- Offer Profile

-

Single-source supplier: your partner for pumps, valves and service

We are your partner for the entire product life cycle with an extensive product portfolio and customized service and spare parts solutions.

For the following applications:

- Water

- Waste Water

- Industry

- Energy

- Building Services

- Mining

THE RIGHT SOLUTIONS FOR EVERY MARKET

-

Future-driven products – since more than 150 years

Our customers are individuals and so are our solutions, products and services. Every sector, market and region has their own special requirements on pumps and valves. When our customers start a new project involving high-efficiency pumps and valves, they know that we at KSB listen to them carefully. We want to understand the particular challenges of each and every project. This is the only way we can find an optimum solution together with our customers and master every challenge.

How we combine our focus on our customers’ requirements and draw on our more than 150 years of passion for technological progress and innovation is what our customers appreciate about KSB. At the same time we give everything to continuously improve our know-how by conducting ongoing research and using the latest technologies.

It is very useful for us in this regard to be present in all relevant markets around the globe with our own factories and development departments. We speak our customers’ language and know first hand what each market requires. Often it’s not only about ever-increasing quality, longevity and energy efficiency for pumps and valves. It’s about individual solutions. Oil and Gas Technology

-

Full throttle into the future: intelligent solutions for climate-neutral fuels

In order to limit global warming to 1.5 °C, the states that ratified the Paris Climate Agreement are committed to making climate-friendly changes to their economies, including the mobility sector. Previously, fossil fuels that produced large volumes of CO2 emissions were burned. Today, however, more sustainable solutions are in demand, with carbon-neutral, non-fossil fuels becoming increasingly important.

It's time to step up a gear – for the sake of our climate!

Technical innovation has been a strong tradition at KSB for 150 years. Developing innovative solutions is our daily work. For many years now, KSB has also been active in the area of biofuels and synthetic fuels. It knows the processes involved and can offer a whole host of state-of-the-art products.

Biofuels and synthetic fuels are gaining importance, especially in those industries in which electrification is only feasible in the long term (for example, shipping and aviation).

-

Biofuel is mostly liquid fuel produced from biomass for use in combustion engines. Renewable raw materials such as rapeseed, sugar beet, wood, straw and residues from the food processing industry can be used as basis. The most important types of biofuels are biodiesel, bioethanol, biomethane and vegetable oil (rapeseed oil).

-

Synthetic fuels or synfuels are produced from a mixture of isolated carbon dioxide and climate-neutral hydrogen. These fuels are currently in the development phase. However, they will play a major role in the future, especially in industries that are not easily electrified

Our non-fossil fuel products KSB is a full-range supplier for pumps, valves and service with decades of experience and in-depth application knowledge. All KSB products offer long-term efficiency as well as reliability and require minimal maintenance, thus ensuring the economic, trouble-free operation of your systems.

Visit all our products

-

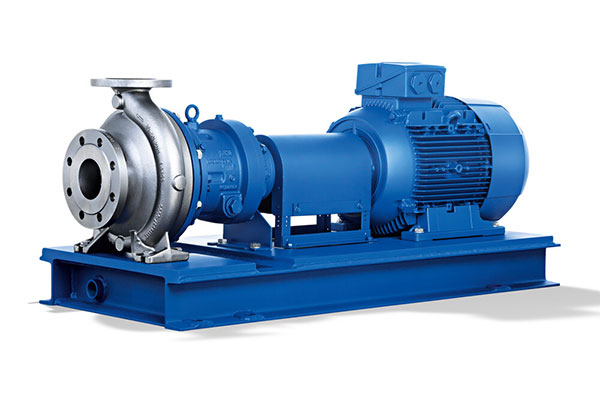

MegaCPK

-

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to DIN EN ISO 5199, dimensions to DIN EN ISO 2858, complemented by nominal diameters DN25 and ≥DN200, in large range of material and seal variants; also available as a variant with "wet" shaft and conical seal chamber. ATEX-compliant version available.

Magnochem

-

Horizontal seal-less volute casing pump in back pull-out design, with magnetic drive, to DIN EN ISO 2858 / ISO 5199, with radial impeller, single-entry, single-stage. ATEX-compliant version available.

