium technology and advanced materials portfolio in new ways to expedite transformation.

EssentiumX develops capabilities in a state-of-the-art eco-system. We use advanced hardware, experimental materials, and cutting-edge software to bring solutions that are not available anywhere else.Our Team

EssentiumX is comprised of experts with backgrounds in advanced material science, design and engineering. We focus on unconventional approaches to additive manufacturing and 3D printing through integration with emerging technologies. We aim to embody agility, expertise, excitement, and acceleration. We believe in the freedom to explore, to provide new opportunities through partnerships, and to trail-blaze pathways to every frontier.