- Offer Profile

-

We bring easier automation to the world’s warehouses

Our automated warehouse solution is totally flexible. And integrated. And scalable. Start with one robot, or one hundred. Then scale up or down as you need. And we’ve built a market-leading, integrated operating system that seamlessly plugs into all known warehouse management systems. It’s as easy as that. Because we want every warehouse to be more productive, more efficient and more successful with automation.

Warehouse Solutions

Our warehouse robots bring easier automation to the world's warehouses.Autonomous. Scalable. Easy

Meet the family the Movu Solutions portfolio is built around a range of innovative sub-systems, which are designed to provide easier, scalable, flexible and energy efficient solutions that are accessible for all kinds of warehouses and quick to roll out.

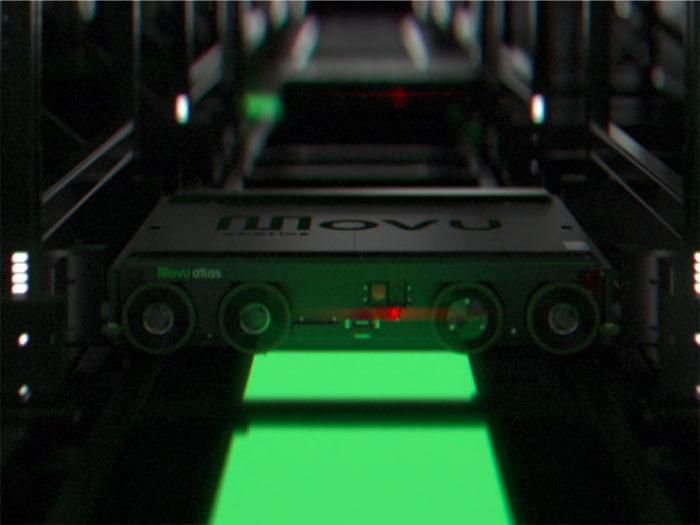

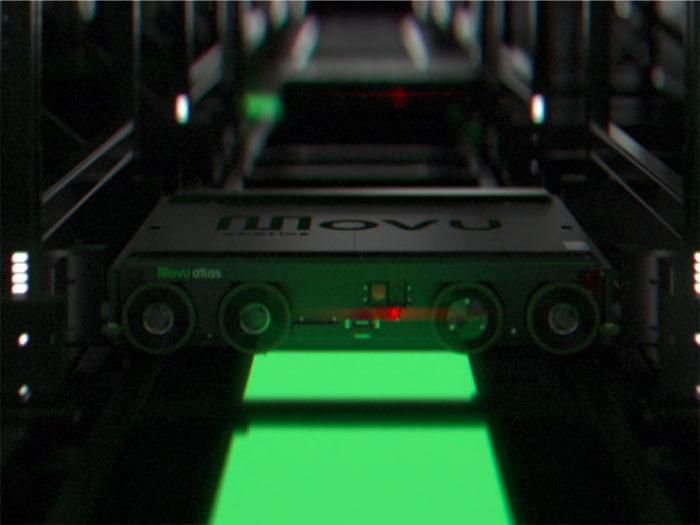

Atlas

-

Atlas. A strong solution to optimise storage space.

The efficient, fast and reliable way to automate your pallet store.

Introducing atlas. The state-of the art solution to maximise pallet storage space by minimizing the number and width of driving aisles.The integrated atlas system comprises a specially designed storage and a flexible number of shuttles, controlled automatically by smart software.

Shuttles move around the warehouse using 2 independent sets of wheels and can carry pallets of up to 1,500 kg

