- Offer Profile

- A Wide Range of Products

and Services

With an ever-expanding catalogue of over 12,000 references, we offer a wide range of products for industrial automation (pneumatic components) as well as fluid control components (solenoid and pressure operated valves). Their reliability, sturdiness, performance and ease of installation are qualities for which they are highly recognised.

Solenoid and Pressure Operated Valves

-

General service, pressure operated, miniature, process, dust collector, proportional valves & more!

ASCO solenoid valves control critical flow of air, gas, water, oil, and steam in applications spanning numerous industries. Our portfolio ranges from two-position on/off valves to flow control systems that impact thousands of users. ASCO's solenoid power management technology sets a new industry standard for reliability and power consumption, accepting both AC and DC voltages while improving performance. These 2-way, 3-way and 4-way solenoid valves can handle most fluid control applications in all commercial and industrial environments. These include ATEX and IECEx certified valves for use in hazardous areas.

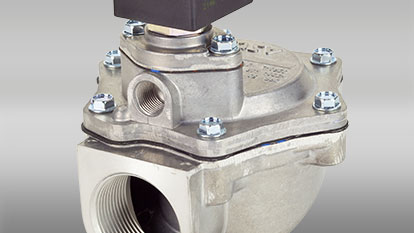

General service solenoid valves

-

ASCO General Service Valves control the flow of neutral gases. They are known for their long life and fast response time.

ASCO offers the world’s largest selection of 2-way, 3-way and 4-way solenoid valves, designed to handle the most demanding fluid control applications. The vast majority of ASCO solenoid valves can be used across many applications in many industries. These valves are commonly called general service valves as they are not designed for a specific application.

ASCO general service valves are available as Normally Closed (NC) and Normally Open (NO). They can also be direct acting and internally piloted.

Please see below our wide selection of ASCO General service valves.

Solenoid valves for dust-collector systems

-

Performance and cost-effectiveness are essential for dust collector systems

What makes ASCO different is its unique combination of quality, performance and value with quick shipment for ensured availability as well as consistent technical support and service for easy assembly, reliable operation and efficient maintenance.

For decades, we've been a leading supplier to original equipment manufacturers (OEMs) and to end users of dust collector systems in a wide range of industries, including the following:

- Concrete Processing

- Grain, Agriculture and Feed

- Metal Working (Abrasive Blasting)

- Food Processing

- Foundries

- Life Science

The ASCO Valve Dust Collector Series are high-flow fast-opening 2-way valves, pilot valves, pilot valve enclosures, and bulkhead fittings that have been specially designed for use in dust collector systems.

Power Pulse Valves

Power Pulse Valves are especially designed for dust collector service applications, combining high flow, long life and extremely fast opening and closing.

Tank Systems

Tank Systems offer highest peak pressure and best flow performance operating features for dust collector applications.

Pilot Valve Boxes

Pilot Valve Boxes with direct operated, integrated pilot valves are especially designed for the remote control of pulse valves.

Sequencers

Sequencers are especially designed for the control of solenoid valves in dust collector systems.

ASCO Micro-Miniature Solenoid Valves

-

ASCO Miniature Valve products include a complete line of general service, isolation, pinch, proportional valves & manifold assemblies

ASCO miniature valves are used for the precise and reliable control of liquids and gases in medical equipment, analytical instrumentation, and industrial applications.

ASCO Miniature Valve Products are assembled and 100% factory tested in an ISO Class 8 equivalent cleanroom.

In addition to our comprehensive catalogue product offering, ASCO has the ability to create customized assemblies. Whether you need a minor modification of a catalogue product or a complete flow control solution, ASCO's trained sales and engineering teams are ready to assist.

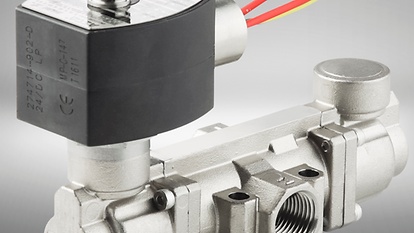

Process Valve Automation

-

ASCO solenoid valves for process valve automation include a complete line of solenoid valves and complete solutions for the control of your actuator and process valve

ASCO solenoid valves are used for the reliable control and automation of actuators installed on process valves.

Our valves are SIL capable and certified to meet the needs of the process industry. They are available with ATEX, CUTR and many other global and local certifications. You are able to select valves that are suitable for your application by using the refiners on the page. You can select low power, low temperature, hazardous area protection mode or functional safety. We also offer direct mount Namur valves for a simpler process valve automation solution.

