KOMP-ACT

Videos

Loading the player ...

- Offer Profile

-

Electrifying the world, one machine at a time.

At KOMP-ACT, we manufacture the industry’s most compact, lightweight, cost-efficient electric actuators, grippers and accessories destined for the motion automation market. Our patented electric solutions designed for maximum reliability and performance can be easily integrated onto new machinery or retrofitted onto virtually any existing machinery where traditional pneumatic actuators are used. Our products are designed and manufactured in Switzerland.

Product Portfolio

Electric Motion Solutions for a Greener Industry

- Compact-Size

- Cost-Effective

- Easy To Use

-33% Cost reduction for machine manufacturing

Inventory management, R&D cycle cost, machine setup and assembly+ 50 % Increase Machine Operational Speed

Increase output rate and motion reliability- 95 % Reduction in Machine Energy Consumption

Reduce energy consumption & C02 emission with a clean technology3 x Longer Life vs Pneumatics

Zero maintenance. Reach upto 30 million cyclesOUR SOLUTION

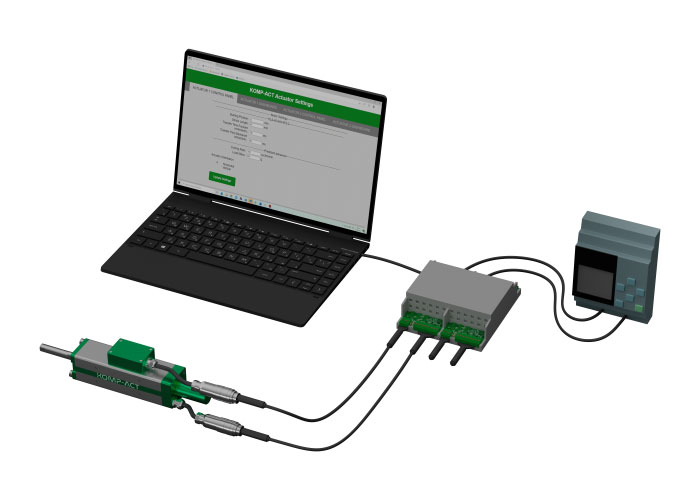

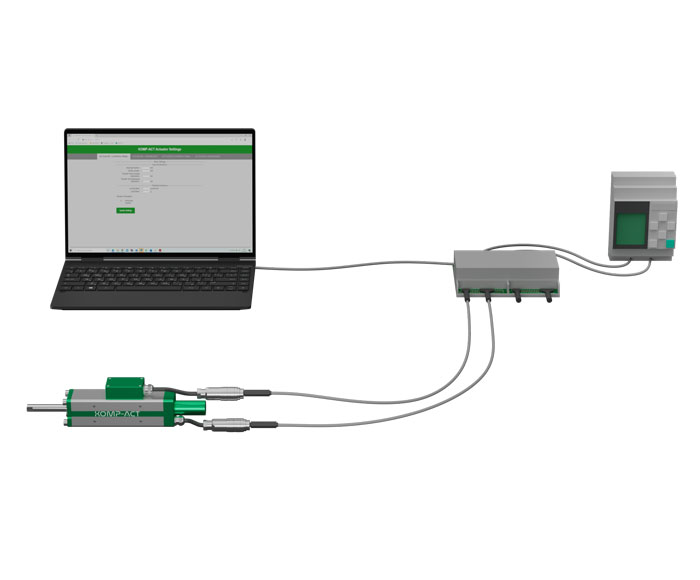

Plug & Play

- Compatible with any PLCs with digital I/Os (*)

Modify actuators settings from any Windows com!

through a dedicated IP address:- Start Stroke

- Stroke Length

- Transfer Time Forward

- Transfer Time backward

- Holding Force (time)

- P I D regulator parameters

- Applied Mass

- Cycling rate

Compatible with Ethercat, Profinet, TCP/IP & Power LinkKEY BENEFITS

- Direct Drive

KOMP-ACT electric actuators use “Direct Drive” technology generating fast and repeatable linear motion, without the need for mechanical transmission elements like ball screws, toothed belts or gearboxes. - Energy Saving

KOMP-ACT linear actuators are up to 95% more energy efficient compared to most pneumatic actuators and at least 50% more energy efficient than any other comparable electric actuator on the market. - Longer uptime

KOMP-ACT linear actuators boast the highest Overall Equipment Effectiveness “OEE” figures to ensure longer, more consistent machine uptime when it counts. - Fast setup

KOMP-ACT’s innovative modular actuator design can be easily integrated onto new or existing machinery and allows for fast replacement with no machine reset or reprogramming required. - Sustainability

When running at full capacity, each KOMP-ACT electric actuator saves more than 1 Ton less of Co2 equivalent per year than a comparable pneumatic actuator. - Swiss made

Like all things Swiss, KOMP-ACT products are engineered for longevity, precision and dependability.

