- Offer Profile

Lead with safety

ELOKON develops and implements Innovative Fleet Management and Assistance Systems for the intralogistics sector in line with the technological advancements of Industry 4.0. Over 4,250 customers around the world benefit from our solutions which improve workplace safety and increase MHE productivity. ELOKON is also one of the leading companies in the field of machinery safety and advises multinational corporations and SMEs on machinery safety issues.

Fleet Management and Assistance Systems

ELOKON solutions at a glance

Despite efforts to make material handling procedures safer, accidents involving forklift trucks are still a cause of too many injuries and even fatalities to personnel. Incidents with trucks and their improper use can also lead to costly repairs and equipment downtime, resulting in lower productivity. At ELOKON, we develop and supply systems that improve safety for your employees who work on or around forklifts and other material handling equipment (MHE). And by making your material handling operations safer, we also improve the productivity of your forklift fleet.

ELOKON's systems ensure the safer and more efficient operation of your internal forklift fleet.

Our products incorporate the latest sensor technology used in the automotive industry to enhance the safety of your workforce and your entire operation whilst maximising the efficiency of your internal forklift fleet. Our product portfolio consists mainly of proximity warning systems, mobile personnel protection devices, fleet management systems, stationary warning devices and radar based systems for speed reduction. We also offer technical health and safety consultancy services to plant manufacturers in areas related to machine safety.

The benefits of ELOKON's safety solutions include:

- Avoiding accidents between trucks and pedestrians in narrow aisles

- Increasing safety awareness and responsibility for forklift operators

- Improving the productivity of mixed fleets through uniform data analysis

- Improving material handling productivity with automatic speed control

- Avoiding forklift truck accidents with active wireless object detection

- Reducing material handling accidents at busy intersections

- Fulfilling liability and insurance requirements

ELOfleet - Smart Fleet Management

Smarter Fleet Management.

Optimise your Fleet. Safe and Efficient.

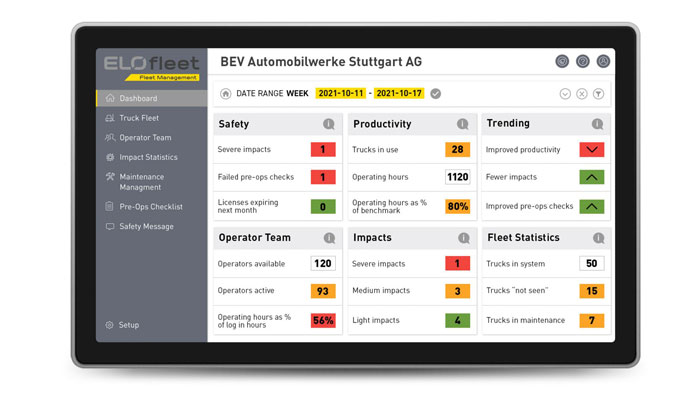

Cloud-based fleet management system: for access control, impact recording and productivity evaluation

- ELOfleet Smart is ELOKON’s innovative fleet management system for mixed forklift fleets. Key features include access control, the recording of damage and impacts and the evaluation of vehicle and fleet performance data.

ELOfleet Smart enables you to easily and cost effectively enhance operational safety when working with forklift trucks and it efficiently improves the productivity of your fleet. The system is OEM agnostic and can be installed on forklifts of any type, any age and any drive type.

The benefits of ELOfleet Smart– they’re clear cut- Safe and efficient management of your forklifts

- Reliable access control

- Customised forklift management

- Enhanced fleet productivity

- Compatible with all types of forklifts

- Prevents unauthorised use

- Monitoring of service and inspection schedules

- Exact driver / vehicle assignment

- Recording of actual operating hours

- Transparency of operating times

- Reduced maintenance costs

- Energy saving through switch-off when idle

- Identification of those involved in impacts

- Collection of customer-specific data

Smartphone app

- Vehicle access control

For authorised personnel only: ELOfleet ensures that forklifts can only be operated by authorised personnel, who log in to the smartphone via RFID using their company ID.

