- Offer Profile

-

Reis Robotics develops and integrates automation equipment and complete turnkey solutions for efficient and sustainable production: specifically for your industry.

Reis Robotics is a globally active automation company and excel in robot technology and system integration. With our headquarter in Obernburg am Main, we are a recognized integrator for complex automation systems in major industries. Our product range includes special robots and automation components for the market segments welding, laser processing, multi-process automation and foundry technology.

Our Products

- The product range of Reis Robotics includes linear robots, gantry robots and the own robot control ROBOTstar VII. In addition, there are the product areas of trimming presses and gravity die casting machines.

Robot Controller Reis ROBOTstar VII

-

The iconic Reis ROBOTstar VII robot controller operated via the familiar reisPAD has set standards in terms of path following accuracy for cutting, welding and positioning applications, simplicity & intuitive use, and ability to control more than 24 axes.

The graphic ProVis graphical visualisation and TouchMotion control enable simple and application-related operation and programming of the robot. The fully integrated SafetyController as well as the freely programmable safety PLC serve to protect people and save an external PLC for smaller applications. Open communication standards enable seamless integration into production systems. Upgrades for existing systems are also possible at any time. Please contact the Reis service department.

Laser Spy

-

Modern laser beam sources are becoming increasingly powerful and overtax conventional safety systems

An example:

- A protective wall of test class T1 in accordance with the IEC/EN 60825-4 standard must withstand “worst-case irradiation” for 30,000 seconds in automated production operation. This corresponds to a 20 kW load for more than 8 hours – too high even for double-wall systems. Even a T2 service life of 100 seconds can hardly be realized economically with passive measures.

- Modern solution Electronically actively monitored laser safety barriers.

- Technology LaserSpy – an active sensor system that detects incorrect irradiation at lightning speed and triggers the safety circuit.

- Ingenious principle The LaserSpy is an optical sensor. It monitors a room devoid of light, such as that created by the construction of a protective wall made of double panels, for the entry of laser radiation. If the first wall is penetrated by a laser beam, the highly sensitive sensor measures the radiation generated in the room, opens the safety circuit and switches off the radiation source via an emergency stop before the beam can escape from the protective wall.

- Intelligent design The LaserSpy sensor has a redundant design and consists of several detectors arranged concentrically around a detector core, as well as evaluation electronics that continuously monitor themselves and thus ensure the correct functioning of the detectors. A laser spy detector can monitor a radius of 3.5 m. When installed, the sensor system complies with protection class IP 65.

- Universal use The individual LaserSpy sensors have a particularly compact design and are easy to install – even on existing double-wall cabin elements. A mounting hole for the sensor core and four fixing holes for the sensor housing on the outer wall of the cabin elements – the prerequisites for installation are quickly created

Laser Optics

- We are happy to provide you with more information about our Reis Robotics laser optics upon request. Please use the contact form below to get in touch with us.

