WESTERIA

Videos

Loading the player ...

- Offer Profile

- Westeria is a German company from Westphalia with over 60 years of experience in manufacturing innovative machinery for recycling and materials handling Since 1956 our product portfolio has grown strongly to provide our customers with high quality machinery, technical know-how and excellent service. We are constantly developing new innovations for what is perhaps today's greatest challenge: making the circular economy a valuable and profitable reality everywhere in the world.

We are constantly developing new recycling machines and conveying systems for what is perhaps today’s greatest challenge: making the circular economy a valuable and profitable reality everywhere in the world.

Wherever piece or bulk goods have to be sorted, conveyed, dosed or distributed, Westeria’s innovations are in demand: economical, robust, durable, reliable and tailored to individual requirements. Whether our colleagues or our customers – for us, the focus is always on people. Individual consulting by competent experts from sales to service. In doing so, we are on the road for you worldwide.

Product Portfolio

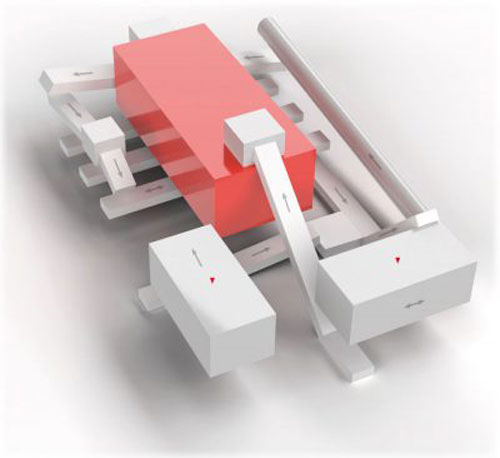

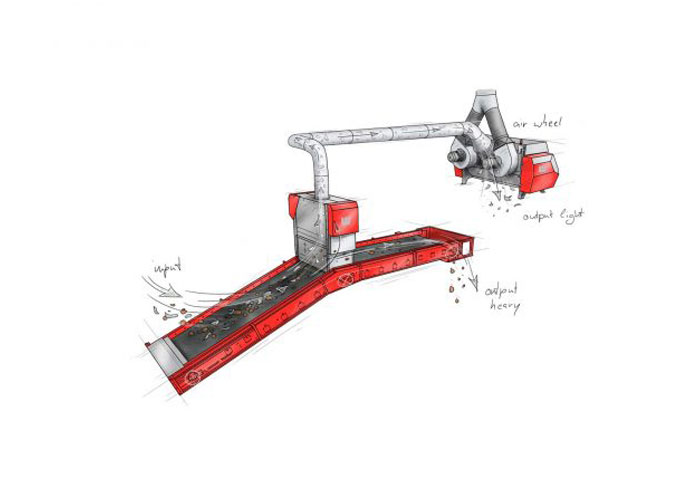

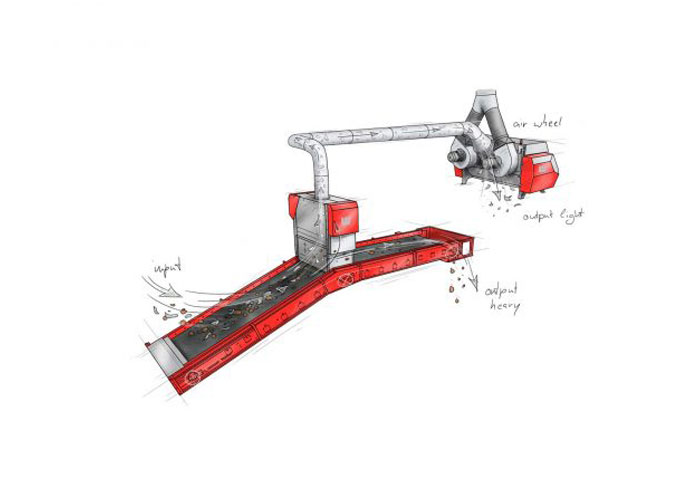

Windsifting

- The entire Westeria windsifter range combines efficiency with lightness, despite its robust construction.

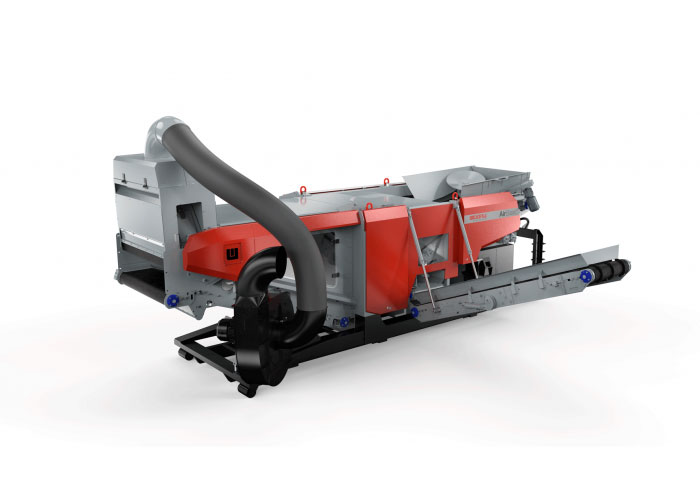

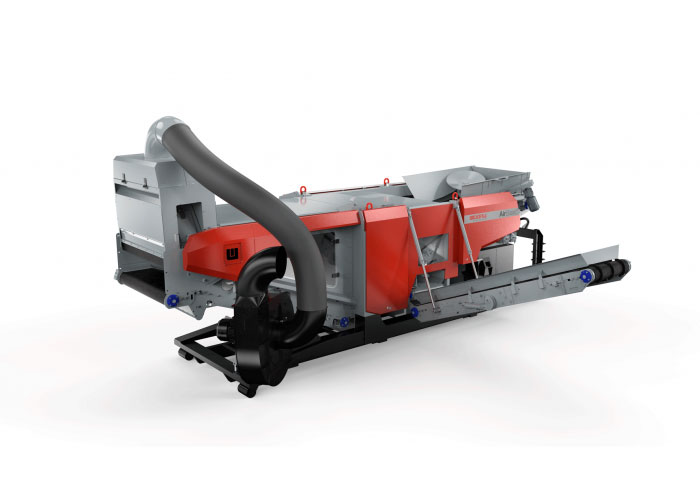

AirStar® - Our best selling windsifter

- The AirStar is the best-selling stationary air classifier from Westeria. 30 years of development resulted in the best windsifter you can imagine.