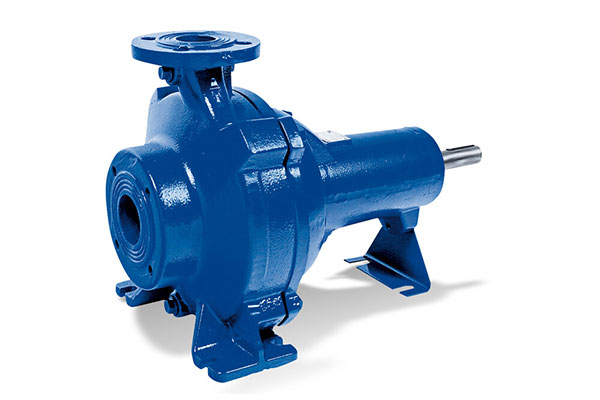

CPKN

-

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to ISO 2858 / ISO 5199. Also available as a variant with "wet" shaft, conical seal chamber and/or semi-open impeller. ATEX-compliant version available.

Efficient water treatment

-

Supplying fresh, clean water every day: A challenge which KSB handles with competence.

As a globally recognised specialist for water treatment, KSB sets standards in waterworks systems and desalination systems from Paris to New York, Sao Paulo, Sydney and Singapore

Water treatment: A complex task bearing great responsibility

Surging global demand for water  especially in industry and households  requires ever more and larger water treatment systems and plants which have to work efficiently. A further challenge is that in future more than 40 % of drinking water will have to be produced via seawater desalination.

Obtaining drinking water or process water often requires mechanical and biological water treatment. In many cases, large masses of water need to be transported as energy-efficiently as possible. Especially in the case of drinking water treatment, all components must also meet stringent hygiene standards as peopleÂs health is at stake.

KSB Multitec

-

Multistage horizontal or vertical centrifugal pump in ring-section design, long-coupled or close-coupled, with axial or radial suction nozzle, cast radial impellers and motor-mounted variable speed system. ATEX-compliant version available.

The multi-stage high-pressure pumps of KSB’s Multitec-RO series are ideally suited to small and medium-sized systems. For example

- In hotels

- Onboard vessels

- In transportable containers

In desalination the pumps handle up to 10,000 cubic metres of water per day. They manage heads of up to 1000 metres and a maximum flow rate of 850 cubic metres per hour.

ETANORM

-

Horizontal volute casing pump, single-stage, with ratings and main dimensions to EN 733, long-coupled, back pull-out design, with replaceable shaft sleeves / shaft protecting sleeves and casing wear rings, with motor-mounted variable speed system. With KSB SuPremE, a magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4/IE5 to IEC TS 60034-30-2:2016, for operation on a KSB PumpDrive 2 or KSB PumpDrive 2 Eco variable speed system without rotor position sensors. Motor mounting points in accordance with EN 50347, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available.

MegaCPK

-

Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to DIN EN ISO 5199, dimensions to DIN EN ISO 2858, complemented by nominal diameters DN25 and ≥DN200, in large range of material and seal variants; also available as a variant with "wet" shaft and conical seal chamber. ATEX-compliant version available.

Main Applications

- Chemical industry (aggressive / other liquids)

- Petrochemical industry (aggressive / other liquids)

- Process engineering

- Refinery

Waste Water Disposal and Transport

-

Waste Water Disposal and Transport

Waste water disposal perfected  with products from KSB Rising global population levels are making waste water transport increasingly important. KSB offers municipalities and industrial companies efficient pumps and valves.

The challenge waste water poses: trouble-free, efficient disposal Absolute reliability is essential in plants for waste water disposal.

At the same time, the pumps and valves used must be energy-efficient in order to keep total cost of ownership low. A difficult undertaking considering that the waste water volumes to be transported and disposed of are increasing worldwide.

In addition, the composition of waste water is becoming increasingly problematic: as a result of water-saving measures, waste water contains more and more solids and less and less water. This requires innovative solutions and advanced technology. The pumps employed must have a long service life, must not clog and should be as energy-efficient as possible. Industrial waste water also places exacting demands on pumps and valves. They must be particularly resistant to wear and corrosion.

Amarex KRT

-

Horizontal or vertical single-stage submersible motor pump in close-coupled design, with various next-generation impeller types, for wet or dry installation, stationary or transportable version, with energy-saving motor and models for use in potentially explosive atmospheres.

Sewatec

-

Volute casing pump for horizontal or vertical installation, with various next-generation impeller types, discharge flange to DIN and ANSI standards. Explosion-proof version available.

Benefits

- Variable hydraulic system: the right impeller with optimum efficiency for every fluid. High operating reliability due to large free passages.

