- Offer Profile

-

THIS IS HOW YOU CHANNEL COMPRESSED AIR.

ITV offers you the optimum conditions, whatever you want to move. The basis of pneumatic controls that change everything. We put you on track to reach your goals!

Hydraulic & Pneumatic fittings, valves, silencers, filters and regulators

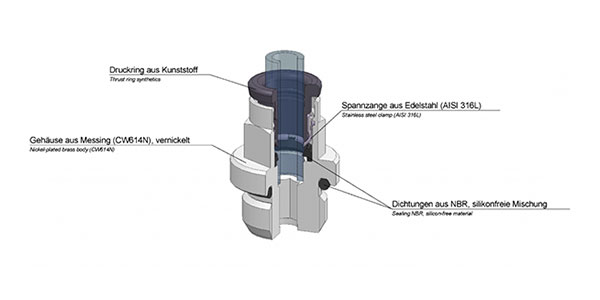

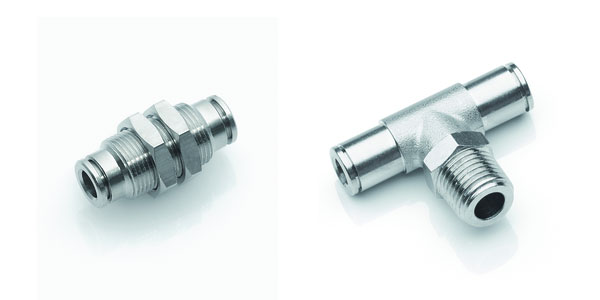

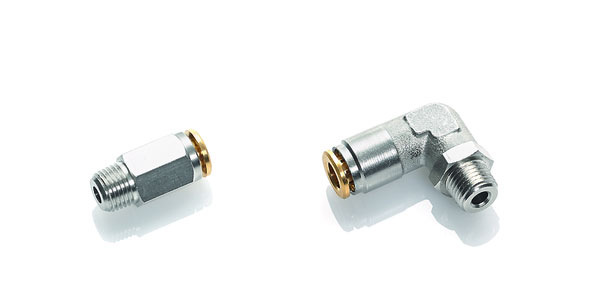

ipso Push-in fittings

-

- Push-in system with stainless steel elastic clamp

- Tube assembly with one movement

- For tubes in various materials (PU, PA)

- Small-scale and low weight

- Silicon-free O-rings

- O-ring in sealing channel – for rough surfaces

- Modular, flexible structure

- Hexagon socket for easy assembly

Operating temperature -20°C bis +70°C

-20°C bis +80°CFor fittings with PVC seal

For fittings with NBR O-ringsOperating pressure Up to 16 bar Dependent on the pressure range of the tube used Vacuum max 98% Materials Brass housing, nickel-plated

NBR seals

Stainless steel clamp

Black thrust ringCW614N and CW617N

silicone-free mixture

AIAI 316L

plasticThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, DIN ISO 261Cylindrical with O-ring seal Medium Lubricated and non-lubricated compressed air Mediums which are compatible with

the component materialsTubes For tubes in line with ISO 14743

Tolerances for external Ø

4 to 8: ±0.1

Tolerances for external Ø

10 to 14: ±0.15 (PU)