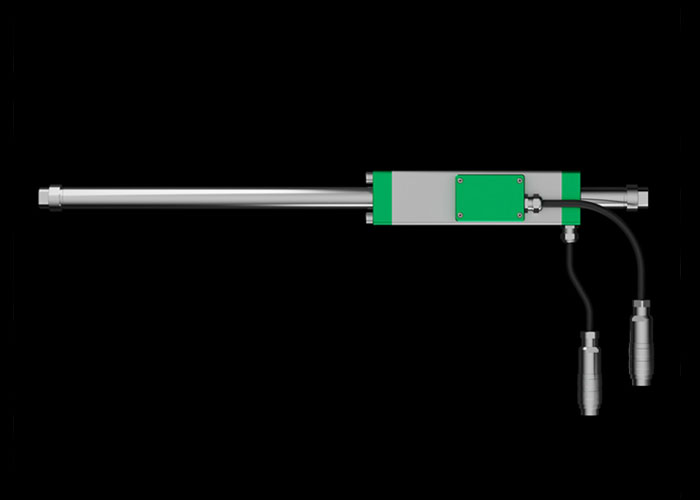

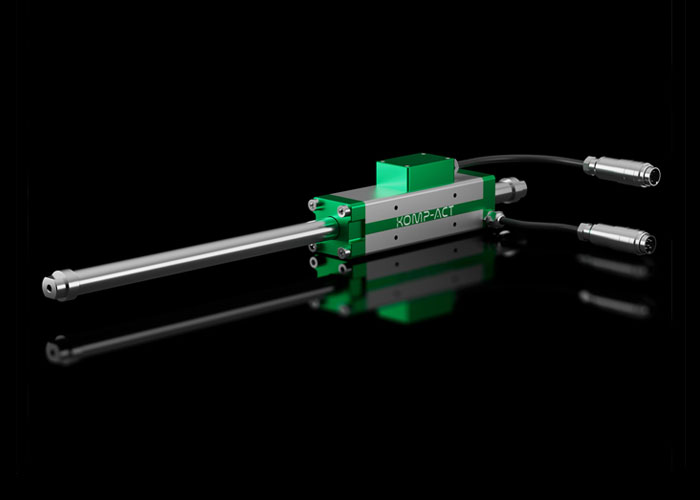

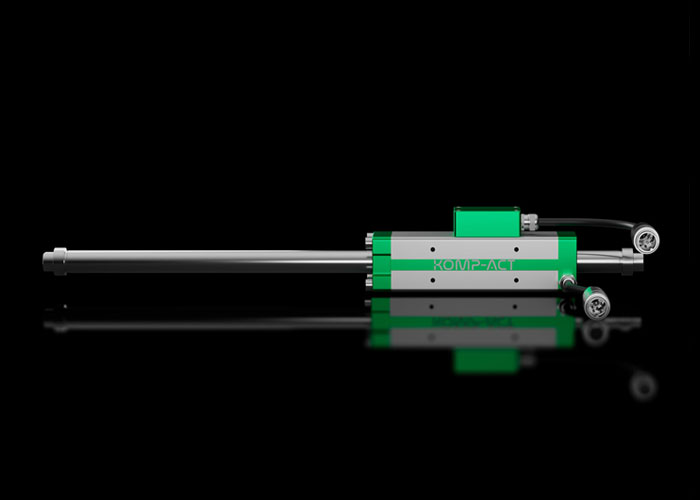

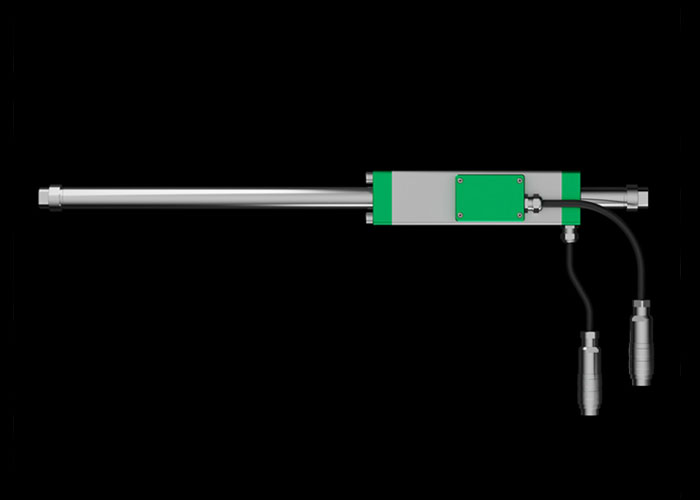

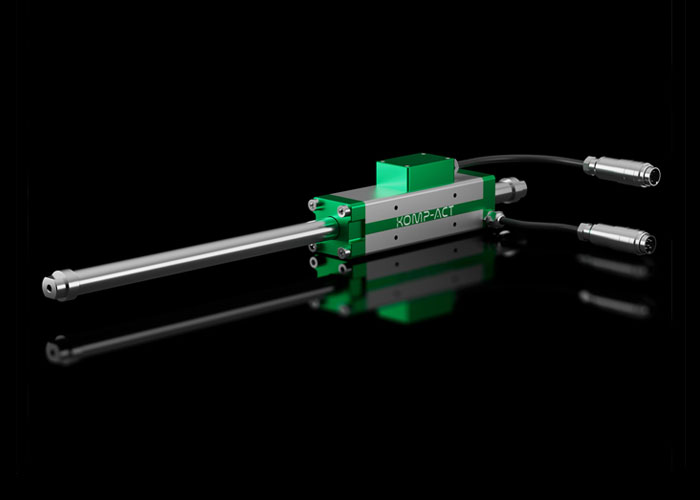

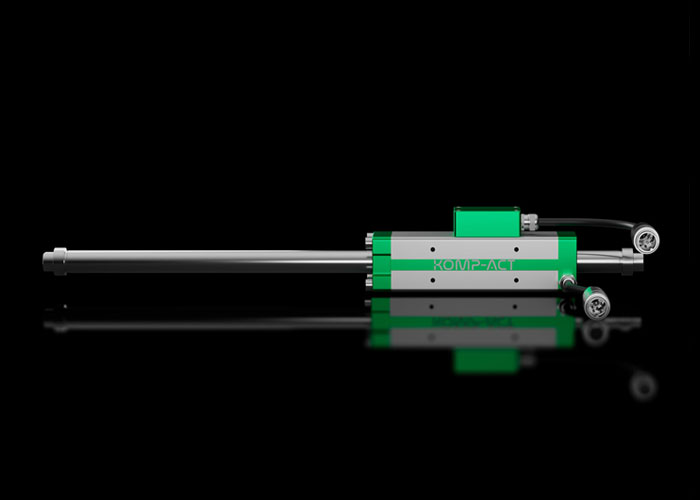

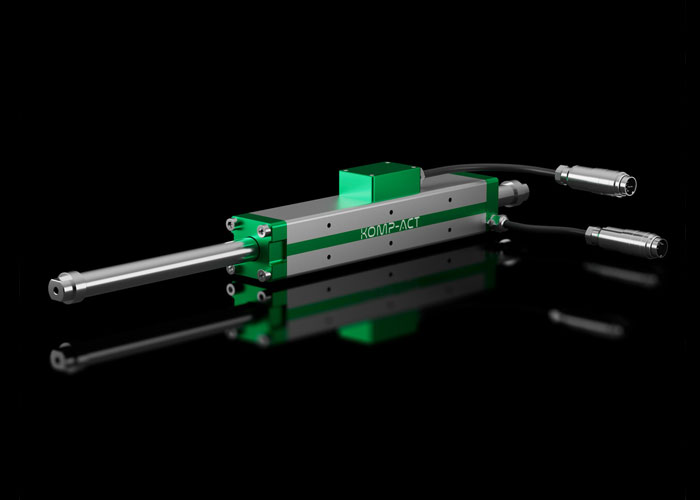

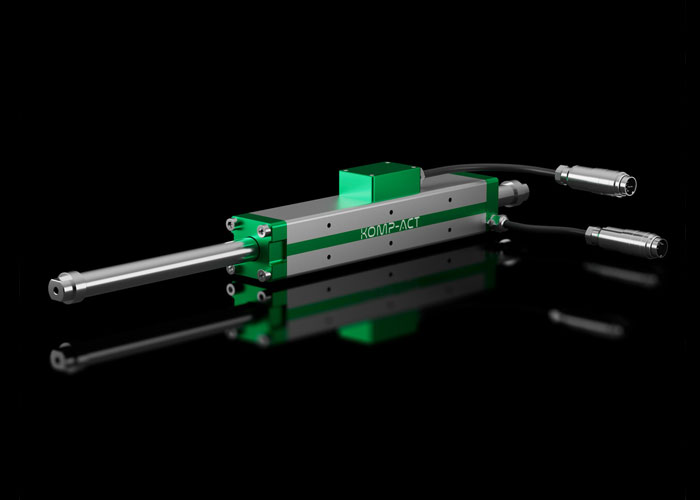

LINEAR MOTORS

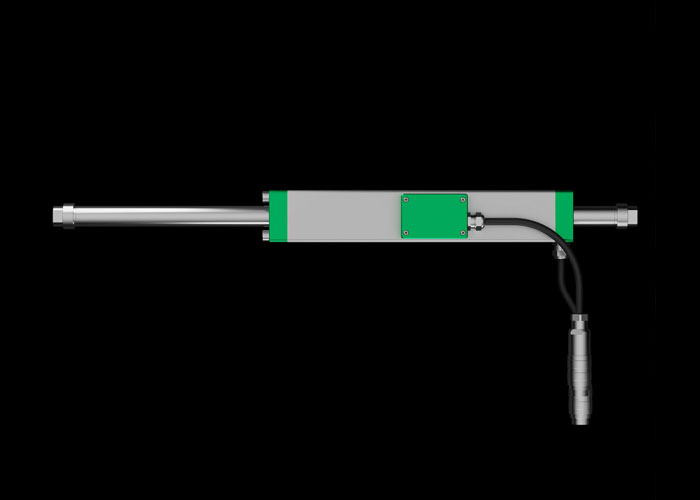

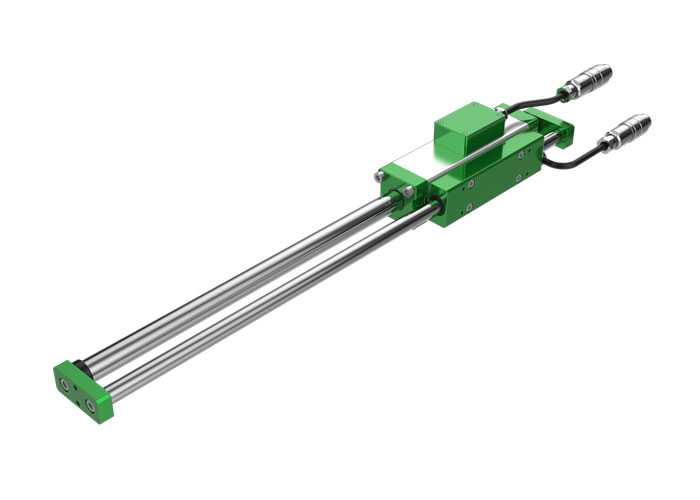

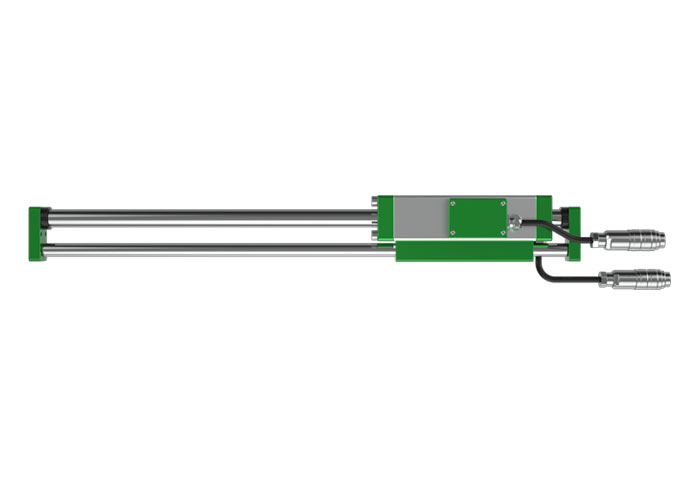

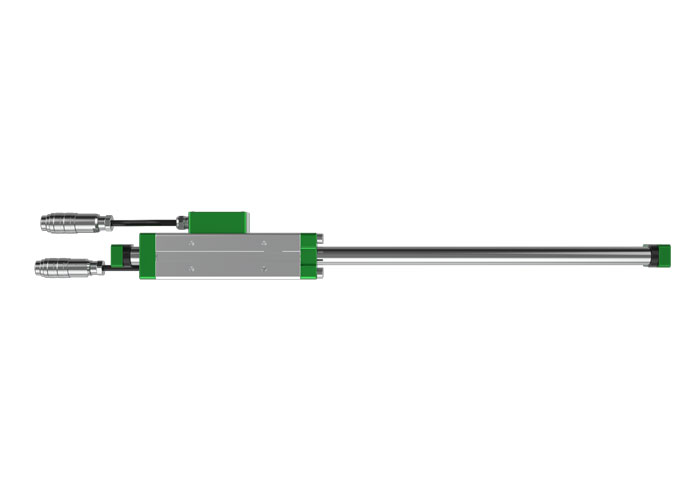

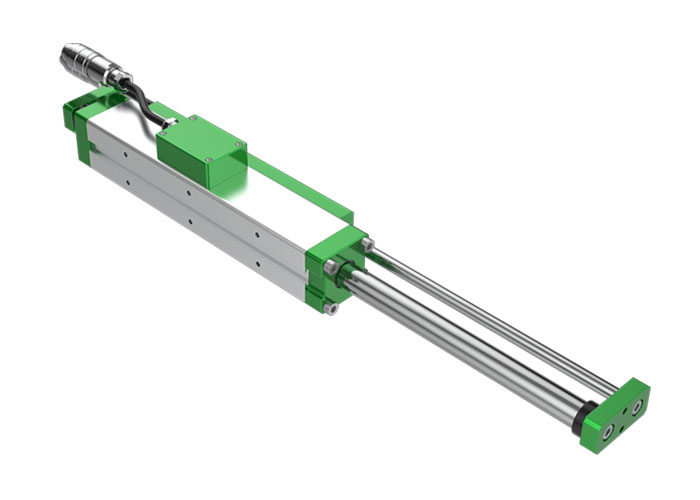

