ES SYSTEMS

Videos

Loading the player ...

- Offer Profile

- ES Systems is a manufacturer of high-quality sensors based on micro-electronics technologies.

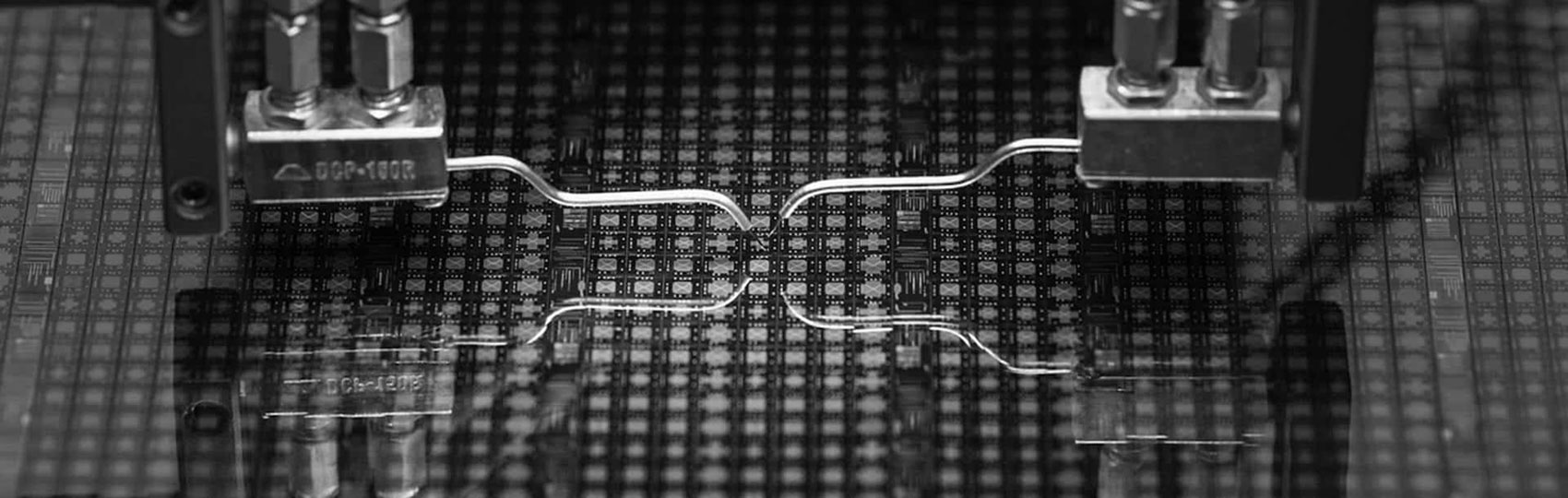

With long experience developing innovative MEMS systems, our sensors solutions are produced via qualified processes in order to accurately measure gas flow, temperature and pressure. Our pressure and flow sensors stand out from the rest of the market, due to their outstanding performance at a competitive cost. ES Systems is able to deliver high-quality and reliable products, combining multiple discipline capabilities in a fast and efficient way starting from the concept and prototyping to full production.

Product Portfolio

ES SYSTEM SENSORS

- ES Systems, a sensor manufacturing company in Europe, has a long experience in delivering high quality and innovative

sensor solutions based on micro-electronics technologies.

Our MEMS-based sensor and sensor systems which are produced via qualified industrial processes, measure pressure, gas flow and temperature. Combining multiple discipline capabilities, ES Systems delivers technologically advanced sensor solutions in a fast and efficient way starting from the concept to prototyping and to full production.

Our flexibility along with our dedication to the client can also ensure a high-end custom-made product, within a limited time frame, ready to be used on any application without additional modifications. ES Systems is employed in sophisticated control and monitoring applications in the industrial, medical and aerospace markets either as stand-alone components or being integrated within the equipment.

Towards the latest requirements and developments of the 4th industrial revolution, ES Systems has developed innovative smart, autonomous, low power and wireless sensors ideal for integration to IoT systems and solutions.

Gas Flow Sensors

- Mass flow meters for gases

A gas flow sensor (alternatively called a flow meter) is an instrument that measures the gas flow rate in a tube. An accurate gas flow measurement ensures a safe, efficient and environmentally compliant operation in all applications and industries.

With a long experience in designing innovative mass flow solutions for medical and industrial equipment, our sensors assist with a quality measurement of the flow rate. We provide high-end products, with cutting edge technology and high-performance capabilities to ensure the accurate measurement of the exact dosing of gases (flow rate) in a variety of processes and applications.