PIN based access control is also an option, as is anonymous operation, without the assignment of drivers to vehicles. Three levels of authorisation can be configured: driver, operations/area manager, workshop personnel.

Electronic checklists

Compliance with obligatory checks: before your personnel can operate a truck, ELOfleet will prompt them to comply with statutory obligatory checks. You can configure these electronic checklists to accord with your own operational requirements. Freely defined questions and multiple choice answers – you can choose what suits.

Impact management

Better safe than sorry: impacts can have an adverse effect on a vehicle’s condition. To keep consequences to a minimum, ELOfleet records accidents involving trucks by means of an MEMS sensor and categorises them according to severity. Subsequent actions can be triggered depending on severity and are adjustable, for example the activation of creep speed, the lockout of the vehicle or the requirement to complete a checklist.

Web based software

- Intuitive and always to hand

Clearly structured data processing: the individually configurable dashboard allows a clear overview of all key fleet data, which can be summarised in daily, weekly or monthly evaluations.

Analysis across multiple sites

10 standard reports are included in the package, to allow flexible analysis according to your individual requirements, also across multiple locations. Identify potential savings within your fleet operation, optimise the deployment of vehicles and improve your productivity.

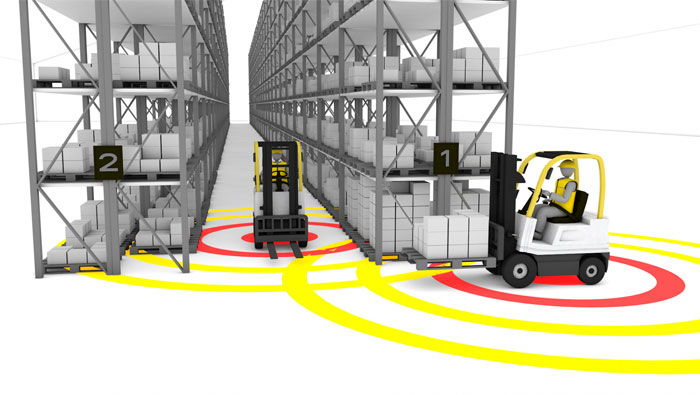

ELOshield - Forklift-Pedestrian Proximity Detection

-

Assistance system for forklift trucks reduces the risk of accidents in high risk or high traffic zones

ELOshield is the innovative personnel detection system from ELOKON. Anywhere where forklift trucks and personnel work in close proximity can constitute a hazard, and protecting the workforce is paramount. ELOshield is a radio-based proximity identification system that considerably enhances safety by automatically detecting when a person enters the danger area surrounding a forklift.

ELOshield can also be used to prevent collisions between forklift trucks or, with the stationary version, for monitoring danger areas such as busy intersections with high levels of internal traffic.

Individually configurable protection zones: ELOshield offers accident prevention using sophisticated warning zones. These zones can be programmed circularly, symmetrically (optional) and even as user-defined fields (optional) with a maximum range of up to 25 metres. Forklift trucks can safely pass other vehicles or pedestrians as they are automatically limited to their own path by the protective zone surrounding them, without causing false alarms.

ELOshield works on robots, cobots (collaborative robots) and AGVs (automated guided vehicles), as well as forklifts and other industrial vehicles. The system can be installed on any type of forklift truck – any brand, any age. Our innovative driver-assistance systems can be fitted to new forklift trucks or retrofitted on your existing fleet.