Advantages- High throughput of up to 400 m³/h

- Purest separation into two or three fractions

- Optimal blow nozzle with 60% higher core radiation speed

AirStar Efficient mobile separation

The AirStar uses a unique, patented Westeria system that offers the highest aerodynamic efficiency and allows a throughput of up to 400 m³/h.

The sophisticated design of our air nozzles allows us to produce a precise, uniform airflow for perfect separation results. In doing so, we can achieve a 60% higher core jet speed than comparable air classifiers and even consume less energy.

The windsifter

for best separation results

Hundreds of customers around the world can confirm that the AirStar delivers what it promises: best separation results, low and easy maintenance, reliable and durable.

The flexible AirStar is available in different versions. Working widths of 1000 – 3000 mm and different sizes of the lightweight material chamber allow the windsifter to be flexibly integrated into any plant. Optionally, our AirLift can be integrated to save space and separate an additional “ultra-light” fraction.

All components of the separator are easily and individually adjustable and accessible to facilitate maintenance. Thanks to the modular design, the machine is easy to customise, can be transported in a space-saving way and can be assembled in just one day.

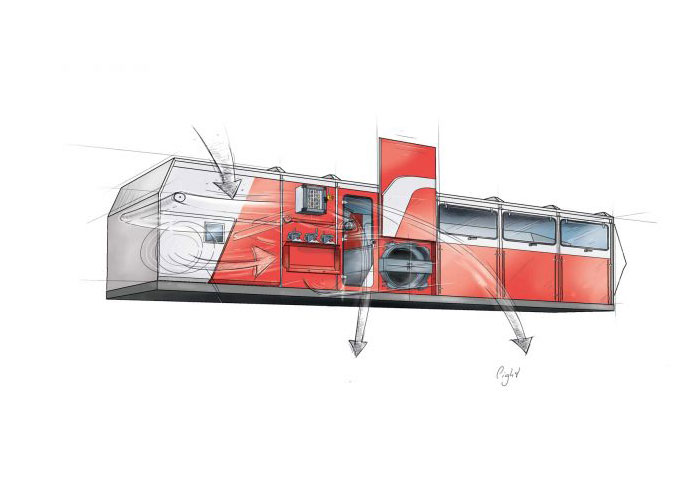

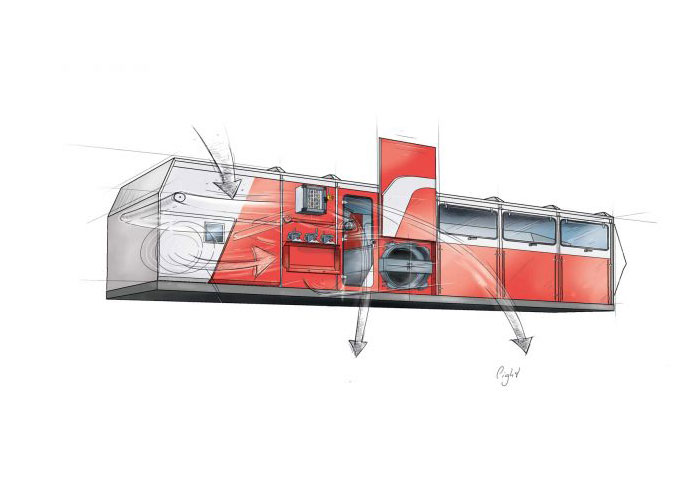

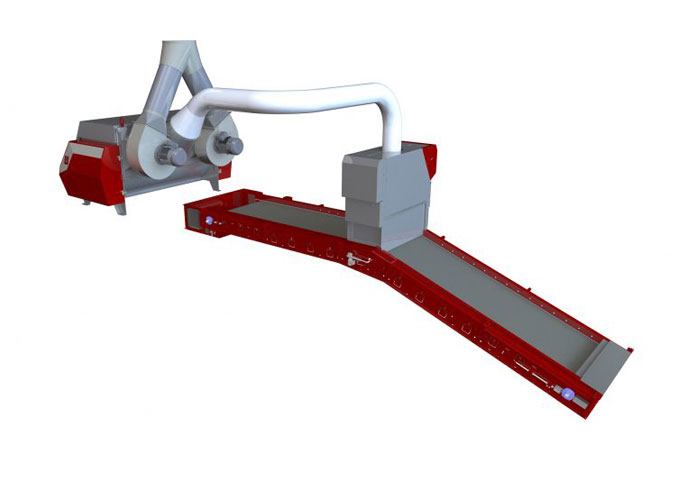

AirBasic® - Mobile separation perfected

-

The AirBasic combines the advantages of our air classifier technology

in a compact, mobile machine.

Advantages- Patented adjustable and precise nozzle system

- Flexible integration with other systems

- 98% guaranteed separation result

AirBasic® Windsifter for flexible solutions

The AirBasic brings the advantages of our proven windsifting technology to a small, mobile machine.

It is available in various options to ensure optimum separation results at any site. The material can be fed from any direction (180°). The AirBasic features a patented adjustable and precise nozzle system that works much more efficiently than comparable products on the market. Thanks to our standardised production process, it can be delivered quickly, regardless of the version or options chosen. Fully equipped, it fits into a 40′ HC container.