10 to 14: ±0.1 (PA)Recommended materials, PU, PA

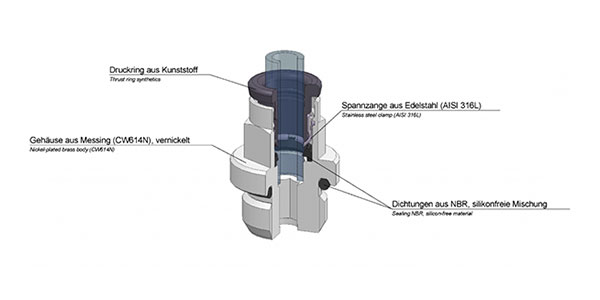

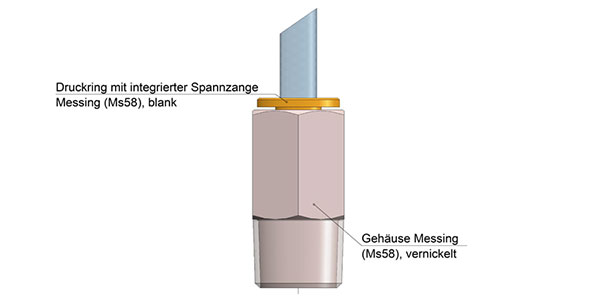

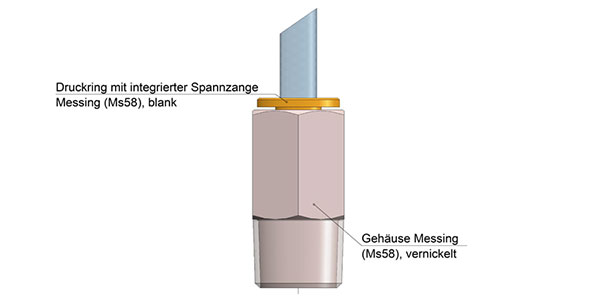

ipso Push-in fittings MR

-

- Push-in system with elastic clamp made of stainless steel

- Thrustring made of brass, nickel-plated, for many applications

- Tube assembly with one movement

- For tubes in various materials

- Small-scale and low weight

- Silicon-free O-rings

- O-ring in sealing channel – for rough surfaces

- Modular, flexible structure

- Hexagon socket for easy assembly

Operating temperature -20°C to +70°C

-20ºC to +80°CFor fittings with PVC seal

For fittings with NBR O-ringsOperating pressure Up to 16 bar Dependent on the pressure range of the

tube usedVacuum max 98% Materials Brass housing, nickel-plated

NBR seals

Stainless steel clamp

Brass thrust ring, nickel-platedCW614N and CW617N

Silicon-free

AISI 316L

CW614NThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, DIN ISO 261Cylindrical with O-ring seal Medium Lubricated and non-lubricated

compressed airMediums which are compatible with the component materials Tubes For tubes in line with ISO 14743

Tolerances for external Ø

4 to 8: ±0.1

Tolerances for external Ø

10 to 14: ±0.15 (PU)

10 to 14: ±0.1 (PA)Recommended materials, PU, PA

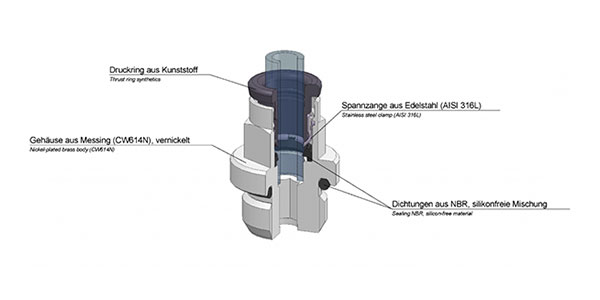

ipso-FKM-Push-in fittings

-

- Push-in system with stainless steel elastic clamb

- Tube assembly with one movement

- For tubes in various materials (PU, PA)

- Small-scale and low weight

- FKM O-rings for high temperatures

- O-ring in sealing channel – for raw surfaces

- Modular, flexible structure

- Hexagon socket for easy assembly

Operating temperature -20°C to +150°C Dependent on the tube’s temperature characteristics Operating pressure Up to 16bar Dependent on the pressure range of the tube used Vacuum max 98% Materials Brass housing, nickel-plated

FKM seals

Stainless steel clamp

Brass thrust ring, nickel-platedCW614N und CW617N

silicone-free mixture

AISI 316L

CW614NThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, DIN ISO 261Cylindrical with O-ring seal Medium Lubricated and non-lubricated compressed air Mediums which are compatible with the component materials Tubes For tubes in line with ISO 14743

