- Offer Profile

- As a leading manufacturer and system supplier, HOMMEL ETAMIC offers a broad portfolio of solutions for industrial manufacturing processes, including high-precision technologies for the pneumatic, tactile or optical measurement and testing of roughness, contour, shape and dimensions as well as the optical inspection of machined surfaces.

Optical Surface Inspection

Our Visionline solutions provide you with a wide range of application options for optical surface inspection and profile measurement.

Optical surface inspection from HOMMEL ETAMIC delivers 100 % quality control in the production of workpieces, ensuring consistently high quality. The procedure is not dependent on the operator and is reliable. The high-resolution camera systems precisely check your workpieces and detect the smallest flaws. Thanks to the high inspection rate, the inspection can be integrated into the line, and matches cycle times, saving you costs in production.

To ensure that the system best meets your requirements, we offer various versions with individually assembled sensors for bore inspection and plane surface inspection - adapted to your needs. The machine can either be loaded manually offline or is available as an automated inline version. The robot-assisted version ensures maximum flexibility. Thanks to our multi-sensor systems, you can effortlessly solve even complex inspection tasks without any problems - such as the inspection of all external and internal surfaces of engine blocks.

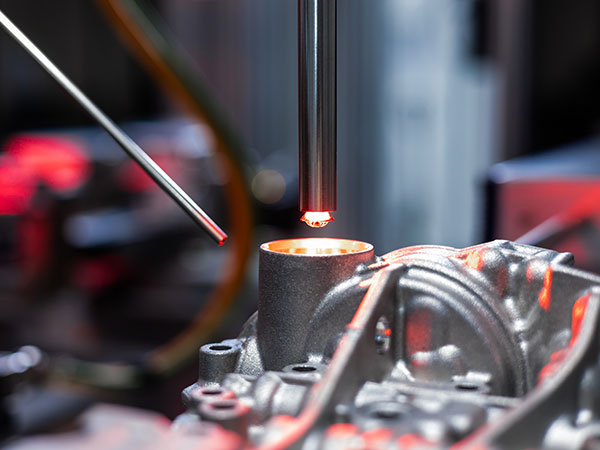

Optical bore inspection

-

Visionline B sensors are especially suitable for bore surfaces. They impress with their 360° all-round vision optics. In this automatic process, a CMOS sensor completely scans the inner surface of the bore and delivers high-resolution and high-contrast images. This allows for the detection of surface defects such as blowholes, porosity and scratches even during production. With Evovis Vision software, your employees evaluate the images easily and intuitively.

Innovative camera and illumination technology, adaptive dynamic masking, and high resolution enable automated 100 Percent inspection of bores within the required cycle time of the production process. The systems allow a fast inspection of the complete bore surfaces, as well as the classification of defect areas.

Sensors

- Visionline B5 for bores from 5 mm

- Visionline B20 for bores from 14 mm

- Visionline B100 for bores from 68 mm

Optical inspection of plane surfaces

-

The Visionline F sensors are specially designed for the automatic inspection of plane surfaces. Thanks to the fly - over technology, image acquisition takes place in the movement at the correct cycle time, thus ensuring the shortest possible inspection times. Thanks to their high speed, they are therefore used for 100 % inspection of technical surfaces.

The plane surface sensor is moved over the workpiece and generates a high - contrast image of the machined surface. The innovative image recording technology determines a topography of the surface, making it possible to distinguish genuine surface defects an d contamination with a high level of process reliability .

- Sensors Visionline F100S, scanning width 100 mm

- Visionline F200S, scanning width 200 mm

- Visionline F400S, scanning width 400 mm

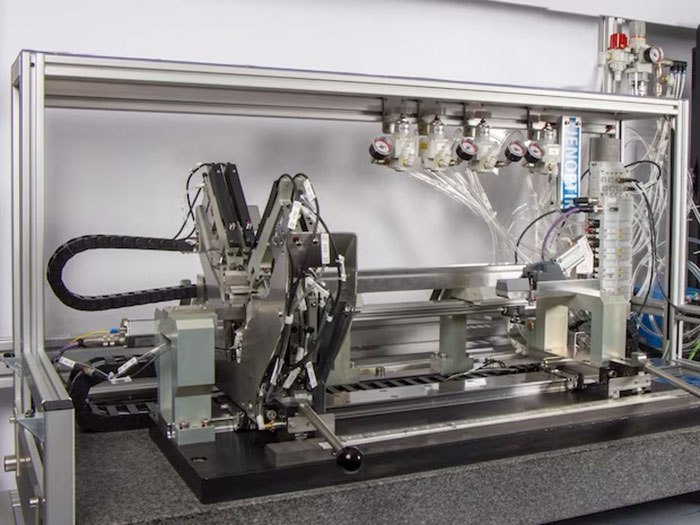

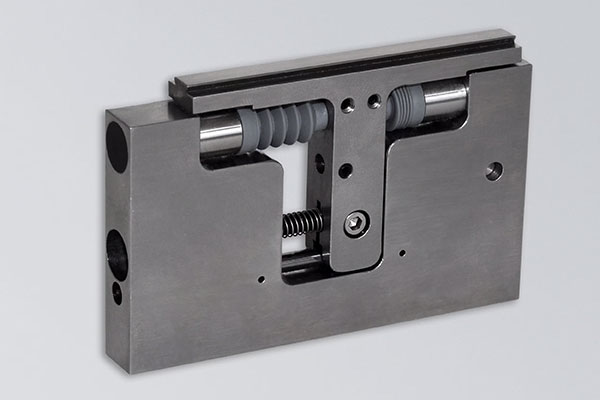

Standalone systems for optical bore inspection - Visionline V200 series

-

The systems for optical bore inspection in the Visionline V200 series deliver reliable and reproducible inspection results without operator influence. Thanks to their compact design and robust construction, they are suitable for offline inspection of bore surfaces in the production area. Equipped with a B5 or B20 sensor, the systems provide high-resolution, distortion-free images of bore surfaces and detect typical surface defects such as blowholes, pores, scratches or cavities. Optional X and Y axes ensure precise workpiece positioning and automated inspection runs.

Advantages:- Wear-free and dependable thanks to optical testing technology

- Fast inspection with short cycles

- Easy retooling of the system when changing workpieces

- Safety in case of misalignment of the workpiece thanks to collision protection

- Reduction of pseudo errors and unrecognized defects (slippage)

Roughness and Contour Metrology

-

Waveline measuring systems offer you numerous evaluation options in the field of mobile and stationary surface measurement.

