- Offer Profile

-

The leading provider of modern storage solutions and inventory management systems

Modula is a leading manufacturer of automated storage solutions, designed to optimize space and improve picking and storage operations for any industrial sector or environment. Our vertical lift module (VLM) line maximizes the storage potential of high-ceiling facilities, securing items in enclosed units up to 54 feet tall. Our horizontal carousels are ideal for low-ceiling environments, as well as those seeking maximum throughput. For both solutions, automated delivery dramatically increases productivity and saves operators from unnecessary bending, walking and reaching for parts.

Modula Vertical Lift Modules

- Modula Vertical Lift Modules (VLMs) are fully automated vertical storage systems that take up a minimum footprint by utilizing the ceiling height available. These systems allow for large inventory of goods to be quickly accessible while being stored in a safe and secure environment and automatically delivered to the operators, with a simple touch on the user friendly Copilot controller or the scan of the barcode.

MODULA LIFT

-

Modula Lift is an advanced automated vertical lift module (VLM) designed to maximize storage efficiency and recover up to 90% of floor space. Engineered for versatility and precision, Modula Lift enables vertical storage of items of various sizes, weights, and types—making it ideal for industries ranging from automotive to pharmaceuticals.

Core Benefits:

- Space Recovery: Save up to 90% of floor space through vertical storage.

- High Payload: Trays can handle up to 990 kg each; total payloads reach up to 90,000 kg.

- Fast Throughput: Up to 120 trays per hour, depending on configuration.

- Smart Operation: Features ergonomic design, safety certifications (TUV), and an intuitive 10.4” touchscreen console.

- Enhanced Security and Efficiency: Stored items remain secure, clean, and organized with minimal energy consumption.

Modula Lift units range in height from 3,300 mm to 16,100 mm, with tray widths from 1,500 mm to 4,100 mm and depths up to 1,257 mm. Multiple bay configurations are available:

- Single or dual internal/external bays

- Opposite or displaced bays

- Dual delivery system for uninterrupted picking

Flexible Storage Capabilities

The system stores:

- Spare parts, tools, and components

- Pharmaceuticals and cosmetics

- Electronic and mechanical items

- Packaging, reels, and small parts

Integration & Technology

- Integrates seamlessly with ERP systems via Modula WMS

- Compatible with technologies like robots, conveyors, manipulators, and Put-To-Light systems

- Supports optional features like RFID readers, LED bars, barcode scanners, automatic doors, and fire safety systems Tray Accessories & Options Includes dividers, partitions, ESD protection, label printers, telescopic bays, and insulated units for outdoor use.

Technical Specifications:

- Unit height:from 3,300 mm to 16,100 mm

- Unit height increment:200 mm

- Tray storage pitch: 25 mm

- Tray widths: from 1,500 mm to 4,100 mm

- Tray depth: 654 mm – 857 mm – 1,257 mm

- Net tray payload: 250 – 500 – 750 – 990 kg

- Total net payload: up to 80,000 kg (depending on model and configuration)

- Gross unit payload: up to 90,000 kg (depending on model and configuration)

- Throughput: up to 120 trays per hour (depending on the configuration)

- Operator interface: industrial console with 10.4” touchscreen technology

- Number of bays: up to 3, also above ground level and on the same side

- Types of bay: internal or external with single or dual delivery level

- Maximum product height: 695 mm (bay S) / 895 mm (bay M) / 1,295 mm (bay XL)

- Minimal energy consumption

- Automatic weight check on tray return

- Dynamic tray height storage

- Zinc-coated steel structure

- Eagle steel-reinforced toothed transmission belt

- Elevator guiding system with 6 wheels in HDPE per side

MODULA SLIM

-

Modula Slim is the smart choice for anyone looking for a vertical storage solution with complete flexibility.

It offers all the advantages of Lift technology in:

- Just 3 m² of floor space

- Only 1.6 m in depth

You can store all kinds of materials and products in Modula Slim: loose materials, containers (boxes, bins, packs, cartons, cases), small items, spare parts, coils, flasks.