Tolerances for external Ø

4 to 8: ±0.1

Tolerances for external Ø

10 to 14: ±0.15 (PU)

10 to 14: ±0.1 (PA)Recommended materials: PU, PA

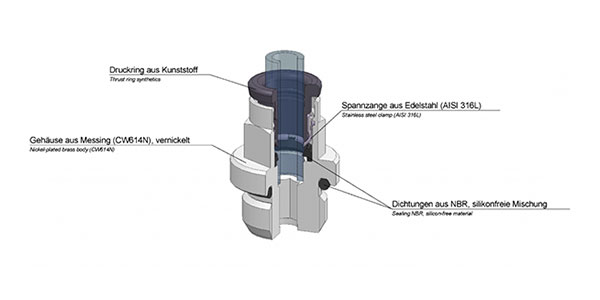

STX – Push-in fittings stainless steel

-

- Fitting 100% stainless steel 1.4401

- Tube assembly with one movement

- For tubes in various materials (PU, PA)

- Small-scale and low weight

- FKM O-rings for high temperatures

- Modular, flexible structure

Operating temperature -20°C to +150°C Operating pressure Up to 16bar Dependent on the pressure range of the tube used Vacuum max 98% Materials Stainless steel housing,

FKM seals

Stainless steel clamp,

Stainless steel thrust ringAISI 316L

silicone-free mixture

AISI 316L

AISI 316LThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, DIN ISO 261Cylindrical with O-ring seal Medium Lubricated and non-lubricated compressed air Mediums which are compatible with the component materials Tubes For tubes in line with ISO 14743

Tolerances for external Ø

4 to 8: ±0.1

Tolerances for external Ø

10 to 14: ±0.15 (PU)

10 to 14: ±0.1 (PA)Recommended materials: PU, PA

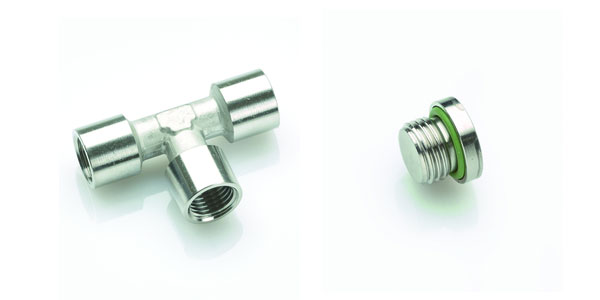

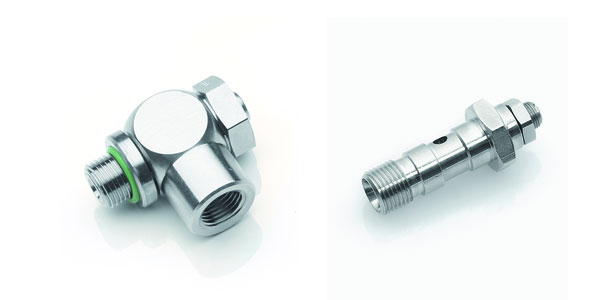

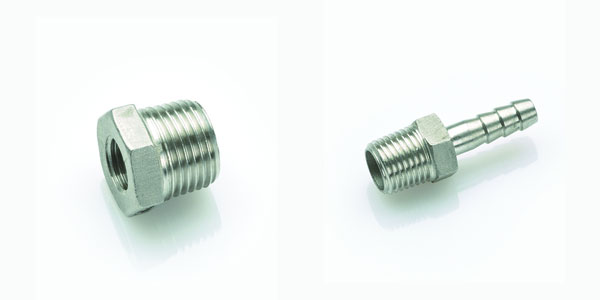

Stainless steel connections

-

- Pure stainless steel fitting

- For challenging applications

Operating temperature -20°C to +150°C Operating pressure Up to 150bar Materials Fittings made of stainless steel 1.4404 (AISI 316L)

