- Offer Profile

-

We are specialists in the field of textile filtration and hose lines. This enables us to serve our customers with customised products that are ideally suited to the plant's respective process step.

Our passion for our products makes us one of the market leaders in our home markets (DACH + Italy). However, we are also growing steadily internationally in selected markets and applications, such as the basic materials industry.

With our sales organisation we are always close to our customers. Our products are manufactured in Schleswig-Holstein, Milan as well as Moravia, USA.

The Textile Filter Technology business unit now operates as Markert Filtration GmbH, the Hose and Coupling Technology business unit as Markert Marsoflex GmbH.

TEXTILE FILTRATION - FILTER CLOTHS

-

Filter cloth for filter presses

Our filter cloths are manufactured especially for horizontal chamber and membrane filter presses of all kinds, up to a plate width of 3 metres. The plastics, yarns and bonds used, and an innovative and perfect design, correspond with your production processes. This allows us to generate an excellent cake-release performance, a clear filtrate, a dry cake, maximum throughput and the longest service life for your applications. In addition, filter cloths have high chemical resistance and the best mechanical resistance with a low level of stretching.

We offer a vast range, from the finest to the coarsest separation performance, tailored to suit your specific requirements, and we can put it all together in the fastest time possible. Benefit from our specialists’ wealth of experience. Make use of the expertise we're gaining every day.

Areas of application:

- Preparation and dewatering of ores

- Chemical and pharmaceutical products

- Food and other versatile filtration processes

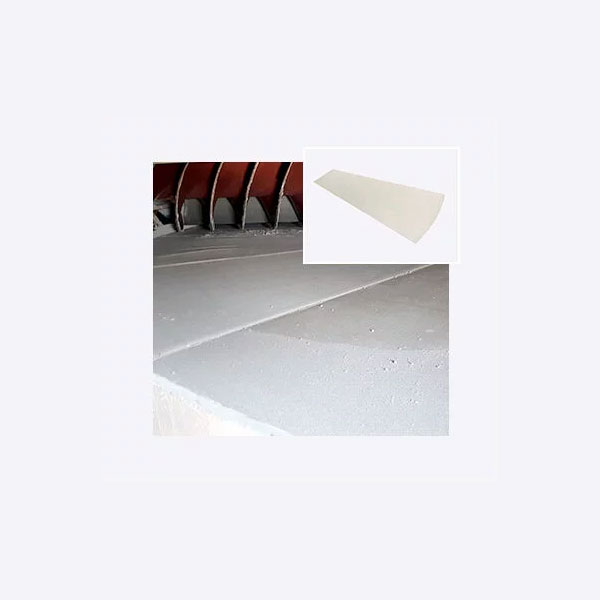

Filter cloths for Mineral & Mining

-

Single cloth with reinforced inlet and hems

In the mining and preparation of natural resources such as aluminium, coal, lime, kaolin, zinc, copper, lead, iron, nickel, silver, gold, lithium, rare earths as well as the mining of pre-products, the necessary machinery is exposed to extreme mechanical load.

Our marsyntex® filter cloths improve your production by longer lifetime, perfect dewatering and cake separation.

System: Filter press for Mining, Metso VPA, Outotec FFP, Diemme Aqseptence

Areas of application: Alumina, Mineral & Mining

Examples of use: div. concentrates and tailings

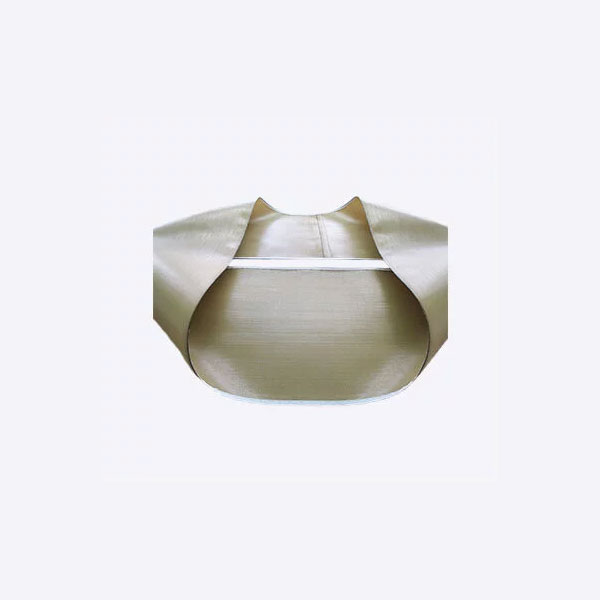

Barrel neck cloths for filter presses

- Our barrel neck cloths are easy to assemble and offer perfect fit. The filter cloths can be combined with backing cloths or support textiles to improve drainage and protect them from damages.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of sugar, production of catalysers

Leak-proof cloths

- Barrel neck cloth with cloth neck and sealing cord for perfect fit.