What Modula Slim can do for you:

- Recovers floor space, maximizing storage density

- Reduces picking times

- Makes materials accessible to all operators, quickly and ergonomically

- Keeps stock levels and all warehouse items under control

- Integrates easily into company processes by communicating with all ERP systems

- Tracks picking and refilling operations, identifying who did what and controls every access

- Eliminates picking and refilling errors by guiding the operator through the process

The compact vertical storage system

Minimum depth, maximum efficiency

Technical Specifications:

- Height: from 2,400 mm to 7,000 mm

- Throughput: up to 190 trays/hour (depending on configuration)

- Unit height increment: 100 mm

- Tray storage pitch: 25 mm

- Tray depth: 425 mm

- Net tray payload: 350 kg

- Bay type: 1 internal bay, single delivery level

- Operator interface: 10.4” industrial touchscreen console

- Power supply: single-phase (230V) or three-phase (400V)

- Energy consumption: 1.2 kW/h for SLIM 1.3 model, H = 7,000 mm

- Transmission: steel-reinforced toothed belt (4 belts)

Quick to Install, Easy to Use

- Built on a pre-assembled base module, easy to move and install

- Plug & Play installation in 48 hours

- Easy integration with ERP systems via Modula WMS

- User-friendly touch screen interface

- Integrated controls: end of picking button, EKS reader, LED bar, etc.

- Ready for use in just a few days, with a noticeable increase in picking speed

Dynamic Tray Storage

Make use of all available space inside Modula Slim—no fixed heights, no wasted space.

- Total payload up to 25,000 kg

- Height up to 7 m, depth only 1.6 m

- Trays automatically positioned to avoid unused vertical gaps

- No issues with unbalanced loads (unlike carousel systems)

- Quiet, low-maintenance V-Shape toothed belt transmission

- Optional features: visual aids, Put to Light, access control systems, partitions, dividers, slotted tray walls

Slim models

- SLIM 1.3

- Tray Width: 1,300 mm

- Tray Depth: 425 mm

- Tray Wall Height: 45 mm

- Net Tray Payload: 350 kg

- Footprint: 1,685 x 1,675 mm

- SLIM 1.9

- Tray Width: 1,900 mm

- Tray Depth: 425 mm

- Tray Wall Height: 45 mm

- Net Tray Payload: 350 kg

- Footprint: 2,285 x 1,675 mm

- SLIM 2.5

- Tray Width: 2,500 mm

- Tray Depth: 425 mm

- Tray Wall Height: 45 mm

- Net Tray Payload: 350 kg

- Footprint: 2,885 x 1,675 mm

Options and Accessories

- Trays: partitions, dividers, slotted tray walls

- Visual Aids: LED bar, laser pointer, alphanumeric bar

- Access Control: RFID, magnetic badge, login/password, EKS reader

- Productivity Tools: 1D/2D barcode readers, Put to Light, ESD protection systems

MODULA PALLET

-

Pallets remain one of the most common methods for moving and storing goods in warehouses.

Modula Pallet is an automated storage system specifically designed for Euro Pallets (1200 x 800 mm) or boxes of the same footprint, managing them safely and efficiently. Built with operator ergonomics in mind, it replaces traditional shelving and ensures that all loading and unloading takes place at floor level, eliminating suspended loads and increasing workplace safety.

With Modula Pallet, warehouses gain a safer, more ergonomic, and highly efficient solution that is easy to install and immediately operational. Key advantages include:

- Pallets are stored vertically, maximizing warehouse height and freeing valuable floor space

- Handling takes place at ground level, removing the need for forklifts for lifting

- Serves as a buffer in shipping and receiving areas, and as temporary storage for inbound and outbound goods

Modula Pallet transforms pallet management by combining safety, ergonomics, and space optimization in one automated solution.

MODULA NEXT

-

Modula Next: the intelligent vertical storage system

Struggling with picking errors in your warehouse? Modula Next is the innovative vertical automatic warehouse designed to eliminate mistakes and safeguard goods.

Unlike traditional storage solutions, Modula Next communicates with the Copilot Console to deliver trays directly to the operator. Access is restricted to a single compartment at a time, thanks to a system of mobile shutters that open only when aligned with the correct item location.