Seals made of FKMThread DIN 3852

DIN 3858Application Pneumatics, food industry, chemical and pharmaceutical industry

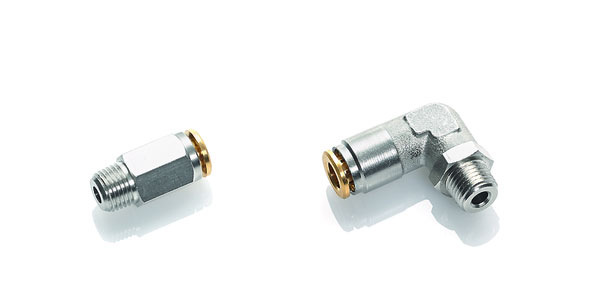

HDS – High pressure push-in fittings

-

- Fitting for the high-pressure range

- Tube assembly with one movement

- Release ring with integrated clamp

- For tubes in various materials

- Small-scale and low weight

- NBR O-ring

- Modular, flexible structure

Operating temperature -40°C to +150°C Operating pressure Up to 250bar Dependent on the pressure range of the tube used Materials Brass housing, nickel-plated

HNBR seals

Brass socket

Brass thrust ring, polished

Parallel thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, UNI 7707

Lubricating oils, greasesCW614N and CW617N CW614N

CW614NThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. thread, UNI 7707Cylindrical with O-ring seal Medium SLubricating oils, greases Mediums which are compatible with the component materials Tubes Recommended dimensions:

4 mm = 4×1.5

6 mm = 6×3Tolerances: ±0,05mm

Recommended materials: PA6-6, tubes

suitable for high pressures

Functional fittings

-

- Throttle and non-return valves with various tube connection options

- Brass, aluminium and plastic throttle valves

- For various applications

Operating temerature -10°C to +70°C

0°C to +70°CNon-return valve, Quick exhaust valve

Valves in generalOperating pressure max. 10bar

0,2 bis 10bar

0,3 bis 10barFlow regulators

– with banjo body

– made of plastic

– block shaped

Bidirectional flow regulators, pressure control

valve, pneumatic switch, slide valve

ipso 032, 033

Quick exhaust valve

VSRMaterials Body, brass, nickel-plated (Ms58)

Body, plastics

Body, aluminium

O-Ring, NBR

Sealing, plastics

Membrane, plasticsFlow regulators with banjo bodies, straight

unidirectional connection, non-return valves,

slide valve, quick exhaust valve

Flow regulators 041, 042, 043

Unidirectional flow regulator (block shaped)

Valves in general

Valves in general

Quick exhaust valveThreads cyl. threads DIN EN ISO 228

con. threads DIN EN ISO 10226 (DIN 2999)

metr. threads ISO 261Medium Lubricated and non-lubricated compressed air

Standard fittings Type 100

-

- Brass fittings

- For connections from M5 to G1“

- High resilience

- Nickel-plating for corrosion protection

Operating temperature max. +150°C Dependent on the temperature range of the tube/pipe used Operating pressure Up to 60bar Dependent on the pressure range of the

tube/pipe used and the temperature usedMaterials Brass, nickel-plated or polished CW614N and CW617N Thread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (ISO7 / DIN 2999)

Metr. thread, DIN ISO 262Medium Pneumatic, oil-hydraulic and hydraulic circuits

Compression Fittings Type 200

-

- Brass fittings

- High resilience due to cutting ring and nut

- Cutting rings in line with DIN 3861

- Swivel nuts in line with DIN 3870

- Nickel-plating for corrosion protection

- For pipe diameters from 4 mm to 18 mm

- Connection sizes from 1/8“ to½“

Operating temperature max. +150°C Dependent on the temperature range of

the tube/pipe used and the temperature usedOperating pressure Up to 60bar Dependent on the pressure range of the

tube/pipe used and the temperature usedMaterials Body and swivel nut, brass, nickel-plated