Wide range of roughness measuring devices

Our product range consists of mobile surface measuring instruments, stationary measuring systems for manual and automated roughness, contour, topography or twist measurement, as well as combined systems for roughness and contour measurements. We also offer measuring stations tailored to meeting your specific measuring requirements.

Our measuring systems operate with high precision and reliability in accordance with current standards. They are easy to operate and are ideally suited for daily use on the shop floor and in the metrology lab. Waveline solutions are the result of our years of experience and comprehensive know-how and can be configured for different measuring tasks depending on the requirements.

Mobile Systems

-

Whether on the shop floor, on the production line or in the metrology lab, our mobile surface measuring devices are the ideal partner for reliable and precise measurements. With their functional design, the devices fit securely in the hand and are positioned precisely on the workpiece.

With various probes and a large range of accessories, they master the most diverse measuring tasks with ease. In terms of accuracy, they are in no way inferior to stationary measuring systems.

Benefits:- High precision: Precise and reliable measurement.

- Versatile: Mobile and stationary measuring instruments for different measuring tasks.

- Compliant with standards: Meet the strict requirements of international standards.

- Easy to use: Intuitive state-of-the-art technology and user-friendly software.

Waveline W5 | Lightweight, small and with long-life battery

-

The mobile roughness measuring device Waveline W5 convinces with safe and highly precise roughness measurement. The system is positioned precisely on the workpiece and does not slip. It weighs little and is compactly built so that you can guide it perfectly in mobile use. What's more, the rechargeable battery won't let you down even with frequent use: One charge is enough for more than 800 measurements.

The roughness probes can be changed easily and quickly, meaning the W5 can be used for countless different measuring tasks as required. The intuitive click wheel and color display ensure that you can operate the mobile roughness measuring device particularly easily.

As an option, you can expand the measuring system with the Waveline P5 printer. To connect the two components, simply use the modern Bluetooth® technology. This allows you to print out your measurement results directly on site without the need for any additional connection cables.

Benefits- High measurement quality: Mobile device with robust, calibrated roughness probe

- Compact and light: Easily portable thanks to the compact design and weight of just 270 grams

- Durable and wireless: Up to 800 measurements possible with just one battery charge; print out via Bluetooth® technology

- Easy to use: Intuitive click wheel operation for parameter selection and all instrument functions

- Clear: Large color display, allowing easy reading of tolerance evaluation results

- Large memory capacity: 5 measuring programs, 100 profiles or 10,000 measurements

- Documentation of the measurement results: optional printer with Bluetooth® technology for instant printout

- Measurement in all positions: also on vertical surfaces or in overhead position

- Optional software: Evovis Mobile for direct control in online mode or further processing of measurement data in offline mode

Waveline W10 | Mobile roughness tester with integrated printer

-

The Waveline W10 measuring device is ideally suited for mobile roughness measurement. It allows you to monitor the surface quality of your workpieces directly in production. The handy measuring system has extensive functions. It offers reliable and precise measurement both during traverse probing and in overhead and vertical positions. The integrated roughness standard is used to quickly check the device and thus ensures consistently high measuring accuracies.

A thermal printer is integrated in the W10. This makes it possible to document the measurement results immediately. Tolerance evaluations, profiles, Abbott curves and statistics can be printed out straight away. The measuring device offers you seven different programs as well as the option to test the instrument. All functions can be operated in a user-friendly manner via the modern color touchscreen. No time-intensive training is required, which saves you time and money.

Optionally, you can extend the measuring system with the Evovis Mobile evaluation software. This was specifically developed for mobile measuring devices, is PC-based and considerably expands the roughness measurement functions. It works in online and offline mode and supports you in selecting the measurement conditions. It also automatically saves your print forms.

Benefits- High-precision: exact measurement of all common roughness parameters

- Compliant with standards: meets the requirements of international standards

- Versatile: allows transverse probing, and overhead and vertical measurements

- 90° probe rotation: for measurements on deep surfaces, in grooves, in recesses or between collars

- Practical: wireless data transmission via Bluetooth® interface; integrated charging cradle for LV17 feed unit

- Easy to operate: large, intuitive color touchscreen

- Clear: results display with tolerance evaluation, surface profiles

- Immediate verification of the device: integrated roughness standard

- Optional software: Evovis Mobile for direct control in online mode or further processing of measurement data in offline mode

Waveline W15 | Mobile roughness measurement with professional evaluation

-

With the compact Waveline W15 set, you can measure surface roughness flexibly at the desired location. The handy traverse unit lies securely on the workpiece thanks to the integrated support prism and ensures precise measurements.

The extendable tripod legs and a 3-point support on the traverse unit make it easy to adjust to the desired measuring position, both horizontally and vertically. For measurements on low-lying surfaces, in grooves, in incisions or between collars, the probe can also be swiveled by 90° without any retooling. With a wide range of skid probes, the Waveline W15 set is ready for all common roughness measurement tasks. As an option, the system can easily be extended to create a compact measuring station for production or the measuring room.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

Benefits- Practical: Handy traverse unit with integrated start button for one-handed operation

- Wireless: Data transmission via Bluetooth® interface

- Highly precise: All common roughness parameters can be measured exactly

- Compliant with standards: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead, vertically or in transverse probing mode

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

Waveline W40 | Flexible surface measurement with free probe system

-

With its handy Waveline Xmove 20 traverse unit, the Waveline W40 set offers flexible options for measuring all common roughness, waviness and profile parameters. Operation is simple and intuitive thanks to the integrated start button and motorized probe lowering for automatic positioning of the probe.

The traverse unit masters measurements in all positions and orientations with ease - even overhead with the probes provided for this purpose. It can be optionally used in a compact measuring station or placed directly on a large workpiece for measurement.

Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

Benefits- Practical: Handy traverse unit with integrated start button for one-handed operation

- Highly precise: All common roughness, waviness and profile parameters can be measured exactly

- Compliant with standards: Meets the requirements of national and international standards, including the new ISO 21920 series of standards

- Versatile: Measures in all positions and orientations, including overhead (depending on the probe)

- Comprehensive: Supports a large selection of reference plane and skid probes

- Automatic: Motorized height adjustment for automatic positioning and lifting of the probe tip

- Professional evaluation: Evovis Mobile Standard measurement and evaluation software

Stationary Systems

-

All measuring station configurations are modular in design and can therefore be easily expanded at a later date. With these systems, you measure surfaces exactly as it fits your individual infrastructure and your specific measurement tasks.