For that reason, ES Systems has developed two distinct types of resistive MEMS flow meters, inline and insertion, that can be used in any application that requires high performance and reliability. Their revolutionary design combined with exceptional technical specifications, outstanding reliability, and competitive prices, makes them one of the best flow measurement solutions in the market.

Innovative gas flow measurement

ES Systems revolutionizes the gas metering industry with fast and accurate measurements of flow over a wide dynamic range. Our sensors are calibrated to measure air; however, other non-aggressive gases are also available upon request.

Additionally, users are provided with a multitude of interface and output options so that the right sensor configuration can be picked depending on the specific requirements of the application and system design. Find our product range of certified sensors & transmitters below.

Key features

ES Systems is a manufacturer of MEMS-based flow measurement sensors with high-end technical specifications. The patented principle of operation, design and manufacturing process of our gas flow sensors provides state-of-the-art performance and technical specifications.- Outstanding technical specifications

High accuracy, very low total error band. Gas flow sensors are calibrated and temperature compensated for bidirectional or unidirectional flow. - Unique durability in high humidity environments

Ideal for medical and industrial applications with high humidity conditions. Ideal for mediums with high humidity such as human breath. - CE certified

All our gas flow sensors are CE certified, making them ideal for retrofit use, where systems are already certified and there is limited budget and time for a second run of certification.

- Outstanding technical specifications

Pressure Sensors

- Pressure sensors for liquids and gases

A pressure sensor is a device responsible for measuring the applied pressure on gases or liquids, which is then expressed as an electrical signal. Following the latest developments in system integration, a demand has been generated for accurate measurements and continuous operation in all industries, especially in the Healthcare and manufacturing industry. Therefore, the integration of safe and reliable sensors is critical.

With a long cross-industry experience in designing innovative pressure sensing solutions, based on MEMS capacitive technology, ES Systems has developed multiple distinct families of pressure sensors, either board mountable or medium isolated. Their revolutionary design and measuring principle combined with exceptional technical specifications, outstanding reliability and competitive prices make them one of the best pressure measurement solutions in the market.

Based on capacitive micro-electromechanical systems (MEMS) technology, our sensors measure everything from less than 0.4 inches of water column (1 mbar) to 14.5K psi (1000 bar) making them ideal for the automation of industrial processes or specialized medical technology applications.

Innovative pressure measurement solutions

ES Systems revolutionizes the pressure sensor industry with fast and accurate measurements over a wide dynamic range. Withstanding up to 100x the rated pressure with no plastic deformation our pressure sensors can be applied in any harsh environmental condition.

Additionally, our absolute, gauge or differential pressure sensors are ready to be installed directly to the end system without further processing. Find our product range of certified sensors, transmitters & transducers below.

Key technology features

ES Systems is a manufacturer of MEMS-based pressure sensing solutions with high-end technical specifications. The MEMS capacitive measuring principle is a patented design and fabrication process exclusively owned and used by ES Systems that provides unique technical specifications.- MEMS Capacitive technology

MEMS capacitive technology is the latest development in the pressure sensing industry that offers great advantages in terms of accuracy, performance, stability and power consumption. Therefore, ES Systems pressure sensors are suitable for applications where measurement reliability and safety are critical. - Unique Overpressure tolerance

Our high-end pressure sensors can withstand up to 100x the rated pressure with no plastic deformation and can be applied to almost every harsh environment. This is a unique feature of ES Systems technology taking both safety & reliability of pressure measurements to a whole new level. - Outstanding technical specifications

High accuracy (<±0.1%FS), very low total error band (<±0.25%FS). All pressure sensors are calibrated and temperature compensated with multiple output options. - Pressure and Temperature Sensor combo

All our MEMS capacitive pressure sensors feature an optional temperature sensor.

- MEMS Capacitive technology

Gas Flow Sensors Product Highlight

ESRF-ESF Sensor

-

Key Attributes

- Calibration Gas Air, other available on request

- Flow Range Up to ±300 ln/min Bi or Unidirectional

- Supply Voltage 5 V

- Output I2C, SPI, 0.5 – 4.5 V

- Total Error ±1.25 % RD

- Effective Resolution 12 bit

- Response Time 35 ms

- Pressure Drop

- Operating Temperature – 20 °C … + 85 °C

- Calibration Temperature 0 °C … + 50 °C

- Humidity 0 % – 95 % RH Non-Condensing

- Size (W x L x H) 44 x 92.8 x 35.4 mm

- Pneumatic Interface 22 mm ISO 5356

- Electrical Interface 2mm Locking Connector

- Typical Applications Medical – Ventilation, Respiration

ES Systems has developed ESRF-ESF, an inline gas flow sensor, based on the hot-film anemometer principle for mass gas flow measurements.