In addition to a comprehensive valve range we offer complete, certified, and ready-to-install solutions, including the Actuator Control System (ACS) and Redundant Control System (RCS). We also have the ability to create customised assemblies in order to meet the requirements of your application. Whether you need a minor modification of a catalogue product or a complete flow control solution, Emerson's trained sales and engineering teams are ready to assist.

See below the complete range of ASCO solenoid valves for process valve automation.

Solenoid Valves for Fuel, Oil and Gas

-

ASCO provides the broadest line of solenoid valves designed to control the flow of fuel gas, liquid propane and all grades of fuel oil used in combustion applications such as: industrial furnaces, ovens, kilns, incinerators, burners and boilers.

ASCO Solenoid operated valves that handle combustion system pilot, main line fuel shutoff and control needs. These valves are available in 2-way normally closed, normally open, manual reset, and 3-way diversion. ASCO valves are available in brass, aluminium, and stainless steel with Features including, pipe taps, visual indication, EN 161 approved, and pipe connections from G1/8" to G1". Most valves are rated for -40ºC service for outdoor installation in extreme cold climates.

ASCO Proportional Technology

-

The ever-increasing demand for high quality, precision, productivity, ease of handling, user friendliness, service etc. calls for high standards from operating and manufacturing equipment and machines. High standards can only be achieved if physical variables (e.g. temperature, pressure, force, velocity, torque etc.) are precisely adjusted to the respective operating conditions, i.e. a continuous adjustment of these variables is the important factor.

There are many different designs and styles of proportional valves for different operating pressures and flow rates, with either electric or electro-pneumatic actuation. The combination of electronics and mechanics in proportional valves offers ideal performance for many industrial applications.

Nuclear Solenoid Valves

-

ASCO offers a complete line of nuclear qualified products

The trusted choice for nuclear power

ASCO is the global leader in nuclear-qualified solenoid valves for nuclear power plants. The ASCO heritage of leadership in this field began with the nuclear industry’s inception. Original equipment manufacturers (OEMs), architect engineers, project managers, and utility engineers rely on us for all their nuclear power projects — from grassroots construction to life extension to modernisation and power uprates.

Our nuclear-qualified and critical-application solenoid valves, pressure and temperature switches, Hydramotor® actuators, and complete engineered valve solutions provide proven service in key safety and balance-of-plant applications, including the following:

- Emergency core cooling systems

- Emergency generator systems

- Steam generator feed water systems

- Containment sampling systems

- Auxiliary feed water systems

- Liquid radiation waste systems

- Turbine bypass systems

Pressure Operated Valves

-

ASCO pressure operated valves uses auxiliary compressed air or a hydraulic source to operate the valve, these valves enables reliable & accurate control in even the most demanding applications, they can be used to control a wide variety of media types.

Pressure operated valve offering include :

- Qualified for long service life

- Robust design particularly recommended for use with steam or corrosive fluids

- High flow rate

- Process safety, anti water hammer design

- Wide range of materials, options & certifications

- Area saving, energy saving (the functional volume of the piston actuator are two to three lower than those of quarter turn valves)

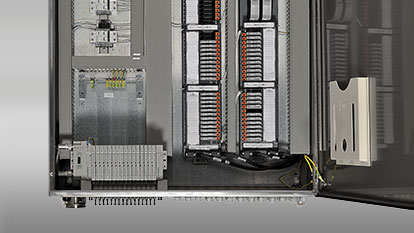

Integrated Solutions

-

Customised pneumatic and electro-pneumatic control assemblies

ASCO offers customised pneumatic and electro-pneumatic control assemblies designed to solve the unique needs of our customers across a wide range of industries. We provide complete fluid automation solutions for process control and machine automation applications.

Valve Monitoring and Position Sensing

-

Switch Boxes and Proximity Sensors

Emerson valve control and position sensing technologies provide absolute assurance in the most challenging applications. These highly reliable final control technologies help you regulate and isolate your process with certainty. The TopWorx and GO Switch product portfolio will help you accomplish this goal.

Switch Boxes

-

With a universal design, modular components, and global certification, there is only one choice when it comes to actuator switch boxes...TopWorx!

The TopWorx switch box family of products combines our design and manufacturing expertise with the best switchbox, switchbox enclosures, bus networking, sensor, and solenoid valve technology available to create the finest actuator switch boxes in the market. TopWorx switch boxes are designed to provide the best fit-for-purpose approach in a wide range of process, application, and service conditions, regardless of actuator / valve type or manufacturer.

