- Offer Profile

-

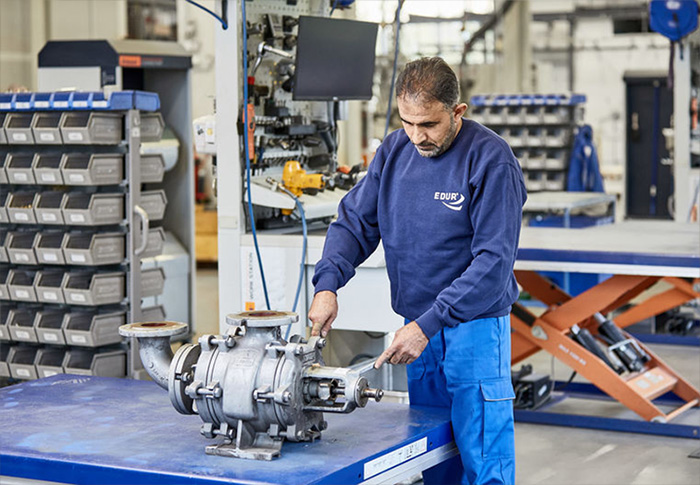

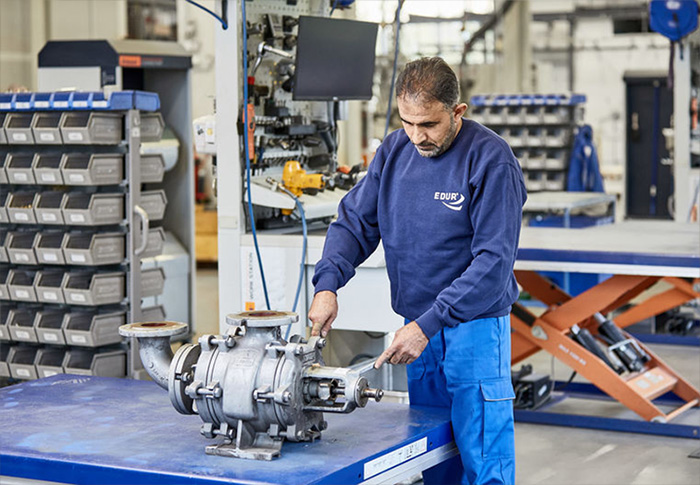

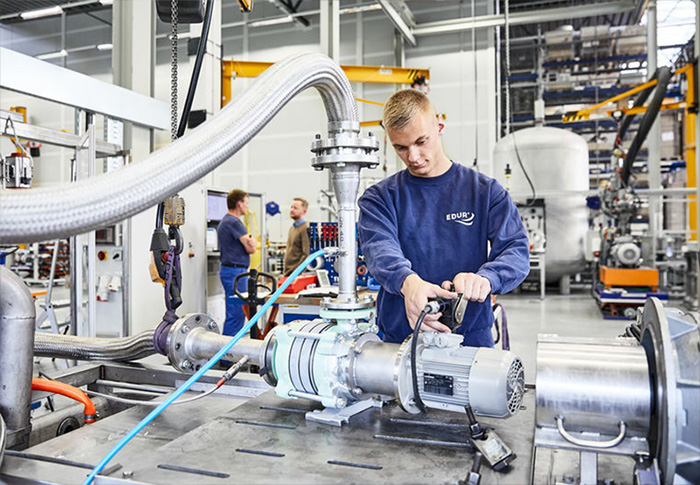

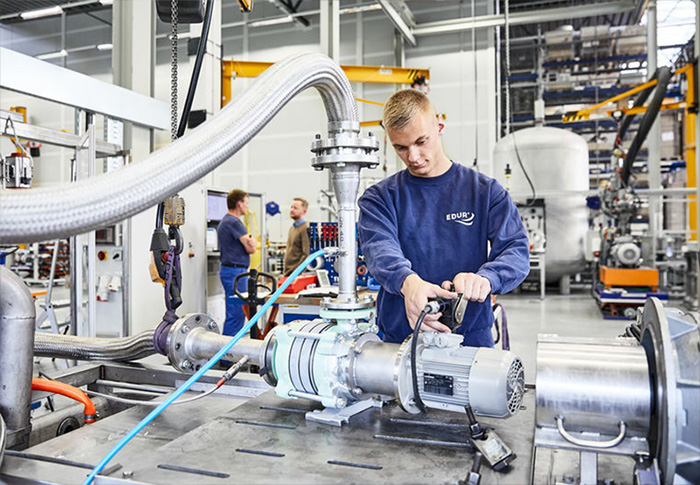

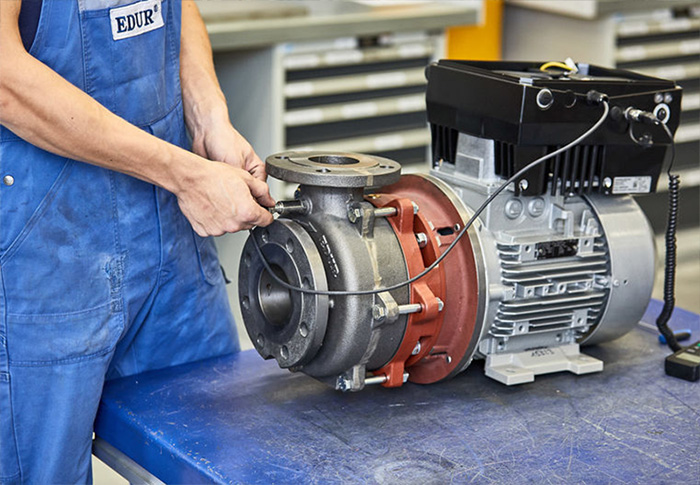

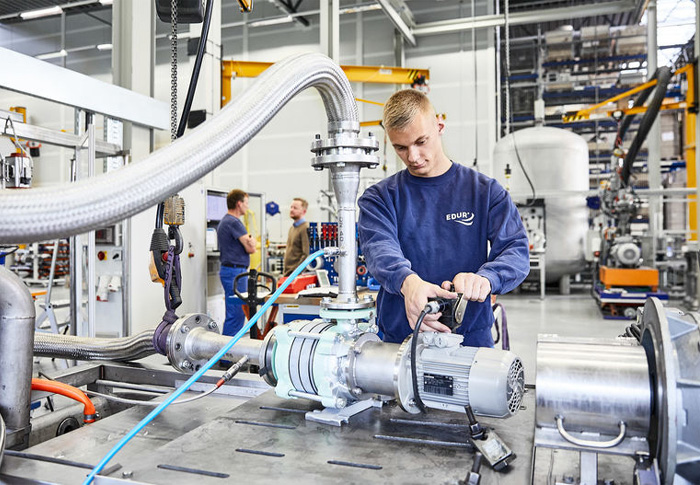

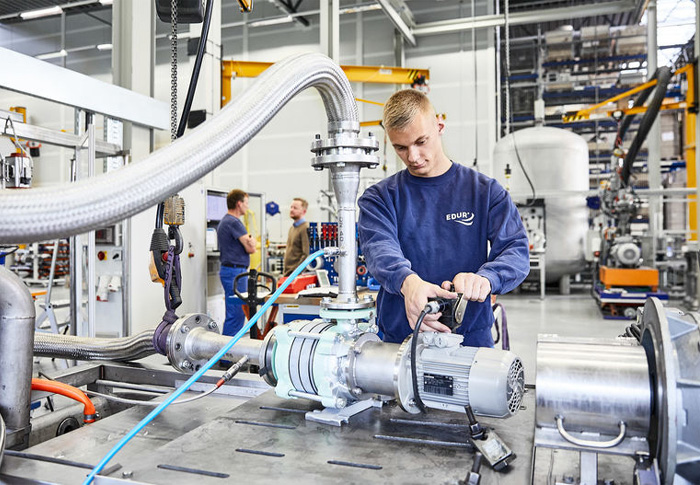

EDUR is your specialist for individual centrifugal pumps. As a developer and manufacturer of centrifugal pumps, we produce custom-fit pumps for your application.

At the same time, we act as a competent consultant and technology partner with international orientation and comprehensive service for our customers.