System: Filter presses

Areas of application: Food, chemical industry

Examples of use: Production of colour pigments, dewatering of yeast and wine lees, battery industry

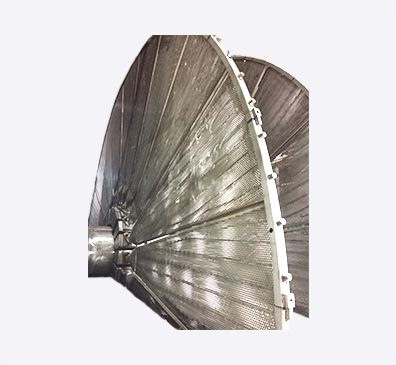

Filter cloth for vacuum pan filters

- With a combination of perfect fit and dimensional stability of the fabric, we avoid foldings and long service life of the filter.

System: Pan filters

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Filter bags

-

The marsyntex® filter bags for disc filters withstand the high mechanical loads of most different areas of application. The excellent cake drying times with best cake separation behaviour possible and the excellent durability are particularly worth mentioning.

Examples of use: Mineral & Mining, alumina

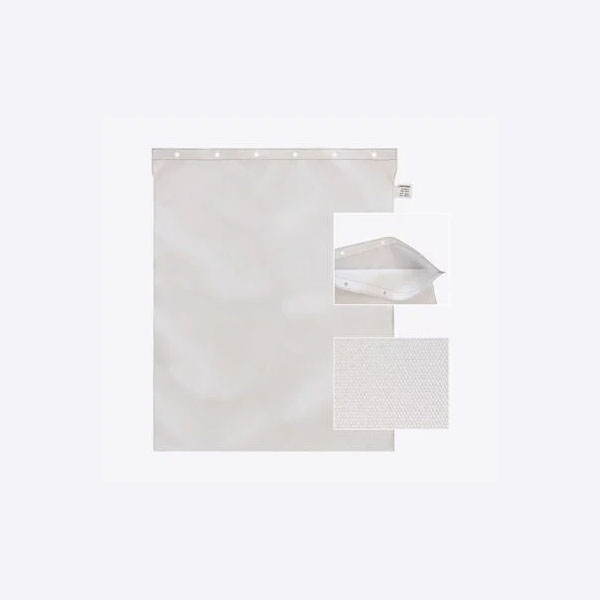

Filter bags for Diastar filters

-

Thanks to production by means of our sewing robots, our Diastar filter bags offer constant and best possible fit. High throughput with simultaneous high filtrate clarity are particularly worth mentioning. Thanks to our modified polypropylene, the bags are also resistant to maximum temperature applications up to 110°C. Depending on the system type, our filter bag consists of 3 - 8 channels, with neck and integrated sealing cord at the top. At the lower rim, there is a weight bar which is reusable, thanks to the removal slot.

System: Backflush filters

Areas of application: Alumina, food

Examples of use: Production of alumina and sugar

Filter bags for Diastar filters with welded holes

-

The filter bags for Diastar filters produced by sewing robots distinguishes itself by its high throughput and simultaneous high filtrate clarity. We produce our ilter bags of 3 - 8 channels, with neck and welded holes for neck pins at the top. At the lower rim, there is a reusable weight bar. The modified polypropylene ensures resistance at maximum temperature applications up to 110°C.

System: Backflush filters

Areas of application: Alumina, food

Examples of use: Production of alumina and sugar

PEEK filter bags for centrifuges

-

Centrifuge insert consisting of a continuously welded PEEK double-layer fabric with PTFE side edge reinforcement. PEEK is a special material which is resistant to high temperatures and chemicals.

Systems: Horizontal peeler centrifuges

Areas of application: Chemical industry

Samples of use: OLED production

Centrifuge inserts

-

For the food, chemical and pharmaceutical industry, we can recommend you our centrifuge inserts. They offer excellent resistance and provide for little particle loss. More advantages include a considerable filter cake and little residual humidity.