This enables us to react quickly and flexibly to individual customer requirements. The benefits of ELOshield:

- Compatible with all major forklift truck models

- Safe pedestrian protection in hazardous areas

- Maximum flexibility

- Customised zones for optimum protection

- Safer and more efficient material handling operations

- Protection of up to 500 employees

- Detection range up to 25 metres

This is how the ELOshield UWB-based protection system works

Proximity Detection System

ELOshield is an innovative, UWB-based protection system designed to shield vehicles and staff (ELOshieldGO). A mobile version (ELOshieldDRIVE) monitors “danger zones” of up to 25 metres around moving vehicles (both vehicle-to-vehicle and vehicle-to-person). A fixed-site version (ELOshieldZONE) monitors accident-prone areas, such as high-traffic aisle intersections. ELOKON GmbH takes great care in compiling the contents of this 3D animation. They are nevertheless only meant to provide non-binding general information and cannot replace detailed individual advice to help the prospective buyer make his decision.

The ELOshield assistance system can only support the driver within the specified system limits. The responsibility for remaining sufficiently alert and carrying out driving or operational duties always rests with the drivers and/or personnel.

ELOshieldGO | Personnel Detection - Truck to Person

- In the version as a personnel detection system, a read / reception module is installed on a forklift truck. ELOshield transmits a radio signal, which is received by person modules and reflected. All employees who could be in the danger area carry a personal module, which is ideally integrated in a safety / high-vis vest. The system detects the distance between the forklift truck and the person at all times on the basis of so-called run-time measurement of the radio signal. If a certain distance is undershot, the forklift truck driver receives visual and acoustic indication of imminent danger. At the same time, ELOshield automatically switches the vehicle to walking speed. The person is also warned by a loud acoustic signal emitted by the personal module, and there is an adjustable vibration alarm for additional awareness.

The system detects persons at a distance of 1 to 15 metres

Two warning ranges (pre-warning, main warning) can be set up, in order to trigger different events in a graduated way (e.g. walking speed, then stop).

Innovative UWB technology

Thanks to the UWB transmission technology, the system is optimally equipped for also detecting persons through materials. There are no dead zones, and multiple persons can be detected simultaneously. The system is also weather-resistant and insensitive to dirt and light. The ELOshield modules are supplied with power by a rechargeable battery. This battery, which has the latest smartphone technology, is extremely reliable.

Manual acknowledgement by the driver

An alarm situation can be deliberately acknowledged for an adjustable time at the forklift truck module by pressing a button on the personal module. The truck module on the forklift truck can also be disabled within the adjustable driver area by pressing a button. If the driver leaves the cab / driver area with his personal module, the module automatically "arms" itself again.

ELOshieldDRIVE – Collision Warning - Truck to Truck

- With the "collision warning" version, a transmit / receive module is attached to each forklift truck. These modules do not only detect personal modules, but also detect each other. In this way, both forklift trucks can emit acoustic and visual warnings if they come dangerously close to each other. Both vehicles can also be automatically braked to walking speed.

Total flexibility thanks to freely configurable zones

ELOshield’s customised zones allow, for example, two vehicles to enter an intersection at the same time. The assistance system can now be programmed to enable forklifts to enter at specific points, e.g. at gate entrances. And if a forklift approaches a gate entrance which it is not authorised to use, the customer can request that the system actively intervenes in the vehicle’s operation.

Semi-autonomous intervention

This is when the assistance system intervenes semi-autonomously in the vehicle’s operation: one option is automatic braking of the vehicle in a dangerous situation. It can also be used to warn drivers and pedestrians who are in close proximity to each other by means of visual, acoustic or vibrating warning signals. The system can also automatically brake both vehicles to walking speed.

ELOshieldZONE | Proximity Detection

- With the "Crossing monitoring" version, a number of ELOshield modules are installed above gates or aisle entrances. They reflect the radio signals of approaching forklift trucks. As soon as a truck comes critically close to a crossing area, it is braked and the driver receives an acoustic or visual signal.

With the "Crossing monitoring" version, a number of ELOshield modules are installed above gates or aisle entrances. They reflect the radio signals of approaching forklift trucks. As soon as a truck comes critically close to a crossing area, it is braked and the driver receives an acoustic or visual signal.