Cutting ring, brass polishedCW614N and CW617N

CW614NThread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (ISO 7 / DIN 2999)Medium Pneumatic, oil-hydraulic and hydraulic circuits Tubes/pipes Suitable for metal pipes (copper, brass, steel, etc.)

and for plastic pipes with inner reinforcement

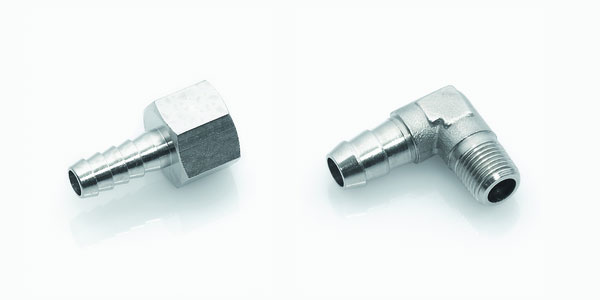

Push-on fittings Type 300 and 400

-

- Brass fittings

- Nickel-plated for corrosion protection

- For various applications

- Rotating fittings, tilting fittings

- O-ring seal in parts

- For tube diameters from 4 mm to 12 mm

Operating temperature -20°C up to +80°C (NBR-Sealing)

-20°C up to +70°C (PVC-Sealing)Dependent on the tube’s temperature characteristics Operating pressure Up to 20bar Dependent on the pressure range of the tube used Materials Body and swivel nut, brass, nickel-plated

NBR O-rings

PVC sealsCW614N and CW617N Thread Cyl. thread, DIN EN ISO 228

Con. thread, DIN EN 10226 (DIN 2999)

Metr. Thread, DIN ISO 262Cylindrical with O-ring seal Medium Pneumatic, oil-hydraulic and hydraulic circuits Tubes Suitable for various plastic tubes Also for reinforced PVU synthetic fibres

Brass fittings

-

- For various applications

- For connections from M5 to 2“

- With nickel-plated or polished surface

Operating temperature max. +150°C Operating pressure Up to 60bar Materials Brass (CW614N/ CW617N) nickel-plated and polished Thread DIN 3852

DIN 3858Medium Air, water, oil, steam, etc.

Stainless steel fittings

-

- High requirements covered due to stainless steel

- For various applications

- For connections from 1/8“ to 2“

Operating temperature max. +200°C Operating pressure Up to 16bar Materials Stainless steel AISI 316 Thread DIN 3852

DIN 3858

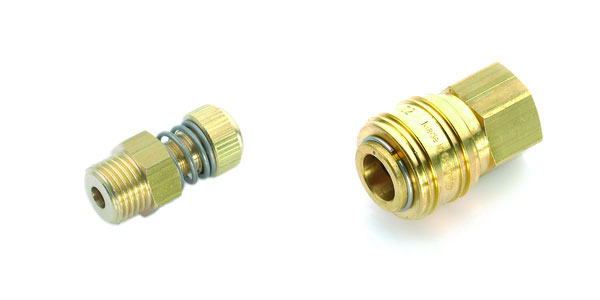

Silencers – Manometers – Couplings

-

- Silencer for various applications

- Versatile thanks to various materials

- Connection sizes from M5 to G1“

- Reduction of noise level

SILENCER Operating temperature depending on the type of silencer Materials Sintered bronze (50µm)

Brass (CW614N)

Stainless steel (AISI 316L and AISI 304L)Thread Cyl. thread, DIN EN ISO 228

Metr. thread, DIN ISO 262Medium Compressed air MANOMETRE Connection back or bottom Ambient temperature -40°C to +60°C Display ranges Various, max. 0-60 bar Materials Plastic housing

Plastic inspection glass

Brass connectiongThread G1/8“ and G1/4“

Connection on the back or underneathNominal sizes 40, 50, 63 Medium Gaseous, liquid, non-viscous and

non-crystallising measuring agents that do not

attack the copper base alloysCOUPLING Handed couplings DN5 or DN7,5 Operating temperature -20°C to +100°C Operating pressure Up to max. 35 bar Materials Brass body (CW614N)