This vending-machine-inspired approach ensures complete control over access, picking, and restocking, drastically reducing the possibility of errors. Even items that are nearly identical, stored side by side with different codes, can be retrieved without risk of confusion.

Beyond accuracy, Modula Next also prevents theft, damage, and unauthorized handling of goods, guaranteeing secure and reliable warehouse operations. It is vertical storage technology that works with the intelligence of a vending system—making error-free picking a standard, not an exception.

Modula Flexibox

Modula Flexibox

- Flexibox: high-throughput bin handling for large order volumes

Built for high-volume picking, Flexibox is an automated vertical warehouse that manages bins at speeds of as many as 180 bins per hour, enabling the simultaneous processing of hundreds of order lines.

It is a strong fit for order management, kitting, and storage. Guided by the WMS, the system presents only the required products to the bay, intelligently grouping bin contents for the operator. Once an order is released from the management system, Flexibox receives it, gathers every bin needed, and brings them to the bay so the operator can work with multiple bins at once.

Picking occurs entirely inside the machine. A central lift retrieves bins from storage one by one according to the order sequence, places them via a telescoping fork onto a service tray, and, once the tray is filled, delivers it to the bay so all items are immediately accessible.

Depending on the model and tray width, between 3 and 9 bins can be staged in the bay at the same time.

Scalable, flexible, fast, and modular, Flexibox accelerates order processing while improving accuracy.

Advanced Picking Solutions

-

Picking solutions for order preparation

Order preparation and picking are always central steps in our approach to warehouse optimization.

With the support of an automated warehouse, both processes become much easier to manage. During picking, automation ensures items are located quickly, retrieved with speed, and handled with fewer errors, making the entire workflow more accurate and efficient.

When preparing orders for different departments, destinations, or production areas, the picking list represents one of the most critical stages. The more effective the warehouse picking strategy, the faster orders can be fulfilled—directly impacting customer and supplier satisfaction.

Adopting an automated solution such as Modula allows not only for faster and more optimized material flows, but also for real-time control over warehouse activity. Accesses, withdrawals, inventory levels, and stock movements can be constantly monitored, ensuring complete visibility and reliability in warehouse management.

Modula Put to Light

-

Smart picking solutions for vertical storage systems

Our advanced picking technologies integrate effortlessly with vertical automated warehouses to boost overall performance. By leveraging state-of-the-art tools, the picking workflow becomes faster, simpler, and far more precise. In high-density vertical storage environments, where optimal use of space is critical, these intelligent systems enable rapid item retrieval within seconds, minimizing mistakes and accelerating order fulfillment. Features such as interactive touch screens, light-guided picking assistance, wearable devices, and compact monitors help streamline daily operations, ensuring a more intuitive and productive warehouse experience.

Modula Mobile Picking App

- The user interface for picking in complete mobility

The new Android application is built to support full mobility across all manual warehouses managed with Modula WMS. Its clear and easy-to-use interface enables warehouse staff to perform picking and deposit tasks directly from a smartphone with just a few taps, ensuring smooth handling of warehouse operations. The mobile device takes the place of the traditional Copilot, allowing more flexible and efficient warehouse management. When required, the app can also work with a barcode scanner or the integrated camera of the device to streamline warehouse processes in Modula. The software is compatible with Android smartphones running versions 8 through 11.

Pick to Color Cart

-

A Smarter Way to Manage Order Picking

With the release of Modula WMS 3.10.22, managing picking carts is now faster, simpler, and more accurate—thanks to the Color-Guided Picking feature. This intelligent system streamlines cart-based order fulfillment without the need for Put-to- Light hardware, helping reduce picking times and limit errors.

How It Works

Each cart is visually identified by a unique color, which guides the operator step-by-step through the picking process. Operators can assign picking orders to a cart either:

- Manually, by selecting orders directly from the “Picking Orders” section in the WMS interface, or

- Automatically, by letting the system distribute tasks based on cart availability and workload optimization.

Modula picking solutions

-

Easy to set up and intuitive to operate, our picking solutions boost your batch and multi-order process. Pair with Modula automated storage solutions, they further drive order accuracy, efficiency and reliability.

Picking Solutions Benefits:

- Improve picking speed: By decreasing the searching time for items and replacing pick tickets and shipping lists.