System: Horizontal as well as vertical peeler centrifuges, top discharge centrifuges, inverting centrifuges

Areas of application: Food, chemical industry

Centrifuge inserts for horizontal peeler centrifuge

-

Areas of application: Food, chemical industry

Examples of use: Production of pharmaceutical active agents, production of plant protection products

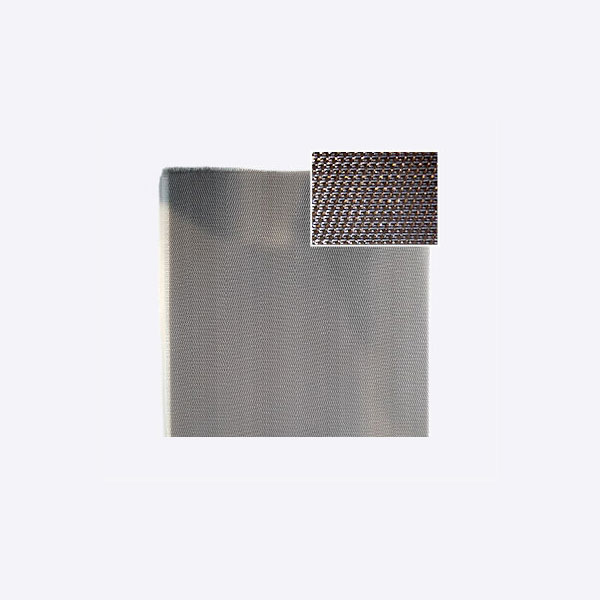

ferrutex® filter bags for disc filters

-

ferrutex®: New path-breaking fabric for iron ore and pelletizing plants. Best cleanability thanks to elastic effect with high mechanical resistance.

System: Disc filters

Areas of application: Mineral & Mining

Examples of use: Iron ore concentrate and pelletising systems, tailings and pastefill

Filter bags for disc filters

- Our filter bags ensure, for example, constantly high throughputs, 100% discharge of the filter cake and an extended service life as well as best cleanability possible. Welded longitudinal seams, instead of the standard sewn seam, ensures little particle loss Optional: Support bag to protect the filter bag and increase drainage and dewatering.

System: Disc filters

Areas of application: Alumina, Mineral & Mining

Examples of use: Concentrates, tailings and pastefill

Filter bags for leaf filters

- Due to perfect fit manufacture in combination with high-performance fabrics, filter covers suitable for the most different pressure leaf filter types ensure best possible service life and filtration. In this connection, the fabrics have to withstand highest requirements and ensure perfect cake discharge as well as clear filtrate.

System: Moore filters, DDS filters, Scheibler filters, AMA, Kelly, Niagara filters, vertical pressure filters, progress frame filters

Areas of application: Alumina, Mineral & Mining, chemical industry and food

Support bags for disc filters

- The support bag supports abrasion protection, extension of the service life and the increase in the drainage area.

Areas of application: Alumina, Mineral & Mining

Examples of use: Concentrates, tailings and pastefill

Support cloth for the centrifuge insert

-

Thanks to the drainage function, the filtration speed is increased and at the same time also the cake dewatering during centrifugation.

Areas of application: Alumina, food, chemical industry

Anode and cathode bags

-

Benefits, special features: Bags for anodes and cathodes are used in many electrolysis processes. After many years of research and development, Markert has developed a new, high-performance fabric for nickel electrolysis that offers the best operating conditions in terms of high mechanical and chemical resistance, low electrical resistance and water permeability.

Equipment: electrolysis baths (anodes and cathode)

Areas of application: Chemical, mining, processing, metallurgy

Examples of use: e.g. nickel electrolysis, electroplating, chlorine

Tube Filter bags

-

Benefit, Feature: Markert Tube Filter bags are characterized by ultra-fine separation of less than 5 microns. They are also manufactured very smoothly to ensure good cake release. We weld our bags at the longitudinal seam to prevent the loss of fine particles.

Equipment: bag filter / tube filter

Areas of application: Chemical, pigments, food, metallurgy

Examples of use: Silica, starch, concentrates

Filter belts

-

Based on our experience, we offer you high-quality marsyntex® filter belts, seamless up to a width of 4.5 m, and the suitable clipper seam connections. We provide you with the perfect solution for your filtration system used and the process conditions.