At the same time, the measuring systems are easy to operate and have a wide range of analysis options thanks to the Evovis measuring and evaluation software.

Benefits:- High precision: Accurate repeat measurement results.

- Versatile application: Can be used for roughness and contour measurement.

- Automated measurement run: Probe arm rises and falls independently.

- Flexible: Probe arms are easy to change.

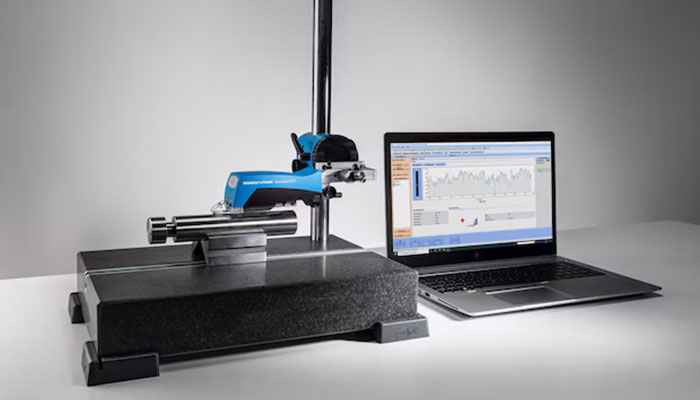

Waveline W600: compact measuring systems with simple operation

-

Waveline W600 roughness and contour measurement systems are easy to operate and, with manual height adjustment, a wide range of mounting options and high measurement quality, are the ideal companion for measurements close to production.

System features:- Universal, easy-to-use measuring system

- High measurement quality thanks to stable mechanics

- Unique traverse concept for optimum accessibility of the measuring points

- Modern touch probes with high resolution

- Interface for probe systems for either roughness or contour measurement with TKU400 or Digiscan probe system

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time due

to automatic probe recognition - Sophisticated probe arm technology

- Probe arms with magnetic coupling for fast and easy probe arm changeover

- All contour probe arms with RFID chip for simplified calibration and automatic configuration

- Measuring points freely accessible thanks to unique traverse unit concept

- Later expansion of the measuring system possible

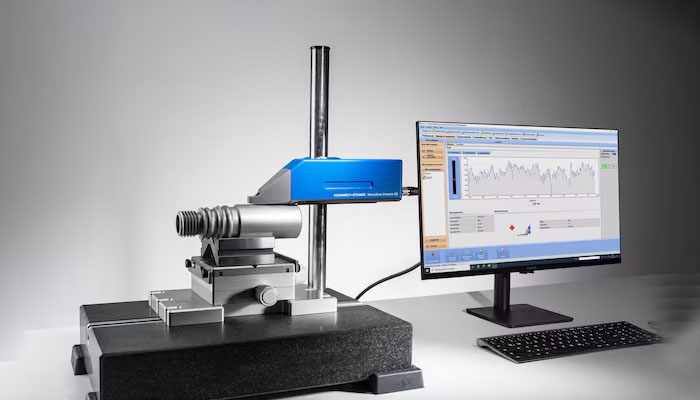

Waveline W800: modular system concept for maximum flexibility

-

W800 measuring systems have been developed for roughness and contour measuring tasks associated with typically manual or semi-automatic measuring processes. The systems are easy to operate and offer a great variety of analyses thanks to the performant measuring and evaluation software Evovis. The result is the highest standard of measuring accuracy in the shortest time.

System features

The quick-change adapter enables probe systems to be changed over without having to use any tools. Probe arms and probe system are equipped with magnetic coupling making the exchange of probe arms easy and fast. This means you can take a flexible approach towards all of your measuring requirements.

The system automatically detects the intelligent contour probe arms with RFID identification and adjusts the optimal measurement conditions, thus practically eliminating operating errors and incorrect measurements.- Universal, easy-to-use measuring system

- Modern, high-resolution probe systems

- High measurement quality thanks to stable mechanics

- Sophisticated probe arm technology

- Unique traverse unit concept for optimum access to measuring positions

- Probe arms with magnetic coupling for fast and easy probe arm change over

- All contour probe arms equipped with an RFID chip for simplified calibration and automatic configuration

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time and automatic configuration feature

- Horizontal motion of the probe system occurs via the traverse unit enclosure, meaning the probe arm is always in front of the traverse unit

- Control panel for easy, direct operation of the most important measuring and control functions as well as emergency stop function with

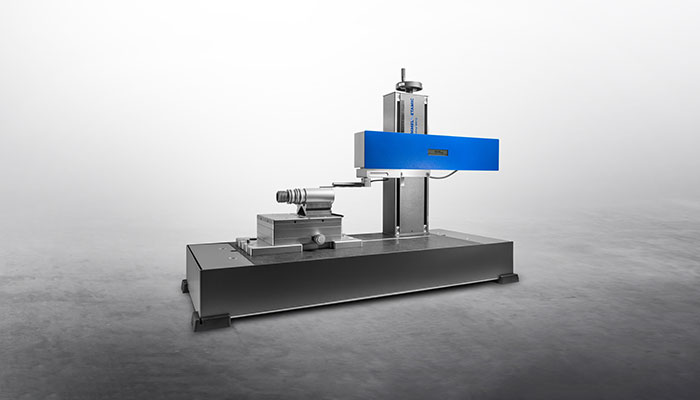

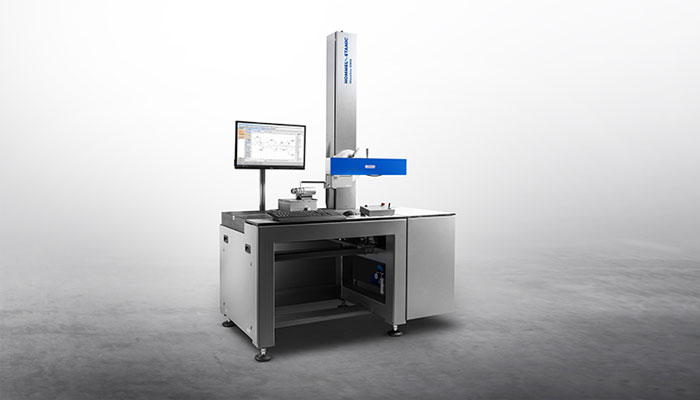

Waveline W900: fast measuring axes for maximum precision and performance

-

The Waveline W900 series was developed for measuring tasks in high-performance areas, e.g. in the environment of automated process chains. The systems have two interfaces for coupling the touch probes and optionally additional axes for automating measuring sequences. The arrangement of the touch probes and the innovative traverse concept ensure optimum access to the measuring points.