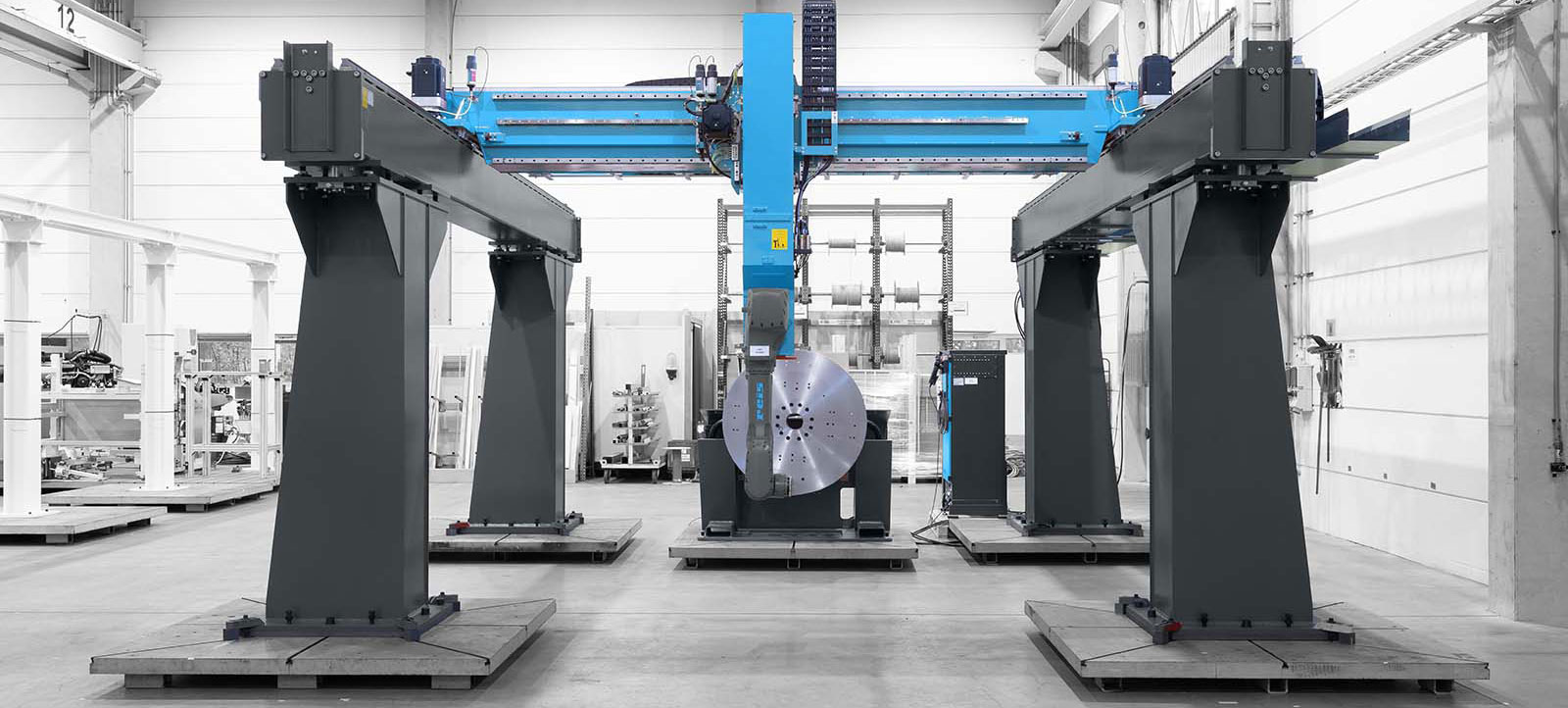

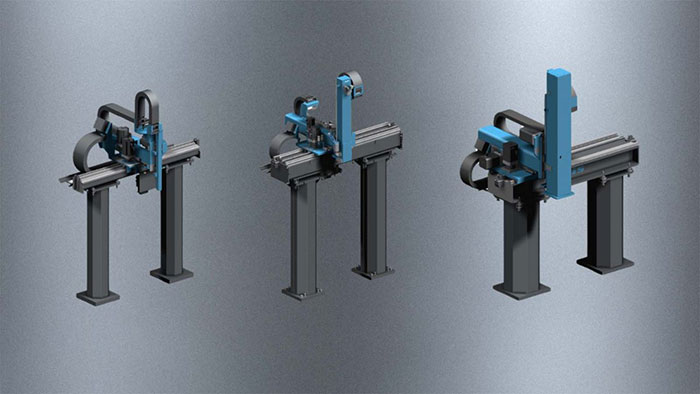

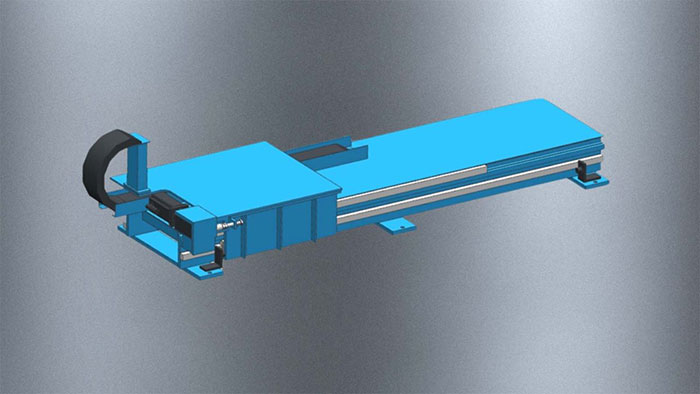

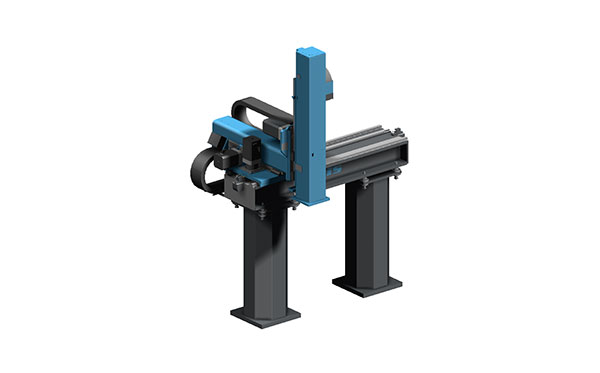

Linear Robots

-

Linear robots usually consist of three linear axes (X, Y and Z), which are arranged orthogonally to each other. Internally at Reis Robotics and in the corresponding documentation and programs, these axes are referred to as A1, A2 and A3. Each of these axes moves along a straight line and is driven by AC servomotors over a gearbox, whereby the power is transmitted via a rack and pinion drive.

Additional axes can be integrated into all linear robots, in particular additional rotary axes, which enable additional degrees of freedom and orientation options in one or more directions. This makes it possible to carry out even complex tasks. Due to the high accuracy of the additional axes and the robots as well as the various degrees of freedom, even demanding process tasks such as welding can be carried out precisely.

The linear robots are usually mounted on columns, leaving the working area, which can be a maximum of 45 meters in one direction due to the A1 axis alone, completely free for applications and various components except for the column mounting.