Product portfolio: CENTRIFUGAL PUMPS FROM NORTHERN GERMANY

- EDUR-pumps are always configured in a customer-specific way. A modular system allows us to provide individual high-quality solutions for different applications. Detailed information about our individual pump types can be found here.

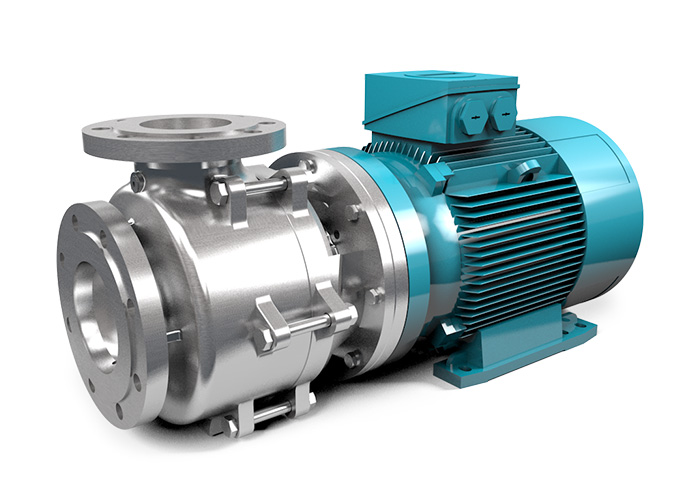

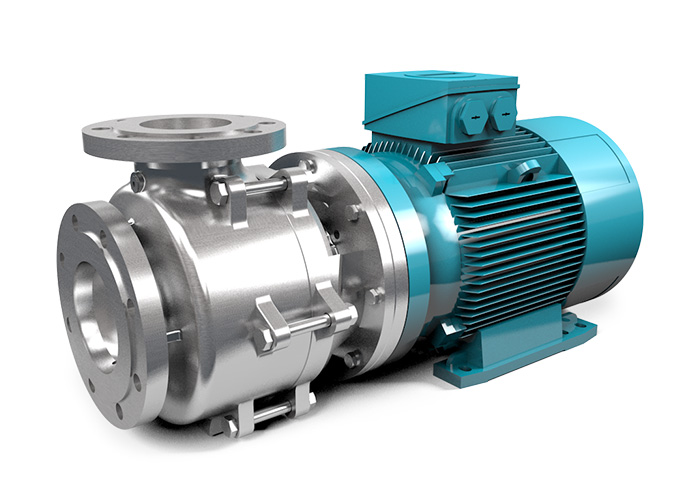

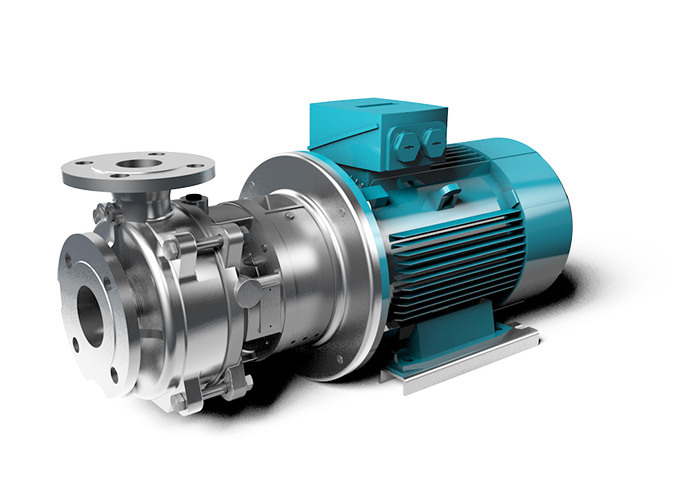

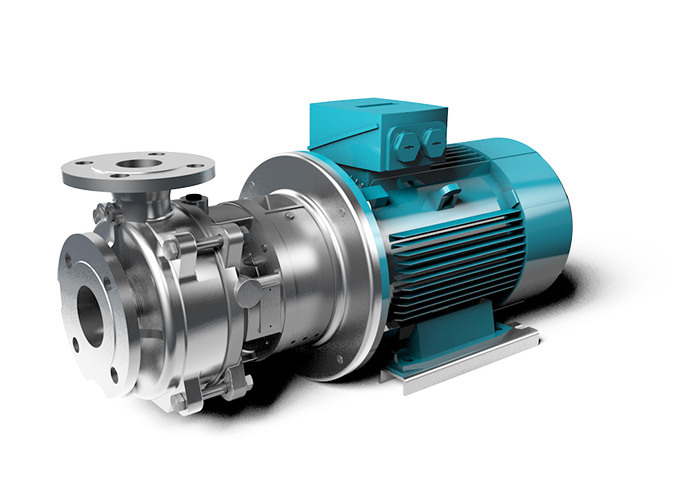

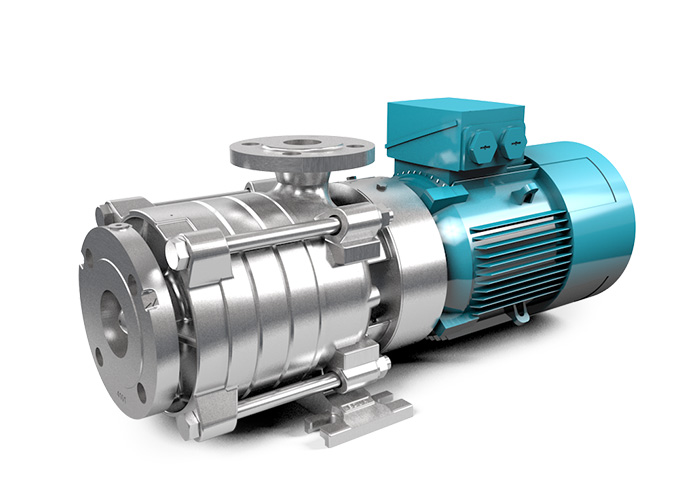

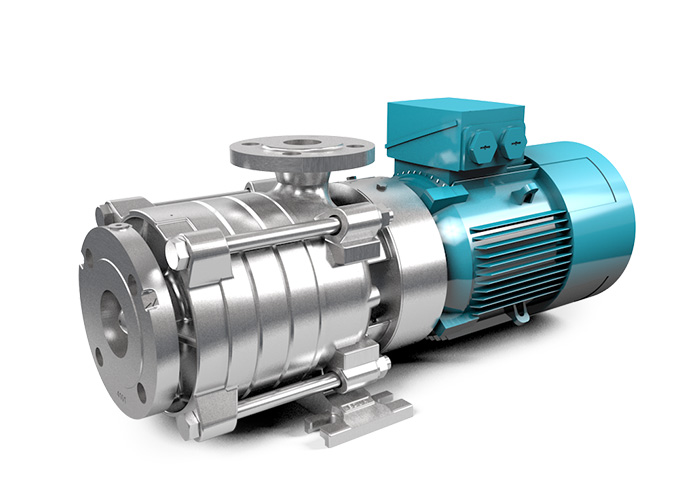

SINGLE STAGE CLOSE-COUPLED PUMPS

-

EDUR-single stage close-coupled pumps are robust and efficient pumps with a long service life. They are characterized by compact assembly, customer-specific design options and a wide range of possible applications.

Fields of Application and Conveyed Fluids

Depending on customer requirements, our single stage close-coupled pumps are used in many applications: They can be used for cooling technology, energy technology, industrial cleaning technology, water and wastewater technology as well as in the chemical industry. The pumps are particularly suitable for the supply of pure or slightly contaminated liquids.

Advantages

Technical superiority

- Variety of seal systems

- Large selection of material options

- Low NPSH (Net Positive Suction Head) values

- Axial thrust-free, open or load-relieved, closed impellers

- Compensation of the radial forces due to diffuser elements in the ring

- Energy-efficient motors

Process safety

- Unsusceptible to certain amounts of solid contents

- Possible protection against dry run

- Possible vacuum operation

- Low-pulsation supply

- Additional safety through the use of monitoring equipment

- Low noise emissions

- Long lifetime

High energy efficiency

- Low flow velocity in the outlet branch

- Low velocity head difference

Assembly-friendly

- Modular design for customized solutions

- Compact close-coupled design / minimal space requirements

- Various installation positions

Field of application

- Flow rate: max. 600 m³/h

- Head: max. 98 m

- Permissible operating pressure: up to 16 bar

- Temperature: -50 °C to +140 °C

- Viscosity: up to 200 mm²/s

SINGLE STAGE INLINE PUMPS

-

EDUR-single stage inline pumps are space-saving, robust and efficient. Due to their reliability, they have been successfully used in many industrial areas.