ESRF-ESF is one of the few gas flow sensors featuring bidirectional gas flow sensing of up to ±300 ln/min with a total error band of Due to the compact design, and versatility, ESRF-ESF gas flow sensors are ideal for medical, process & pharmaceutical equipment where high accuracy and reliability are of the essence.

Calibration gas is air but other non-aggressive gases are available upon request.

Advantages- Bidirectional flow meter (inhale-exhale)

- High accuracy

- Long-term stability

- Flow & temperature sensor combo

- Competitive cost

- CE certified

Ideal for Medical Applications

ESRF-ESF flow sensor is designed but not limited to usage on the following medical applications: Ventilation, Anesthesia, Inspiratory flow sensing, Gas mixing, Respiratory measurements, Drug delivery, Expiratory flow measurement, Metabolic Measurements, Proximal Flow measurement, Proximal flow measurement for infants / neonates, Expiratory flow measurement for infants / neonates, Ventilation & Anesthesia for infants / neonates, Respiratory measurements for infants / neonates, Metabolic Measurements for infants / neonates, Oxygen concentrators and conservers, Respirators and ventilators, Nebulizers, Continuous positive airway pressure (CPAP), Anesthesia machines, Anesthesia delivery machines, ventilators, ventricular assist devices (heart pumps), spirometers, laparoscopy

ESRF-ESF can also handle condensed humidity that might be caused by exhaling in the breathing cycle making it ideal for medical applications such as respiration devices, where high accuracy and reliability are of the essence.

Industrial Applications

ESRF-ESF is designed but not limited to usage on the following industrial applications: Mass flow controllers (Telecommunication systems, Environmental climate controls, Fuel cell controls, Process gas control welding equipment and lasers), Analytic instrumentation (spectrometry, chromatography), Air-to-fuel ratio, Fuel cells, Fume hoods, Gas leak detection, Process control gas monitoring, Vacuum pump monitoring, Clogging detection, Flow measurement, Air volume measurement, Process automation, Burner control, Environment monitoring, Laboratory

ESRF-HF Transmitter

-

Key Attributes

- Calibration Gas Air, other available on request

- Flow Range Up to 1500 ln/min , Unidirectional

- Supply Voltage 14 V to 32 V

- Output 4-20 mA

- Accuracy ± 2 % m.v. + 0.3 % F.S.

- Resolution 12 bit

- Output Update Rate 10 Hz

- Duty Pressure 11 bar

- Operating Temperature – 40 °C … + 85 °C

- Calibration Temperature 0 °C … + 50 °C

- Humidity 0 % – 95 % RH Non-Condensing

- Size ( Ã x L) 35 x 56 mm

- Pneumatic Interface Ã20, Ã25, Ã32

- Electrical Interface Cable

ES Systems has developed ESRF-HF, a family of insertion gas flow transmitters, based on the hot-film anemometer principle for mass gas flow measurements.

The ESRF-HF is a family of mass flow transmitters which enable fast and accurate measurements of gas flow over a wide dynamic range. Each transmitter integrates a MEMS flow sensor and readout electronics inside a housing with very small form factor made from stainless steel. The duty pressure of the flow transmitter is 11bar. All measurement data are fully calibrated, and temperature compensated on board, leading to a reduced temperature coefficient and high measurement accuracy.

The standard system provides analog signal output, with excellent repeatability and hysteresis combined with good resolution. Calibration gas is air, but other non-aggressive gases can be also available upon request.

The compact size of the ESRF-HF flow transmitters combined with the ruggedized stainless-steel housing makes them ideal for use in industrial applications within confined spaces. For easier handling and mounting, a series of in-line pipe adaptors (Ã20, Ã25, Ã32) is also available upon request.