- Improve inventory management: Paperless picking solutions offer a real-time view of current and forecast inventory, increasing profitability.

- Increase profitability: An accurate view of inventory helps prevent over-or under-ordering, saving costs and improving overall performance.

- Improve picking accuracy: Light devices guide users, making picking accurated and eliminating errors.

- Simple and intuitive solutions: Computer-aided picking and inventory tracking improves worker effectiveness and satisfaction.

- Easy learning curve to operate: Thanks to a simple and easy-to-follow user guidance, the training period is very short.

Modula Picking Stations

-

The Modula Picking Station is ideal for operations with predetermined put positions.

To handle batch or multiple order processes, the Picking Station keeps everything moving. Use one or several at predetermined put positions. The Picking Station gives you a flexible and accurate way to process more orders in less time. Thanks to paperless picking, there are no more order lists to handle. As a result, the picking process is faster and more efficient.

Designed to meet the needs of any warehouse operations, it easily integrates with both manual or automated handling systems like belt conveyors.

Features:

- Put to Light displays at each order location

- Put to Light for order consolidation

- Multiple order locations

- Clear, easy-to-follow user guidance

- Scan or touch light validation to improve order and accuracy

- Put to Light for batch picking

- Ergonomic design

- Real-time inventory and order updates

Modula Picking Cart

-

Need to move retrievals to different locations? Use the Modula Picking Cart – a Put to Light station on wheels.

The Modula Picking Cart is the ideal picking solution for a paperless batch or multiple order processes where operations need more mobility. With put-to-light display to guide operators, and a wireless connection to the WMS for batch and route optimization, the mobile picking cart increases productivity and accuracy while offering great flexibility.

Designed to meet the needs of any warehouse operation, it easily integrates with both manual or automated handling systems

Features:

- Put to Light displays at each order location

- Put to Light for order consolidation

- Multiple order locations

- Clear, easy-to-follow user guidance

- Scan or touch light validation to improve order and accuracy

- Put to Light for batch picking

- Real-time inventory and order updates

- Ergonomic design

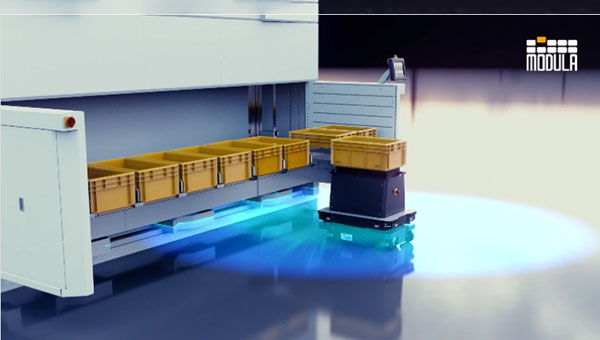

Modula Robotics integrations

-

Modern intralogistics demands efficient material handling, seamless picking and depositing, and user-friendly management through advanced WMS software.

By combining Modula vertical storage systems with robotic automation, warehouses can achieve a new level of efficiency. Smart integration ensures smooth communication between storage technology and robotic components, creating highly optimized warehouse operations that maximize both productivity and available space.

Automation with robotics—whether through warehouse robots, robotic cabinets, or other automated solutions—delivers precision, speed, and reliability. Modula’s robotic integrations are designed to coordinate complex systems, enabling streamlined processes and consistent throughput.

With robotic support, downtime is reduced and productivity rises. Integrated automation transforms warehouses into intelligent hubs where picking, replenishing, and movement tasks are handled with minimal effort. Robots are rapidly becoming indispensable in logistics due to their scalability, versatility, and growing affordability.

Modula solutions can work hand-in-hand with various robotic technologies, including:

- Autonomous Mobile Robots (AMRs)

- Anthropomorphic robots

- Mobile platforms such as MIR (Mobile Industrial Robots)

These integrations make it possible to optimize production flow, supply chain management, and warehouse processes in even the most complex industrial environments.

Thanks to continuous advances in technology, robotic automation is no longer a distant goal— it is already a vital element of warehouse logistics and automated picking today.