Our portfolio of TopWorx D-Series and T-Series products ensure safety, reliability, performance, and service life objectives are met. Our modular design and worldwide certification enables easy model and option selection, to reduce complexity and drive standardisation.

TopWorx D-Series valve controllers are certified for use in every world area. They carry IECEx, ATEX, UL, and CSA certification in a single model, making it easier for global customers to standardise across plants in all world areas.

TopWorx T-Series switchboxes deliver outstanding value by providing full functionality in compact, direct-mount enclosures.

Proximity Sensors

-

The GO™ Switch proximity sensor is the all in one position sensor and limit switch.

GO proximity sensors are rated for use in nuclear power plants, explosive atmospheres, high temperature environments, under water and in all other locations. They enable process management and control under the most demanding conditions while providing higher reliability, cost savings and less down time.

Hazardous Area Certified

Proximity sensors are suitable for use in Flameproof/Explosion Proof, Non-Incendive, Intrinsically Safe hazardous areas with IECEx, ATEX, CUTR, InMetro, UL, CSA, JIS, KOSHA, and NEPSI.General Purpose

Quality engineered products that meet ordinary location requirements. Suitable for use in multiple industries, such as automotive, marine, military vehicles, manufacturing, amusement parks, material handling, gaming and entertainment, and heavy equipment. Setting the standard for reliable performance.Nuclear Qualified

Qualified and tested to meet AP1000, IEEE RCC-E Candu KHNP, TBE/KBE and other Global Nuclear requirements. Designed for long-life dependability in containment LOCA, containment non-LOCA (Harsh Duty), and Mild duty applications.Extreme (High and Low) Temperature

Rated for continuous operation in high temperatures up to 204°C. Especially useful in steam turbines as well as high heat boilers, dryers, steel processing, and aluminium die-casting. Extreme low temperatures as low as -60°C.Submersible

Available with subsea connectors for continuous submersion. GO™ Switch submersible proximity sensors are submersible up to depths of 7,010m/23,000ft and offer trouble-free position sensing in applications such as offshore oil platforms, lock and dam gates, ships and vessels, pin placement detection, wastewater rendering areas, bilge level, high pressure washdown, draw bridges and subsea valve position monitoring.High Pressure

High pressure options up to 960 bar. Typical application for hydraulic and pneumatic cylinders.

Air Preparation

-

Filters, Regulators, Lubricators - FRL, Vacuum, Filters & More!

ASCO compressed air treatment products include filters, regulators, lubricators, emergency shut-off / soft-start valves, and accessories. Our broad line of high-flow, modular, and in-line products include sizes from 1/8" to 1" and offer the performance and flexibility to meet today's demanding applications.

FRL - Filters, Regulators, Lubricators

- The ASCO Filter, Regulators & Lubricators range offers high performance and versatility in an extremely compact modular packages. Available in port sizes 1/8 – 1 1/2 and features one of the highest flow characteristics of any FRL's on the market, compared to its size resulting in a lower pressure drop. A lower pressure drop can deliver savings in energy consumption.

The robust corrosion resistant construction, a temperature range of -40° C to 80° C and a broad range of options such as ATEX and CU-TR makes them suitable for many uses, including those in harsh environments. Typical applications include industrial automation, process industries, breathing air, food packaging and paint spraying.

ASCO & Numatics Vacuum Products

Disposable In-Line Filters

-

Numatics offers a broad range of miniature plastic and metal filter products. Element grades include coalescing, particulate, HEPA, ULPA, activated carbon and silica gel

Disposable filters are used in applications that include but are not limited to medical, pharmaceutical, instrumentation, gas sampling and intake filters.

Numatics disposable in-line filters include the PL Series polyurethane straight and nylon dual barbed styles as well as the PT Series nylon straight and 90 degree barbed styles. Both offer coalescing and particulate element grades. Our PH and PX Series extended polyester housings offer particulate as well as HEPA and ULPA elements grades. The PH Series also offers a clear polycarbonate desicant dryer option utilizing blue silica gel. The all metal MF Series also offers both coalescing and particulate element grades.The all metal MF Series also offers both coalescing and particulate element grades.desicant dryer option utilizing blue silica gel. The all metal MF Series also offers both coalescing and particulate element grades.

Replacement Filter Elements

-

Replacement filter elements include form, fit and function particulate, coalescing and adsorbing elements for many of the leading filter manufacturers

With pleated particulate media offers increased surface area thereby extending service life.

Our unique coalescing borosilicate glass vacuum forming process provides a tortuous path of varying density. This allows particles to be trapped through the entire element cross section thereby lowering pressure drop while maximizing capacity.