We achieve continuous filtration efficiency and long service life. In the following, we present you different solutions.

They can be individually used in most different areas of application on the following systems: Filter belts for belt filters, tower presses, rotary filters, double-belt presses.Examples of use: Mineral & Mining, alumina, food, chemical industry

Filter belt for phosphoric acid

-

Benefit from the impressive characteristics of thefilter fabric DID 11137. Used in the phosphogypsum filtration area, the process sequence of your system is clearly optimised.

System: Horizontal vacuum belt filters

Examples of use: Phosphogypsum filtration

Filter belt for tower press

-

Our dimensionally stable belts are available up to a maximum width of 1.7 m and lengths up to 215 m. They ensure reliable straight running with perfect separation effect. Apart from that, they offer excellent cleanability and mechanical resistance. Air permeability is possible within a range from 0.5-270 dm³/dm²*min. The marsyntex filter belts are pre-stretched to minimise shrinking and stretching.

System: Tower press

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of concentrates, calcium phosphate, calcium chloride

Rotary filter cloth with rubber profiles

-

The profile ensures straight running and thus optimises guidance of the belt.

System: Rotary filters

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of starch, zeolites and copper concentrate

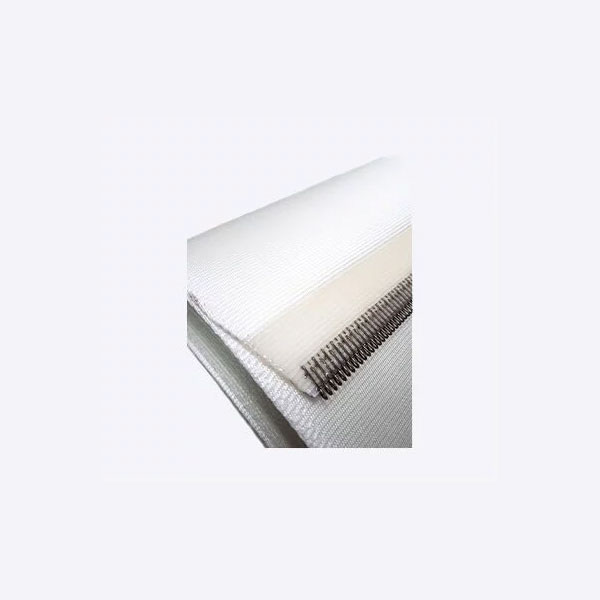

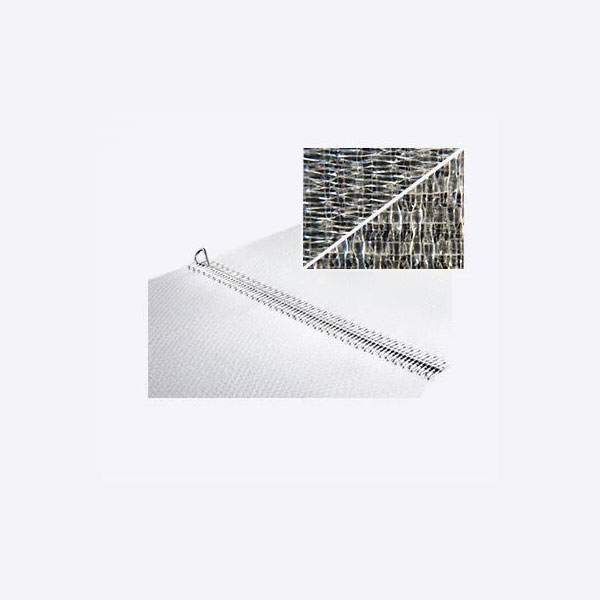

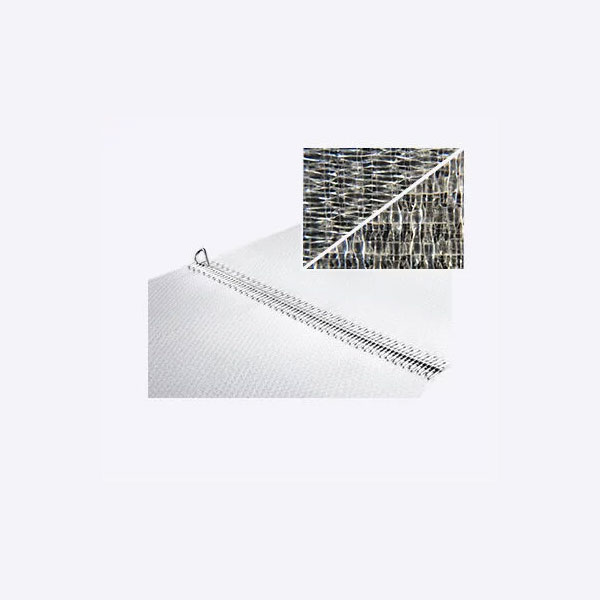

Filter belt with coated clipper seam

-

The integrated clipper seam prevents particle loss.