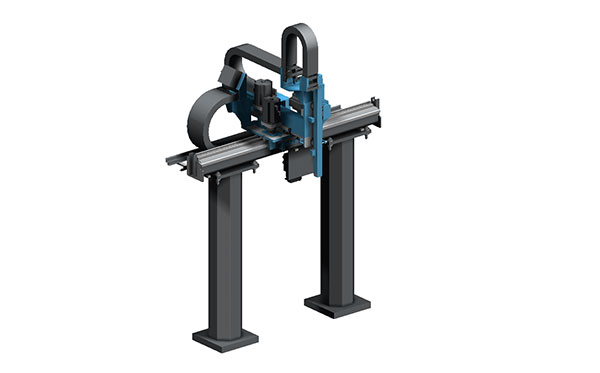

Laser cutting gantry

-

YOUR BENEFITS

- Combined with the very low interference contours of the robot kinematics, this is ideal for interlinking work sequences for loading and unloading, but also for palletizing or transferring

- modular design with workspaces from 0.5 m³ to 90 m³

- state-of-the-art servo drive tech nologies are used to achieve the best possible dynamics, perfor mance and reliability

Area Gantry Robots

- Coming Soon

Linear Travel Units

- Coming Soon

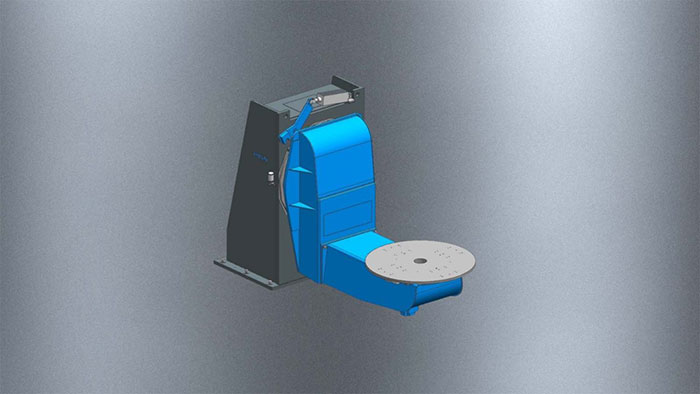

Positioner

- A whole range of peripheral modules in various designs are available for the provision of workpieces, such as the turning, tilting and swivel-tilting modules, which enable optimum positioning of the component in the robot’s working area. The product range includes positioners with a load capacity of 200 kg to 12,000 kg. We also develop peripheral modules for interchangeable workstations: rotary tables (manual and electric), H-positioners, Turn-tilt positioners, Indexing tables for setting up several stations.

