- Offer Profile

- AD AGRO systems GmbH & Co. KG (AD AGRO) offers a complete range of services covering the planning, turnkey construction and subsequent management of biogas plants worldwide. From small agricultural plants tailored individually to local circumstances, to 5 MW industrial projects; whether renewable resources or waste plants; whether fermentation residue separation or drying – working as a partner to agriculture and industry, AD AGRO taps into the new opportunities for using biogas as a future energy source. As a biogas plant builder we also collaborate with experienced, powerful partners.

What is biogas?

-

Biogas is a mixture of methane and carbon dioxide, as well as water vapour, nitrogen, oxygen, hydrogen, ammonia and hydrogen sulphide, and is the end-product of an anaerobic fermentation process. It can be obtained from manure and other organic substances. In a system known as a digester, which is heated and airtight, micro-organisms break down the biomass at a temperature of between 35°C and 55°C.

How does a biogas plant work?

The principle is quite simple. Biogas is produced in a digester and is then converted into electrical energy and heat in a CHP unit. Our latest developments allow refined raw biogas to be fed into local gas networks. The fermented residue can be utilised as a valuable fertiliser. The energy produced represents an important contribution to active environmental protection, because it is derived from renewable materials.

Ten good reasons to choose biogas- Biogas means independence from oil and gas imports.

- Biogas plants generate thermal as well as electrical energy.

- Biogas plants can heat buildings but also process water.

- Rural areas are made more economically viable.

- Biogas slurry is a valuable agricultural fertiliser.

- Biogas slurry can be a substitute for mineral fertilisers, and protects drinking water.

- Biogas slurry has a high level of plant availability and can even be used as a top dressing.

- Biogas is eco-friendly, economical and dependable.

- Energy is generated instead of simply throwing away organic residues.

- The fermentation process reduces weed seeds’ ability to germinate.

BIOGAS PLANTS NEW CONSTRUCTION

-

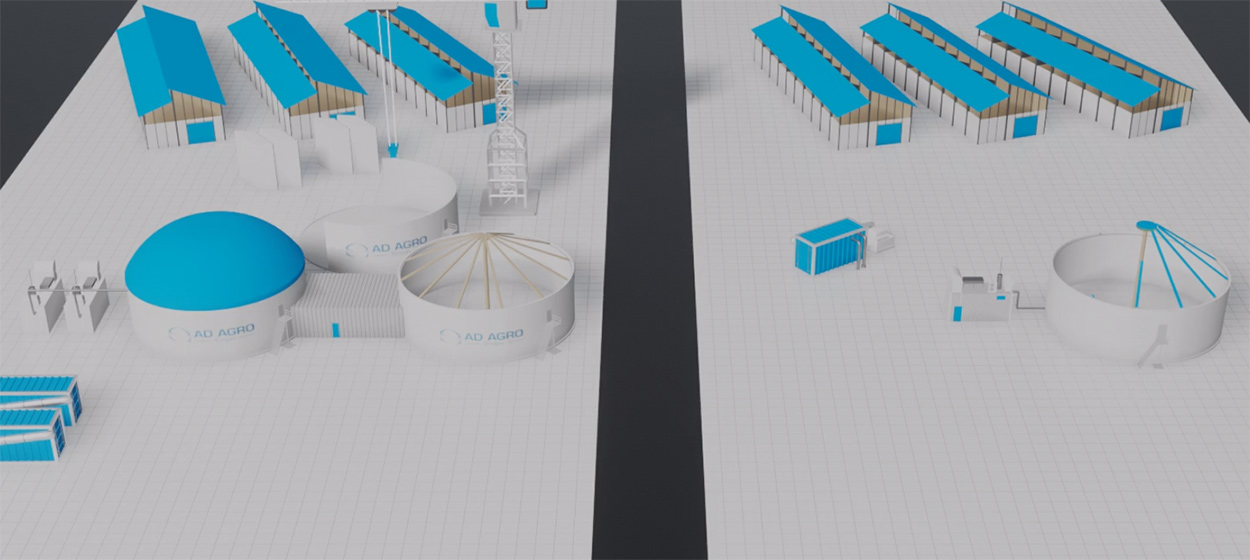

3 types of biogas plants for any size

Mini Ferm - 75kW yard system

-

- 75 to 150 kW

- flat digester

- robust gas Otto engine

- short construction time

- farm and agricultureWith the plant system up to 75 kWel output you get even more out of your barn

Liquid manure brings money!