Pressure sensors, transmitters & transducers Product Highlight

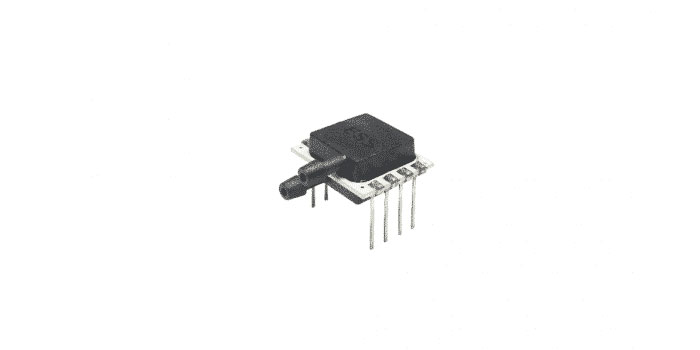

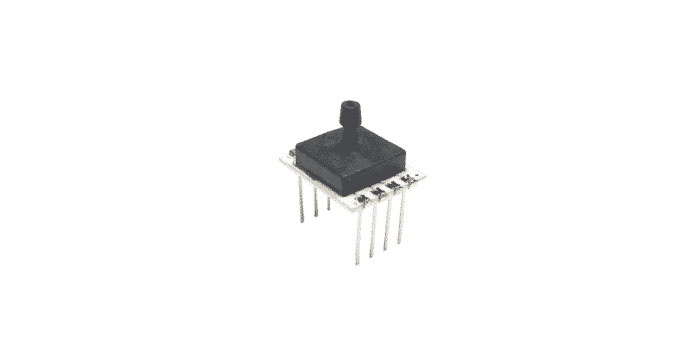

ESCP-BMS1 Sensor

-

Key Attributes

- Pressure Type Absolute, Gauge, Differential

- Pressure Range, Absolute 200mbara … 10bara

- Pressure Range, Gauge 0barg … 11barg

- Pressure Range, Differential ±10mbar … ±1bar

- Power Supply 3.3V

- Current Consumption, full operation

- Accuracy ±0.15% FSS

- Total Error Band ±0.25% FSS

- Operating Temperature -20C … +85C

- Compensation Temperature 0C … +60C, -20C … +85C

- Digital Output Calibrated Pressure & Temperature

- Analog Output Calibrated Pressure

- Overpressure Tolerance Up to 100x

- Media Compatibility Gases

ES Systems has developed a series of board mountable pressure sensors targeting a variety of markets requiring high resolution and accuracy for gas pressure measurements. The ESCP-BMS1 is a silicon capacitive pressure sensor with state-of-the-art performance and exceptional quality. The MEMS pressure sensor die is underpinned by ES’ innovative SOI-surface micromachining technology.

ESCP-BMS1 is an absolute, gauge or differential pressure sensor of ultra-high resolution with analog (0-3,3V), SPI or I2C interface. The output is fully calibrated, and temperature compensated based on the internal temperature sensor and the factory calibration coefficients which are stored in the embedded memory. The sensor is ready to be installed directly to the end system without further processing with medical, HVAC, industrial, commercial & automotive applications. The total error including repeatability, hysteresis, non-linearity, thermal offset and calibration error between 0°C and 60°C is better than 0.25% FS.

Different power modes are available enabling low power operation. The sensor can be configured to provide both high accuracy 32-bit pressure and temperature outputs.

ESCP-BMS1 is a silicon capacitive pressure sensor with excellent long-term stability. The sensor is incorporated in a standard 8-pin DIP package with a single or two pneumatic ports. The top port is the high side and the bottom port is the low side.

Advantages- Based on silicon capacitive technology

- Exceptional accuracy

- Long-term stability

- High overpressure tolerance

- Low power

Industrial Applications

ESCP-BMS1 is designed but not limited for usage on the following industrial applications: Air Flow Measurement, Air Compressors, Air Movement Control, Actuators, Analytical Instruments, Automated Pneumatic Assembly Equipment, Chemical Analysis Controllers, Factory Automation, Fire Suppression System, Flow Calibrators Gas Chromatography, Gas Flow Instrumentation, Gaseous Leak Detection, Industrial Controls, Industrial Gas Supply, Industrial Pneumatic Devices, Leak Detection, Modulated Furnace Controls, Oxygen Concentrators, Panel Meters, Pressure Switching, Pressure Valves, Process Control Pumps, Remote Monitoring Devices, Robotics, Valves, Vacuum Pump Monitoring and Variable Air Volume (VAV).

Medical Applications

ESCP-BMS1 pressure sensor is designed but not limited for usage on the following medical applications: Anesthesia Equipment, Breathalyzers, CPAP Equipment, Drug Dosing Equipment, Hospital Beds, Hospital Gas Supply, Hospital Room Air Pressure, Massage Machines, Medical Instrumentation, Nebulizers, Patient Monitoring Equipment, Respiratory Equipment, Sleep Apnea Equipment, Spirometers, Ventilators and Wound Therapy.

HVAC Applications

ESCP-BMS1 is designed but not limited for usage on the following HVAC applications: Airflow Monitoring, Clogged Filter Detection, Duct Air Flow, Environmental Control Systems, Filter Monitoring, Blocked Filter Detection and Indoor Air Quality.