System: Tower press, belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry

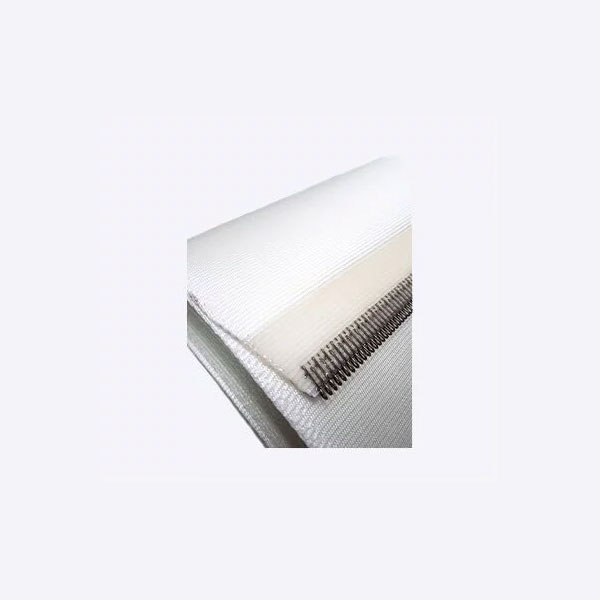

Filter belt made of double-layer fabric with clipper seam

-

This special binding ensures absolute freedom from folds, good cake separation and excellent dewatering behaviour (maximum width 4.5 m).

System: Belt and rotary filters, vacuum filters

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Production of zinc oxide, jarosite, nickel, zinc and copper concentrate, tailings

Filter belt with seamless overlap

-

The seamless overlap of the belt allows for a smooth transition at the scraper.

System: Belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry

Filter belt with overlap and dewatering zone

-

The dewatering zone prevents collection of solid material between the fabric layers.

System: Belt and rotary filters

Areas of application: Food, chemical industry

Filter belt with flexible plastic pintle wire

-

Thanks to the integrated plastic wire and the seam, this corrosion-resistant filter belt allows easy assembly. As opposed to steel wires, breaking of the wire is not possible.

System: Belt and rotary filters

Areas of application: Food, chemical industry

Filter belt with especially strengthened side edges

-

The strengthened side edges promote straight running of the belt and thus prevent fraying of the fabric edges.

System: Belt and rotary filters

Areas of application: Mineral & Mining, food, chemical industry

More products

Micro sieve

- System: Micro sieve drum

Examples of use: 4. Cleaning level sewage water in treatment plants

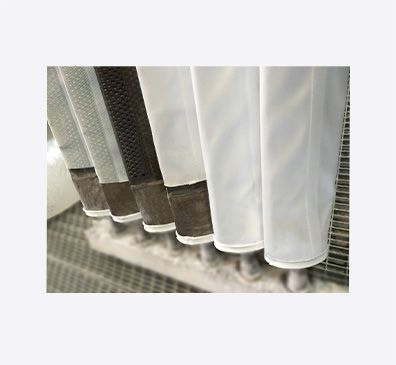

Filter hoses for cartridge filters

- Our marsyntex® filter hoses, filter fabrics and support fabrics are supplied in seamless, sewn or welded variants. In this connection, we use textile, high-quality materials.

System: Cartridge filters

Areas of application: Chemical industry, alumina & food

Examples of use: Production of chlorine (chlorine electrolysis), production of sugar

Fluidisation funnels

- marsyntex® fluidisation funnels are used in silo vehicles for the even, trouble-free transport as well as for fast unloading of bulk goods.

System: Silo vehicles

Areas of application: Food, chemical industry, Mineral & Mining

Examples of use: Use in the loading and transport of bulk goods

Catching baskets for pelletising systems

- marsyntex® catching baskets are used in the pharmaceutical industry and are especially produced for catching the pellets (pharmaceutical active agents).