Business Cases

Depending on the transponder module and the crossing area, different information can be transmitted to the approaching forklift truck. For example, crossing point 1 is not so heavily frequented, i.e. it is sufficient to reduce the speed by half in this case.

However, accidents have occurred frequently at crossing point 2, meaning that the speed needs to be drastically reduced. The ELOshield stationary modules can also be connected to rotating beacons or acoustic signals in order to signal the danger of an approaching forklift truck.

ELOshieldSPEED – Automatic Speed Adaption

- Where the risks in warehouses or production facilities are particularly high, due to, for example, mobile robots, AGVs and humans working in close proximity, this functionality can be used to define individual danger zones. Vehicles entering these zone are automatically braked to the stipulated speed. Once the vehicle leaves the defined zone, the original speed is automatically resumed.

Individually defined areas

In order to provide a high level of protection for areas of the warehouse where, for example, humans, cobots and industrial trucks are working together, this innovative system can automatically intervene. The specific area of the warehouse is individually defined during installation and entrances and exits are fitted with stationary modules that communicate with the industrial trucks. Customer requirements can be implemented individually, so that just one area of a warehouse or entire halls can be defined as a hazardous area.

Automatic speed adjustment

High risk areas require special solutions to protect the workforce, and one of these is automatic speed adjustment. Once the vehicles drive into the defined area and the vehicle sets detect the antennas, the vehicle speed for this area can be reduced. As soon as the vehicle is outside the danger zone, its normal speed is automatically resumed.

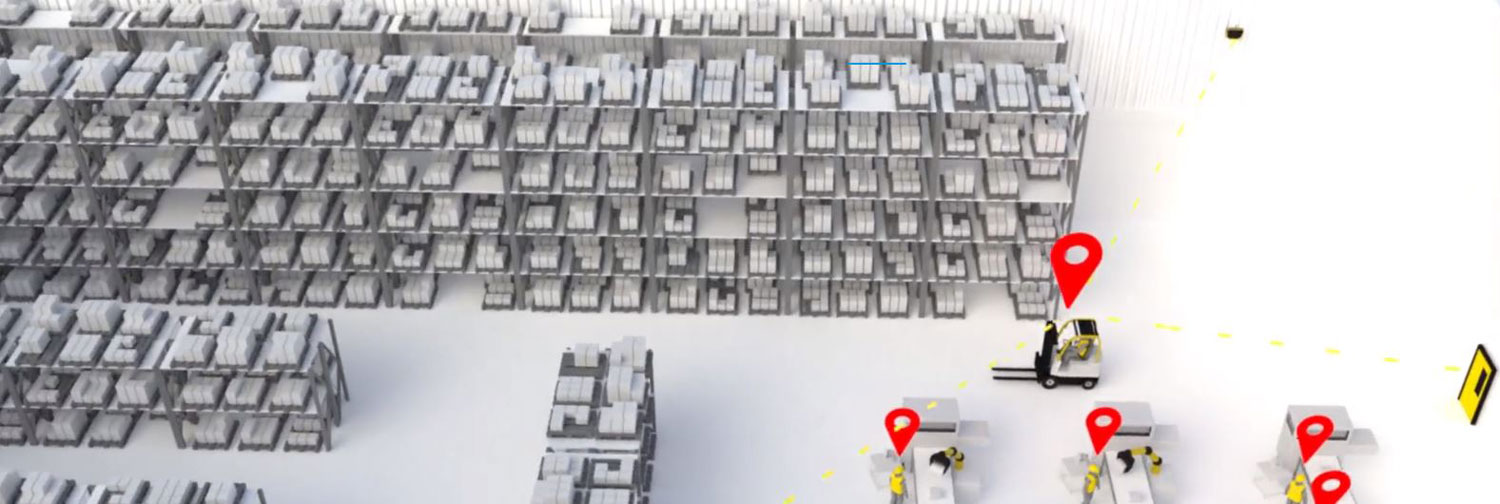

ELOcate - Warehouse Real-Time-Localisation-System

-

ELOcate is a radio based Real-Time-Location-System (RTLS), which can track and locate all movements within the warehouse.