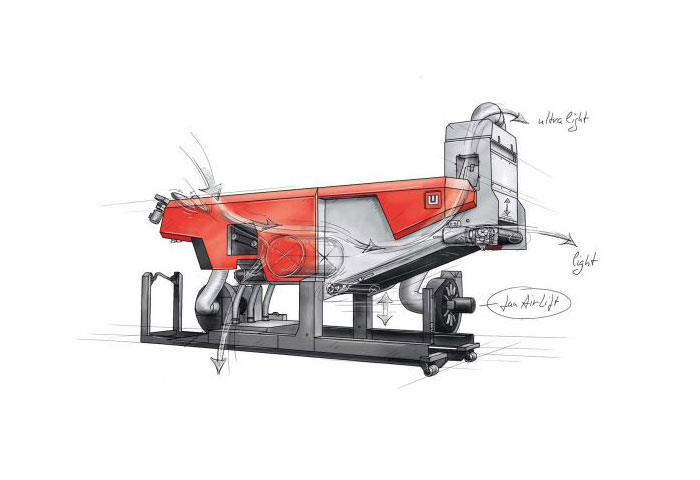

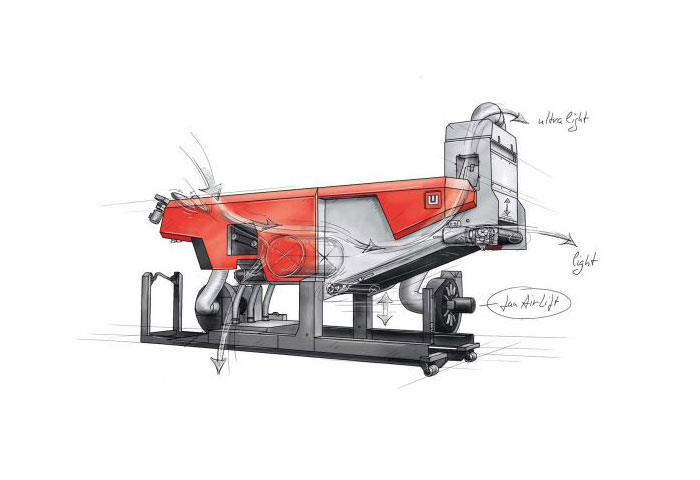

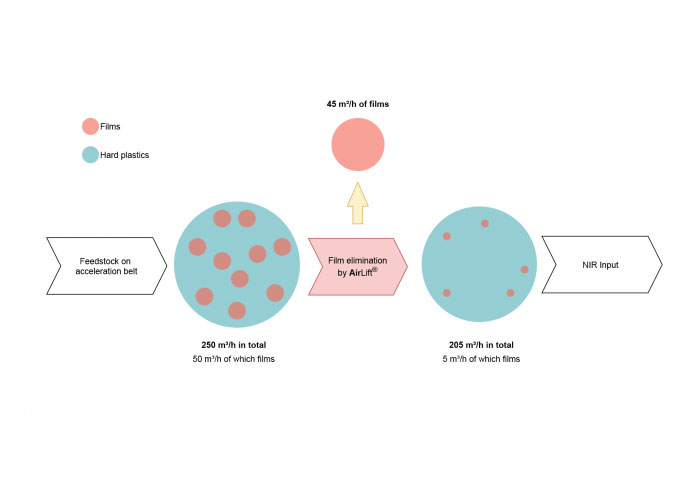

AirLift® - High-precision lightweight separator

- The AirLift separates what previously could not be separated. Materials with very similar specific densities are its specialty. This air classifier also ensures maximum efficiency when used upstream of the NIR classifier.

Advantages- Higher efficiency than normal overband suction systems

- Precise adjustment of ballistic trajectory, air speed and visibility

- Purity levels up to over 99

- Max. Flow rate 120 m³/h

Putting an end to nuisance

Air classifiers are a core element of systems for separating components of different weights contained in waste streams. Our AirLift vacuum air classifier is a particularly effective design.

The ultra-light separator enables sorting processes in which the specific weights and ballistic flight properties of the respective constituents differ only slightly. Applications include, for example, the recycling of PET bottles, where the valuable PET fraction can be cleaned with high efficiency and purity from light impurities such as labels made of PE film or paper. The AirLift also masters the great challenge of freeing biological waste from plastic contaminants outstandingly.

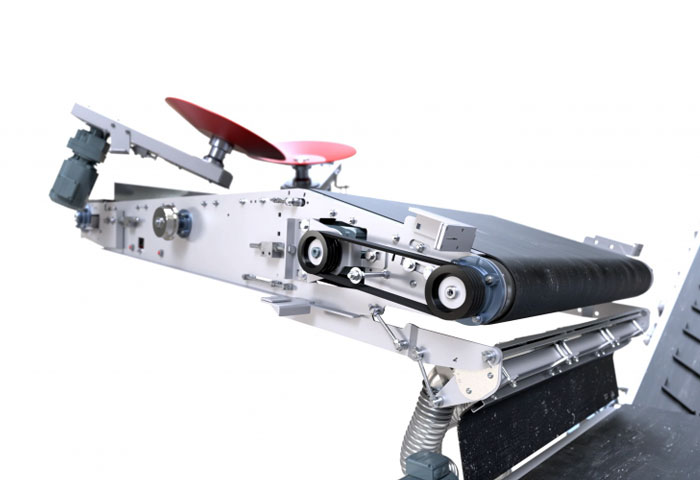

AirLift® move - Free from all impurities - more flexible than ever before

- The mobile version of our widespread over belt windsifter frees your material from impurities as uncomplicated as never before.

Advantages- High purity of over 99 %

- Max. Flow rate 120 m³/h

- Precise adjustment of ballistic trajectory, air speed and visibility

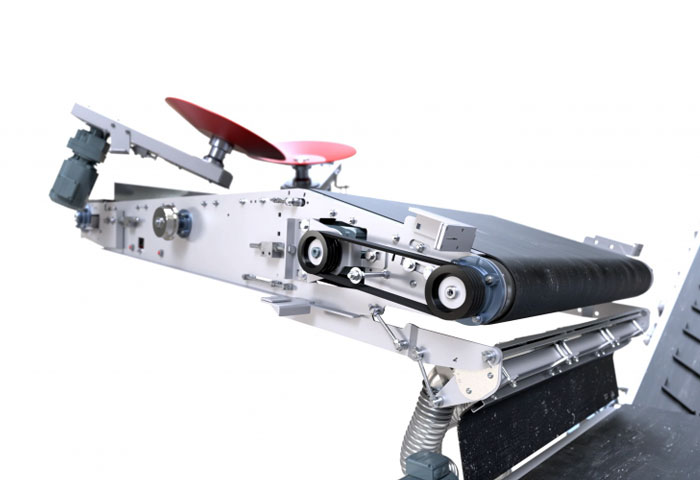

- DiscSpreader and prefeeding belt integrated as standard

AirLift® move Flexible separation

Now also mobile! Our proven technology of the AirLift windsifter is now more flexible than ever. The AirLift move brings effective separation to any location.

The ultra-light separator is already widely used as a stand-alone version for the removal of impurities. Materials with similar specific densities are easily separated by the unit. For compost processors, the AirLift move therefore enables the effective and efficient removal of films from the valuable organic material.