Fields of Application and Conveyed Fluids

Our single stage EDUR-pumps in inline design are especially used within cooling technology, energy technology, industrial cleaning technology, water and wastewater technology or other industrial applications. They are most suitable for the supply of clean or slightly contaminated liquids.

Advantages

Technical superiority

- Axial thrust-free, open or load-relieved, closed impellers

- Compensation of the radial forces due to diffuser elements in the ring housing

- Low NPSH (Net Positive Suction Head) values

Process safety

- Possible protection against dry run

- Possible vacuum operation

- Excellent control behaviour

High energy efficiency

- Low flow velocities

- Low velocity head differences

Assembly-friendly

- Modular design for customized solutions

- Compact close-coupled design / minimal space requirements

- Pullback design

- Operational spacer coupling

Field of application

- Flow rate: max. 220 m³/h

- Head: max. 66 m

- Permissible operating pressure: up to 10 bar

- Temperature: -40° C to +140° C

- Viscosity: up to 200 mm²/s

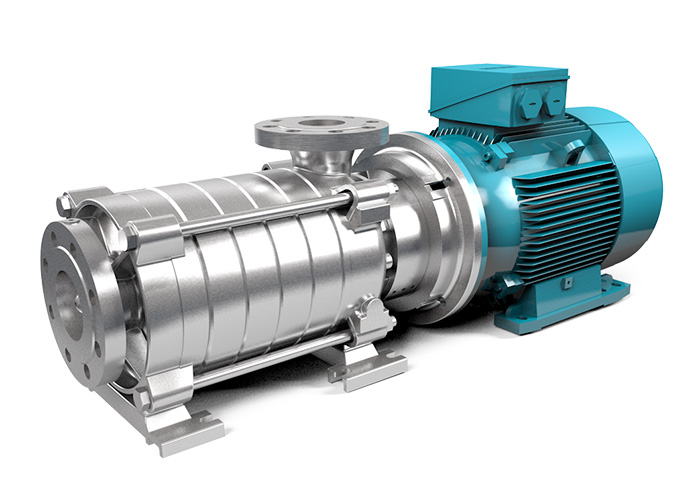

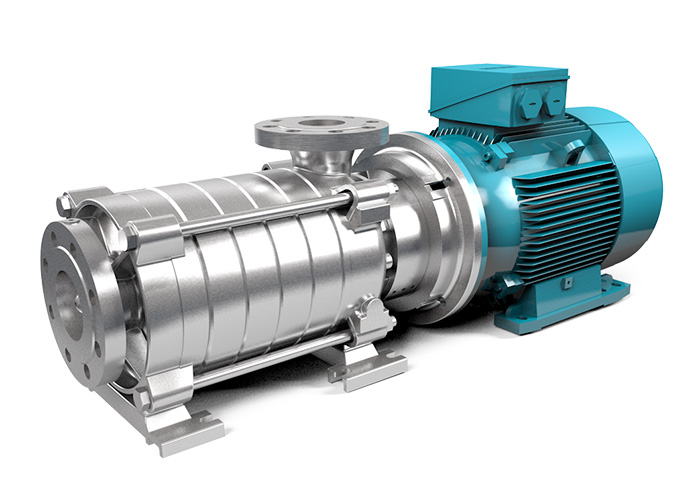

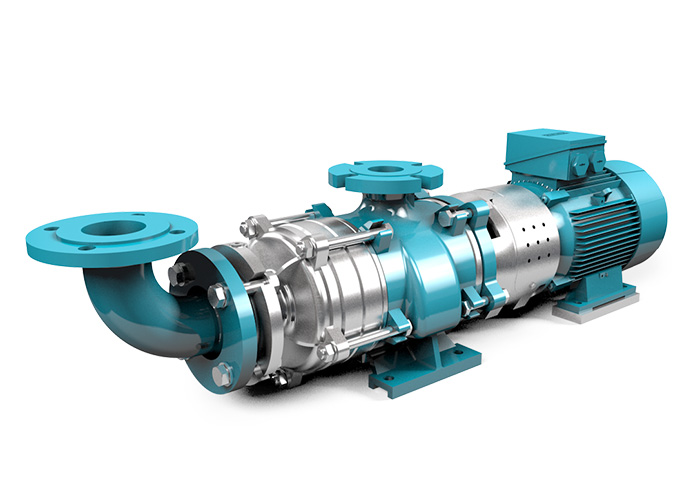

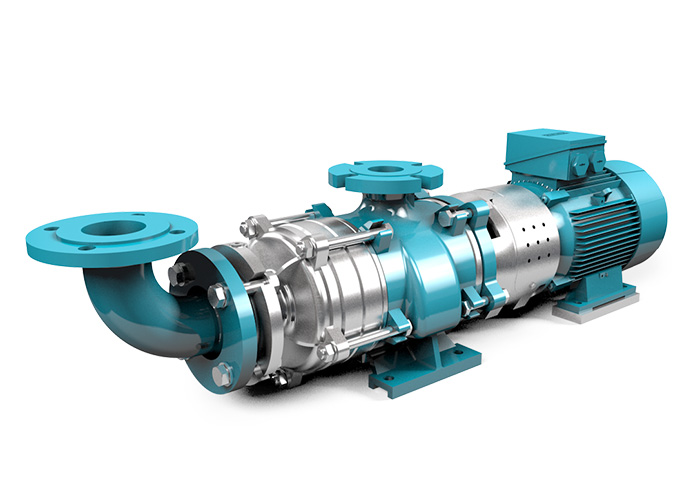

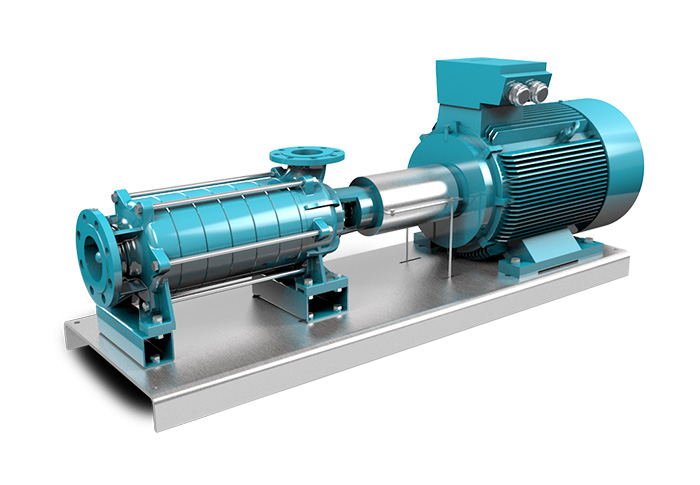

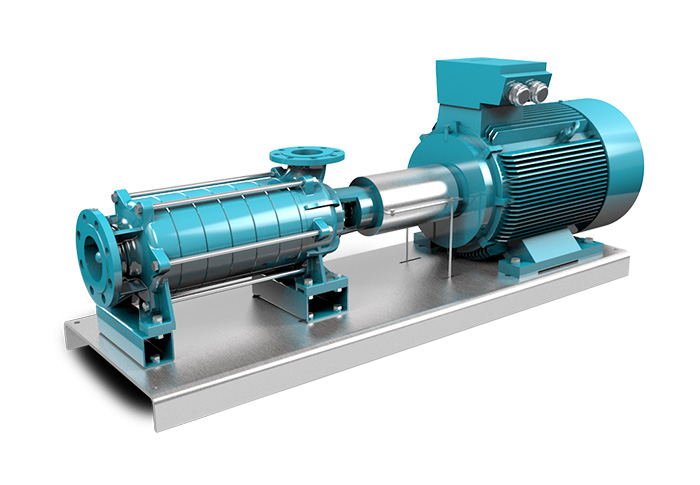

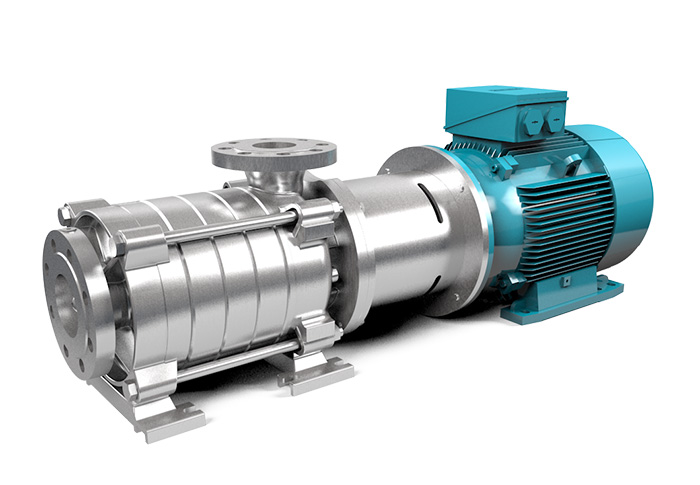

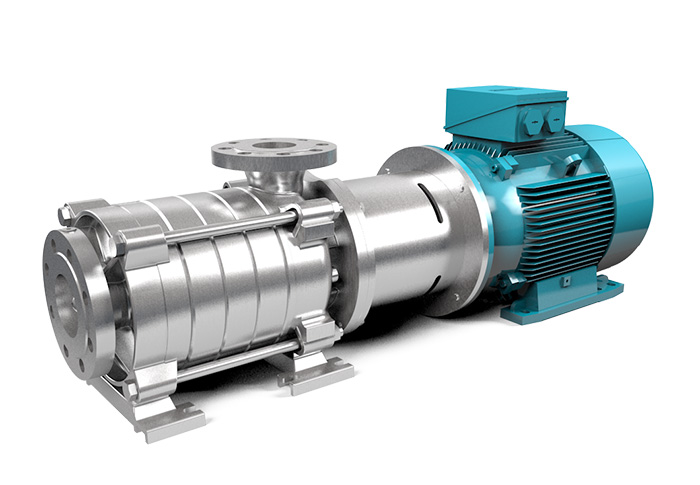

MULTISTAGE CENTRIFUGAL PUMPS

-

Multistage centrifugal pumps from EDUR, characterized by a compact sectional construction in horizontal or vertical design, are used to achieve high pumping pressures.

Fields of Application and Conveyed Fluids

Multistage centrifugal pumps are used within water technology, energy technology, industrial cleaning technology and in cooling technology as well as in the field of liquefied gas applications. They are applied when higher pumping pressures are required for conveying pure or slightly contaminated liquids.

Advantages

As all EDUR-pumps, multistage centrifugal pumps stand out due to their efficiency, economy and reliability. Moreover, further product advantages are outlined below:

High energy efficiency

- Low flow velocities in the outlet branch

- Low velocity head differences

Technical superiority

- Variety of seal systems

- Axial thrust-free or axial thrust-relieved closed impellers

- Compensation of the radial forces due to diffuser elements in the ring housing

Process safety

- Gas-loaded liquid conveyance is possible

- Excellent control behaviour

- Low NPSH (Net Positive Suction Head) values up to 0.5 m

Assembly-friendly

- Large flange nominal widths

Field of application

- Flow rate: max. 170 m³/h

- Head: max. 300 m

- Permissible operating pressure: up to 40 bar

- Temperature: -50° C to +220° C

- Viscosity: up to 115 mm²/s

MULTISTAGE INLINE PUMPS

-

Multistage inline pumps from EDUR stand out due to their compact and vertical design. They are especially used in applications where high pumping pressures are needed.

Fields of Application and Conveyed Fluids

EDUR-multistage inline pumps are applied within water technology, cooling technology, energy technology and in other industry branches. They are especially used where higher pumping pressures are required for conveying pure or slightly contaminated liquids.