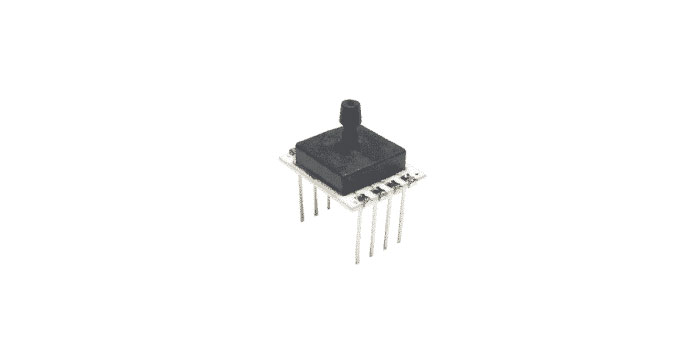

ESCP-BMS1 Sensor

-

Key Attributes

- Pressure Type Absolute, Gauge, Differential

- Pressure Range, Absolute 200mbara … 10bara

- Pressure Range, Gauge 0barg … 11barg

- Pressure Range, Differential ±10mbar … ±1bar

- Power Supply 3.3V

- Current Consumption, full operation

- Accuracy ±0.15% FSS

- Total Error Band ±0.25% FSS

- Operating Temperature -20C … +85C

- Compensation Temperature 0C … +60C, -20C … +85C

- Digital Output Calibrated Pressure & Temperature

- Analog Output Calibrated Pressure

- Overpressure Tolerance Up to 100x

- Media Compatibility Gases

ES Systems has developed a series of board mountable pressure sensors targeting a variety of markets requiring high resolution and accuracy for gas pressure measurements. The ESCP-BMS1 is a silicon capacitive pressure sensor with state-of-the-art performance and exceptional quality. The MEMS pressure sensor die is underpinned by ES’ innovative SOI-surface micromachining technology.

ESCP-BMS1 is an absolute, gauge or differential pressure sensor of ultra-high resolution with analog (0-3,3V), SPI or I2C interface. The output is fully calibrated, and temperature compensated based on the internal temperature sensor and the factory calibration coefficients which are stored in the embedded memory. The sensor is ready to be installed directly to the end system without further processing with medical, HVAC, industrial, commercial & automotive applications. The total error including repeatability, hysteresis, non-linearity, thermal offset and calibration error between 0°C and 60°C is better than 0.25% FS.

Different power modes are available enabling low power operation. The sensor can be configured to provide both high accuracy 32-bit pressure and temperature outputs.

ESCP-BMS1 is a silicon capacitive pressure sensor with excellent long-term stability. The sensor is incorporated in a standard 8-pin DIP package with a single or two pneumatic ports. The top port is the high side and the bottom port is the low side.

Advantages- Based on silicon capacitive technology

- Exceptional accuracy

- Long-term stability

- High overpressure tolerance

- Low power

Industrial Applications

ESCP-BMS1 is designed but not limited for usage on the following industrial applications: Air Flow Measurement, Air Compressors, Air Movement Control, Actuators, Analytical Instruments, Automated Pneumatic Assembly Equipment, Chemical Analysis Controllers, Factory Automation, Fire Suppression System, Flow Calibrators Gas Chromatography, Gas Flow Instrumentation, Gaseous Leak Detection, Industrial Controls, Industrial Gas Supply, Industrial Pneumatic Devices, Leak Detection, Modulated Furnace Controls, Oxygen Concentrators, Panel Meters, Pressure Switching, Pressure Valves, Process Control Pumps, Remote Monitoring Devices, Robotics, Valves, Vacuum Pump Monitoring and Variable Air Volume (VAV).

Medical Applications

ESCP-BMS1 pressure sensor is designed but not limited for usage on the following medical applications: Anesthesia Equipment, Breathalyzers, CPAP Equipment, Drug Dosing Equipment, Hospital Beds, Hospital Gas Supply, Hospital Room Air Pressure, Massage Machines, Medical Instrumentation, Nebulizers, Patient Monitoring Equipment, Respiratory Equipment, Sleep Apnea Equipment, Spirometers, Ventilators and Wound Therapy.

HVAC Applications

ESCP-BMS1 is designed but not limited for usage on the following HVAC applications: Airflow Monitoring, Clogged Filter Detection, Duct Air Flow, Environmental Control Systems, Filter Monitoring, Blocked Filter Detection and Indoor Air Quality.