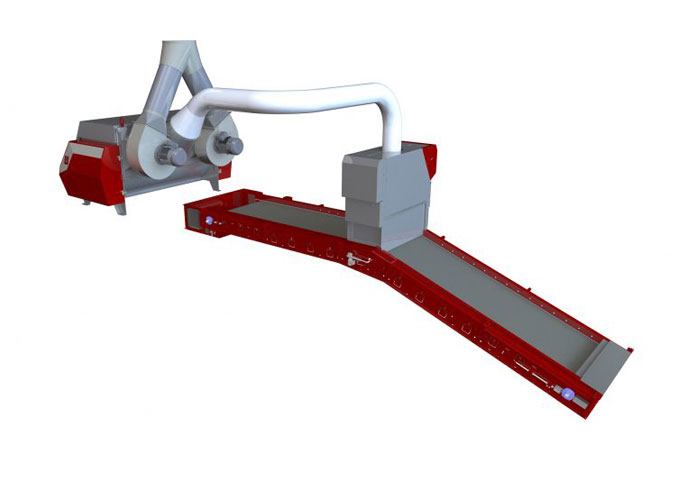

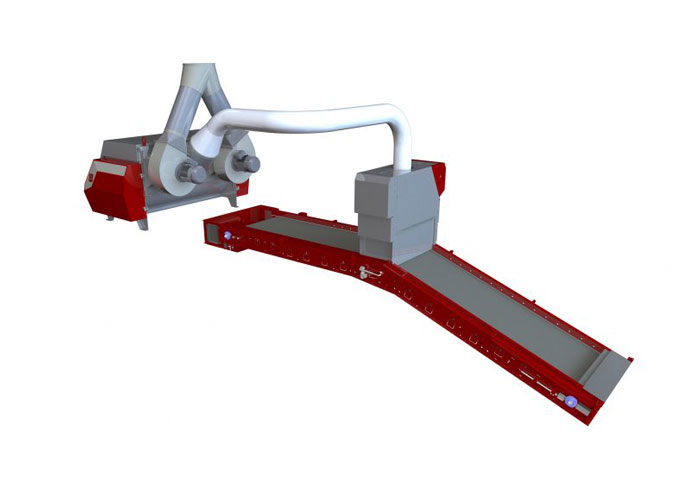

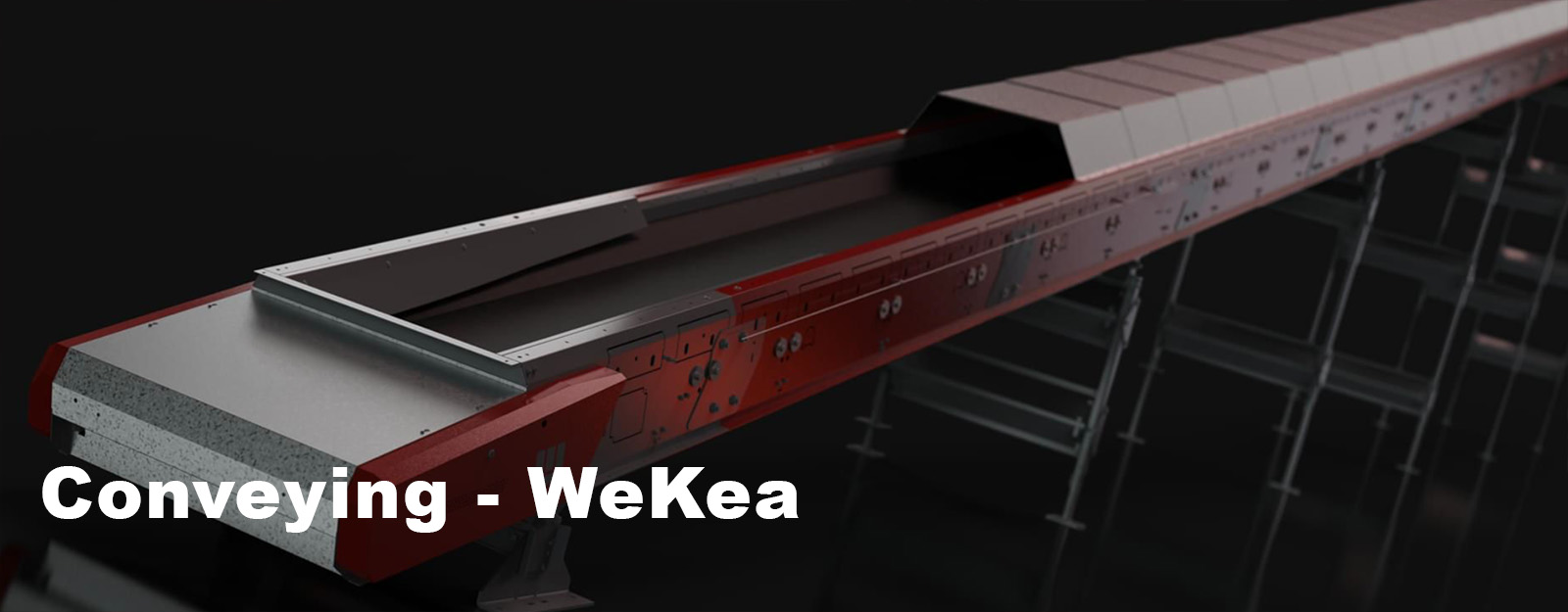

Conveying

- Conveyor belts from Westeria can be used flexibly for various applications.