- Max loads carried: 1500kg

- Min temp: -25° C

- Max temp: +45° C

- Max speed: 1.4 m/s

- Acceleration: 0.4 m/s2

- Deceleration: 0.5m/s2

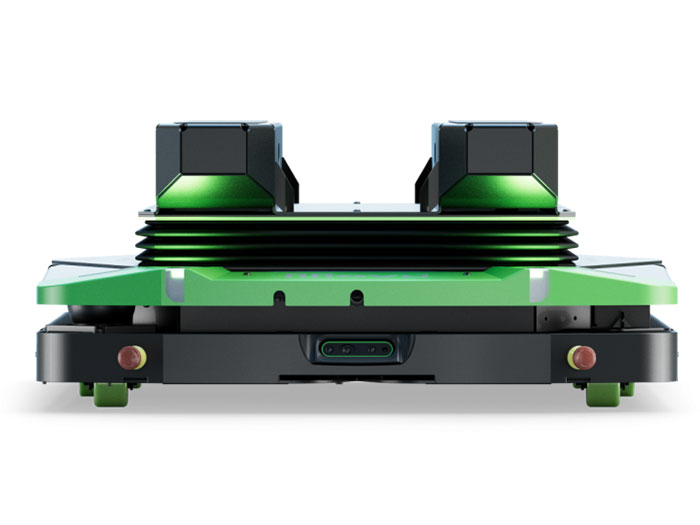

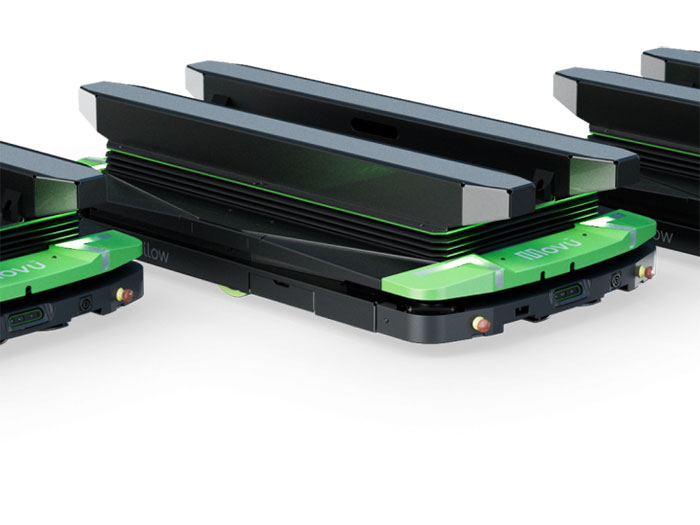

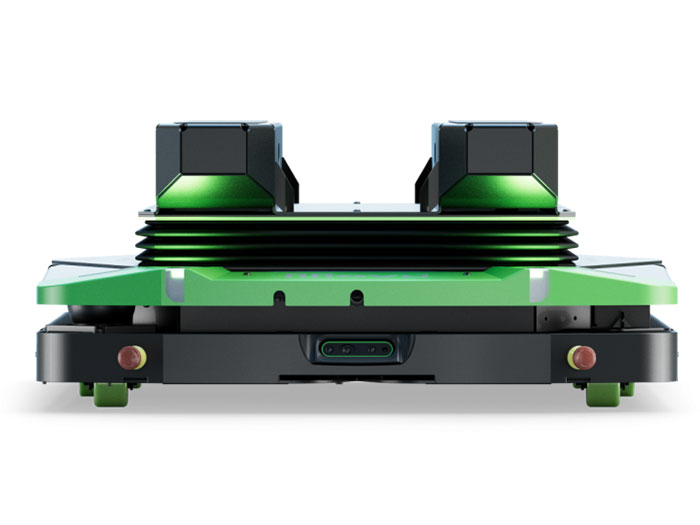

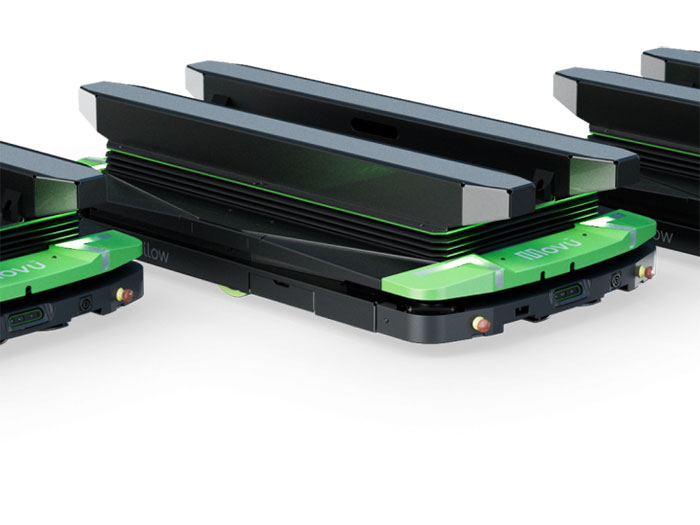

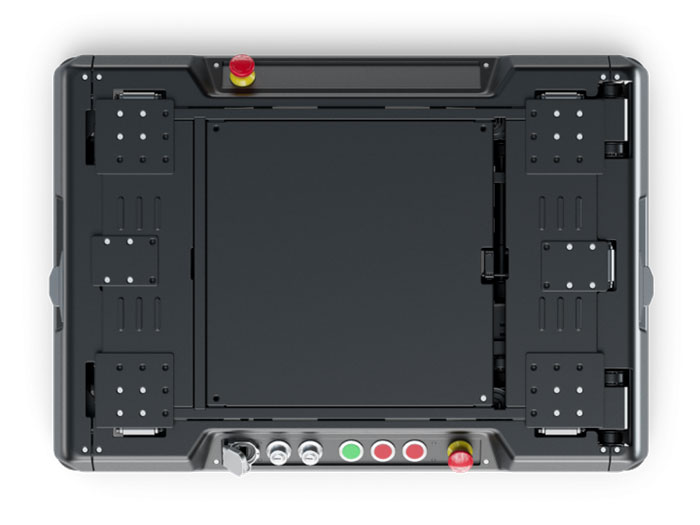

Ifollow

-

It’s called ifollow. But it’s more of a leader.