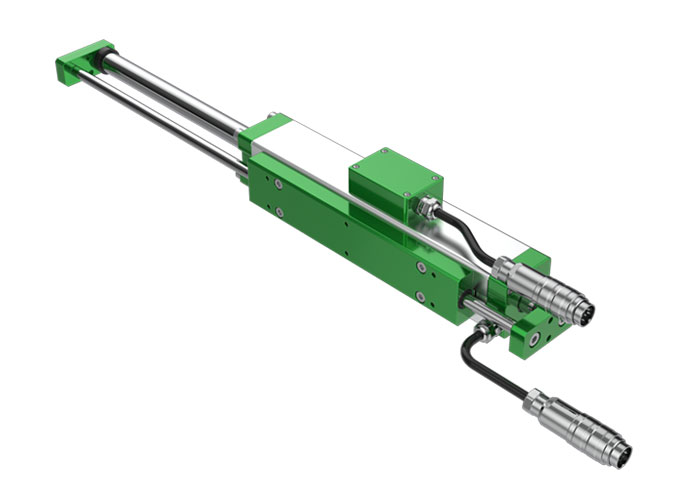

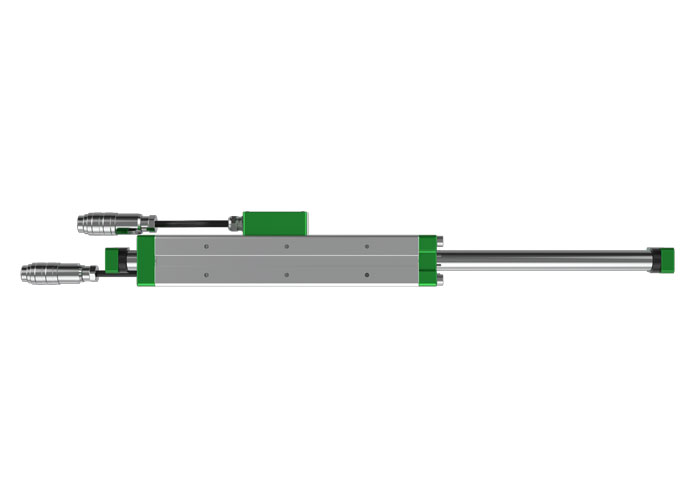

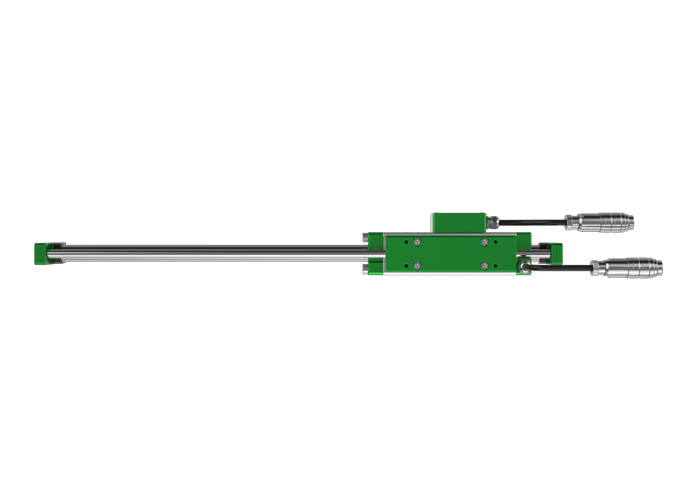

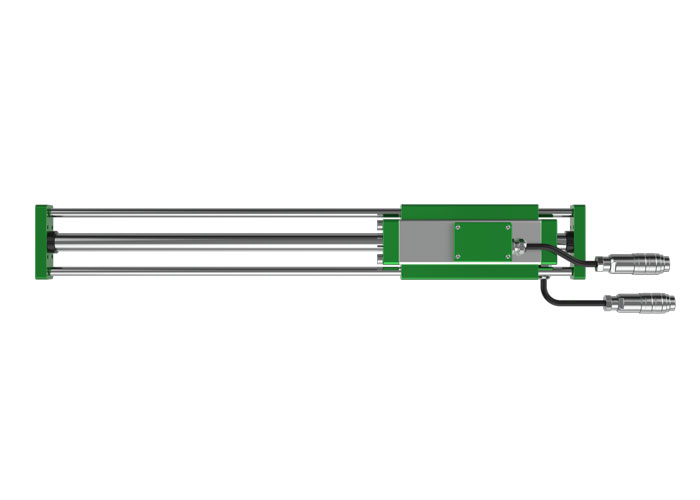

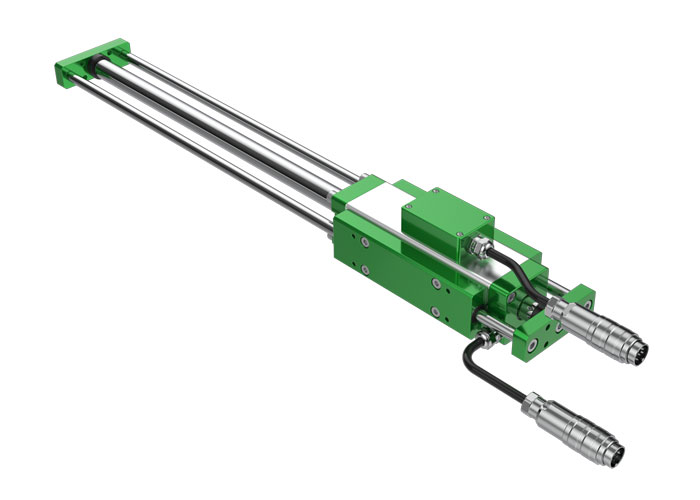

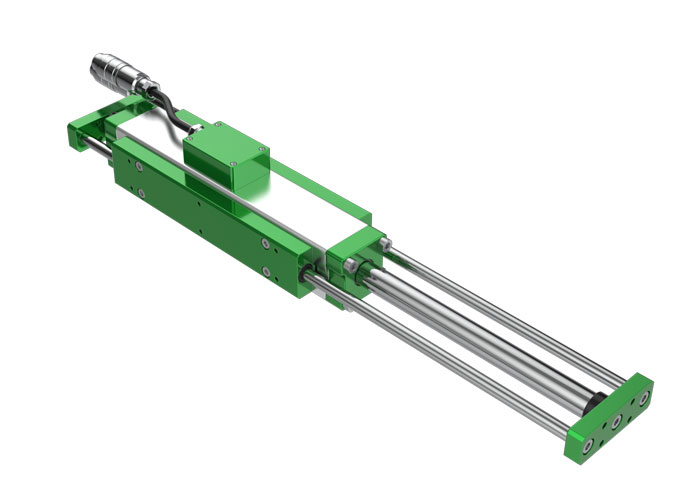

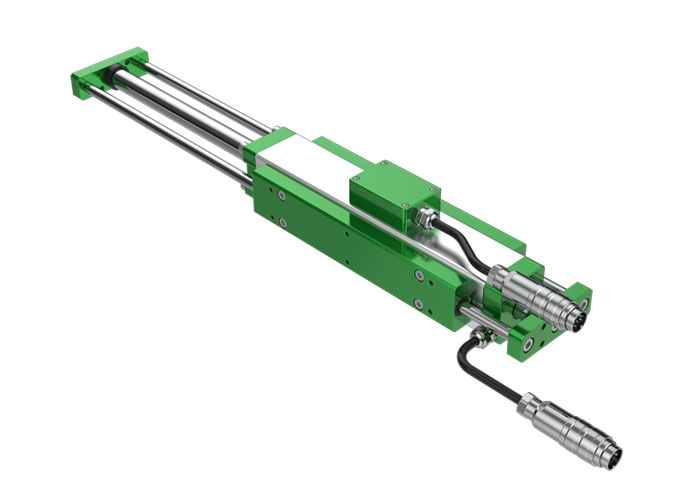

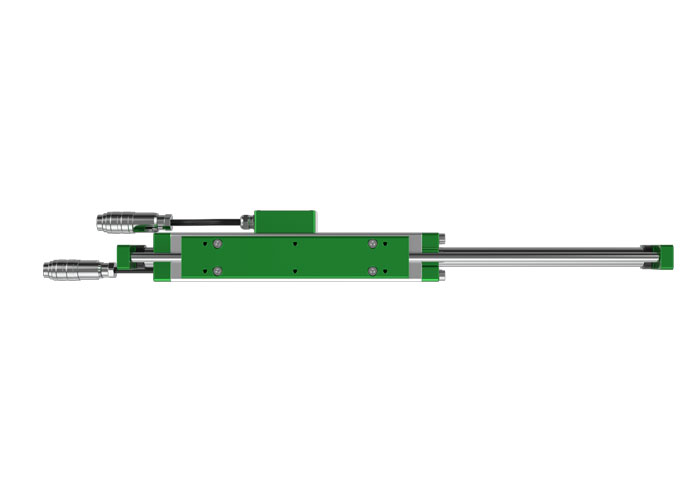

KLM-40-0F2

TECHNICAL DATA

- Continuous force 15 N

- Peak Force 45N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 3.3 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Max. Average Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C