System features

W900 measuring systems are used especially in automated measuring sequences for particularly fast and precise results. With their measuring axes, they guarantee short measuring cycles for complex measuring tasks and thus meet the highest demands on measuring technology. The high-precision traverse unit delivers excellent measuring accuracy in conjunction with the Nanoscan touch probe for combined roughness and contour measurement.- Fast measurement technology

- Highly flexible, dynamic measurement

- Excellent measuring accuracy in combination with Nanoscan probe system

- Extensive options for automated, CNC-controlled measurement runs

- Dual operation of two probe systems; a roughness probe system can also be installed on the front of the traverse unit; also suitable for optional rotary module

- Optional motorized tilt unit for precise adjustment of the tilt angle and automatic alignment of the probe to the workpiece level

- Measuring Z column with linear scale at a resolution of 0.1 μm for measurement of vertical distances outside the Z measuring range of the probe; requires probe arm with double probe tip

- Additional motorized Y axis or X-Y axis combination for automatic zenith search, topography measurement and workpiece positioning

- Optional rotational axis for roughness measurement on cylindrical workpieces in circumferential and axial direction

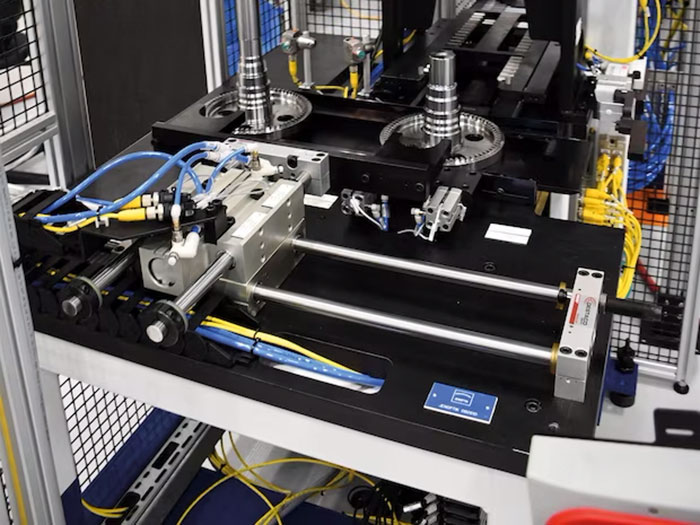

Automated Solutions

-

Individually designed, automated roughness and contour measuring stations

Automated solutions offer CNC controlled roughness and contour measurement. The measuring stations are extended by additional axes and/or handling systems – perfectly matched to the respective measuring requirement.

We also design measuring stations that are individually tailored to your needs.

Optional automated axes

-

Fully automatic measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 Percent inspection of complex components. They are configured workpiece-specifically with CNC axes and fixtures. Thus, the systems perform complex measuring tasks on the respective workpieces fully automatically.

System features- Automated surface measurements for workpiece-specific applications

- Independent, simultaneously operating CNC axes

- Individual fixtures, optionally with automatic identification of the workpiece

- Extensive safety features

- High reliability due to sophisticated technology

- Simple measuring program creation for fully automated processes via Evovis software

- Transfer of measurement results for further processing to statistics programs such as qs-STAT®

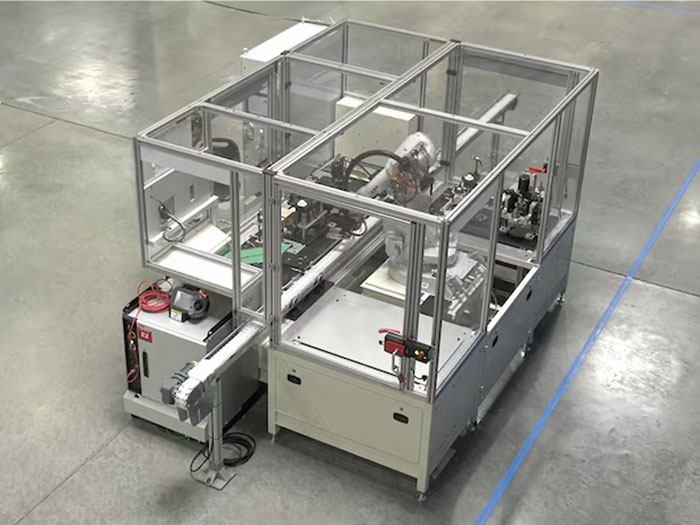

Optional handling systems

-

Fully automated measuring stations offer reliable, operator-independent measuring sequences for both random sample measurement and 100 % inspection of complex components. With the help of handling systems adapted to the measuring station, not only components are moved, but also probe arms are exchanged according to the measuring task and the measuring program.

System features- Fully automatic measurement of roughness and contour in one sequence

- Processing of parts magazines without operator intervention

- Fully automatic probe arm change and recognition

- Positioning of the parts for optimal accessibility of the measuring point

- Interfaces to different measuring and handling systems

Semi-automatic measuring stations Waveslide

-

Waveslide measuring stations are individually tailored to suit specific measurement tasks. They are based on proven system components and provide reliable, semi-automatic measurements in the manufacturing environment. These systems are extremely robust and operate with high precision. Workpiece positioning is manual via guided air slides, the measuring process is fully automated.

System features- Manual, simple positioning of the workpiece (alternatively of the measuring column) via air slide

- Guided X-Y positioning via air slide with additional fine adjustment

- Suitable for large and heavy workpieces

- Flexible use for roughness and contour measurement tasks

Fully automated measuring stations Wavemove

-

Wavemove measuring stations offer individual, CNC-controlled, fully automatic roughness and contour measurement on the shop floor. They are based on the W800/W900 platform and are expanded workpiece-specifically with up to eight independent CNC axes and workpiece fixtures. This ensures the precise measurement of all required features - completely without operator influence and fully automated.