Modula Lift with special AMR bay

New application with special bay and comb tray

This innovative solution integrates a Modula vertical storage system with a dedicated bay featuring a comb tray and an autonomous mobile robot (AMR) equipped with a specialized ROEQ module.

The Modula comb tray is engineered to accommodate up to nine boxes. These are automatically managed by the AMR, which retrieves the boxes without human intervention and transfers them directly into the warehouse storage system.

AMR-assisted manual picking

-

AMRs are 100% mobile and autonomous systems that represent an alternative to conveyors when it comes to optimising warehouse processes

Autonomous Mobile Robots (AMRs) are fully mobile and independent systems that provide an alternative to traditional conveyors for optimizing warehouse operations.

To support operators, AMRs can be deployed directly in the bay. In this setup, the AMR collects the material that the operator has picked from the Modula storage system.

Guided by the Copilot system, which specifies the storage location, required quantities, and actions to be performed, the operator retrieves the products from the tray and places them onto the AMR.

The robot then autonomously follows the operator during the picking activity and can continue its workflow by delivering goods to other departments, all without requiring human supervision. This streamlines processes, reduces manual transport, and increases overall efficiency.

Special solutions

-

Our mission is clear: to deliver warehouse storage solutions to companies of all sizes and across every industrial sector. This also means addressing unconventional scenarios and meeting highly specific requirements.

Over the years, we have developed and engineered special applications for businesses that need to store sensitive goods, including electronic components, pharmaceuticals, and food products.

We have also designed fire protection and anti-seismic safety systems to minimize the impact of fires or earthquakes, ensuring the highest level of security for stored materials.

Modula Climate Control

-

All the benefits of a Lift with thermal insulation and refrigeration systems

Need to store products automatically while maintaining a constant temperature? Required to comply with strict safety regulations when handling sensitive goods?

Modula Climate Control is a temperature-controlled warehouse designed to safeguard materials that are sensitive to changes in temperature and humidity.

Based on the structure of a Modula vertical automatic warehouse, the system is enhanced with thermal insulation and refrigeration technology to maintain stable internal environmental conditions for reliable refrigerated storage. The insulated shell is built with polyurethane foam panels that cover every side of the warehouse, ensuring maximum isolation.

The front wall features a thermal break system with multiple independent outward-opening windows, allowing operators to access the full bay without compromising internal temperature.

Depending on the required storage conditions (temperature and relative humidity) and the surrounding environment, the ideal technical configuration can be defined. Modula Climate Control is suitable for frozen storage, cold storage, and controlled-temperature applications—whether used as an automated frozen food warehouse or as a precision refrigerated storage facility.

Modula Clean Room

-

The storage system for clean rooms

Do you operate in clean rooms? Need precise control over the particles entering your storage environment to safeguard your products?

Modula Clean Room is a storage system specifically engineered for clean room operations, designed to minimize the introduction, generation, and retention of airborne particles.

Companies working in semiconductors, hospital equipment, chemical, electronics, or pharmaceutical sectors must comply with strict quality standards. Modula Clean Room provides the ideal solution for these demanding environments, ensuring compliance while protecting sensitive materials.

Modula Fire Fighting

-

Modula FF: the fire fighting system

A fire can be extinguished in different ways, all of which act on the four factors of the “tetrahedron of fire”—the combination that triggers the chemical reaction behind combustion.

Accordingly, there are four main methods to put out a fire:

- Fuel reduction or isolation

- Oxygen reduction or isolation

- Heat reduction

- Blocking the chain reaction of the above factors

The system used in our warehouse fire suppression solution focuses primarily on the fourth factor: blocking the chain reaction. It employs a condensed aerosol of potassium carbonate, which reacts with flame free radicals and disrupts the combustion process.

This automatic fire fighting system uses a completely non-toxic extinguishing agent consisting of ultra-fine solid particles (less than 10 micrometers in diameter). These particles remain suspended in the air for longer and leave significantly less residue compared to traditional extinguishing methods.

When the aerosol density around the flame is correctly calibrated, the extinguishing effect is extremely powerful, ensuring effective fire protection for warehouse environments.

Modula Anti-seismic

-

Modula’s approach to creating a safe warehouse environment combines anti-seismic reinforcement with seismic isolation.