- Slider mass 200 + 1 gram / stroke

- Stator body mass 825 g

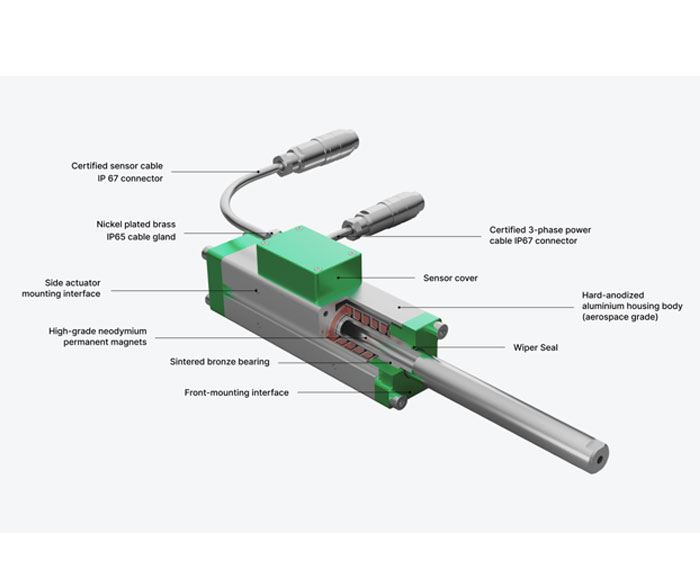

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

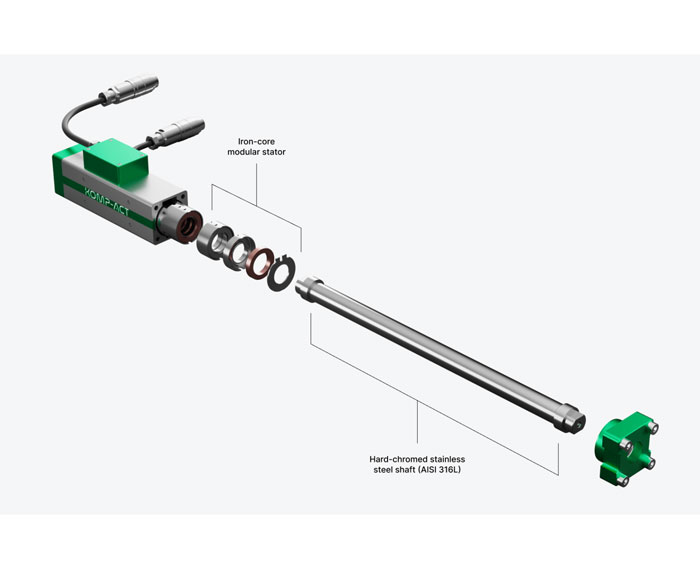

- Shaft Material Hard chrome plated stainless steel (AISI 316L)

Notes:

KLA actuators shall be used with KOMP-ACT’s electronic controller KDRV-1-MK

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts. It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 400 mm. Available in two model with different axial length which offers different forces up to 90 N.

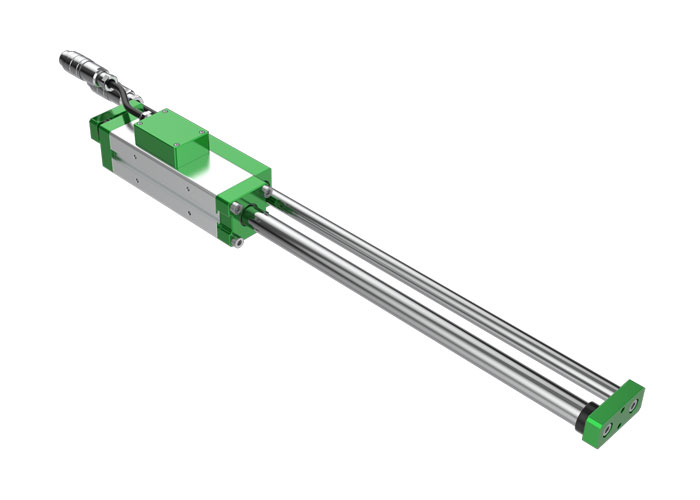

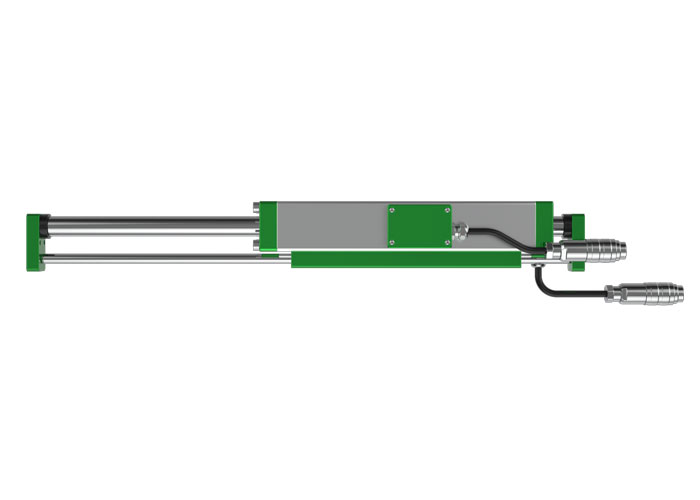

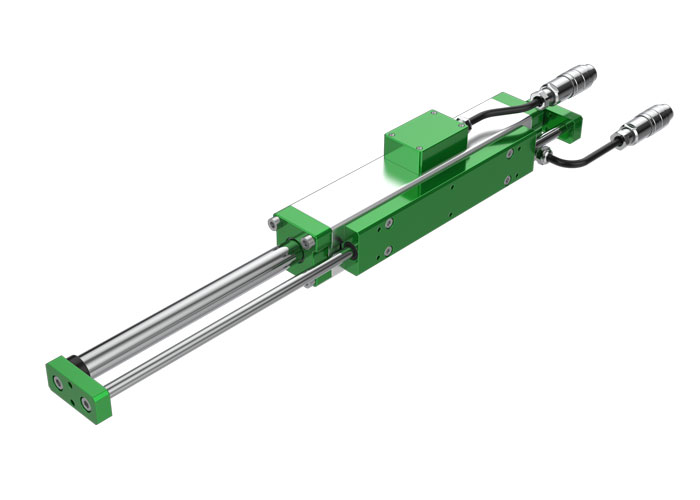

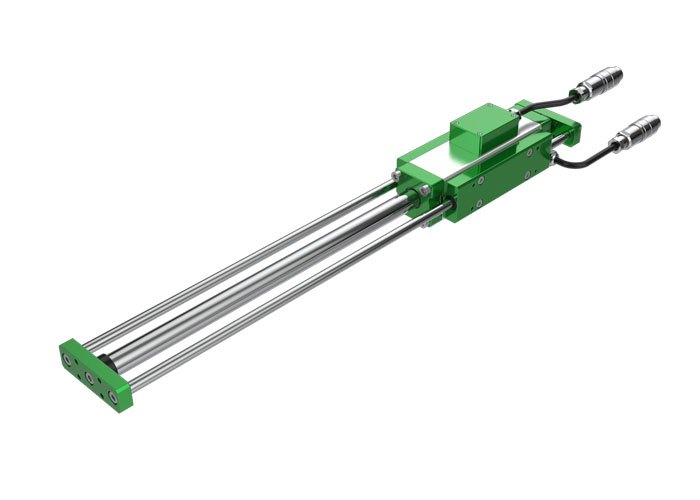

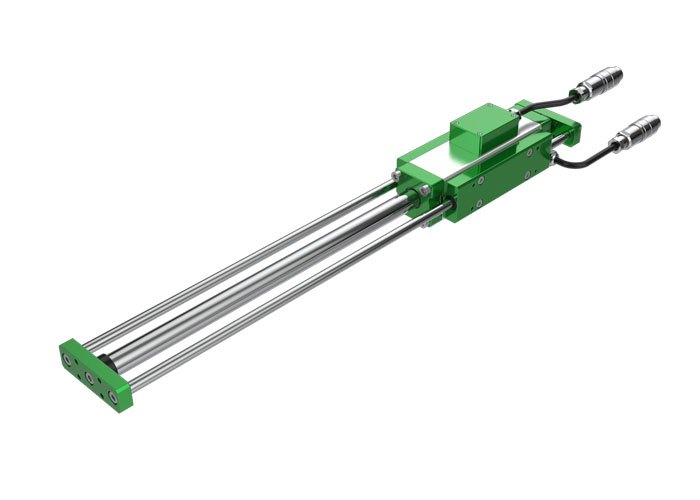

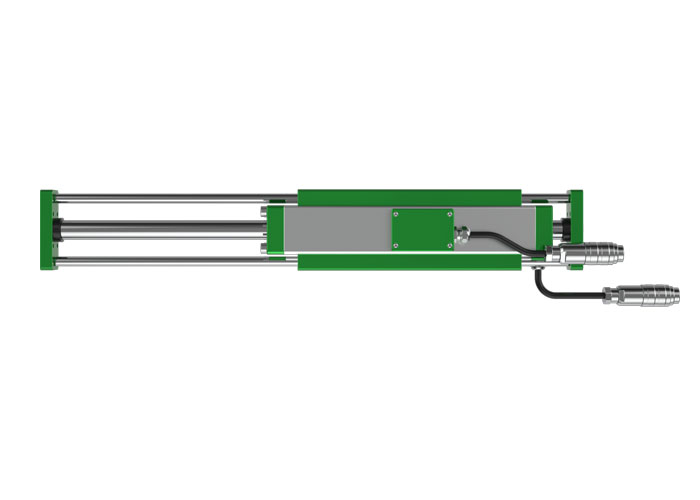

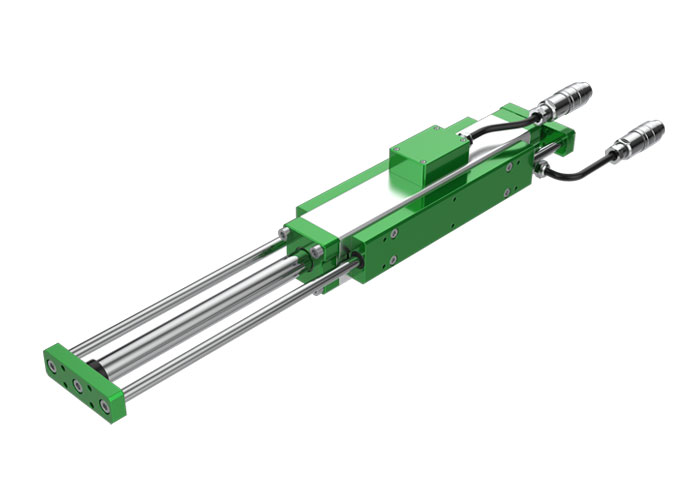

KLM-40-0F4

TECHNICAL DATA

- Continuous force 30N

- Peak Force 140N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 6.6 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Top Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C

- Slider mass 240 + 1 gram / stroke

- Stator body mass 1125 g

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

- Shaft Material Hard chrome plated steel

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts.

It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 240 mm. Available in two model with different axial length which offers different forces up to 90 N.