System: Fluid bed dryers

Areas of application: Food

Examples of use: Pharma tabletting

Filter discs

- These filters are suitable above all for suspensions with a low solid content. We offer solutions in a wide variety of pore sizes.

System: Horizontal disc filters

Areas of application: Food, chemical industry

Filters for fluid bed dryers

- The high-quality processing of the marsyntex® filters for fluid bed dryers guarantees perfect filtration. The welded seam enables us to guarantee little particle loss of your medium. We offer the marsyntex® filters for fluid bed dryers in different sizes, weaving patterns and air permeabilities in an antistatic execution.n an antistatic fabric.

Examples of use: Food, pharma

System: Fluid bed dryers

Areas of application: Food, chemical industry

Loading hoses

- Loading hoses guarantee effective and emission-free discharge, loading and delivery of bulk goods in all weather conditions.

Examples of use: Bulk good loading

System: Loading systems

Areas of application: Alumina, food, chemical industry

Filters for dust filtration

- In addition to perfect filtration performance and efficiency, marsyntex® dust filters offer easy cake discharge, manufacturing quality for a long service life and high temperature resistance.

Examples of use: Filtration/retention of dust (concrete/lime works)

System: Cartridge filters

Areas of application: Food, chemical industry

Filter plates and membranes for filter presses

- We supply suitable filter plates for all filter presses and tower presses. This includes e.g. chamber plates and membrane plates as well as loose membranes for exchange or upstream installation.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Examples of use: Filter presses in all production areas

Steel segments for disc filters

- Our disc filter sectors offer high durability with simultaneous very low weight of less than 10 kg. Thanks to their special design, they are the perfect supplement for the marsyntex® filter bags.

Areas of application: Alumina

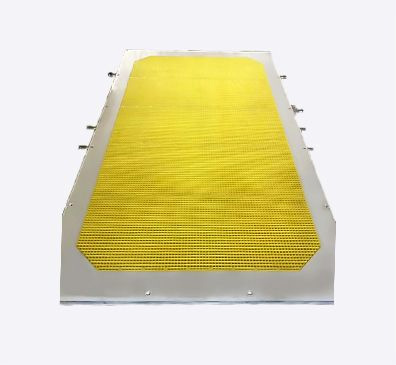

Plastic support grids for automatic press filters

- Depending on the application temperature, we can offer you plastic support grids made of different materials. They offer perfect dewatering performance and high durability.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Plastic segments for disc filters

- marsyntex® plastic segments for disc filters distinguish themselves by their easy handling.

Areas of application: Alumina, Mineral & Mining

Rubber membrane for filter presses and tower presses

- Depending on the application conditions, we offer rubber membranes made of different materials.

Areas of application: Alumina, Mineral & Mining, food, chemical industry

Feeding shoe for mining cloths

- Use of the marsyntex® feeding shoes makesany additional sealing unnecessary. It allows for simple and easy filter cloth exchange and operation of the filter cloth.

Areas of application: Alumina, Mineral & Mining

HOSES TECHNOLOGY

-

Markert offers Hoses and hose assemblies for industrial use in the chemical, petrochemical, pharmaceutical and food industries, as well as in plant engineering, by freight carriers or tank terminals.

Hose assemblies are omnipresent in industrial applications, whether in a refinery or in high-purity pharmaceutical processes: Industrial hose assemblies are used universally. It should be noted, however, that hose assemblies are pressurised components that often carry critical media and vary enormously:

- PTFE liner material

- Cover material

- Vacuum resistance of the hose

- Abrasion properties of the cover

- Integration of the fittings

- Conductivity

- Approvals for materials used

In order to reliably rule out any risk to people, the environment and the plant, expert advice is absolutely essential. As the manufacturer, we are your expert and at your side to assist you with advice and action.

Markert has decades of expertise and offers the widest range of products on the market. Coupled with our large central warehouse and quick response times, we are your contact when it comes to industrial hose assemblies.