- Double mechanical seal in tandem arrangement with fluid reservoir makes for high operating reliability.

- Low maintenance thanks to grease-packed rolling element bearings

Amaline

-

Wet-installed horizontal propeller pump with submersible motor, equipped with direct drive or spur gear, ECB propeller with rigid, fibre-repellent blades, bolt-free connection to the discharge pipe. Explosion-proof version available.

Main Applications

- Recirculating activated sludge from the nitrification to the denitrification stage of activated sludge tanks

- Economic handling of stormwater, river water, surface water and polder water at low heads

- Generating flow in water bodies

Pump automation

KSB Guard

-

The first and easiest step towards digitalising your plant

The smart and comprehensive monitoring service for pumps and other rotating machinery, available 24/7 and also for non-KSB pumps. Benefit from predictive maintenance with KSB: comprehensive transparency, increased availability, enhanced operating reliability and efficient operation (of fixed-speed pumps). Important operating data such as vibrations, temperature, operating hours and load condition (of fixed-speed pumps) can be accessed via KSB Guard, anytime and from anywhere. In addition, deviations from normal operation trigger immediate notifications via the KSB Guard web portal and/or app. The experts at the KSB Monitoring Centre also provide support in analysing causes.

More efficiency, more reliability

- Reliable

KSB Guard monitors the status of your pumps at regular intervals and notifies you immediately of any deviations. This allows you to fix problems before more substantial damage occurs. - Quick

KSB Guard saves resources starting with the installation: the sensor unit is easy to install and pumps are quickly registered. - Straightforward

KSB Guard provides specific status data to help you plan maintenance intervals. You also know sooner what to expect when performing maintenance work.

- Reliable

Amacontrol

-

Protection module for water and waste water products as all-in-one device. Depending on the variant, it can be used for motor temperature measurement, bearing temperature measurement, leakage measurement, vibration measurement, voltage measurement and current measurement as well as for diagnosing a pump, pump system or submersible mixer to ensure trouble-free and reliable operation.

Main Applications

- Protecting and monitoring pumps, pump systems and submersible mixers in the most diverse of applications

- Diagnosing pumps, pump systems and submersible mixers to ensure trouble-free and reliable operation

- Analysing and linking data for condition monitoring

- The protection module cannot be used as the sole temperature monitoring device for explosion-proof motors in Âflameproof enclosure Ex d type of protection.

Cervomatic EDP.2

-

Automatic control unit for pressure-controlled starting and either pressure-controlled or flow-controlled stopping and monitoring of a single pump.

Main Applications

- Spray irrigation systems

- General irrigation systems

- Rainwater harvesting

- Water supply systems

Controlmatic E

-

Automatic control unit for pressure-controlled starting, flow-controlled stopping and monitoring of a single pump

Main Applications

- water supply systems

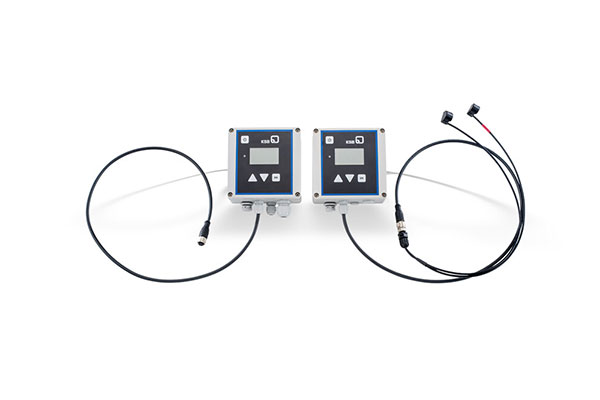

KSB Leakage Sensor

-

The KSB Leakage Sensor is an intelligent monitoring system for measuring and displaying mechanical seal leakage on site. It comprises a leakage measuring instrument and a display unit.

Main Applications

- Plant engineering

- Industry

- Heat transfer fluid pumps

- Demanding fluids

LevelControl Basic 2

-

Level control unit for controlling and protecting either one or two pumps. DOL starting up to 4 kW, star-delta starting up to 22 kW. Higher ratings on request.

Main Applications

- Grey water

- Waste water

- Service water supply

MSE/MSD

-

MSE: Compact switchgear for level-dependent control and protection of one single-phase AC motor (230 V / 50 Hz). The motor is started DOL.