ESCP-MIT1 Transmitter

-

Key Attributes

- Pressure Type Absolute, Gauge

- Pressure Range Up to 400bar

- Power Supply +8V … +32V

- Total Error

- Operating Temperature -20C … +85C

- Compensation Temperature 0C … +60C, -2oC … +85C

- Digital Output Calibrated Pressure & Temperature

- Analog Output Calibrated Pressure

- Output 4-20mA, 0-10V, I2C

- Overpressure Tolerance Up to 100x

- Media Compatibility Gases, Liquids

- Material Options SS 316L, Hastelloy, Titanium

- Connection Type M12, ISO4400, Cable

- Pneumatic Interface G1/2″, G1/4″, 1/2″ NPT, 1/4″ NPT

ES Systems has developed a series of medium isolated pressure transmitters suitable for applications with harsh environmental conditions where resistance to corrosive fluids or gases is required. Each sensor integrates a MEMS capacitive pressure sensor die, and a CMOS ASIC for the signal conditioning. The MEMS pressure sensor dies are underpinned by ES’s innovative microfabrication process for silicon capacitive sensors.

The ESCP-MIT1 of capacitive pressure sensor dies integrated into the medium isolated pressure systems provide state-of-the-art accuracy and resolution, excellent long-term stability combined with very good repeatability and hysteresis. The total overall error, including thermal offsets, is lower than ±0.25% FS.

The ESCP-MIT1 is a family of heavy-duty pressure transmitters made from stainless steel 316L. Each transmitter consists of an ESCP-MIS1 sensor, which is O-ring fitted to the housing. The pressure transmitters come in various standard pneumatic ports as well as custom ones upon request. The electrical interface can be either analog (4-20 mA, 0-10 V) or digital (I2C). The sensors can be provided calibrated and compensated at various temperature and pressure ranges from 1 bar to 400 bar. Custom configurations of a variety of pneumatic interfaces, Hastelloy or Titanium material, and output interface are available upon request.

ESPP-MIT1 Transmitter

- Key Attributes

- Pressure Type Gauge

- Pressure Range Up to 1000bar

- Power Supply +8V … +28V

- Total Error

- Operating Temperature -40oC …+125oC

- Compensation Temperature -10oC …+80oC

- Output Calibrated Pressure

- Output Interface 4-20mA, 0.5V-4.5V, 1-5V, 0-5V

- Overpressure Tolerance Up to 5x

- Media Compatibility Gases, Liquids

- Material Stainless Steel 17-4PH

- Connection Type M12, ISO4400, Cable, Packard

- Process Interface G1/2″, G1/4″, 1/2″NPT, 1/4″NPT, …

- Dimensions Height: 66.5mm | diameter Ã23.5mm

ES Systems has developed a series of strain gauge pressure transmitters featuring very good accuracy at a low cost. Each module is based on an all-welded hermetically sealed structure in a single stainless-steel piece. The ESPP-MIT1 is a medium isolated pressure sensor suitable for gas or fluid pressure measurements in harsh industrial or HVAC environments.

The output is fully calibrated and temperature compensated based on the internal temperature sensor and the factory calibration coefficients which are stored in the embedded memory. Thus, the transducer is ready to be installed directly to the end-user system without further processing.

ESPP-MIT1 comes with a variety of electrical interfaces output signal types and process interfaces. It is one of the most cost-effective solutions especially when high volumes are required.

Advantages- Excellent performance

- Very low cost

- Micro-fused technology

- Compact structure

- Integrated fully sealed stainless steel construction

- Calibrated & temperature compensated output

- Wide range of process interfaces

- Certified (CE)

- included in price

Industrial Applications ESPP-MIT1 transmitter is designed but not limited to usage on the following industrial applications: Central air conditioning control systems, Engineering machinery, Energy & water treatment systems, Hydraulic & pneumatic systems, Industrial process control & automatic detection systems, Pumps & compressors and Refrigeration systems.

ESCP-SAPT Transmitter

-

Key Attributes

- Pressure Ranges (Absolute) 7 bar, 22 bar, 150 bar, 310 bar

- Media Compatibility Hydrazine, MON, NMH, Green Propellant, IPA, GHe, GN2, GXe, Deionized H20, HFE

- Proof Pressure 2 x Operating Pressure (MEOP)

- Burst Pressure 4 x Operating Pressure (MEOP)

- Accuracy ±0.3 % FS

- Pressure Output Type Analog Output 0 – 5.0 V

- Material / Including Wetted Surfaces Ti (Ti6AI4V) / Ti grade 1

- Mounting 4 Mounting Screws

- Electrical Interface Flying Lead Harness

- Power Supply 7 – 30 VDC

- Power Consumption

- Pneumatic / Hydraulic Interface Weldable Inlet Tube

- Mass

- Operating Temperature -20oC … + 75oC

Internet of Things (IoT) Sensor Technology

- The Internet of things (IoT) is the network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, actuators, and network connectivity, which enable these objects to connect and exchange data. Each thing is uniquely identifiable through its embedded computing system but can interoperate within the existing Internet infrastructure.