Stainless steel springs and snap rings

Perbunan sealNominal sizes DN 5 and DN 7.2 Unilateral seal Thread Cyl. thread, DIN EN ISO 228 Medium Compressed Air

Water

Tubes

- Various materials for different applications

- Broad range of colours (e.g. for identifying different mediums)

- Roll lengths 25 m, 50 m and 100 m

PA-POLYAMIDE

– Flexible

– Easy to lay

– Low weight

– Good UV resistance

– High abrasion resistance

– Water-resistant

– Good temperature resistancePU-POLYURETHANE

– Classic pneumatic tube on polyester basis

– High pressure-resistance

– Good aging characteristics

– Flexible

– Good resilience

– Good tear resistance

– High abrasion resistance

– Good cold flexibilityPU-POLYURETHANE, FLAME-RETARDANT

– Self-extinguishing in case of fire

– Fluorine and halogen-free

– Free of paint adhesion inhibitors

– High abrasion and chafing resistance

– Listed from V2 to V0 in combustibility class UL94VPE-POLYETHYLENE

– Low weight

– Good shock resistance

– Largely resistant to acids, alkalis and saline solutionsASS-PU TUBE

– Antistatic

– Special polyurethane tube

– Surface resistance < 104Ω

– Pressure-resistant

– External calibration

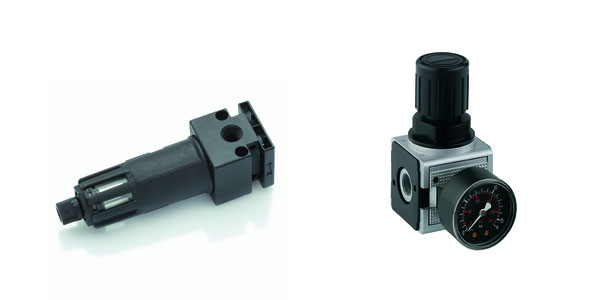

FRL Standard

-

- Robust design

- Modular structure

Operating temperature Up to +50°C Operating pressure Max. 25 bar, depending on design Materials Body made of aluminium pressure die-casting

Cup made of metalThread DIN 2779 Connection sizes G1/4“ to G1“ Medium Compressed air

FRL Special Series

-

- High performance data

- Modular structure

- Simple handling

Operating temperature Up to +50°C Operating pressure Max. 16 bar, depending on design Materials Body made of zinc pressure die-casting

Cup made of plasticThread DIN 2779 Connection sizes G1/8“ to G1“ Medium Compressed air

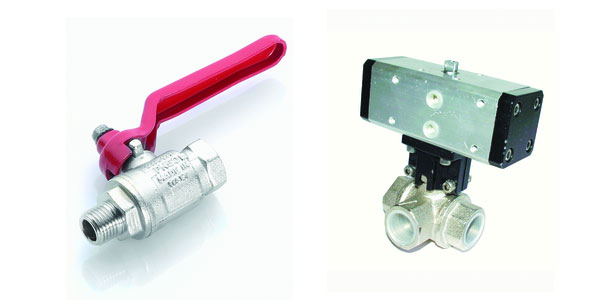

Ball-valves

-

- Various lines for flexible applications

- Mini ball valves also with plug connection

Magnet valves

-

- 2/2-way design

- Direct acting

- Positivley controlled

- Pilot control

Operating temperature -10°C to +90°C

-10°C to +140°CNBR

FKMElectrical connection For PG9/ PG11 connector in line with ISO 4400 Protection class IP65 When using a connector Materials Brass housing (CW617N)

Valve seat made of brass (CW617N)

Interior components made of stainless steel

Sealing material made of NBR or FKMThread Cyl. thread, DIN EN ISO 228 Application Compressed air, neutral gases, non-viscous

and neutral mediums