With cattle or pig manure from 100 GV, yields of up to yields of up to 20% can be achieved.

Through the implementation of the new EEG 2014 75 kW plants will be remunerated for electric power up to 23.72 cents per kilowatt hour.

You continue to take care of your animals - the manure ensures you the additional yield!MiniFerm biogas plants are suitable for every barn

This type of plant is excellently suited for the exclusive use of farm manure, for example liquid manure, dung or HTK.

By utilizing feed residues from livestock farming, the economic efficiency is increased.

MiniFerm biogas plants guarantee independence from fluctuating substrate or lease prices.

UniFerm- 250kW – 2MW Plant

-

- 250 kW - 2 MW

- flat digester

- long-term proven

- upward compatible

- high efficiency

- robust technology

- agricultureThis type of plant is particularly suitable for the use of farm manure (dung, slurry, HTK) and agricultural substrates such as corn, grass, cereal GSP, beets, etc. The UniFerm biogas plants can be operated highly efficiently using the AD AGRO-Separator system.

UniFerm systems are based on fermentation tanks made of concrete, stainless steel or coated steel with diameters between 16 and 36 meters and heights between 5 and 10 meters. Large tank volumes and thus long residence times guarantee you a very high gas yield from the input materials used.

MegaFerm - Plants starting at 500kW

-

- from 500 kW

- worldwide proven

- high digester

- highest dry matter intake

- mesophilic and thermophilic process

- very low energy consumption

- Agriculture and industryA special feature of the MegaFerm plants are the fermenters made of reinforced concrete or enameled steel with a fixed ceiling and up to 24 m high. The "slim" high tanks with volumes of up to 7,625 cubic meters allow the use of large input volumes with optimum efficiency of the agitator. Thanks to the central agitator technology, even very difficult substrates can be fermented with low internal power requirements

Because the input materials are constantly mixed, the tank volume is optimally utilized, thus enabling higher digester loads and shorter residence times. Since no floating layers are formed, gas production is quasi-continuous with constant gas quality.

Biogas existing plants

-

Operate existing biogas plants profitably again? We take care of your biogas plant

Optimization of your biogas plant roof

- Modern foil roofs

have large and flexible gas storage tanks. Can your roof also store 3,500 m³ of gas and more?

Biogas plants with flex CHP

- Future-proof biogas plants

are flexibly operated with Flex-BHKW. Single, double or quadruple superstructure!

Can your plant do the same?

Increase profitability of your biogas plant

- "fit for future"

the 3F program from AD AGRO.

Tailor-made, sustainable and future-oriented solutions for your success!

Cost reduction through efficient techniques

- Reduce costs

through the use of energy-efficient components, sophisticated load management and optimized programming

- all coordinated with each other.

References

-

Benefit from 10 years of experience in biogas engineering, and more than 150 completed projects.

Here is a brief overview of our latest biogas plant projects. We have built numerous biogas plants in Germany and abroad over recent years. Whether small agricultural plants or industrial plants of several megawatts, all of these projects have been tailored carefully to each situation. It is of course only a small selection of our projects, since showing you all of them would be beyond the scope of this website. Rinderzucht Müller GbR

-

Location: 28870 Ottersberg - Narthauen, Germany

Output: 265 kWel

Input materials: manure, dung, feed residues

Heat usage: agricultural operations

Year built: under construction

Mecholupska zemedelska a.s.