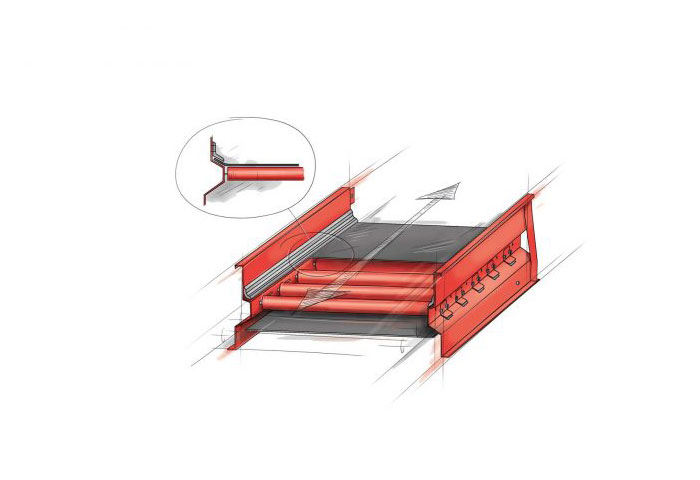

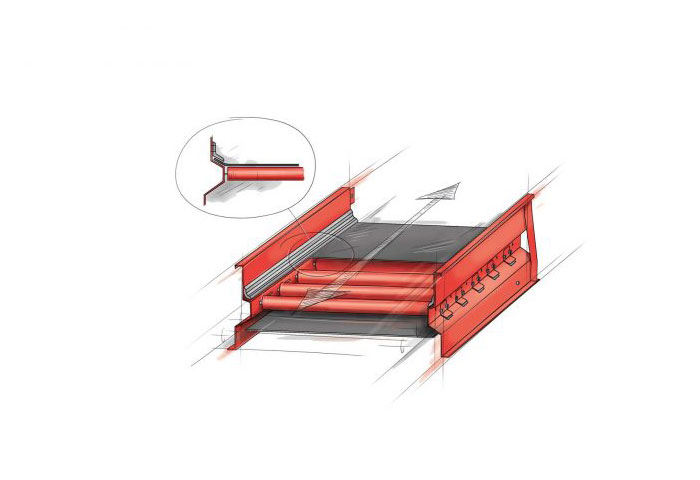

WeKea® - The revolution in conveyor technology

- Conveyor belts as easy as never before.

With our online configurator, you will receive an official

official offer within a few minutes.

Your benefits- Configured quote in minutes

- Delivery within shortest time

- Low delivery costs due to efficient shipping

Conveyors rethought

The logical conclusion from over 60 years of experience in conveyor technology and recycling: With the new WeKea conveyor system, Westeria is revolutionizing the procurement process for conveyor belts. With our online configurator, you will receive an official quotation within minutes. Thanks to the modular design, your conveyors will be ready for shipment in no time at all and will consume significantly less loading space. And, of course, quality has been our top priority throughout the entire development process. That is the philosophy of Westeria.

FlatCon® - The versatile

- A wide range of applications and materials can be covered thanks to the flat belt conveyor's standard side slide supports and optional side seals.

Total flexibility- Take advantage of our WeKea system

- Also available as customized variant with individual engineering

- Extremely versatile

Sophisticated in every detail

The versatile FlatCon combines the advantages of a rolling and a sliding discharge conveyor.

By using lateral sliding supports, this combines optimal side sealing with energy-saving drive power. As with the UCon, SteelCon and ChainCon you can benefit from the WeKea System. In years of work, we have put all our experience into revising the standard versions so that we have integrated a large number of technical innovations as standard. In addition, as a customized variant, every requirement can be individually covered by our engineering team.

The standard options include the rubberized drum as well as a reversible version or the T cleat belt.

UCon® - The classic trough conveyors.

- The UCon is Westeria's solution for all types of bulk materials. It can be equipped with additional side seals along any length.

Effective solution- Ideal for all bulk materials

- Proven and optimized for years

- Easily accessible idlers also with side sealing

The classic among conveyors

The UCon is Westeria’s solution for all types of bulk materials. It can be equipped with additional side seals along any length. Furthermore, its design has been perfected so that, in contrast to conventional conveyors, the idlers can be reached and replaced very easily for maintenance purposes. Large volumes are no problem for the UCon: With additional side elevations, a particularly large loading height can still be achieved even with top belt covers.

SteelCon® - The robust one

- A true powerhouse. Designed for the toughest applications, it manages the most demanding tasks in conveying a wide variety of materials.

Absolute stability- Extra strong construction for strongest materials

- Large drive drum for optimum transmission of the drive force

- Optional special belt for high resistance

Strong in all requirements

The SteelCon, designed for the toughest applications, is a true powerhouse. Its weight alone of over 1/2 ton per 3 m segment is proof that it can handle the most demanding tasks in conveying scrap and other heavy or aggressive material flows for a long time. Standard galvanized steel side guides can be equipped with optional additional wear plates. Numerous technical innovations are integrated as standard.

In addition, as a customized variant, every requirement can be individually covered by our engineering team.

BendCon® - The perfect bend - carried by rollers

- The BendCon is the ideal solution for all conveying tasks with upward bend.

Advantages- Saving of a transfer due to upward bend

- Angle can be aligned or adapted to special conditions

- Applicable for bulk material of all kinds

BendCon® Conveying with upward bend

The BendCon is a roller carried bend conveyor and the ideal solution for all conveying tasks with upward bend.

The angles of the bend conveyor belt can be configured according to your special requirements. Thus, it can be used for bulk materials of all kinds. The conveyor belt system has proven itself, for example, as a discharge belt for shredders. The well thought-out and robust roller system and the corresponding belt conveyor leave nothing to be desired and effortlessly transport the feed material. An additional advantage of the bend upwards is the saving of a transfer point and thus the overall height within a plant.

PipeCon® - Air guided tube belt conveyor

- The PipeCon is an air-guided conveying system for any type of bulk material with precisely defined particle sizes, such as in the wood and cement industries.

Advantages- High conveying capacity with up to 500 t/h

- Optional maintenance walkway possible as access to all relevant areas

- Reliable sealing system which prevents gravel leakage

PipeCon® Conveying materials with exact grain sizes

The PipeCon is a conveyor system designed for transporting bulk materials of all kinds over long distances. Extremely high conveying capacities (up to 500 t/h) are possible in the perfectly sealed pipe conveyor. The supports can be up to 60 m apart, with a total length of more than 300 m.

The belt floats on an air buffer generated by integrated fans. The 2.2 kW fans are located every 50 m at the top of the pipe conveyor. This drastically improves efficiency and minimises wear parts and maintenance of the machine. A maintenance walkway can be mounted directly on the belt, eliminating the need for an additional steel structure. The one-sided access is completely sufficient for full maintenance.

The tensioning station can be flexibly positioned on the floor so that the conveyor can be easily integrated into any plant design. In addition, a double scraper system is installed, which prevents uncontrolled falling of dust or trickling material. The PipeCon consists of 12 m long segments that can be quickly assembled. Due to our transport system, three of these segments can be safely transported and quickly unloaded in a 40′ containerert.

Dosing

- The Westeria dosing systems with their special modular principle are perfectly engineered in every detail.

DoseCon® - Perfect dosing made easy

- High-precision dosing is the key to efficient material use. The DoseCon weighing and dosing conveyor precisely doses material based on weight.

Advantages- Fully automatic dosing and weighing function

- Automatic detection of material blockages

- Highly versatile

Precise and reliable

The Westeria dosing conveyor is capable of conveying coarse-grained and fine-grained material for a variety of different processes. With the help of the integrated belt scale and the software developed specifically for this purpose, the speed of the belt is controlled in such a way that a uniform loading of subsequent components takes place.