System features- Automated surface measurements for workpiece-specific applications

- Robust measuring stations suitable for production

- Transfer of measurement results to programs such as the qs-STAT® statistics software

- Flexible system concept for numerous applications

- Simple measurement program creation

- Independent, simultaneously operating CNC axes

- Individual workpiece carriers, optionally with automatic identification of the workpiece

- Extensive safety features

- Also suitable for large and heavy workpieces

Form Metrology

-

High-quality measuring systems fur unequivocal measurement of form and positonal tolerances

Form measuring instruments from HOMMEL ETAMIC check form and position tolerances of your workpieces – even in tough industrial environments.

We provide you with solutions for a wide range of tasks in form measurement – from the fully automatic CNC measuring station for all form and positional tolerances to combined form and roughness measuring systems to solutions for special crankshaft and camshaft measurements.

Formline solutions achieve high measurement accuracy even in production environments. At the same time, they are easy to operate thanks to user-friendly software and can be adapted to numerous measuring tasks with a wide range of accessories.

Individual form measuring systems for your requirementsFor special requirements, we develop measuring systems that are specially tailored to your needs. You benefit from our extensive knowledge in the development of special solutions - for example for brake discs.

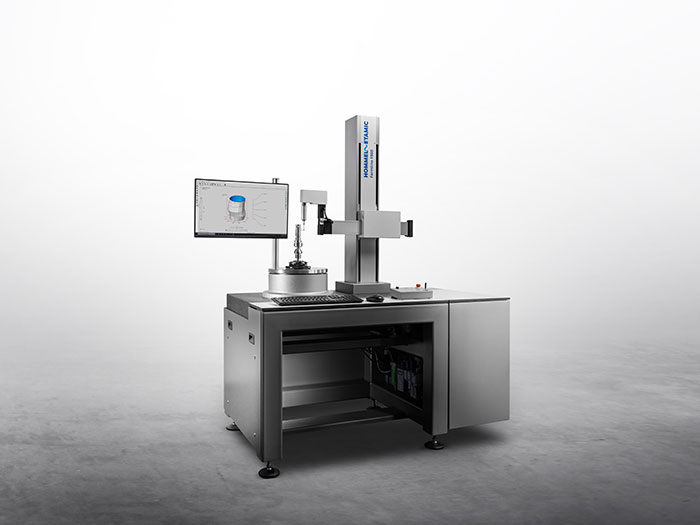

Formline F900

- High-quality measuring systems for form and positonal tolerances

Our form measuring systems are equipped with a high-precision rotary table with air bearings and are extremely robust. They are suitable both for measuring tasks in series production

and for use in the measuring room with frequently changing measuring tasks.

The systems offer a high degree of automation with automatic workpiece alignment and CNC-controlled measuring axes. With the optional tilt and rotation module, even hard-to-reach

probing positions are reached without interrupting the CNC run.

Equipped with an optional double-tipped probe arm, the form measuring systems also perform roughness, waviness and twist measurements – all in one setup.- Measurement of form, run-out and position tolerances

- Determination of specific characteristics such as conicity, crowning or dominant roundness waviness

- Optional roughness, waviness and twist measurement

- Magnetic probe coupling for fast probe arm changes

- Convertible, double-tipped probe system for form and roughness

System features:- Highly accurate air bearing rotary table with outstanding rigidity for consistently high precision

- High resolution with 0.1 μm in the R/Z axis and 360,000 points in the C axis

- Integrated linear scale and active level control

- CNC controlled motorized tilt and rotation module for fully automatic measurements

- Double-tipped probe system can be switched from form to roughness during the CNC run

- For roughness measurement, the probing force can be programmed in any position of the probe arm in accordance with standards

- Axes with high resolution and very low interference

- Automatic zenith alignment of the probe arm through 3-ball system

Highlights:- Time saving thanks to very fast, fully automatic centering and leveling and CNC controlled measuring axes

- Flexible use with free probe system in C, Z and R direction for form, roughness, waviness and twist measurement in a single clamping operation

- Heights of vertical measuring axis: 350, 550 or 900 mm

- Vibration-damped instrument table with container for PC and system electronics

- Magnetic probe arm coupling for fast changing of the probe arm and protection in case of collisions

- Flexible access to external/internal measurement positions thanks to fully automatic probe positioning, fully automatic, freely adjustable probe

force and reversible scanning direction

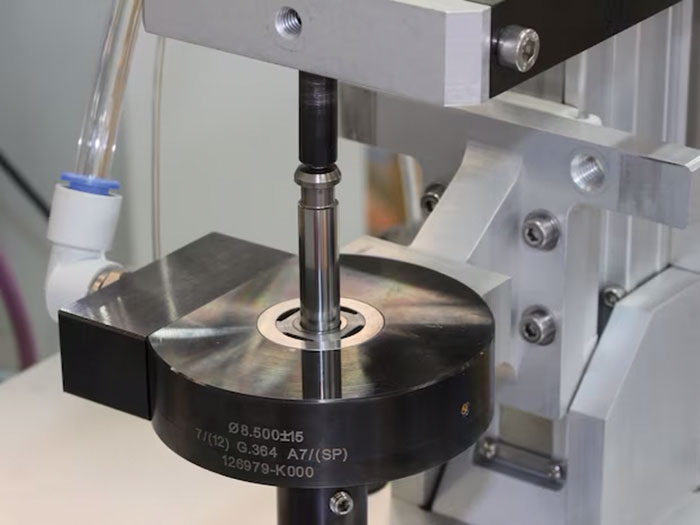

Formline CFM3010

- Crankshaft and camshaft measuring machine

The fully automatic, high-resolution Formline CFM3010 measuring system flexibly and reliably determines form and position deviations of different workpiece types. Thanks to its outstanding basic accuracy and robust design with vibration decoupling, the system is suitable for use in the measuring room or in the production environment.

Optimized CNC processes in conjunction with high measurement and travel speeds as well as fast measurement value recording ensure short measuring cycles.

Extensive accessories such as followers and drivers ensure safe handling of complex workpieces.

Benefits:- Precise: high-resolution measuring system for exact results

- Reliable measurement results: no mechanical transverse forces

- Constant: repetitive accuracy of up to 0.3 µm

- Reliable analysis: detection of form and dimensional deviations using the Turbo Shaft software

- Robust: suitable for use in metrology lab and production environments

Dimensional Metrology

-

Precise quality control at every stage of the production process

As a leading manufacturer of metrology systems, HOMMEL ETAMIC offers a broad portfolio of measurement solutions for industrial manufacturing processes. Our technologies include pneumatic measurement, tactile or optical measurement of roughness, contour, form and dimensional features, as well as optical inspection of machined surfaces.