As a result, the sensors used in IoT play an extremely important role, with various applications.

Some of the most common types of sensors in IoT are temperature, level, and pressure sensors, as well as gas flow sensors used to measure and monitor a plethora of gases in industrial and medical environments.

The IoT allows objects to be sensed or controlled remotely across existing network infrastructure, creating opportunities for more direct integration of the physical world into computer-based systems and resulting in improved efficiency, accuracy, and economic benefit in addition to reduced human intervention. When IoT is augmented with sensors and actuators, the technology becomes an instance of the more general class of cyber-physical systems, which also encompasses technologies such as smart grids, virtual power plants, smart homes, intelligent transportation, and smart cities.

Towards the latest developments and activities, ES Systems offers complete IoT solution integration services according to each customer’s requirements and applications, pioneering in the IoT sensor technology field.IoT in Industrial Automation & Manufacturing

IoT sensors have been widely used in manufacturing during the last decade. Due to their capability of communicating with other sensors and remote devices, it has been made possible for many industries to solve the modern-day automation challenges and work with a great amount of data.

IoT – based sensors can be used in Brownfield or Greenfield plants in order to increase productivity, minimize costs and adhere to legislation in order to protect the environment – among other things.Developed Application example – Smart Factory

ES Systems has developed a complete smart system solution for condition monitoring of industrial equipment. The system features synchronous sensor sampling with wireless communication enabling optimal vibration and condition monitoring of equipment. The wireless capability enables installation at remote locations with minimal installation cost while supporting WiFi and BLE 4.0 wireless protocols allowing installation and communication integration in existing wireless infrastructures. The data collected from the system are transferred to the cloud or to secure servers where end users can execute their predictive maintenance algorithms. For more information, click here.IoT Sensors for the Industrial Field

ES Systems has developed a complete smart system solution for condition monitoring of industrial equipment.

ESMS-ECM

ESMS-ECM is the first condition monitoring system worldwide that supports wireless and synchronous multichannel data sampling, enabling optimal vibration and condition monitoring of equipment – a necessary feature for vibration monitoring and frequency pattern analysis in the industrial field.IoT and sensors in Healthcare

IoT in the medical field has opened up a world of possibilities, increasing the potential to sustain patients’ health and safety with more efficiency and convenience. Medical IoT devices and machines can deliver excellent care while they have a major impact on reducing healthcare costs significantly.

Application example – Smart Sensor Nodes

ES Systems has developed multiple sensor node systems featuring various sensors for environmental monitoring that can be utilized in a variety of applications and industries. Each system can integrate gas flow, humidity, temperature, TVOC, CO, NO2, CO2, pressure, acceleration, and numerous other sensors that can be integrated into custom-tailored PCBs that fit each user’s tailored defined mechanical specifications. These sensing nodes can integrate both wired and wireless communication enabling optimal connectivity capabilities. The wireless capability of IoT devices in healthcare enables installation in remote locations with minimal installation cost. These sensing nodes can support various wireless communication protocols making them easy to integrate into any network infrastructure.IoT Sensors for the Medical Field

Below, you may find 2 products with IoT technology that we recommend for medical applications:

ESEN-MESN

This sensing system can be integrated into custom-tailored boards while it enables installation into any network infrastructure with the minimal installation cost. ESEN-MESN features multiple sensors for environmental monitoring that can be utilized successfully in the Healthcare sector.

ESEN-5000

The sensing system of ESEN-5000 is designed for patient room environment monitoring. It supports wireless communication enabling optimal connectivity capabilities that are necessary for the medical field. Also, it integrates different types of sensors in IoT, such as pressure, humidity, temperature, luminosity, accelerometer, and magnetometer sensors that can be integrated into custom-tailored designs that fit each end-user’s tailored defined specifications. Applications

Medical Applications

- In healthcare, the efficient operation of medical devices is crucial – sometimes even a matter of life or death.

Subsequently, the sensors in medical devices can play a very important role where accuracy, reliability and long term performance are of great significance.

For all those applications that require high levels of precision and low total error band, specifically designed sensors or “medical sensors” can be used in order to enhance effectiveness along with the reliability of operation.

To sustain and meet these needs, ES Systems has manufactured healthcare sensors that greatly enhance the quality and reliability of medical devices.