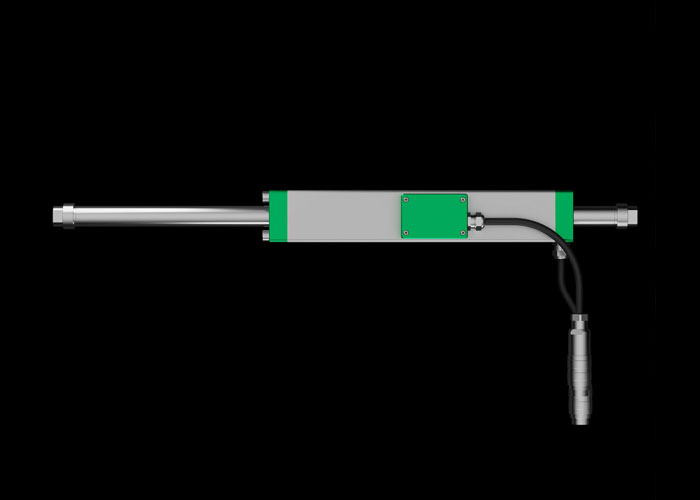

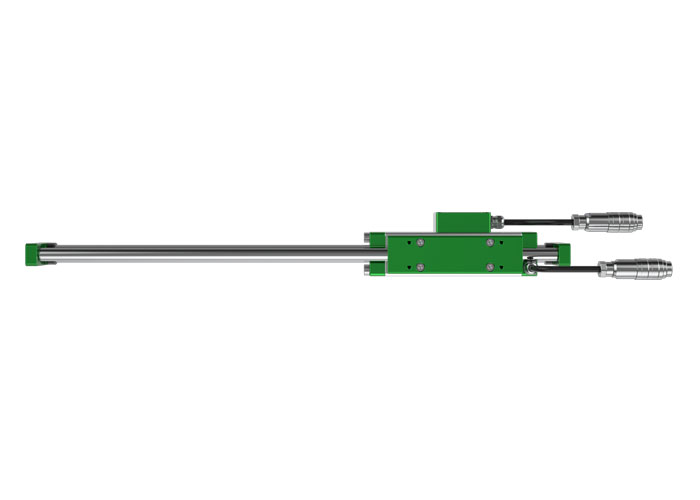

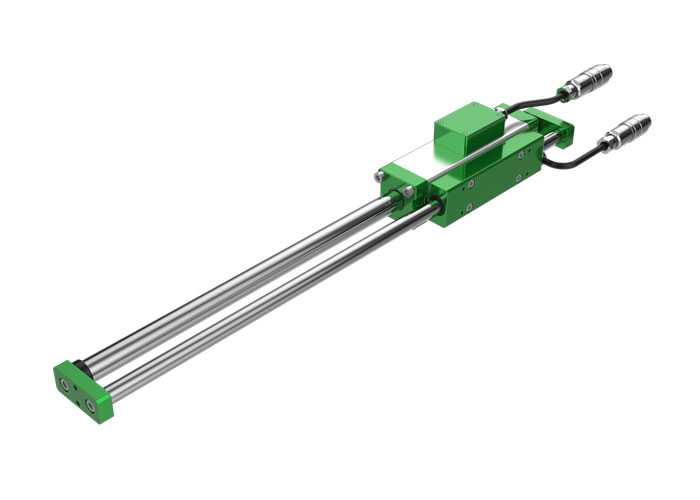

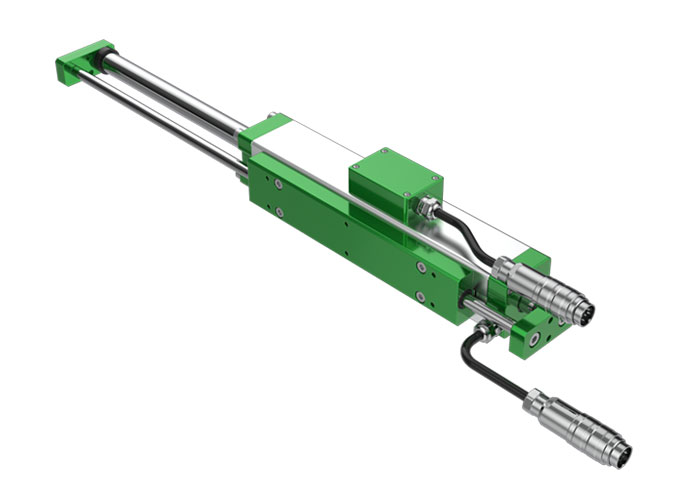

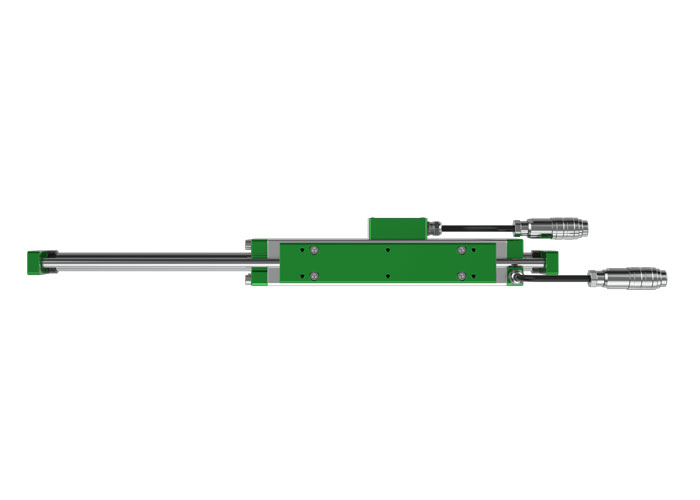

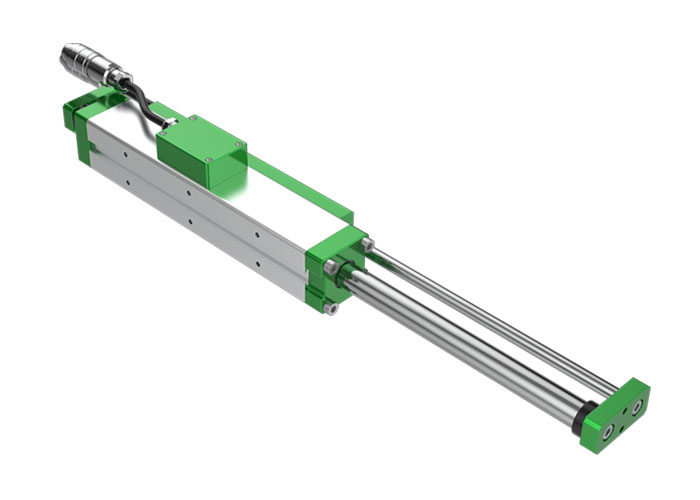

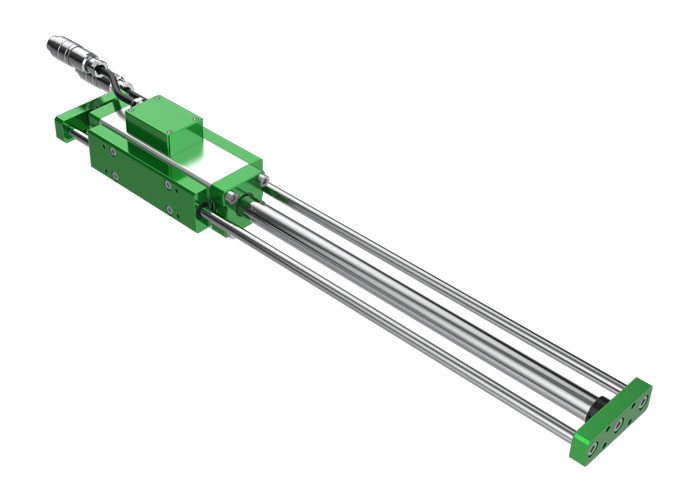

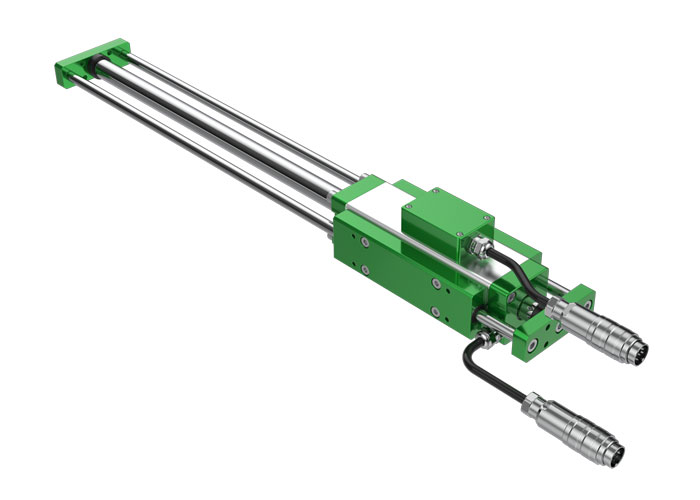

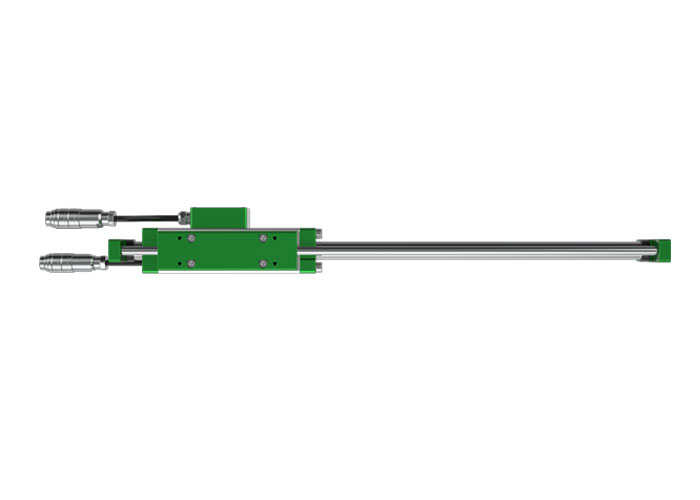

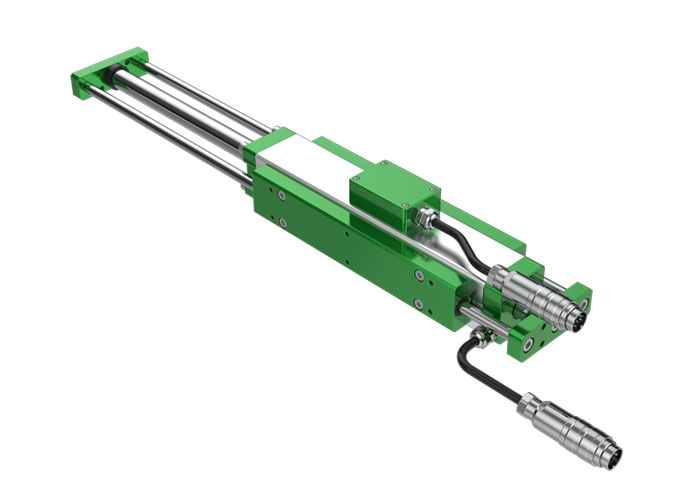

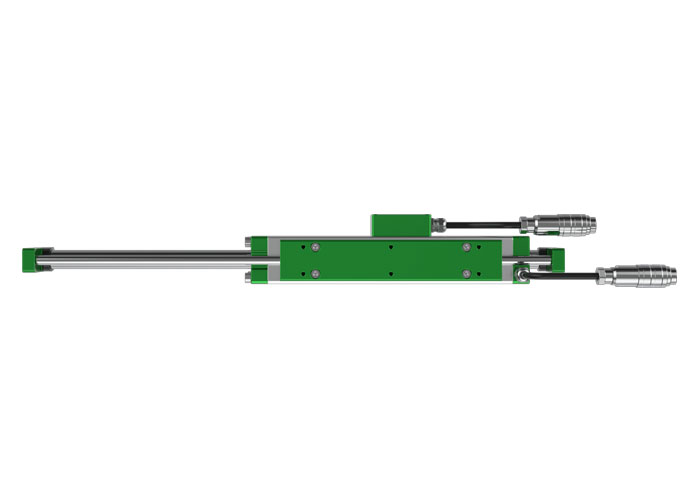

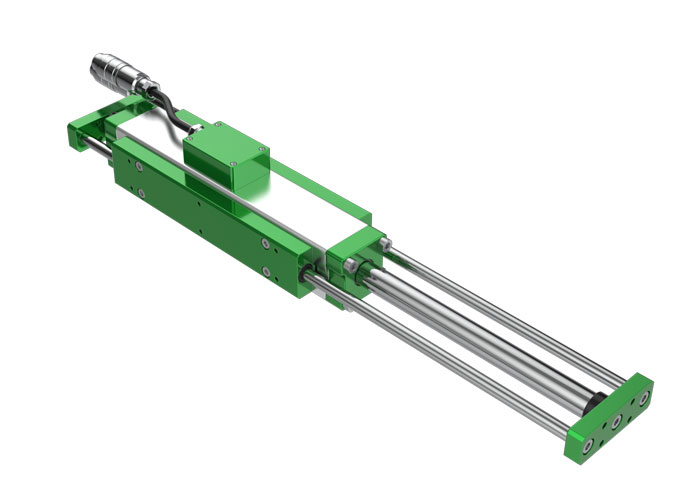

KLM-G-40-0F2

- TECHNICAL DATA

- Continuous force 15 N

- Peak Force 45N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 3.3 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Max. Average Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C

- Slider mass 200 + 1 gram / stroke

- Stator body mass 825 g

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

- Shaft Material Hard chrome plated stainless steel (AISI 316L)

Notes:

KLA actuators shall be used with KOMP-ACT’s electronic controller KDRV-1-MK

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts.

It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 400 mm. Available in two model with different axial length which offers different forces up to 90 N.