Comprehensive services such as consulting, training, DAkkS DKD calibration and service, including long-term maintenance contracts, round off our worldwide range of metrology services for quality assurance in industrial manufacturing.

Our measuring systems ensure the quality of the workpiece throughout the entire production process and provide precise measurement data in the shortest possible time. Automatic measuring technologies enhance overall productivity during production through efficiently designed inspection solutions – whether inline or offline, or using spot checks through 100 % inspection of all manufactured workpieces.

Gageline product range:- Manual measuring gages

- Semi-automatic measuring stations

- Fully automated measuring machines

- Tactile and pneumatic sensors

- Displays and measuring computers with evaluation software

Applications:

- In-line and Off-line

- Pre- or post-process

- Final inspection

- Metrology lab

- Statistical process control (SPC)

- 100 Percent control

- Sample measurements

System Solutions

-

Metrology solutions for any industry

Gageline offers dimensional measuring solutions that can be integrated into your production processes. The degree of automation and the technology used depends mainly on the production requirements and the measuring task.

From simple measuring stations to fully automated solutionsGageline solutions are robust and precise thanks to “plug-and-play” technologies that can be used as stand- alone control devices, or integrated into manual, semi- automatic, or fully automated measuring solutions that deliver scalability and evolve with your processes.

Dynamic measurements as well as statistical process control (SPC) insure part quality through interlinked measuring machines that are integrated into the production line.

The following examples show Gageline applica tions ranging from simple, manual measuring stations, to fully automated measuring machines, all capable of being seamlessly integrated into your production processes

Manual measuring systems

Manual tabletop gage for inner diameters

- Simple, cost-effective measuring chain

Simple manual measuring stations consist of three basic components: a measurement display, a pneumatic or tactile measuring device, and a master (standard). These gages are inexpensive, easy to use, do not require prior knowledge and deliver immediate measurement results.

Customer requirements- Workpiece: ball joint pickle fork separator

- Measurement of two inner diameters

- Post-process, 100 percent control operation

Air spindle with two elongated jets

- Gageline solution with air tooling

- Mounting on table

- 2 Pneutamic digital comparators

- 1 air spindle with 2 levels for the 2 diameters and elongated jets to take into account the surface finish

- 2 standards according to DIN 2250 B (Min/Max)

- Immediate display of measurement results

- Ease-of-use

- Portability

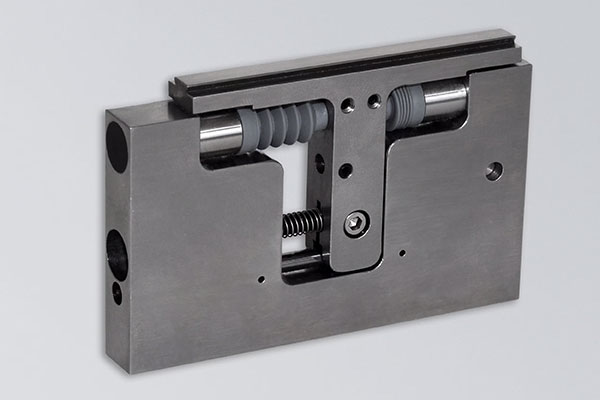

Manual bench gage for shafts

- Expandable bench gage measuring system

Measuring stations similar to these are normally placed close to the production line and can be used for taking sample measurements, or for final inspection. Work- piece loading/unloading, measuring and mastering are completed manually by the operator.

Customer requirements- Workpieces: Drive shafts of a ten-speed gearbox

- 3 shaft types

- Multiple O.D. sizes ranging from 23 to 39 mm

- Tolerance range from ±7 µm to ±13 µm

Gageline solution with air tooling and tactile sensors

- Gageline solution with air tooling and tactile sensors

- Fully adjustable table top fixture

- Multi-sensor compact bench gage

- 1 special tactile snap measuring device for the ±13 µm tolerance range

- 2 mastering standards according to DIN 2250 B (Min/Max)

- Interchangeable/replaceable non-contact air snap gages

- Dual pneumatic and tactile technologies for management of different tolerance ranges

- Compact measuring station

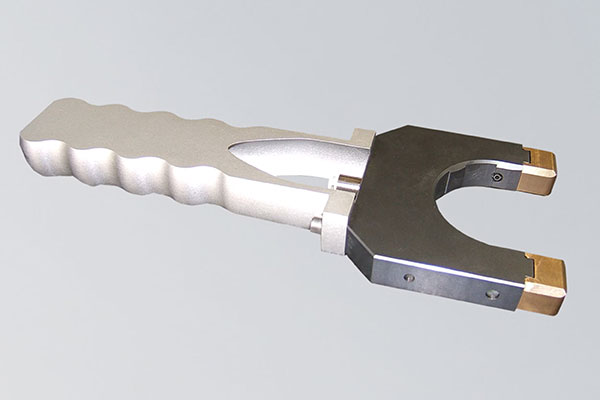

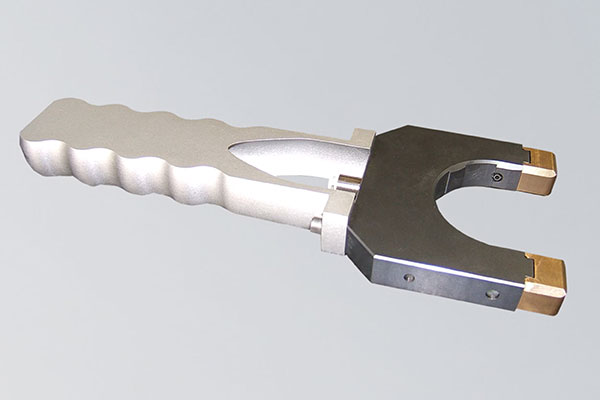

Manual measuring station for cylinder heads

- Bench gage table top system

Manual measuring systems range from very simple solutions, to more complex systems that integrate dozens of different measuring devices. This is the case with cylinder head inspection with hand-held air tooling for example.

Customer requirements- Workpiece: 2 different off-road vehicle cylinder heads which are bulky, difficult to handle and have small margins of tolerance

- Ergonomic measuring station

- Reliable measuring results

- Part features:

- I.D. of exhaust guides, intakes and bores

- Roundness and concentricity

- Seat angle

- Radial run-out of the valve seats

Air spindle with two elongated jets

- Gageline solution with air tooling

Bench style gaging station utilizing multiple manually operated pneumatic devices that allow the operator to fully inspect a cylinder head.