The fast, flexible way to automate your warehouse.

Introducing ifollow. The ready- made system of autonomous mobile robots (AMRs), powered by smart, plug-in software.Even if your warehouse has static or moving obstacles, ifollow gets around them. Shifting loads of up to 1.2 tons, without needing any new infrastructure.

It moves effortlessly over your existing surface, to and from your existing rolls, palettes and frames.

- Battery life: 8 hours

- Charging: 2 Hours

- Payload capacity: 1200 kg

- 360° secured technology

- 24 hours setup time

- 2 m/s top speed

escala

-

escala by name. Scalable by nature.

Your fast and simple robotic goods-to-person fulfillment system.

Introducing escala. The world's most flexible automated storage and retrieval solution. Escala is a next-generation 3D robot that can move in three dimensions.It moves smoothly, autonomously and is rapidly expandable.

- > 5 Storage containers

- 24/7 Charging

- All kinds of standard bins

- 50 kg Payload capacity

- 50 m2 Footprint

- > 300 mm Euro bin handling

eligo

-

Movu eligo. The (automatic) piece picking robot

The fast, reliable and intelligent way to streamline your order fulfillment process.Movu eligo. Fully automatic bin picking, from a single-SKU source bin into multiple mixed-SKU destination bins. Around the clock and with higher pick accuracy and quality.Achieves 600 picks per hour, handling goods of any kind, from 1cm to 30 cm up to 2 kg. With flexibility to handle changing product mixes, this leads to greater accuracy and a strong return on investment (ROI).

For end-to-end automated storage and picking, Movu eligo integrates with Movu escala. Advanced software, machine vision and intelligent grippers gently grasp items from bins retrieved by Movu escala, placing them in delivery bins.

- 2kg Max load

- 30 cm Pick item dimension

- 600 items/hr

- > 99% Pick accuracy

- 24/7 Run-time

- AI Intelligent handling

Software

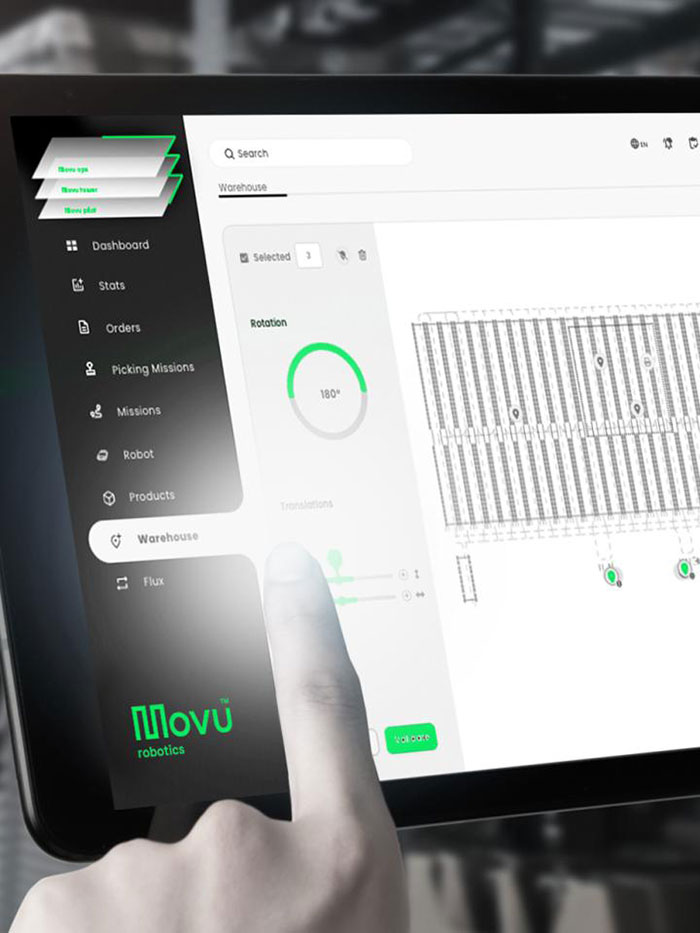

Movu Warehouse Execution System (WES)

-

For automated warehouse management

Software for managing shuttles and autonomous mobile robots (AMRs) in warehouses is a crucial tool for optimising the operation and control of these systems. It facilitates the efficient management, coordination and monitoring of shuttles and robots, ensuring a smooth flow of materials.