Reinforcement focuses on strengthening the warehouse structure, while isolation separates it from the energy generated by seismic acceleration. Instead of making the warehouse excessively rigid and heavy, Modula concentrated on analyzing seismic motion and its effects—particularly the horizontal component of peak ground acceleration (PGA).

The seismic isolator is only activated during an earthquake. Under normal conditions, it has no impact on warehouse operations, ensuring seamless functionality day to day.

All calculations and simulations for Modula’s anti-seismic systems were validated through testing at Pavia’s Eucentre Foundation, the leading European center for earthquake risk research and training.

Modula WMS: Warehouse Management System

- What is WMS (Warehouse Management System)?

Modula WMS (Warehouse Management System) is the dedicated software developed by Modula to control and optimize every operation inside a vertical warehouse. Far more than an automatic shelving system, it acts as the thinking brain of the warehouse, managing access, picking activities, location handling, and stock levels.

With Modula WMS, complete traceability of all warehouse operations becomes possible. Not only can you track products, but you can also monitor their exact location, analyze movement frequency, and intelligently manage related data such as batch numbers, serial codes, production dates, expiration, and product maturity.

The software also records operator activity, showing who accessed a specific drawer, while supporting advanced features such as slotting (subdividing drawers into compartments), monitoring occupancy volumes, and calculating the degree of saturation for improved warehouse efficiency.

Modula WMS

-

Modula WMS Base is the entry-level warehouse management software, designed for companies starting out with WMS and not yet connected to an ERP or other systems. It comes included with every Modula automated warehouse and can manage up to three workstations, including one server.

Main functions of Modula WMS Base:

- Management of item master data

- Visual tool for warehouse location management

- Control of movements through picking and refilling operations

- Handling of immediate warehouse movement requests

- User management with three levels of hierarchical access

- Physical inventory management within the warehouse

- Manual data import and export to and from ERP systems via fixed-format ASCII files

- Advanced security features that limit access to trays and item codes based on user roles

Modula Software Integrations

-

For companies requiring a complete WMS solution integrated with their corporate ERP systems, Modula WMS Premium is the most advanced package. It includes all the features of WMS Base, plus a wide range of additional capabilities for comprehensive warehouse control.

Main features of Modula WMS Premium:

- Automatic item-compartment allocation and dynamic location management

- Batch management

- Customizable automatic import/export in ASCII, ODBC, Excel, and XML formats

- Material status management

- Pack type management

- Expiry date management

- Advanced user management with configurable authorisations per user

- FIFO (First In, First Out) and sub-code priority materials management (e.g., oldest batch code picked first)

- Justification management for immediate requests

Modula IOT

-

Modula Link is a WMS tool that allows an external host system to directly control a group of Modula OS machines using commands sent through a TCP/IP socket connection.

It functions as a communication server by opening a configurable TCP port and waiting for instructions. When a valid command is received from the host system, Modula Link processes it and sends back a response.

The system can be set up to work with a single client (mono-client) or with multiple clients at once (multi-client).

For example, if the host system requests a tray, it issues the appropriate command. Once the tray is positioned in the bay, Modula notifies the ERP. After the task is completed, the ERP sends a final command to return the tray to storage.

Modula AI Services

-

For collaborators with WMS installed, but who want to manage warehouse movements

Modula Driver is a logistics software package designed for advanced warehouse management through movement orders such as picking, refilling, or inventory tasks.

These orders are usually transmitted via an intermediate database or text file and contain lists of trays to be handled along with their related picking instructions.

Unlike other WMS solutions, Modula Driver does not manage item records, stock levels, or storage locations—these remain under the control of the company ERP. Instead, it ensures the ERP has accurate information about the trays to be moved and the items stored within them.

For every operation, the ERP sends details of the required tray, which Modula Driver processes and forwards. Operators can then view incoming orders on the Modula console and choose which ones to execute. On the picking screen, the order details are displayed, and operators can confirm the action. The confirmed quantity can be adjusted if requirements change or stock is insufficient.

Once the order is finalized, Modula Driver communicates the result back to the ERP, which then continues its workflow with updated data.