- 3 pneumatic Valvescan gages mounted on balancers (2 for intake and exhaust and 1 for the exhaust)

- 3 air gages for seat angle control and seal control

- 3 air gages for valve seat control

- 2 DIN 2250 B Min/Max standards

- Dynamic measurements

- Non-contact pneumatic measurements

- Retractable overhead reels for ergonomic workstation

Semi-automatic solutions

Compact pneumatic measuring station Gageline SG500

- Semi-automatic I.D. and O.D. solutions

SG semi-automatic solutions are capable of static and dynamic measurements for inner and outer diameters on cylindrical workpieces.

These types of systems are suitable for:- I.D. and O.D. checks on different levels

- Dynamic measurements for I.D. or O.D. workpieces (profile evaluation)

- Scan/Match between mated workpieces

- Conicity

- Workpieces: valve body and valve shaft

- Measurement of valve body I.D and valve shaft O.D.

- Automated measuring sequence

- Deviation check between mated workpieces

O.D. measurement

- Gageline solution with air tooling

- Valve body I.D. inspection on multiple levels

- Valve shaft O.D. inspection on multiple levels

- Manuelle Beladung, automatisierte Messabläufe

- Manual load, with automatic measuring runs

- Synchronous recording of measured values and position in Z (using CANopen motion controller)

- DIN 2550 B Min/Max standards

- IP65 protection for use on the shop floor

- Easy test plan control

- Automated measurement sequences

- High linearity due to precision high pressure pneumo-electronic transducer

- Fast measurement cycles

Semi-automatic measuring station for seat rails

- Semi-automatic measuring stations

Semi-automatic measuring stations are capable of managing a high number of measurements thanks to cutting edge metrology software, fully automated sequencing and extremely capable hardware. Part loading and unloading can be completed manually, or automated through conveyor, robot, or other automatic part handling technologies. Customer specifications play a large part in determining the which one is utilized.

Customer requirements- Workpieces: seat rails

- Dimensional measurement of

- Profiles

- Bearing rolling zones

- Lock interface

- Measurement conditions

- Cycle time <1 minute

- Manual operator load

- Manufacturing environment

- Check of 40 essential dimensions, more than 120 in total

- Different rail lengths

- Measurement of first batch parts

Part-specific tactile measurement

- Gageline solution with tactile sensors

- Semi-automatic, off-line tactile measuring solution

- ZDB inductive sensors with XP206 measuring blocks

- PS100 measuring communication modules

- CANopen communication protocol

- Sirius measuring computer with evaluation software

- Part compensation management

- Mastering standards based on part design (Min/Max)

Special Features

- Robust system technology

- Industry 4.0 machine communication

- Mastering standards based on series production part

- Fast measuring times with >120 measurements per minute

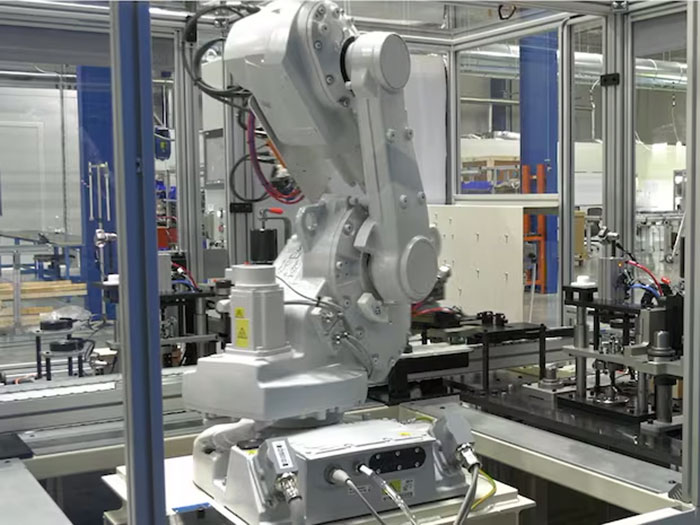

Fully automated turnkey solutions

Automated in-line measuring station for gears

-

Fully automated turnkey solutions

Fully automated “off-line” measuring solutions utilize tactile and pneumatic technologies, in combination with automated part handling capabilities, and are typically integrated parallel to the manufacturing line. The pneumatic and/or tactile sensors are engineered to rigorous specifications and are placed according to customer part tolerance requirements. The evaluation software manages the test plans, pilo- ting of the part and/or sensors, and if required ensures part classification and sorting.

Customer requirements- Workpieces: Hybrid powertrain gears

- 100 percent high speed production control

- Measurement of dimensional part features of the pinion and conformity of pinion teeth