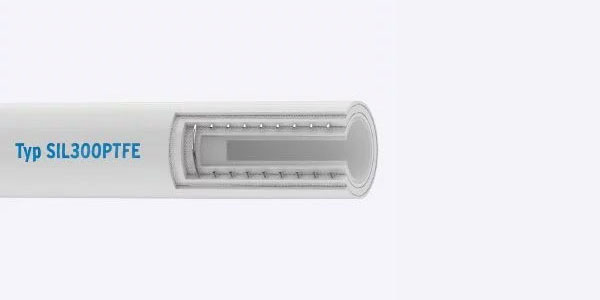

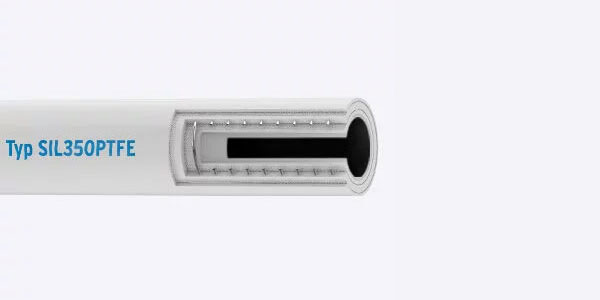

Hoses

- From the correct PTFE liner for the medium to be transported, the correct pressure carrier for the operating pressure, the suitable hose cover for the intended application and a stainless steel spiral for vacuum use, we make you the best possible product for your conditions of use – always with the required conductivity. Whether it’s for loading and unloading tankers or for blood plasma applications in a pharmaceutical industry clean room, we will find the perfect hose for you.

PTFE hoses

Silicone hoses

Rubber hoses

Composite hoses

Food hoses

Tanker and bunker hoses

Operating media hoses

Stainless-steel corrugated tube hoses

Custom components

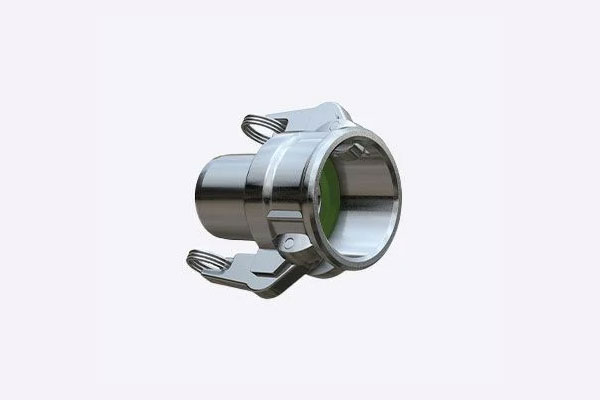

Hose couplings & hose fittings

-

If a hose is integrated with fittings, this creates what is known as a hose assembly. The variety of materials and designs for hoses is immense, but is dwarfed by the greater variety when it comes to fittings and connections.

The correct binding technology must be used to connect the hose and fitting. Regardless of whether it's clamp collars, press fittings or PTFE lining: as a manufacturer of hose assemblies, Markert has decades of experience so that every connection proves safe and reliable in use.

In addition to the fittings and connections listed below, Markert offers a wide range of special connections that can be used to reproduce any plant situation. If necessary, we also manufacture fittings from Hastelloy, for example, or we can create customised designs: we will be happy to advise you.

Quick couplings

Linings and coatings

Safety couplings

Hose connections

Seals

Accessories

-

Due to the wide range of applications for industrial hose assemblies, there are many requirements when it comes to design and handling.

Harsher operating conditions such as:

- Chafing on floors and edges

- "Running over" the hose assembly

- Kinking

- Lacking the minimum bending radius

- Frequent pressure and load changes

- High bending cycles

- Torsion of the hose assembly

- Tensile and compressive loads

- Abrasion

- High exposure to UV radiation

- Excessive temperature load

can drastically reduce durability.

Appropriate additional equipment can increase the durability of the hose assembly and make handling significantly easier.

Kink protection, which provides reliable reinforcement for the hose assembly at the insertion point, and heat protection (Pyro), which provides protection against several hundred degrees Celsius, are common additional features. There are also a wide range of other tools and product features, such as:

- Hose reel

- Hose suspension

- Balancer

- Abrasion protection

- Hose holder

- Protection against over run

- Impact ring

- Swivel joints

We will be happy to advise you so that you can get the right additional equipment for your hose assembly.

Rubber Kink Protection Plus

- In cooperation with leading customers and our R&D department, we developed the Rubber Kink Protection Plus.

Pyro heat protection

- Your production operations won't break a sweat: Whether hose, belt or mat, offers products which are resistant even to extremely high temperatures.

IBC connections

- We offer various connections for your IBC container.