In combination with other Westeria components, such as the ChainCon chain belt conveyor and our hopper systems, the entire process can be automated right from the start and guarantees ideal preloading of the DoseCon. Optimal material dosing is the key to efficient use of resources, for example in fuel feeding in cement plants.

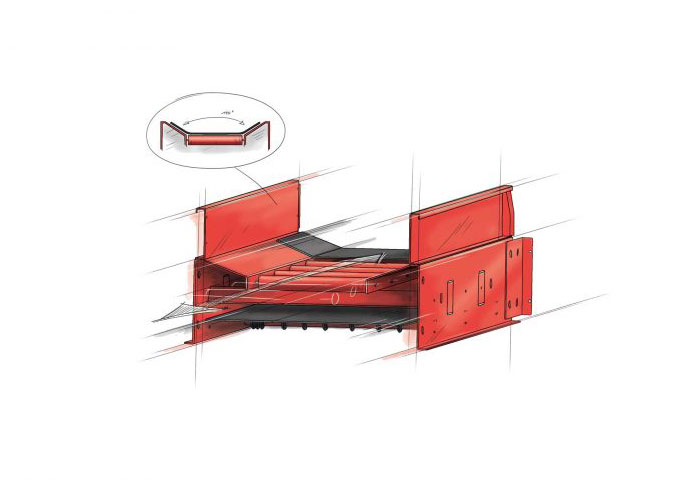

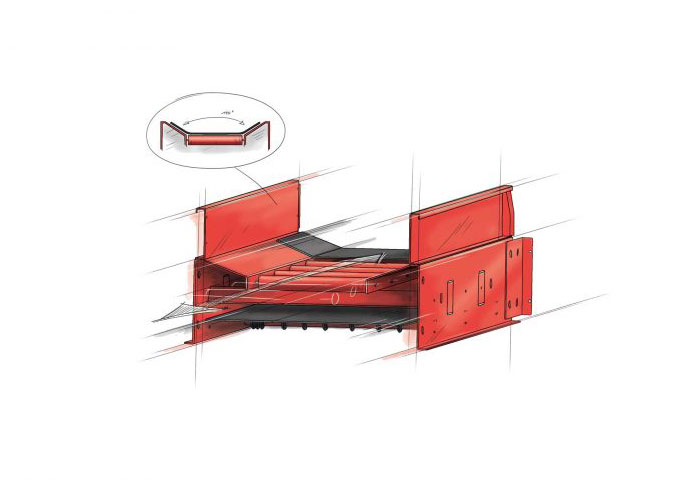

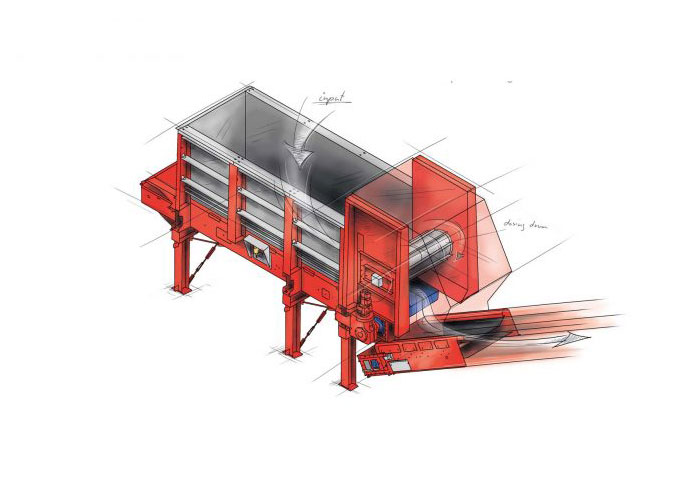

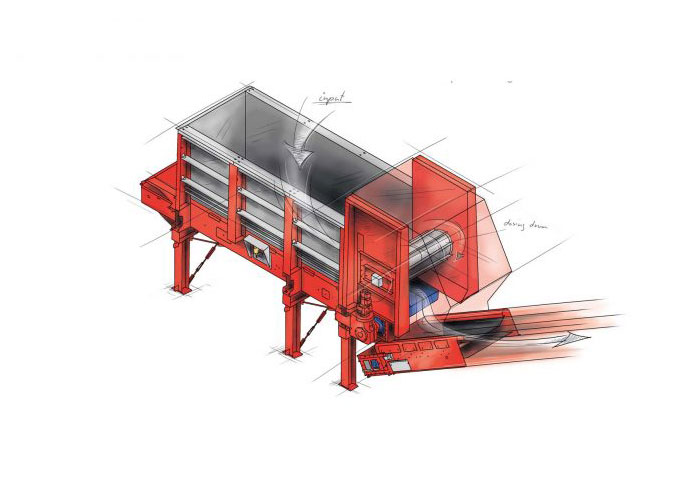

MovingFloor® - Material dosing with full flexibility

- The MovingFloor is a hopper system that allows you to dose any type of material and guarantee a smooth and continuous flow.

Advantages- Modular construction

- Flexible in application

- Delivery within 6 weeks

MovingFloor® Bunker system with flexibility

Fully automatic material feed. Flexible configuration and quick delivery thanks to the modular system.

The feed hopper, which is technically sophisticated down to the last detail, offers maximum flexibility despite the use of standard components. The system is designed in such a way that the MovingFloor can be enlarged at any time and is capable of bunkering a wide variety of materials and feeding them evenly. Substitute fuels, compost, mixed construction waste and much more can be processed without any problems. The components can be delivered within 6 weeks and shipped in standard sea containers.