PumpDrive 2/PumpDrive 2 Eco

-

Modular self-cooling frequency inverter that enables continuously variable speed control of asynchronous and synchronous reluctance motors by means of analog standard signals, a field bus or the control panel. As PumpDrive is self-cooling, it can be mounted on a motor, on the wall or in a control cabinet. Up to six pumps can be controlled without needing an additional controller.

Main Applications

- Air-conditioning systems

- Heat generation / heat distribution

- Water supply systems

- Water extraction / water withdrawal

PumpDrive R (KSB202)

-

Modular self-cooling frequency inverter that enables continuously variable speed control of asynchronous and synchronous reluctance motors by means of analog standard signals, a field bus or the control panel. As PumpDrive R is self-cooling, it can be mounted on the wall or in a control cabinet. Up to six pumps can be controlled without needing an additional controller. PumpDrive R extends the power range of PumpDrive 2 up to a rated power of 250 kW (standard) / 1400 kW (on request).

Main Applications

- Air-conditioning systems

- Heat generation / heat distribution

- Water supply systems

UPA Control

-

The KSB switchgear is suitable for level control and protection of submersible borehole pumps, submersible motor pumps and dry-installed pumps with single-phase AC motors 1~ 230 V or three-phase motors 3~ 230 / 400 V / 50 Hz. The motor is started DOL. Enclosure: IP56, dimensions: 205 × 255 × 170 mm (H × W × D).

Main Applications

- Switching of submersible borehole pumps

- Switching of dry-installed pumps

- Switching of systems with pressure switch or float switch

- Dry running protection

Valve automation

AMTROBOX

-

Multi-functional AMTROBOX limit switch box. For open/closed position signalling via mechanical limit switches or proximity sensors. AMTROBOX (R1149) mounts on MR manual gearboxes, ACTAIR NG pneumatic actuators and HQ hydraulic actuators.

Main Applications

- Water

- Waste water

- Energy

- Industry

AMTROBOX M

-

Limit switch box specially designed for manual actuation. For open/closed position signalling via mechanical limit switches or proximity sensors. AMTROBOX M mounts on the S series of quarter-turn levers (R1020) and manual gearbox types MA 12 and MA 25 (R1021).

Main Applications

- Water

- Waste water

- Energy

- Industry

AMTROBOX R

-

Sturdy and multi-functional. For open/closed position signalling via mechanical limit switches or proximity sensors. AMTROBOX R (R1187) mounts on MR manual gearboxes, ACTAIR NG pneumatic actuators, HQ hydraulic actuators and any actuators with VDI/VDE interface.

Main Applications

- Water

- Waste water

- Energy

- Industry

AMTRONIC

-

On/off control of pneumatic quarter-turn actuators and open/closed position signalling. Mounts directly on ACTAIR NG actuators with no need for a bracket, providing a rugged, compact and integrated solution. Its integrated directional control valve eliminates the need for any pneumatic lines between AMTRONIC and the actuator. The actuating time of the actuator can be set via AMTRONIC's air flow reducer. AMTRONIC can be connected to Profibus DP or AS-i field buses. AMTRONIC has been specially developed to reduce control unit cabling. Connection via field bus enables both power supply and control information exchange with the process control system.

Main Applications

- Water

- Waste water

- Energy

- Industry

BOATRONIC MS / BOATRONIC MS-420

-

BOATRONIC MS: Measuring computer for measuring BOA-Control and BOA-Control IMS using ultrasonic sensors; directly displays DN, fluid handled, current flow rate and fluid temperature without prior input of valve travel; 4-key operation for all menu options, data transfer between BOATRONIC MS and customer's IT system via USB interface; self-checking and calibrating upon start-up; fluid data can be selected, with battery compartment for 4x1.5V AA MIGNON batteries (not included in scope of supply); automatic warning when voltage drops below the permissible minimum voltage (BAT); scope of supply includes magnetically attaching sensor set for measuring all BOA-Control globe valves. BOATRONIC MS-420: Measuring computer for permanent measurement set-ups with BOA-Control IMS using ultrasonic sensors; directly displays DN, fluid handled, current flow rate and fluid temperature; analog transmission (4-20 mA output signal) of current flow rate and fluid temperature, 4-key operation for all menu options, self-checking and calibrating upon start-up, fluid data can be selected, 24 V DC power supply.