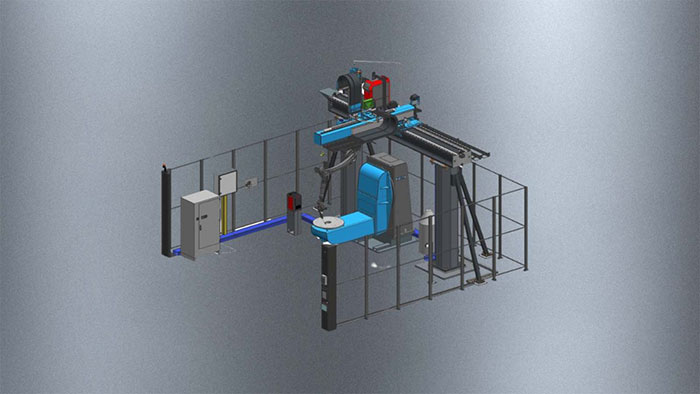

Production Cell

- Whether welding, cutting, lasering, fettling and deburring – our modular production cells offer high quality and performance at an attractive price. In addition to our application expertise and perfectly matched components, our cell portfolio is flexible to use, preconfigured, quickly integrated into production environments and easily scalable.

Articulated arm robot

-

Advantages:

- Top class technology top class

- Perfect coordination with the control system

- Maximum performance thanks to high-quality materials

Linear Robots

-

Linear robots usually consist of three linear axes (X, Y and Z), which are arranged orthogonally to each other. Internally at Reis Robotics and in the corresponding documentation and programs, these axes are referred to as A1, A2 and A3. Each of these axes moves along a straight line and is driven by AC servomotors over a gearbox, whereby the power is transmitted via a rack and pinion drive. Additional axes can be integrated into all linear robots, in particular additional rotary axes, which enable additional degrees of freedom and orientation options in one or more directions. This makes it possible to carry out even complex tasks. Due to the high accuracy of the additional axes and the robots as well as the various degrees of freedom, even demanding process tasks such as welding can be carried out precisely. The linear robots are usually mounted on columns, leaving the working area, which can be a maximum of 45 meters in one direction due to the A1 axis alone, completely free for applications and various components except for the column mounting.

Advantages:

- Large work area

- Combination of linear and rotary movements

- Optimum space utilization

- Optimized positioning

- Speed and efficiency

- Precision and repeat accuracy

- Flexible positioning

- High speed

- Safety

- Adaptability

- Efficient space utilization

- Robustness and reliability

RL16

- Nominal payload on axle A3: 16 kg

- Payload range (depending on stroke A3): 14 kg – 32 kg

- Speeds:

- A1: 3 m/s

- A2: 3 m/s

- A3: 4 m/s

- Working space:

- min.: 0,5 m³

- max.: 22,5 m³

RL50

- Nominal payload on axle A3: 50 kg

- Payload range (depending on stroke A3): 33 kg – 81 kg

- Speeds:

- A1: 3 m/s

- A2: 2 m/s

- A3: 3 m/s

- Working space:

- min.: 1 m³

- max.: 169 m³

RL80

- Nominal payload on axle A3: 80 kg

- Payload range (depending on stroke A3): 55 kg – 127 kg

- Speeds:

- A1: 2,6 m/s

- A2: 2 m/s

- A3: 3 m/s

- Working space:

- min.: 1 m³

- max.: 255 m³

RL300

- Nominal payload on axle A3: 300 kg

- Payload range (depending on stroke A3): 252 kg – 324 kg

- Speeds:

- A1: 2 m/s

- A2: 1,7 m/s

- A3: 1 m/s

- Working space:

- min.: 1 m³

- max.: 225 m³

RL600

- Nominal payload on axle A3: 600 kg

- Payload range (depending on stroke A3): 563 kg – 695 kg

- Speeds:

- A1: 2 m/s

- A2: 1,5 m/s

- A3: 1 m/s

- Working space:

- min.: 1 m³

- max.: 225 m³

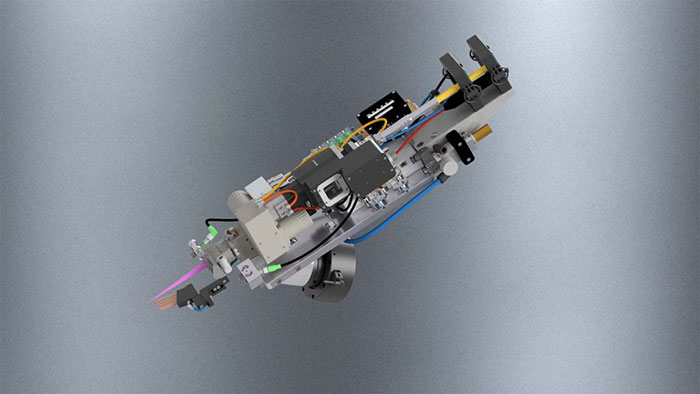

Laser cutting gantry

RLP70

-

BETTER RESULTS IN LARGE WORKSPACES FOR MORE QUALITY AND PRODUCTIVITY

In its maximum confi guration, the RLP70 linear gantry robot has three cartesian axes and three rotary axes, which are fully synchronized and interpolated servo axes controlled by the robot controller. The double-sided bearing of the fi rst axis ensures maximum dynamics with very high stability.

The experience gained from a large number of installed handling applications and our expertise as one of the leading providers of intelligent automation solutions for more than fi ve decades have been incorporated into the development of the new RLP70.

The Linear Portal RLP70 has been conceptually developed for high-precision and very dynamic laser welding and cuמּ ing tasks. If the RLP70 is extended with two or three-axis laser-specifi c wrist axis modules and a fi bre-guided laser, either highly integrated laser cuמּ ing optics or laser welding optics can be adapted and complex 3D applications can be realized.

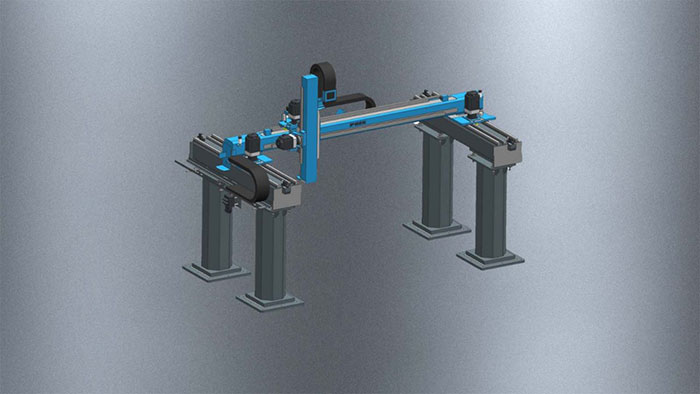

RLP250

-

FOR ENHANCED QUALITY AND PRODUCTIVITY IN LARGE-SCALE WORKSPACES

In its maximum confi guration, the RLP250 linear gantry robot has three cartesian axes and three rotary axes, which are fully synchronized and interpolated servo axes controlled by the robot controller. The double-sided bearing of the fi rst axis ensures maximum dynamics with very high stability.

The experience gained from a large number of installed handling applications and our expertise as one of the leading providers of intelligent automation solutions for more than fi ve decades have been incorporated into the development of the new RLP250.

The option of adding two or three-axis laser-specifi c wrist axis modules enables our customers to also use the RLP250 linear gantry robot for welding applications

RLP300

-

FOR ENHANCED QUALITY AND PRODUCTIVITY IN LARGE-SCALE WORKSPACES

In its maximum confi guration, the RLP300 linear gantry robot has three cartesian axes and three rotary axes, which are fully synchronized and interpolated servo axes controlled by the robot controller. The double-sided bearing of the fi rst axis ensures maximum dynamics with very high stability.

The experience gained from a large number of installed handling applications and our expertise as one of the leading providers of intelligent automation solutions for more than fi ve decades have been incorporated into the development of the new RLP300.

RLP600

-

FOR ENHANCED QUALITY AND PRODUCTIVITY IN LARGE-SCALE WORKSPACES

In its maximum confi guration, the RLP600 linear gantry robot has three cartesian axes and three rotary axes, which are fully synchronized and interpolated servo axes controlled by the robot controller. The double-sided bearing of the fi rst axis ensures maximum dynamics with very high stability.