Should any irregularities or risky scenarios occur, ELOcate automatically triggers notification of these. Users can monitor all movements in real time via a web application. This allows warehouse route planning to be optimised, work processes to be made safer and accidents to be prevented.

More control in vulnerable areas

ELOcate has a geofencing function for safeguarding areas such as junctions where visibility is limited. If a truck drives over a predefined boundary, the system can automatically limit its speed and warn people and vehicles in the vicinity. ELOcate also triggers a notification in the event of unauthorised entry into access-restricted zones.

The benefits of ELOcate:

- Precise real-time location of vehicles, objects and people

- Less interaction between people and vehicles

- Automatic notification of relevant incidents via web application

- Safer mobility around the warehouse

- High levels of productivity thanks to optimised routes and processes

- Reduced costs and faster ROI

- OEM independent and suitable for forklifts, AGVs and AMRs

ELOcate brings more transparency to intralogistics Real-time location of vehicles, mobile objects and people

-

ELOcate is a radio based Real-Time-Location-System (RTLS), which can track and locate all movements within the warehouse.

Should any irregularities or risky scenarios occur, ELOcate automatically triggers notification of these. Users can monitor all movements in real time via a web application. This allows warehouse route planning to be optimised, work processes to be made safer and accidents to be prevented.ELOcate has a geofencing function for safeguarding areas such as junctions where visibility is limited. If a truck drives over a predefined boundary, the system can automatically limit its speed and warn people and vehicles in the vicinity. ELOcate also triggers a notification in the event of unauthorised entry into access-restricted zones.

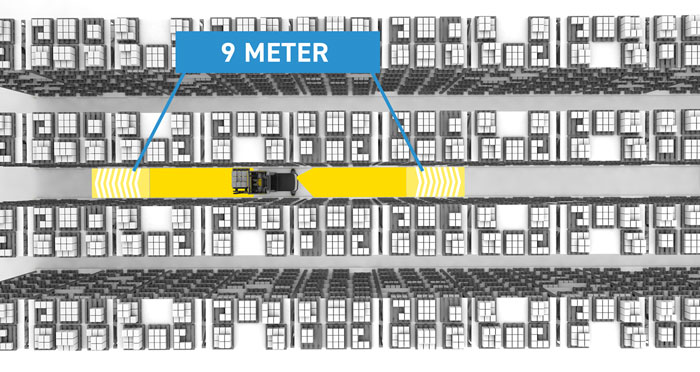

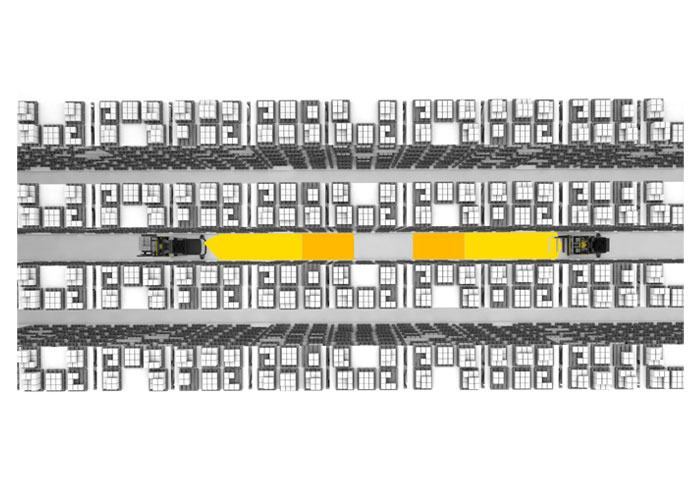

ELOprotect - VNA Personnel Safety System

Safety system for forklift trucks provides mobile personnel protection and collision avoidance in warehouses

ELOprotect is a self-actuating laser scanner anti-collision system for safety and more throughput in very narrow aisles. The mobile personnel protection system is an automatically operating safety device for protecting personnel when industrial trucks are being used in narrow aisles.