Main Applications

- Hot-water heating systems

- Air-conditioning systems

- Cooling circuits

- Drinking water supply

SMATRONIC AS-I / MA / PC

-

SMATRONIC AS-I

Electro-pneumatic digital positioner for connection to an AS-i field bus. Certified by AS International. Mounts on ACTAIR NG/DYNACTAIR NG actuators with direct compressed air supply, or on any type of quarter-turn actuator with VDI/VDE 3845 interface and linear actuators with NAMUR interface.

SMARTRONIC MA

SMARTRONIC MA (R1310) is an electro-pneumatic digital positioner powered via the 4-20 mA signal. Mounts on ACTAIR NG/DYNACTAIR NG actuators with direct compressed air supply, or on any type of quarter-turn actuator with VDI/VDE 3845 interface and linear actuators with NAMUR interface. SMARTRONIC MA reduces investment, commissioning and operating costs as the unit consumes no air while idle.

SMARTRONIC PC

SMARTRONIC PC (R1312) is an intelligent, compact and innovative positioner. The integrated control offered by this multi-functional control unit represents the latest in open-loop and closed-loop control technology for valves. The unit attaches directly to ACTAIR NG and DYNACTAIR NG actuators with no need for a bracket or external piping, providing a rugged, compact overall solution. SMARTRONIC PC offers four functions: programmable characteristic curves for valve opening and closing, intelligent positioning, process monitoring and control. SMARTRONIC PC is PC programmable and can be connected to a Profibus DP field bus.

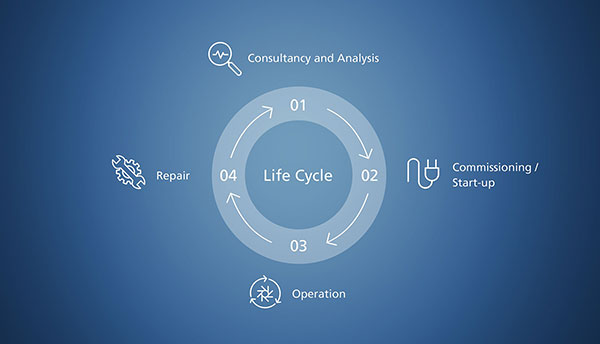

Technical Services - KSB SupremeServ

-

Always there for you

From initial consultancy, planning, installation, operation and maintenance to classic and digital service concepts: KSB is on hand to help you over the entire life cycle of your system. And this with more than 3500 specialists in over 190 service centres around the globe.

We offer:

- Consultancy and analysis

- Commissioning

- Operation

- Repair

-

KSB products are available for the following markets

Water

-

Efficient and clean solutions for the complete water cycle

KSB systems for extracting and transporting water and disposing of waste water are reliable and economical.Water means life. By providing reliable and efficient systems, KSB helps to ensure that people around the world have access to water and that water gets to wherever it is needed reliably.

General industry

-

Innovations for the future of industry

High-efficiency pumps and valves from KSB help ensure that our customers can realise sustainable and reliable production.

Our industrial customers are very well aware of the fact that KSB provides technologically advanced pumps and valves as well as customised solutions that fulfil even the most complex of requirements. We accompany them from initial planning through to operation and the end of the life cycle of our products, which are known for their high operating efficiency and sustainability.

Building services

-

Pumps and valves for building services applications

KSB pumps, valves and systems deliver convenience, hygiene and safety in modern buildings and provide the basis for their efficient operation.

From water supply to drainage, heating and air-conditioning systems through to fire protection: no modern building can be operated without pumps and valves. KSB offers tailored and standardised solutions for various types of buildings.

Mining

-

Robust pumps for mining

Safe and efficient operation in the mining industry requires highly reliable and durable equipment.

Minerals are the raw material used as the basis for many products used in our daily life. KSBÂs line of GIW® pumps are used to move slurry, a mixture of mined material suspended in water, across long distances or within a processing plant.

Petrochemicals/ Chemicals

-

Pumps and valves for the petrochemical and chemical industries

Comprehensive solutions from KSB ensure reliability and safety in the oil, gas and chemical industries.

High temperatures, aggressive and flammable fluids  the extreme conditions in the petrochemical and chemical industries require sophisticated and often complex solutions. Thanks to innovative designs and comprehensive service, KSB maximises performance and reliability.

Energy

-

Innovative solutions for energy supply applications

Pumps and valves from KSB ensure smooth operation in power stations around the world.

Efficiency and reliability are the key features of power station pumps and valves from KSB. Energy suppliers also value numerous other benefits offered by our technologies.