- 4 different types of fixed gears

- 6 types of mobile gears

- >50 different controls

- Sorting of defective gears

- <30 s cycle time

Robot loading

- Gageline solution with tactile sensors

- 100 percent automated production control

- Optical management of gear diversity

- Dynamic measurement of center distance and roundness

- Detection of shocks on the teeth

- Sorting and storage of defective gears

- Automatic calibration of control stations

- Loading, unloading, and handling of parts by 6 axis robot

- Automatic measurement program selection

- Gear heights tolerance 100 µm, R&R <10

- Diameter tolerance <10 µm

Highlights

- Fully automatic

- Detection of defective gears

- Identification and sorting of defective parts

- Integration of optical sensors

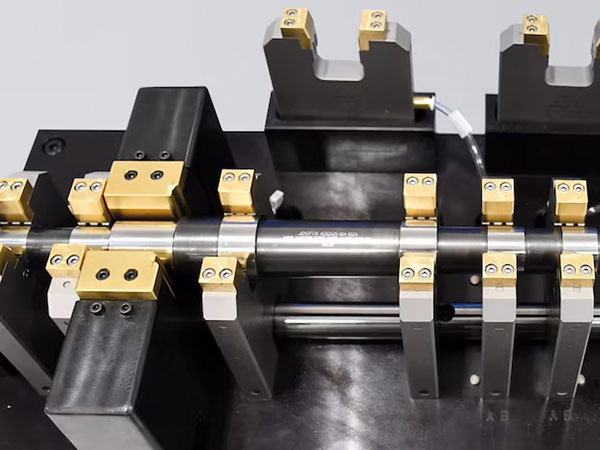

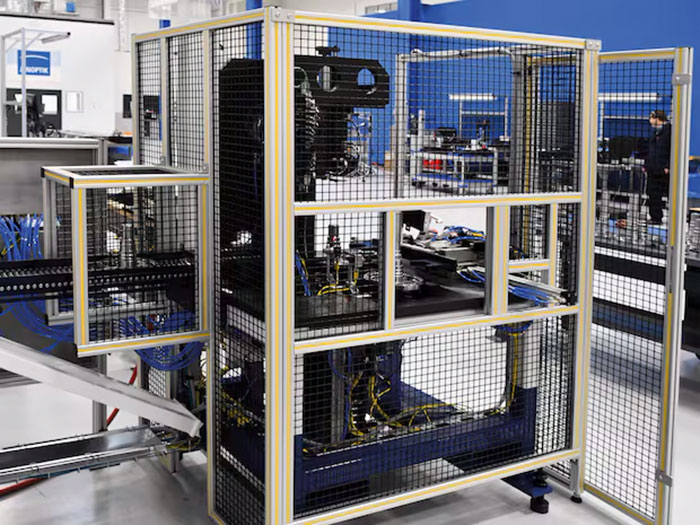

Automatic bench gage for transmission shafts

- Fully automatic in-line measuring machine

Automatic measuring stations deliver user-independent, reproducible results. Robot-loading of the workpiece guarantees fast and precise positioning. Automatic measuring runs produce results within the given cycle times and allow for fast evaluation.

These stations are conceived in a project process in order to guarantee perfect implementation into the customer‘s production line.

Customer requirements- Workpiece: output transmission shaft

- 19 dimensions to control for each part

- Automatic in-line post-process measuring gage

- 2 different shaft types (short and long)

- Cycle time: 50 s per part (part load/unload included)

Gageline solution with tactile sensors

- Gageline solution with tactile sensors

- Fully automatic in-line inspection station with ZDB sensors

- Implementation of 2 stations: 1 for gaging and 1 for sorting

- Integrated conveyor linking the 2 stations

- Sorting station

- Measuring computer with full SPC capability and qs-STAT® certified interface

- HMI integrated into measuring computer

- Certified mean standard for short part, with adaptor for long part, and protective storage box

- Manual calibration mode

- Built-in changeover between long and short part type

- Sorting function of defect parts

- Unique measuring station managing diversity

- „Plug-and-play“ workstation

Standard components

-

Standard components for simple and complex measuring chains

Our dimensional metrology checks diameters, lengths, distances, shape, and position of your workpieces either with tactile or pneumatic sensors depending on measuring task and process-integration. The robustness and precision of our measuring solutions are the result of the know-how we have acquired over several decades. This experience can be found in our standard modules developed in-house and which equip our customers‘ simplest „at-line“ manual measurement gages as well as their complex measuring machines, integrated into the most efficient production lines.

Pneumatic measurement convinces with a very high resolution. It is extremely robust and insensitive to dirt, making it perfect for use under tough manufacturing conditions. Our pneumatic process meets the high standards of DIN 2271.

Tactile measurement uses contacting sensors that record the measured values extremely quickly. Typically, tactile sensors are used in multi-point measurement technology where the individual measured values must be recorded quickly in order to maintain a short cycle time.

Pneumatic measuring components

- A pioneer in pneumatic, non-contact measurement technology, we are a world-renowned specialist with more than 70 years of experience. Pneumatic metrology uses air jets in combination with air to electronic converters to create a high pressure air circuit that allows sub-micron measurement of precision parts. Our pneumatic technology is capable of measuring a variety of part features, including I.D., O.D., roundness, cylindricity, parallelism, conicity and even distances between axes.

Tactile measuring components

- Tactile measurement technologies offer excellent quality, reliability, and robustness. Tactile sensors are particularly suited for large tolerance ranges and for workpieces with distinctive roughness characteristics.

Digital comparators

- The Pneutamic and Digitamic are electronic comparators used to visually display information from a pneumatic or tactile measurement circuit. Easy to use, they do not require any adjustment and can be used by operators without any particular expertise in metrology.

Probe satellites

-

Probe satellites function as a receiver for pneumo-electronic transducers, or LVDT tactile sensors. Each measurement circuit is attached to one channel on the probe satellite, which corresponds to an assigned I.D. in the evaluation software.

The PS50 & PS100 probe satellites can perform dynamic or static dimensional measurements, with the option of connecting to a large variety of either Jenoptik, or other commercially available sensors.

Measuring computers Sirius and Vega

- Sirius and Vega industrial computers can be combined with Tolaris Premium and Tolaris Expert evaluation soft ware, to offer flexible solutions that help control your production processes. They are designed for dimensional measurement analysis, as well as for encoder and joystick control.

Optical shaft measuring technology

-

The measuring systems of the Opticline optically scan rotationally symmetrical workpieces. They thus measure the shafts without contact and are suitable for partially or fully automated use, especially in the automotive industry, the production of turned and ground parts, and in medical technology. In a very short time, complex workpieces of various sizes are analyzed directly in industrial production. The Opticline measuring stations impress not only with their high measuring speed and precision, but also with their optimum ease of operation thanks to the "Tolaris Optic" measuring and evaluation software. Operator influence is almost completely eliminated at the Opticline measuring systems. All measurement results are documented and stored in an audit-proof manner. The Opticline thus ensures an efficient and controlled manufacturing process and guarantees production quality.

The technology of optical shaft metrology is constantly being further developed. Thanks to their robustness, Opticline measuring stations can be easily integrated into production lines and used for 100 Percent measurements. They are built modularly on a standardized platform and customized with additional features. For example, optical measurements can be supplemented by tactile sensor technology to produce a 3-D analysis. Opticline measuring stations are durable and virtually wear-free - it is not for nothing that Opticline products have been in demand on the market worldwide for more than 30 years.

Opticline CS

- Opticline CS series shaft measuring systems have been designed for production-related applications and offer a high degree of measuring performance and absolute precision from 2 μm in an extremely compact design.

Opticline C

- Opticline C series shaft measuring systems offer maximum gage repeatability and reproducibility from 1 μm. With different configurations, such as a high-precision C-axis or multi-sensor system, the performance capability can be customized to suit your requirements.

Opticline CA

- Thanks to their special open machine concept, the high-precision Opticline CA systems are ideal for PLC measuring stations with manual loading and automated production.