If a narrow aisle forklift truck drives into an aisle, ELOprotect is automatically activated and monitors the danger area in the current direction of travel whilst the vehicle is moving. When the vehicle is stationary, ELOprotect monitors both potential directions of travel in order to prevent anyone approaching unnoticed.

If a person is detected in the aisle, ELOprotect automatically brakes the vehicle to a stop. As soon as the driver has made sure that the danger is no longer present, he can reset the alarm by pressing the operating button (deliberate acknowledgement), and the forklift can resume operation. If the forklift leaves the aisle, ELOprotect is automatically deactivated. ELOprotect is officially recognised in Germany as a replacement measure for operating the narrow aisle warehouse – "replacement measure" because it replaces the safety distance that is otherwise required in narrow aisles. If the safety distance is not maintained, the warehouse cannot normally be operated.

Meet the highest requirements: powerful, add-on options and easy to handle

ELOprotect can be pre-installed in your narrow aisle truck manufacturer's factory. ELOprotect can also be retrofitted onto your existing fleet at your site.

The basic configuration of ELOprotect consists of evaluation electronics, two laser scanners and a display and operating module. Depending on your requirements, ELOprotect can be equipped with additional options:- Automatic triggering of creep speed if the laser scanner is covered in order to avoid manual deactivation of the mobile personnel protection system.

- Optional comfort activation and deactivation so that cross traffic in front and any walls that are present do not lead to interference of alarm triggering.

The benefits of ELOprotect:

- Compliance with all legal provisions - Type-examination tested

- Maximum safety for people and vehicles

- Comfort modules for more efficiency

- Compatible with all major forklift truck models

- More throughput in very narrow aisles

- Internationally deployable system

- Intelligent technology for automatic safety

Providing double protection

The personnel protection system ELOprotect conforms to the valid EU Directives. ELOprotect is type-tested according to the requirements of annex IV of the Machinery Directive.

ELOprotectPRO - enhanced warehouse safety- with maximised range

- The latest version of ELOprotect incorporates a new laser scanner which offers even more user benefits. It has a longer detection range – now 9m up from 7m - which enables truck speeds to be increased. This allows for enhanced productivity whilst ensuring the highest levels of safety. The scanner’s more compact size makes it easier to integrate on all VNA trucks and also opens up new installation possibilities. As the new scanner is more dust and dirt resistant it is suitable for use in tough industrial environments minimising any risk of false alarms.

Your benefits at a glance

- Higher detection range of 9 metres

- Faster driving speed

- Convenient ex-works installation or retrofit onto existing trucks

- Reduced size offers more installation possibilities

- Copes with tough industry applications (much more dust resistant minimising false alarms)

- Compatible with all truck types thanks to standardised interfaces

- Higher productivity

- Type-examination tested with Performance Level d (SIL 2)

- Software inverts display screen if assembled upside down, for clear view

ELOprotect ACS - VNA Anti Collision System

-

ELOprotect Anti Collision System (ACS) is a safety system which autonomously protects vehicles from colliding with each other in very narrow aisles (VNA). When a pre-defined minimum distance is breached, ELOprotect ACS prevents a collision by intervening to automatically slow down the trucks.

Laser technology for all-round safety

This safety system uses intelligent technology to enable two forklifts to operate simultaneously in one narrow aisle. Each truck is fitted with two lasers, and unlike ELOprotect they are also equipped with an additional evaluation unit that constantly scans the immediate surroundings.

If objects are detected in the protection zones, ELOprotect ACS automatically reduces the vehicles’ speed, or brings them to a standstill if necessary. Drivers also receive visual and acoustic warnings.