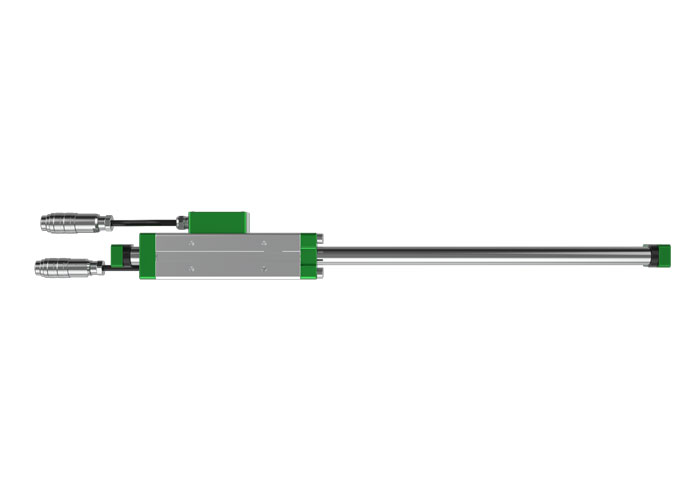

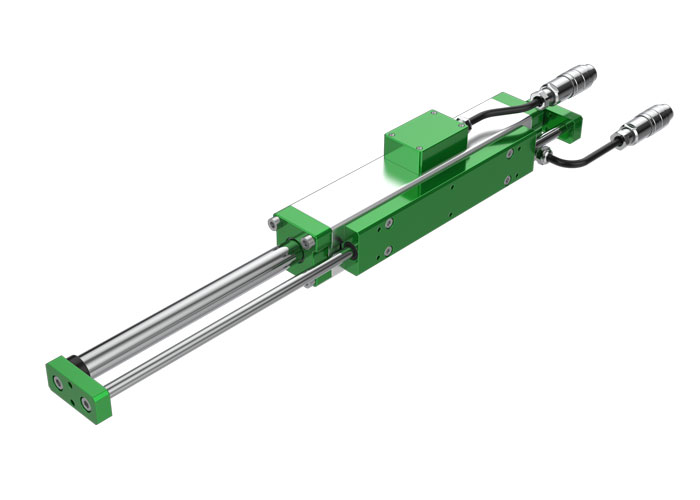

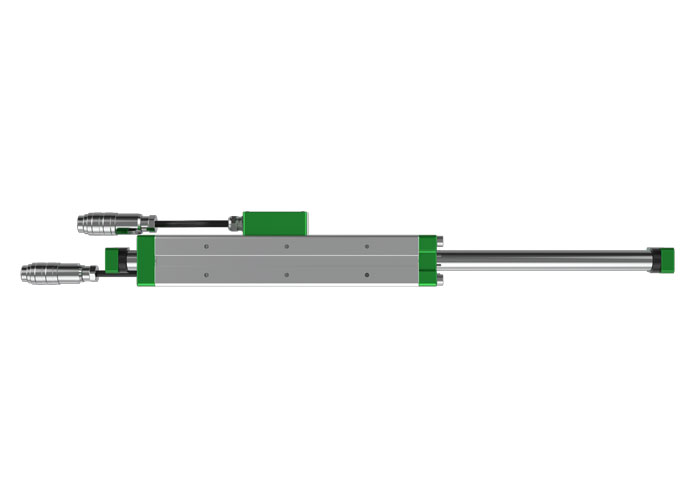

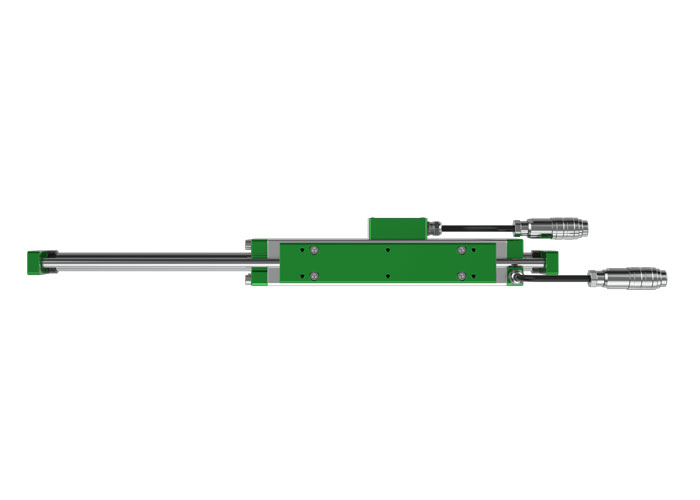

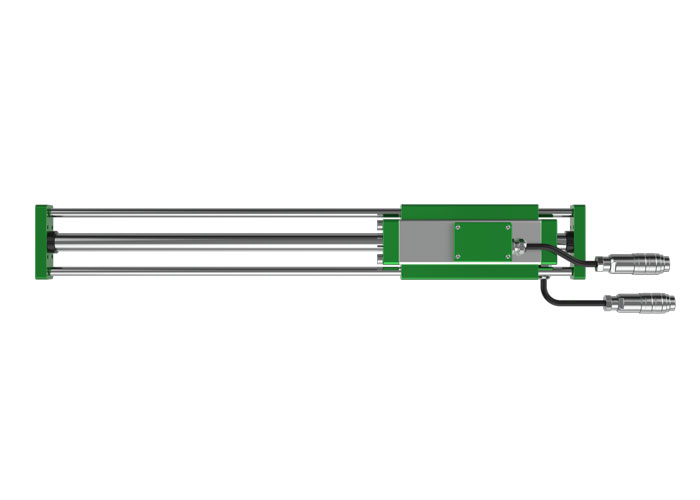

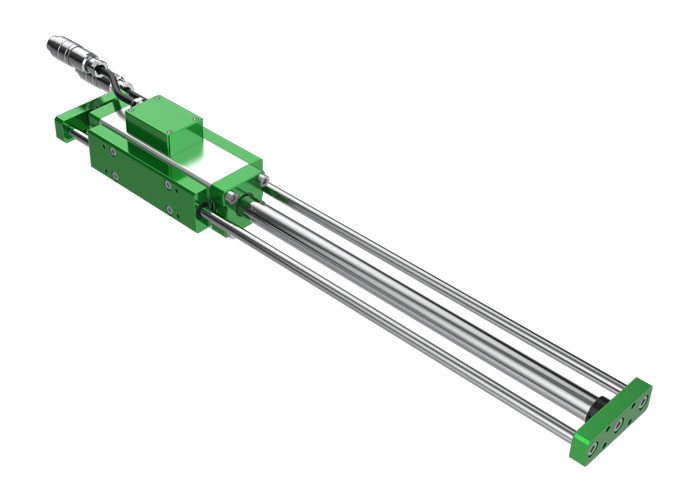

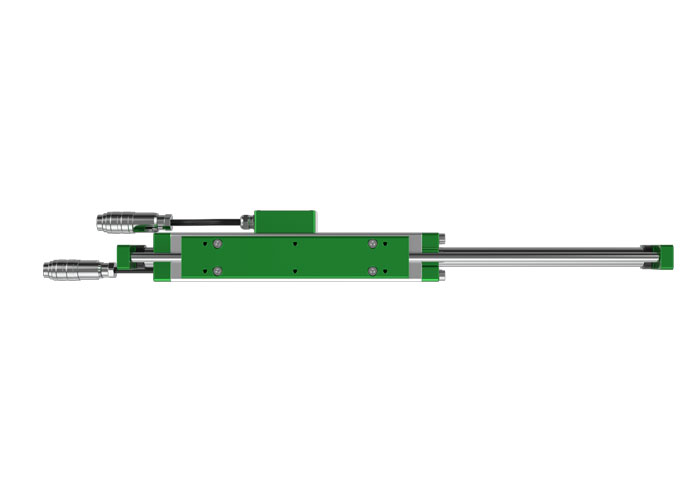

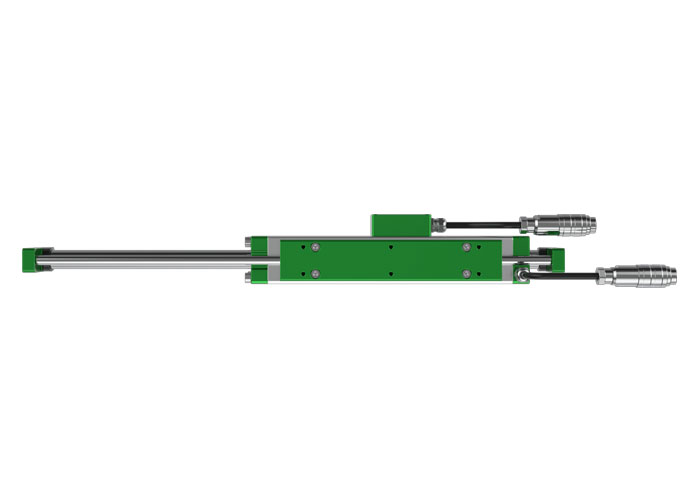

KLM-G-40-OF4

- TECHNICAL DATA

- Continuous force 15 N

- Peak Force 45N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 3.3 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Max. Average Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C

- Slider mass 200 + 1 gram / stroke

- Stator body mass 825 g

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

- Shaft Material Hard chrome plated stainless steel (AISI 316L)

Notes:

KLA actuators shall be used with KOMP-ACT’s electronic controller KDRV-1-MK

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts.

It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 400 mm. Available in two model with different axial length which offers different forces up to 90 N.

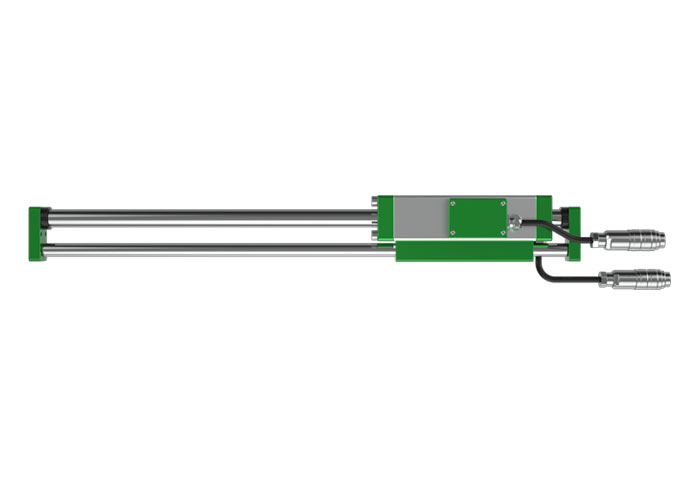

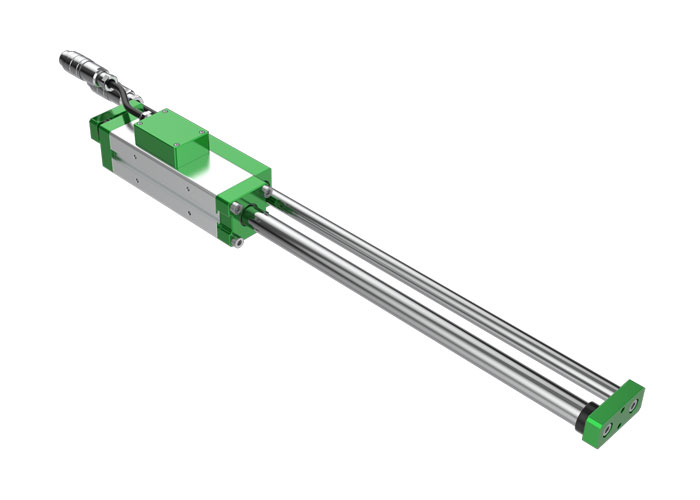

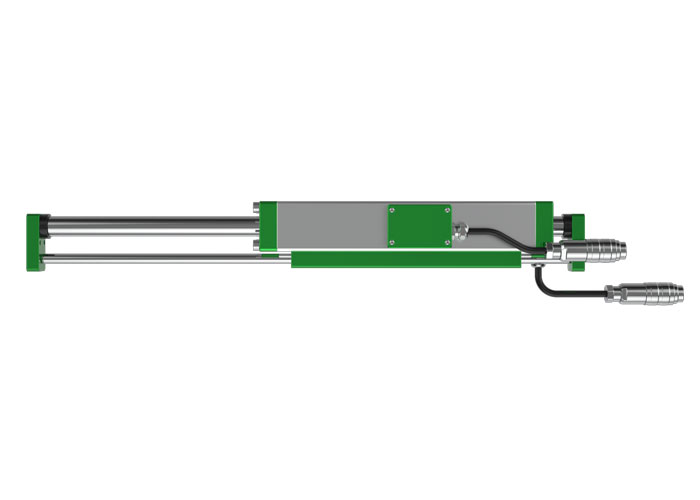

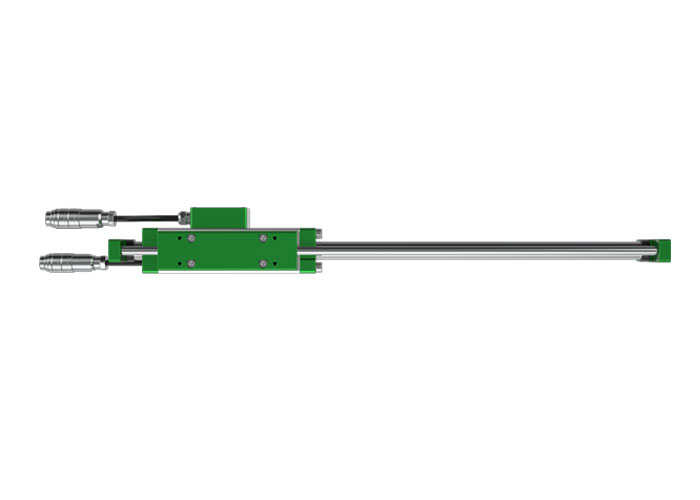

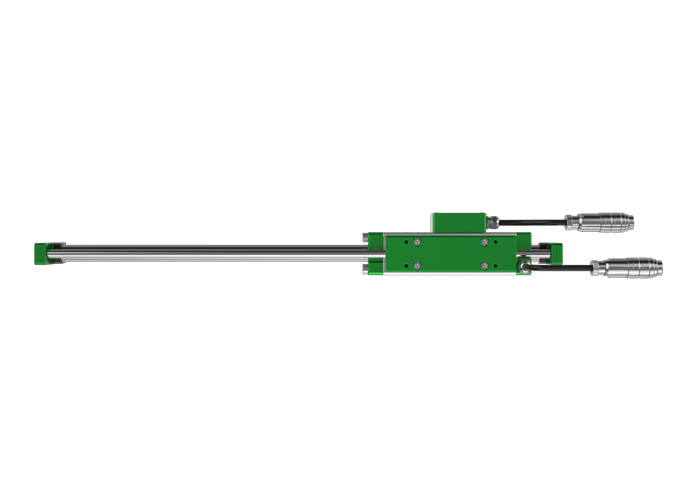

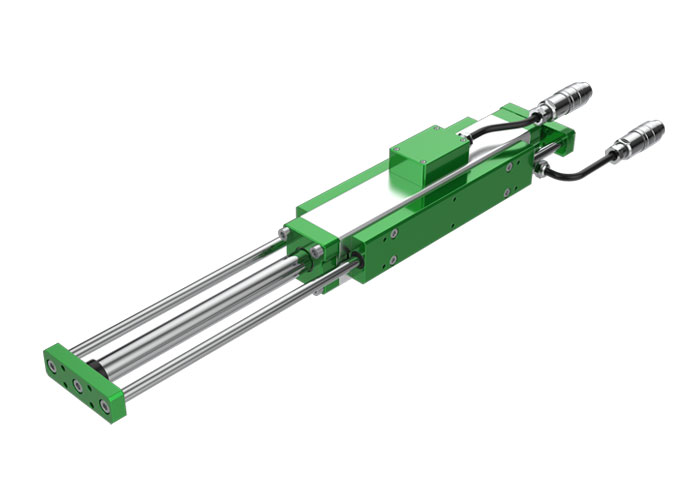

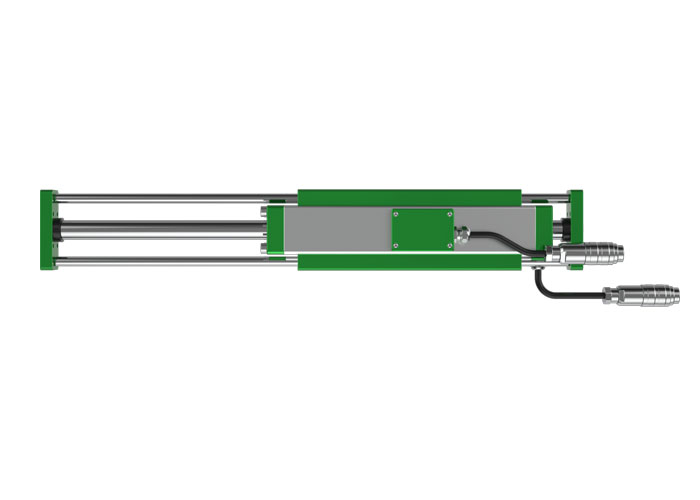

KLM-G2-40-OF2

- TECHNICAL DATA

- Continuous force 15 N

- Peak Force 45N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 3.3 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Max. Average Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C