Adsorbing grade elements are made from non-woven impregnated activated carbon media.

Numatics crosses elements for fifty five major compressed air filter brands including: Airtek, Balston, Deltech, Finite, Hankison, Norgren, Pall/PPC, Pneumatech, Wilkerson and Zander.

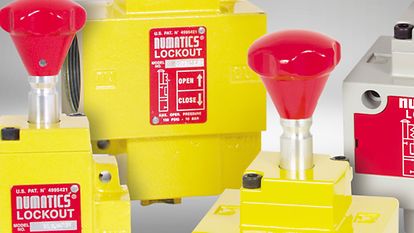

Lockout & Shut off Valves

-

Lockout and shut off valves prevent unauthorised pressurisation of an air system during service or maintenance

Lockout valves employ a unique, one piece center spool design that accommodates a user-supplied padlock in the closed position. When locked in the closed position, the system controlled by the lockout valve cannot be operated until the padlock is removed.

Lockout valves are available in several different designs, including standard manual full flow quick exhaust (VL Series - yellow body), Slo-Start™ full flow quick exhaust (VT Series - yellow body) and the Shut-Off Valve (VSL Series - grey body).

The Shut-Off Valve (VSL Series - grey body) has a restricted exhaust and is typically used at the beginning of the FRL assembly. The addition of the Slo-Start™ feature to the lockouts allows for the downstream pressure to gradually increase prior to opening to a full flow condition.

Compressed Air Preparation

-

Reservoirs

Compressed air reservoirs with a capacity of 1-90 l.Pressure gauges from AVENTICS

Pressure Gauges

Clearly visible pressure indicators in different sizes and versions.Maintenance Units and Components

Modular maintenance units, flexible and robust with connection sizes G1/8 to G2 as well as precision pressure regulators for high demands on dynamics and accuracy.

Accessories & Options - ASCO & Numatics

-

Electrical, Flow Controls, Valves, Switches, Sensors, Fittings, Tubing & More!

ASCO offers a wide variety of accessories and optional features to meet specific application requirements including accessories tailored for specific valve types and applications. These include digital sensors that can display values and output to control systems, PNP and NPN switches, and power clamps suitable for a wide variety of environments. ASCO also offers a wide range of products and accessories for air preparation and handling.

Electrical Accessories

-

ASCO DIN Connectors are designed using the DIN 43650 form standards consistent with our solenoid valve coil designs and permitting industry interchangeability. Available for user wiring, or factory pre-wired installations.

ASCO Electronic timers are solid state electronic timers used to automatically control ASCO solenoid valves.

Filter Elements & Strainers

-

ASCO Filter Elements & Strainers Should be used whenever it is essential that fluid be free of foreign solid matter. Assure proper flow and prevent damage to valves, controls, and other equipment

Fittings & Tubing ???

- ASCO offers special silicone tubing and hose guides for use with our Pinch valves

Flow Controls & Valves ???

- ASCO Flow Controls & Valves comes with spring loaded disc that allows free flow in one direction and an adjustable flow in the other

Pressure Gauges

- FRL accessories includes mechanical pressure switches, regulator gauges, FRL brackets, and accessories

Silencers / Mufflers

- Accessories include nickel plated brass and composite fittings, flow controls (in port & in line), pilot operated checks, quick exhaust valves, mufflers, speed control mufflers, breather vents, check valves, and tubing

Solenoid Operators / Assemblies

- ASCO offers a wide range of electrical and mechanical options which can customize valves to your precise application

Switches & Sensors

-

Pressure Sensors from ASCO provide accurate measuring and linear electrical output signals for many process fluids. The MEMs based sensor and one-piece pressure cavity provides stable output measurements from 0 to 10,000 psi and supplies high sensitivity, low drift and highly repeatable signaling. Electrical options include flying leads, pins, spade terminals, or explosion-proof or intrinsically safe versions. Mechanical options include panel mounting, 316ss pressure vessel or inconel with process connections of 1/8-1/2 inch NPT, and other specialty threading. Output signal options include 4-20m Amp or 1-5 Volt.

Pressure and Temperature Switches from ASCO are a range of miniature to industrial size switches designed to signal when process media reaches a set point of pressure or temperature. The transducer will operate a mechanical snap switch when the set point has been reached, and will reset when the process media conditions drop below the dead band. Options include fixed or adjustable dead band and a a wide range of set points of vacuum to 8000 psi and temperatures of -60ºF to 640ºF (-51ºC to 337ºC).

ASCO & Numatics Vacuum Products