The experience gained from a large number of installed handling applications and our expertise as one of the leading providers of intelligent automation solutions for more than fi ve decades have been incorporated into the development of the new RLP600.

Articulated arm robot

RV6-1215

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV6-1215 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 6 kg. The RV6 is ideally suited for testing & measuring tasks as well as handling and laser applications. With its minimal footprint, it is also ideally suited for installation in systems with very limited space.

RV6-1590

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV6-1590 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 6 kg. The RV6 is ideally suited for testing & measuring tasks as well as handling and laser applications. With its minimal footprint, it is also ideally suited for installation in systems with very limited space

RV6-1790

- HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS The REIS RV6-1790 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 6 kg. The RV6 is ideally suited for testing & measuring tasks as well as handling and laser applications. With its minimal footprint, it is also ideally suited for installation in systems with very limited space.

RV16-1600

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV16-1600 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 16 kg. The RV16 is ideally suited for testing & measuring tasks as well as handling and laser applications. With its minimal footprint, it is also ideally suited for installation in systems with very limited space.

RV20-1803

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV20-1803 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 20 kg. The RV20 is ideally suited for testing & measuring tasks as well as handling and laser applications. With its minimal footprint, it is also ideally suited for installation in systems with very limited space.

RV30-1665

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ARM ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV30-1665 is a highly developed 6-axis articulated arm robot that off ers exceptional precision and dynamics with a nominal payload of 30 kg. The RV30 is ideally suited for testing and measuring tasks as well as milling, handling and laser applications. For extremely high-precision tasks in the high-end range, the mechanics can also be equipped with secondary encoders.

RV30-2257

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV30-2257 is an advanced 6-axis articulated robot that off ers exceptional precision and dynamics with a nominal payload of 30 kg. The RV30 is ideal for general handling tasks.

RV45-2118

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV45-2118 is an advanced 6-axis articulated robot that off ers exceptional precision and dynamics with a nominal payload of 45 kg. The RV45 is ideal for general handling tasks

RV60-1959

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV60-1959 is an advanced 6-axis articulated robot that off ers exceptional precision and dynamics with a nominal payload of 60 kg. The RV60 is ideal for general handling tasks.

RV150-2390

-

HIGHLY DYNAMIC 6-AXIS ARTICULATED ROBOT FOR PRECISE INDUSTRIAL APPLICATIONS

The REIS RV150-2390 is an advanced 6-axis articulated robot that off ers exceptional precision and dynamics with a nominal payload of 150 kg. The RV150 is ideally suited for testing and mea suring tasks, as well as milling, handling and laser applications. For extremely high-precision tasks in the high-end sector, the mechanics can also be equipped with secondary encoders.

Industries

Handling & Processing – We automate diversity

- We are your reliable partner for the conception, planning and realisation of turnkey automation solutions. Our focus is on multi-process automation, such as the production of solar modules, as well as the interlinking of your machinery and automation in the food and catering sector. In addition, we are specialists in solving logistics tasks, such as palletizing or depalletizing, and complete our portfolio by integrating AGV and AMR fleets.

Welding & Cutting - perfect cuts, strong connections, individual solutions

- Welding & Cutting stands for flexible, scalable and smart solutions for automated welding and cutting. The application portfolio covers a very wide range of process methods such as MIG/MAG and TIG applications through to laser welding and laser cutting applications as well as laser additive manufacturing. We are experts in fully automated tank welding and complete assembly lines as applied in the automotive or heat pumps industry. In our in-house technical center, we can carry out feasibility studies for all processes so that we can find the right solution for your requirements. The modular portfolio can then be easily integrated to provide a cost-efficient and high-quality solution.

Casting & Deburring - customised automation for the foundry

- We use our decades of experience in the foundry industry to master your challenges together with you. As a specialist in the automation of foundry processes, we offer a wide variety of solutions for the processes of die casting, low-pressure casting, permanent moulds, sand casting and grey cast iron. We accompany you with our ideas and technologies from the first concept to the turnkey solution. Our portfolio includes foundry robots, trimming presses for standard and GIGA castings size in the e-mobility segments, foundry machines as well as robotic trimming and fettling cells.