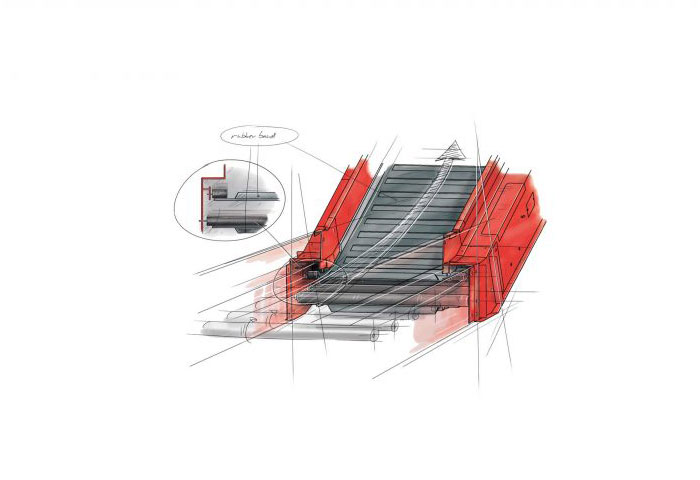

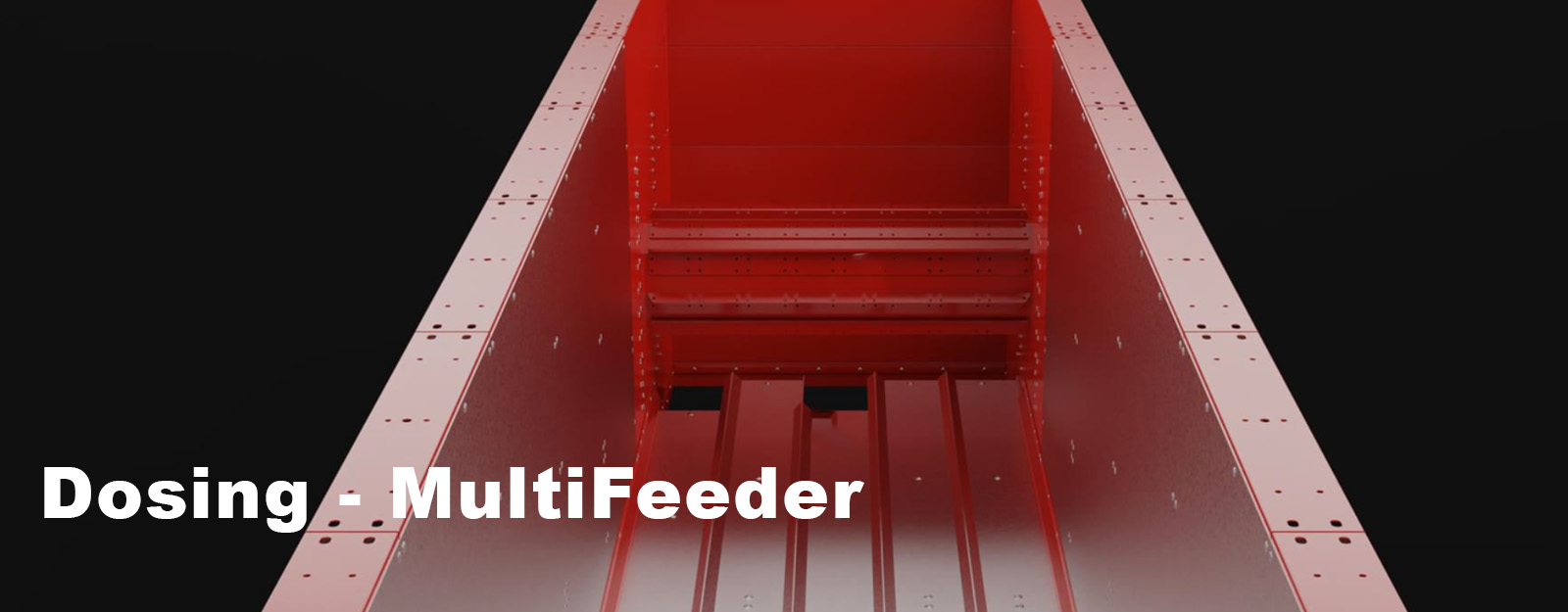

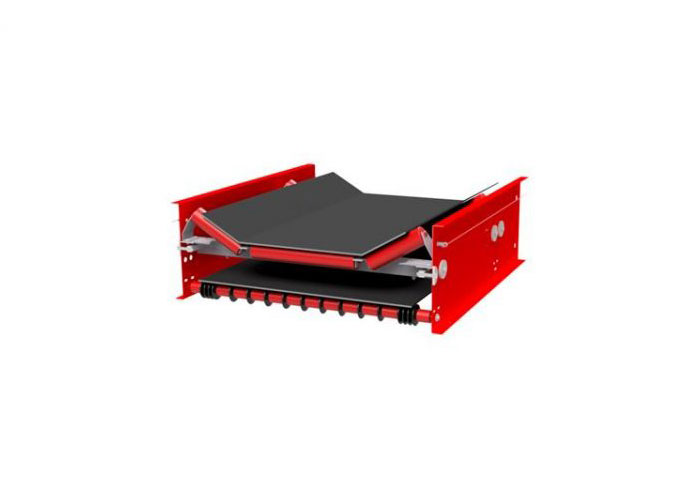

MultiFeeder® - The space saving solution for material feeding.

- The MultiFeeder is a storage hopper system specially designed for fully automatic, linear distribution of input materials.

Advantages- Space-saving and easy to integrate into existing plants

- Different floor designs: belt conveyor, apron conveyor or walking floor

- Shipping in standard sea containers thanks to modular design

Storage hopper system with linear distribution.

MultiFeeder is a storage hopper system specially designed for fully automatic, linear distribution of input materials.

It is space-saving and can be easily integrated into existing plants. It is the ideal starting point for material processing. For irregular material feeds, the MultiFeeder temporarily stores the material in the hopper and doses it evenly onto the next conveyor for maximum efficiency. Thanks to its easy-to-assemble modular design, it can be shipped in standard sea containers.

Spreading

- The Westeria material distribution systems ensure perfect material spreading for all kind of detection and separation processes.

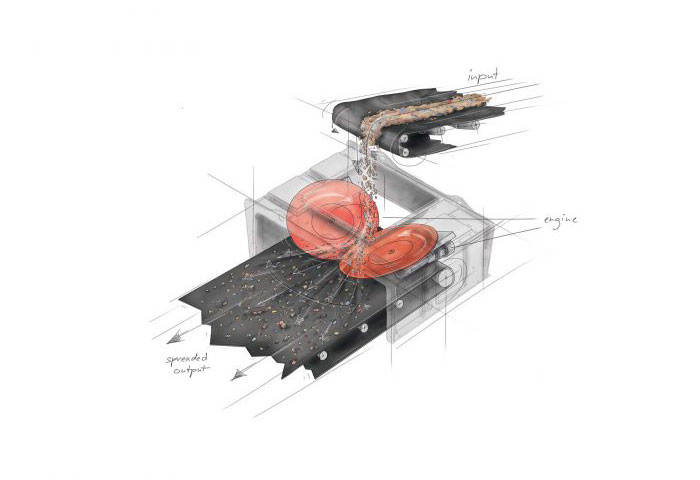

DiscSpreader® - Optimum material distribution - Simple and compact

- The patented DiscSpreader is the unique solution for optimal material distribution. The compact unit can be easily mounted on any type of conveyors and is extremely easy to maintain.