-

Location: Predslav/Katovy, Czech Republic

Output: 1.200 kWel

Input materials: maize silage, manure

Heat usage: agricultural operations

Year built: 2012

Zemedelska spolecnost Komorno a.s.

-

Location: Letiny/Blovice, Czech Republic

Output: 834 kWel

Input materials: maize silage, manure

Heat usage: agricultural operations

Year built: 2012

EBB Sp. z o.o.

-

Location: 63-722 Borzęciczki Ul, Poland

Output: 2 x 500 kWel

Input materials: maize silage, manure

Heat usage: in planning

Year built: 2012

EnGas-Systemtechnik GmbH

-

Location: 26607 Aurich, Germany

Output: 1.000 kWel

Input materials: maize silage, manure

Heat usage: industrial estate

Year built: 2012

OOO AltEnergo

-

Location: Belgorod / Russland

Output: 2.400 kWel

Input materials: maize silage, manure, residual meet, stomach/intestinal contents, fur/hair residue, sewage sludge

Heat usage: -

Year built:

2012

Bioenergie Süderwalsede GmbH & Co. KG

-

Location: 27386 Süderwalsede, Germany

Output: 600 kWel

Input materials: maize silage, pig manure

Heat usage: shed (in planning)

Year built: 2011

Josef Kurmann Biogas GbR

-

Location: 26219 Bösel, Germany

Output: 370 kWel

Input materials: maize silage, pig manure, turkey droppings

Heat usage: sheds

Year built: 2011

Brand Biogas GmbH & Co. KG

-

Location: 26197 GroÃenkneten-Sage, Germany

Output: 250 kWel

Input materials: maize silage, cow manure, pig manure, dung

Heat usage: sheds

Year built: 2011

HORAL a. s. Hlaska

-

Location: 51601 Liberk-Hlaska, Czech Republic

Output: 600 kWel

Input materials: maize silage, grass silage, cow manure

Heat usage: -

Year built: 2011

Ecoenergy Societa´ Agricola S. r. l.

-

Location: 42010 Rio Saliceto, Italy

Output: 999 kWel

Input materials: maize silage, pig manure

Heat usage: in preparation

Year built: 2011

Barrelmann Energy GmbH

-

Location: 21401 Bavendorf, Germany

Output: 250 kWel

Input materials: maize silage, pig manure

Heat usage: private households, sheds

Year built: 2011

Rolnická a.s. Králiky

-

Location: 50401 Nový Bydzov, Czech Republic

Output: 1.800 kWel

Input materials: maize silage, grass silage, grain, cow manure

Heat usage: housing, cow sheds

Year built: 2010

MP Biogas GmbH & Co. KG

-

Location: 27404 Wense, Germany

Output: 340 kWel

Input materials: maize silage, turkey droppings, cow manure

Heat usage: housing, pig sheds

Year built: 2010

Weytec B. Weyhausen

-

Location: 26209 GroÃenkneten, Germany

Output: 2 x 250 kWel

Input materials: maize silage, cow manure, turkey droppings

Heat usage: turkey sheds

Year built: 2010

Biogas Altbarnim Betriebs GmbH & Co. KG

-

Location: 15320 Neu Trebbin, Germany

Output: 536 kWel

Input materials: maize silage, cow manure

Heat usage: cow and pig sheds

Year built: 2010

Vorm Placken Biogas Westrittum GmbH & Co. KG

-

Location: 26197 GroÃenkneten, Germany

Output: 250 kWel

Input materials: maize silage, cow manure, turkey droppings

Heat usage: turkey sheds, private customers

Year built: 2009

TMZS Biogas GmbH

-

Location: 49326 Melle, Germany

Output: 536 kWel

Input materials: maize silage, chicken droppings, CCM, green rye

Heat usage: chicken sheds, wood drying

Year built: 2008