Movu follows a clear philosophy with its software: our customers should be able to work with it immediately and without any problems. That’s why we only have one software interface for integration into the customer's system; the rest is handled internally by our modular software.

- Movu ops: Software for managing all operations. Movu ops takes the orders from the higher-level customer system and prepares them for Movu tower.

- Movu tower: Checks the available resources, selects the most suitable shuttle or AMR, and then sends the order to Movu pilot.

- Movu pilot: Ensures the execution of the order at the level of the individual shuttle or AMRs.

Applications

-

The right solution for every application area

From goods receiving to storage, from order picking to cold storage, from space optimisation to the loading zone, from pallets to containers: Movu solutions make automation easier – and your warehouse operations more flexible, more productive and more profitable.

Picking

-

Boost your order picking productivity through automation

Accurate, flexible and rapid order picking is increasingly becoming a critical factor for a successful warehouse. To achieve this, warehouse operators must overcome four key challenges:

- Labour shortages: The labour market is tight and is set to remain so for the foreseeable future. In addition, workers are not available 24/7 or are absent due to holidays or illness.

- Worker stress and shortage: Order picking is a physically demanding job, and fewer and fewer people are willing to do such work.

- Increased peak times: Seasonal peaks and the increase of promotions and sales days such as "Black Friday" require maximum flexibility in order picking.

- Smaller units: The trend towards convenience products means smaller and smaller units that need to be picked, leading to fewer pallet loads and more small, frequent picking orders.

Fixed systems, such as conveyors, are expensive, material-intensive and require extensive electrical and often structural work. They are inflexible and take up a lot of space. Automated guided vehicles (AGVs) are also inflexible in many ways, as they are usually restricted to pre-defined routes.

The alternative is intelligent robotic systems that adapt to your warehouse structure and budget. As a leader in robotic solutions, Movu Robotics can help you to significantly boost your picking productivity through automation.

Staging

-

Make better use of staging areas with automation

A staging area is a zone within a warehouse, usually free of racking and located in front of the loading docks. This is where goods are temporarily placed on the floor until they are transported or loaded elsewhere. The staging area can be used for various purposes, such as receiving goods, shipping or other functions such as cross-docking.

- Goods receiving area: In this zone, all necessary checks of the incoming products are carried out on the staging area. This includes, for example, checking whether the goods are free of defects and comparing them with the information in the order documents.

- Shipping area: Here the goods are sorted according to orders or transport routes and usually then loaded onto trucks. In addition, staging areas are sometimes used for other tasks, for example as picking zones for the preparation of orders that are subsequently consolidated, which can further complicate the efficient management of these areas.

Dense storage

- Dense storage: More storage without increasing floor space

The demand for warehouse space is growing unabated. As a result, property prices are exploding, especially in prime locations. The situation is further exacerbated by dwindling supply. In the USA, for example, the supply of warehouses has reached its lowest level in more than two decades.

So, it becomes necessary for warehouse operators to make the most out of the available space. This is often compounded by the fact that processes are also becoming increasingly demanding due to the expansion of online retailing and an omni-channel policy. Compacting warehouse space, while at the same time increasing efficiency in the storage and retrieval processes – is this at all compatible?

Requirements for an automated high-density warehous:

- Access: Dense storage systems can be challenging to access and retrieve items. It must be ensured that the correct pallets or containers are retrieved at all times.

- Space optimisation: Dense storage systems are designed to maximise storage capacity, but this can also be a challenge. Many automated storage systems are rectangular and therefore cannot use certain areas of a building.

- Scalability and flexibility: As your business grows, your storage system should be able to grow with you to accommodate new stock or meet changing storage requirements.

- Integration with other warehouse processes: Dense storage systems should be able to integrate seamlessly with other warehouse processes to ensure maximum productivity.

Cold Chain Automation

-

Cold chain automation with Movu robotic solutions

Cold chain logistics comprises the technologies and processes that ensure the safe transport of temperature-sensitive goods along the entire supply chain. The global cold store market is estimated at around USD 139 billion and is expected to grow by an average of 17 percent per year until 2030. Experts estimate that since the start of the coronavirus pandemic alone, consumption of chilled and frozen products has increased by ten percent.