Flexible retrofits, whatever brand you useAll ELOKON systems work on almost all forklift trucks, regardless of the manufacturer or drive type. Our ability to retrofit existing fleets also allows us to customise our products to your individual requirements.

Laser technology for all-round safety

- This safety system uses intelligent technology to enable two forklifts to operate simultaneously in one narrow aisle. Each truck is fitted with two lasers, and unlike ELOprotect they are also equipped with an additional evaluation unit that constantly scans the immediate surroundings.

If objects are detected in the protection zones, ELOprotect ACS automatically reduces the vehicles’ speed, or brings them to a standstill if necessary. Drivers also receive visual and acoustic warnings.All ELOKON systems work on almost all forklift trucks, regardless of the manufacturer or drive type. Our ability to retrofit existing fleets also allows us to customise our products to your individual requirements.

The benefits of ELOprotect ACS:

- Collision protection for forklift trucks

- Compliance with statutory requirements

- Includes personal protection up to 7 metres

- Maximum safety for personnel and vehicles

- Improved occupational safety in the warehouse

- Intelligent technology for automated safety

- More throughput in narrow aisles

- Can be used internationally

- Double protection for your workforce, machines, and company infrastructure

ELOprotect ACS – how it works

- If two trucks are simultaneously in the same narrow aisle, a standard personal protection system with a 7 metre range is not sufficient to offer effective truck-on-truck collision prevention. Due to the relative speeds of the two vehicles to each other, much wider protection zones are required. If multiple trucks are travelling in the one aisle, an additional safety device with Performance Level D is mandatory according to the DIN 15185-2 standard that applies in Germany.

ELOprotect ACS provides this protection by using intelligent laser technology. Two specially developed scanners, which constantly monitor the immediate surroundings, extend the system’s range to 15 metres. The anti-collision fields are always active in the most recent direction of travel once the truck enters the aisle. This also applies when the vehicle comes to a standstill.

If a second vehicle enters the extended collision protection zone of 15 metres, ELOprotect ACS automatically reduces the speed of the truck to creep speed. When entering the personal protection zone of 7 metres, the vehicle is brought to a standstill. Drivers also receive visual and acoustic warnings.

Once the danger has been averted in the collision protection zone, the alarm is automatically reset. In the personal protection zone, the driver can switch off the alarm and continue working as soon as the person leaves the zone. In this way, accidents between two trucks in a narrow aisle as well as with pedestrians can be virtually ruled out.

ELOspeed - Indoor/Outdoor Speed Control

-

ELOspeed - radar based driver-assistance system

Automatic speed reduction of vehicles to prevent accidentsIn production and warehousing facilities, the transition from outdoor to indoor working areas poses a particular risk. Forklift drivers are typically permitted to accelerate to maximum speed when outside, but are supposed to slow down when transitioning indoors for safety reasons. ELOspeed, a radar-based system developed jointly with our automotive industry customers, allows vehicles to operate at full speed outdoors, but automatically slows them down to a programmable speed limit as they come inside.

How it works

ELOspeed is an OEM independent product, which enables quick and easy implementation of speed reduction requirements. With its universal interfaces, ELOspeed can be integrated into any kind of vehicle. ELOspeed detects superstructures (i.e. roofs) across a range of up to 24 metres with its radar-based sensor system, and then automatically reduces the vehicle's speed to walking pace.

There are four settings for ELOspeed's reaction time and eight settings for its detection range. This means that even complex operational conditions can be catered for. The sensitivity of the controllable transmitter also ensures that small superstructures such as bridges, tree canopies and pipelines will not trigger any unnecessary reduction in the forklift's speed.The benefits of ELOspeed are obvious:

- Prevent accidents

- Automatically reduce the speed of your MHE in high risk areas

- Compatible with all major forklift truck models

- Simple installation

- Extreme reliability and weatherproof

- Safer and more efficient material handling operations