It goes without saying that the sensor medical technology has recently seen tremendous development.

Nowadays, different types of medical sensors are essential throughout healthcare and hospital departments. To meet the increasing needs for high accuracy and stability, with an orientation to the highest standards, ES Systems has developed a series of cost-effective pressure and flow sensors for medical applications.

The ES Systems’ sensors used in healthcare can find use in several respiration and ventilation devices. For example, they can be applied in ventilators providing breathing assistance to patients being in critical condition. Furthermore, they can be implemented in respirators used to measure and control the flow rate and the exact dosing of any gas.

Additionally, size is very important when it comes to health monitoring sensors.

For this reason, ES Systems’ flow sensors, due to their compact size, could be placed within several medical sensory solutions, such as standard diameter tubes to nebulizers and anesthesia machines, in order to control any amount of drug delivered in gas form.

Finally, the pressure sensors used in medical field can monitor a patient’s condition by providing definite and reliable diagnostics in a broad range of conditions such as measuring blood pressure or even administering the right volume of fluid in infusion pumps.

Industrial Applications

- Factories are constantly seeking ways to maximize their throughput and performance. Lately they have also been regulated to reduce any negative impact on the environment along the way. The most efficient way to implement this is through systems and sensors

used in industrial automation.

Therefore, in an attempt to efficiently control the processes and utilize the maximum capacity of facilities, the types of sensors used in manufacturing have seen a remarkable progress in recent years. The applications of sensors in manufacturing are numerous, and their role is pivotal in terms of quality, safety, and energy conservation.

Among the industrial sensor manufacturers, ES Systems offers specialized technical expertise and high-quality of products. More specifically, the types of sensors used in automation include pressure and flow sensors that can assist in any industrial application where efficiency is vital.

What are industrial sensors?

Industrial pressure sensors are robust and reliable sensors designed to operate in harsh environments that play a key role in monitoring industrial processes. Also, industrial flow sensors are used to assist in the measurements of the flow rate and the control of the dosing of any gas with precision.

ES Systems’ sensors used in industries can give you the edge in terms of technology, providing you with long-lasting sensors with wide applications in the industry. Applications of sensors in industries can include HVAC systems where it is important to reduce energy consumption and control heating, ventilation, and air conditioning with more precision.

Additionally, sensors used in automation can collect real-time data on environmental and flow conditions that can be used as the base for optimization, and likewise in gas meter industry for smart gas metering.

Aerospace Applications

- The aerospace industry is an extremely demanding market that requires:

- high performance

- reliability

- long term stability material integrity

These characteristics are especially of great significance when it comes to sensors for aerospace applications.

Aerospace sensors include several applications, such as the measurement of fuel pressure in the propulsion tank of satellites. An aerospace pressure sensor in this situation is particularly demanding.

From high resolution and high accuracy to particle radiation tolerance and stability under extreme environmental conditions, an aerospace pressure transducer should be operable under severe circumstances.

ES Systems has developed high accuracy and cost-effective pressure sensors for customers to develop and manufacture cutting-edge aerospace solutions.

HVAC Applications

- Heating Ventilating and Air Conditioning (HVAC) systems were never as important as they are today, due to the great significance of safe indoor air quality (IAQ), not only in homes but in large buildings like factories and hospitals, too.

An HVAC system is a complicated one, with several components, one being sensors. HVAC sensors can be used for a number of operations in order to improve system performance: air conditioner sensors, furnace sensors as well as several temperature sensor types can all be found in one single system, ultimately ensuring health and safety.

In detail, the types of sensors used in HVAC may include temperature, humidity, occupancy as well as pressure sensors, the latter being the most prevalent.

HVAC pressure sensors

HVAC pressure transducers monitor pressure levels and measure the pressure drop across devices, alerting the system when maintenance and filter replacement is required.

ES Systems, following the increased requirements in the field, has developed a series of board mountable pressure transducers for markets that require high resolution and accuracy for gas pressure measurements.

More specifically, the ESCP-BMS1 is an absolute, gauge or differential pressure sensor of ultra-high resolution with analog (0-3,3V), SPI or I2C interface.

It can be used when optimal HVAC performance is required, as its total error including repeatability, hysteresis, non-linearity, thermal offset and linearity error being better than 0.25% FS.

ESCP-BMS1 is designed but not limited for usage on the following HVAC applications: Airflow Monitoring, Clogged Filter Detection, Duct Air Flow, Environmental Control Systems, Filter Monitoring, Blocked Filter Detection and Indoor Air Quality.