Advantages- 360° material feeding

- Up to 7 m shorter system than other distribution systems

- Precise alignment of the distribution discs

The simple way to perfect distribution

Optimal material distribution is essential for many sorting processes, whether NIR, ballistic sorting or air separation. Only if the entire belt width is really evenly loaded with material, the sorting machines are used profitably.

The DiscSpreader is the simple answer to this problem. Conventional distribution systems – such as vibratory tables, have a number of disadvantages: In addition to the considerably longer installation length, these devices also reach their limits with vibration-absorbing materials, such as lightweight films. Furthermore, even with low-adhesion materials, the longer contact with the surface leads to a significantly higher cleaning effort.

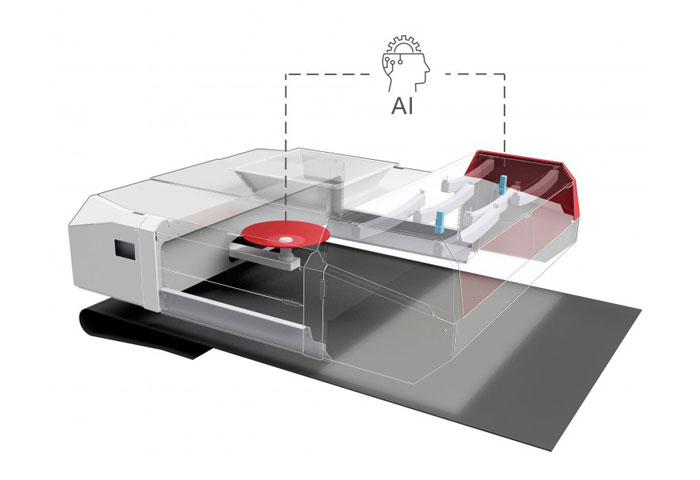

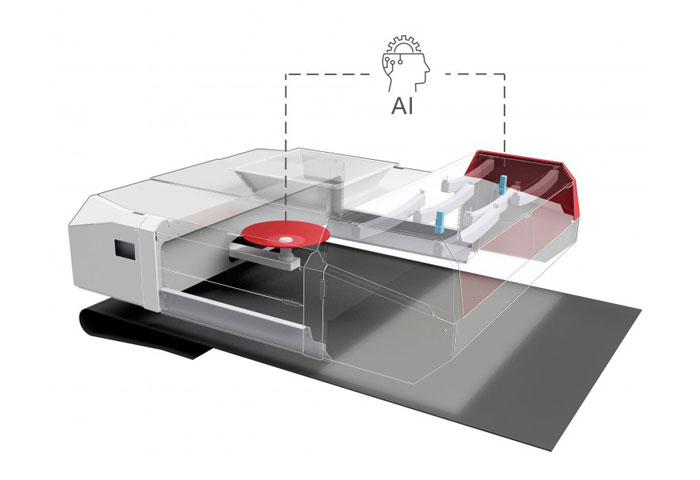

DiscSpreader® automove

- Permanently optimal material distribution thanks to artificial intelligence. Together with leading AI experts, we provide ideal material distribution for every material.

Key advantages- Permanent monitoring of the distribution quality

- AI controlled disc alignment

- Highest effectiveness for subsequent separation

DiscSpreader® automove Optimal material distribution system

Our DiscSpreader are known for their perfect material distribution of glass, wood, compost, scrap, slag, waste or any other type of bulk material.

Our space-saving disc distributor has been popular for years. Our latest further development offers you numerous additional advantages. There is no longer any need for staff to re-align the distribution disc if the distribution quality is no longer optimal. Together with leading AI developers from the Technical University of Cologne, we have developed a solution that automatically aligns the discs with the help of artificial intelligence. Cameras above the conveyor belt permanently monitor how the material is distributed.

The self-learning algorithm permanently collects new data and can thus adjust to any change in the material flow at lightning speed. The patented system is mounted directly on the accelerator belt and thus ensures maximum efficiency of subsequent sorting units.

Materials

- Westeria offers you a comprehensive product range for processing a wide variety of materials. On this page you will find a selection of materials for which we offer optimally tailored solutions.

Refuse-derived fuel (RDF)

- Promoter natural resources

Refuse-derived fuels have long played an important role in the circular economy. Recycling companies ensure that waste from municipalities or industry becomes alternative raw materials and fuels.

One of the main customers for these substitute fuels is the cement industry, which thus supports the reduction of the demand for fossil fuels.

Our machines are part of this cycle, dosing and conveying these substitute fuels into the combustion plant.

Plastic

- Convertible material

Plastic is a convertible material with countless areas of application. If the plastic waste is sorted by type, it can form valuable starting material for the manufacture of new plastic products. The use of plastic recyclates is demanded by society and increasingly implemented by politicians. In the coming years, the circular economy will move from being a theoretical model to an everyday reality. Today, waste management companies already need precisely functioning sorting technology in order to be able to extract the purest possible secondary raw materials from the waste stream. Only high-quality recycled plastics can be used to manufacture products that can be used in the long term.

Organic waste

- Processing technologies make a valuable contribution

Organic waste is one of the most important and versatile renewable energy sources in Europe. It is stored solar energy in the form of energy crops, wood or residual materials such as straw or organic waste.

Biological drying reduces the moisture content of the waste to such an extent that subsequent mechanical sorting can take place very efficiently.

The AirLift move frees your material from impurities as uncomplicatedly as never before and thus achieves a high quality of the product.

Waste

- Waste is a recyclable material

From this mixed waste, the non-recyclable materials are separated from recyclable ones, with the recyclable fractions being separated and returned to the cycle. Our machines ensure high throughput, purity and an optimal result in the separation of light & heavy materials for any type of waste.

Technology Center

We are testing your Material

- At our site you will find a complete facility where we test the separation performance of our customers’ materials with all our machines. We give you the assurance that you will get the same results with your application.

Every feed material is different and has its specific properties. We have always kept this in mind when developing our machines. In order to be able to examine the separation results of your individual material in advance, we look forward to your visit to our TechCenter. Remote trials with video evaluation are also possible without any problems.