- Slider mass 200 + 1 gram / stroke

- Stator body mass 825 g

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

- Shaft Material Hard chrome plated stainless steel (AISI 316L)

Notes:

KLA actuators shall be used with KOMP-ACT’s electronic controller KDRV-1-MK

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts.

It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 400 mm. Available in two model with different axial length which offers different forces up to 90 N.

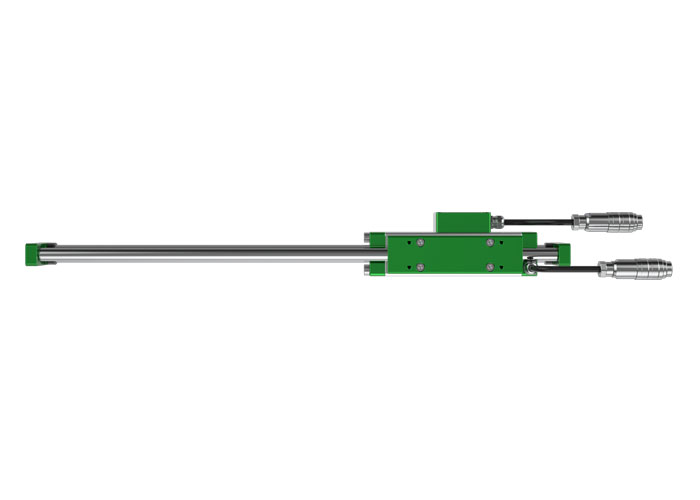

KLM-G2-40-OF4

- TECHNICAL DATA

- Continuous force 15 N

- Peak Force 45N

- Continuous current 2A

- Peak current 6 A

- Phase resistance 3.3 Ohm

- Stroke length 40, 80, 120, 160, 200, 240 mm

- Repeatability ± 0.150 mm

- Accuracy ± 0.5 mm

- Acceleration 22.5 m/s^2

- Max. Average Speed 2 m/s

- Power supply 24V or 48V

- Operating temperature -20…+45 °C Slider mass 200 + 1 gram / stroke

- Stator body mass 825 g

- Rod bearings Sintered bronze

- Housing Material Hard-anodized aluminium (aerospace grade)

- Shaft Material Hard chrome plated stainless steel (AISI 316L)

Notes:

KLA actuators shall be used with KOMP-ACT’s electronic controller KDRV-1-MK

KOMP-ACT linear motors is the new born of the actuators family. It is the most powerful, efficient and compact design for mainstream application requiring average precision, medium to high speed and good to high cycling rate. It works at 24 or 48 Volts, it is the most efficient actuators of its category, dissipating only few tens of Watts.

It offers a compact and built-in design, (do not require heat sink or fan), to work at stroke up to 400 mm. Available in two model with different axial length which offers different forces up to 90 N.

CONTROLLER

KDRV-1-MK

-

CHARACTERISTICS

- Number of axes 1-axis

- Motor type DC, linear

- Signal type USB

- Technology electronic

- Other characteristics programmable

- Product Applications OEM

KOMP-ACT ‘s electric linear actuators are fully programmable with an easy-to-use and simple end-user interface accessible via the electronic controller.

The controller can program and actuate two actuators independently to perform two different and independent tasks (in terms of stroke, transfer time forward and backward). The control algorithm automatically calculates the optimum motion profile to reach the maximum efficiency.

DIRECT DRIVE GRIPPER

KPG-2

- CHARACTERISTICS

- Operation electric Type parallel

- Number of jaws 2-jaw

- Applications handling, for small loads, for bottles, for packaged goods

- Options compact, lightweight, magnetic, maintenance-free, modular, linear, high-speed, high-efficiency

- Stroke 6 mm (0.236 in)

- Grip Strength 12 N

KOMP-ACT’s gripper has an iron-core body but, compared to other iron-core motors available on the market, it can reach a higher cycling rate and faster acting time, which makes our product suitable for high-speed machine applications and medium-accuracy industrial use cases.

To ensure complex automation processes, KOMP-ACT’s electric direct-drive grippers are also available with a sensor position and a magnetic lock, which grips parts inboard or outboard without additional energy sources.

Technology

Technology

-

Actuators are the unsung heroes of the manufacturing industry to provide essential linear motion in fabrication processes. Thanks to their low cost and simple technology, pneumatic actuators have remained the industry standard since 1920’s. But, like other archaic technologies, pneumatic actuators lack flexibility, must be adjusted often, have a short lifetime, and they consume a great deal of energy.

To put this in perspective, every single pneumatic actuator on the planet is responsible for producing more CO2 emissions than a passenger car (between 1.3 and 15 Tons per year)! In the world, there are over 40 million actuators (estimated) running 24 hours a day.

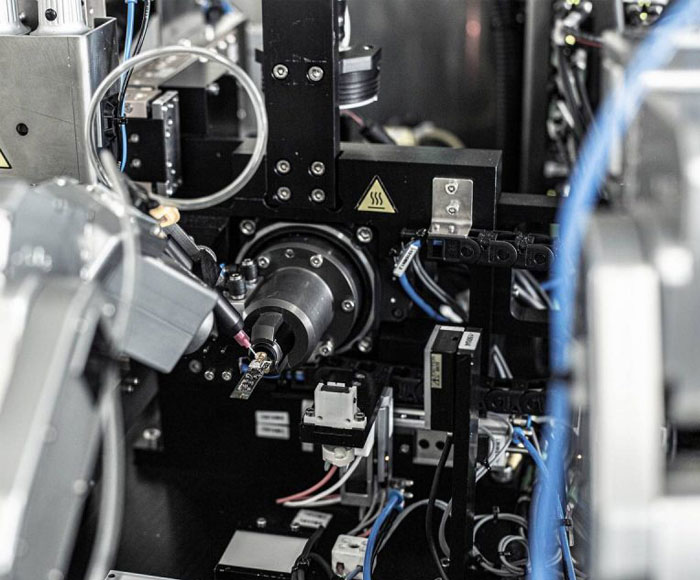

In the domain of assembling, packaging and conditioning machines, linear fast movements are required, mainly realized by pneumatic devices with low efficiency and poor flexibility.

Today tubular linear motor technologies are the best candidates for pneumatic replacements; however, they are commercialized only by very few suppliers worldwide and are offered at very high price with respect to pneumatics, limiting the widespread transition to a fully electric machinery industry.

Our Solution

-

KOMP-ACT has developed a patented solution proving better performances in terms of speed-cycling rate & efficiency than pneumatic devices and other electric solutions.

The solution comprises an enhanced electromagnetic design technology (more compact), proprietary electronics and software control which allows machines programmability & data monitoring system to prevent inadvertent downtime; KOMP-ACT products are produced with novel manufacturing and assembly technologies developed in collaboration with the Polytechnic of Lausanne (The EPFL).

Unlike any other

-

KOMP-ACT uses electromagnetic technology which does not require mechanical transmission elements like ball screws, toothed belts, or gearboxes to move the shaft, unlike other traditional electromechanical actuators.

Our main innovation consists in the use of tubular linear motion technology with an iron core 3-phase stator which provides higher continuous force density and better heat dissipation with respect to ironless technology, thus enabling higher dynamic performance.

In addition, the use of iron core technology reduces the amount of copper needed to produce force, resulting in lower ohmic resistance and high energy efficiency due to low power losses (copper losses).

As an integral part of our “Pneumatic Zero” initiative, KOMP-ACT aims to replace expensive electric and poor pneumatic performance with clean, lean and green technology.

MORE COMPACT

Thanks to their independence from external compressed air tanks or integrated motors, our actuator’s small footprints can fit the most space-restrained applications.

MORE PERFORMANT

Our actuators reach peak force between 1 and 2,5 milliseconds and have been implemented on machine applications running at 170 cycles/min at full stroke.

MORE RELIABLE

Our intelligent embedded sensors guarantee that motion profiles stay constant throughout their entire lifespan, resulting in virtually no maintenance required.

MORE COST EFFICIENT

Our solution can slash up to 95% in direct and indirect energy costs.

Plug & Play

- Thanks to their complete built-in design, KOMP-ACT actuators do not require any additional accessories like other similar electric solutions, which enable customers to achieve significant space and assembly time savings.

KOMP-ACT electric actuators have two cables: power and command which are connected to the electronic controllers.

Two electric actuators can be connected and manage to one single controller. The actuators settings can be done through the web server interface, accessible by connecting a Windows laptop to the controller with a USB cable or directly with field bus (require Controller with Field Bus).