Advantages

Technical superiority

- Axial thrust-relieved impellers

- Diverse connection variants (flange, clamp and others)

Process safety

- Easy exchange due to standardisation

- Drinking water approval on request

Low maintenance

- Dismounting of the mechanical seal without disassembly of the motor lantern

- Optional: Cartridge seals

Field of application

- Flow rate: max. 120 m³/h

- Head: max. 342 m

- Permissible operating pressure: up to 35 bar

- Temperature: -30° C to +140° C

- Viscosity: up to 115 mm²/s

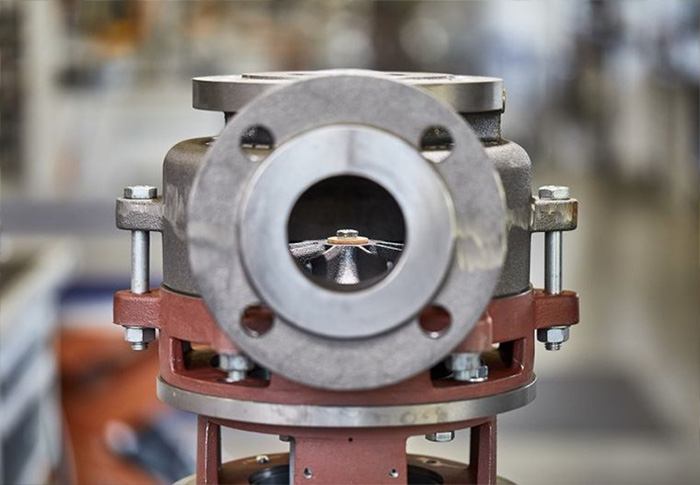

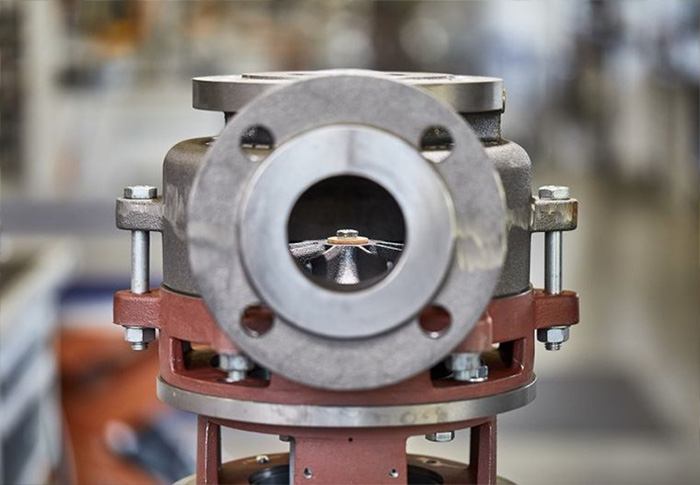

TORQUE FLOW PUMPS

-

Torque flow pumps from EDUR have a compact design that is unsusceptible to cavitation. They ensure smooth transport of solids-containing fluids.

Fields of Application and Conveyed Fluids

EDUR-torque flow pumps are especially used within water and wastewater technology as well as in industrial cleaning technology. Here, torque flow pumps are used both for the supply of solids-containing fluids and for the supply of suspensions. Typical conveyed fluids are

- Wastewaters

- Cooling lubricants interfused with chips, grinding oils or suds

- Lime milk

- Fluid media transported within liquids.

Advantages

Technical superiority

- Pulse transmission due to a setback free-flow impeller

- Free ball passage up to 80 mm diameter

- Optional: Anti-abrasion coatings

Process safety

- Solids co-transport

- Single- and double-acting mechanical seal

- Unsusceptibility to cavitation

- Gentle product supply

- Unsusceptibility to fibrous waste and clump formation

Assembly-friendly

- Various installation positions

- Compact close-coupled design

Low maintenance

- Pullback design

- Robust design

Field of application

- Flow rate: max. 390 m³/h

- Head: max. 61 m

- Permissible operating pressure: up to 16 bar

- Temperature: -50° C up to +180° C

- Viscosity: up to 60 mm²/s

- Solids content: up to 15 %

SELF-PRIMING CENTRIFUGAL PUMPS

-

Self-priming EDUR-centrifugal pumps are particularly suitable for slightly contaminated as well as gas-emitting liquids. Due to their characteristic design, they can also suck up and further supply lower-lying liquids.

Fields of Application and Conveyed Fluids

EDUR-self-priming centrifugal pumps are mainly used within energy technology, water and wastewater technology, cooling technology, industrial technology as well as in liquefied gas applications.

In contrast to non-self-priming pumps, self-priming centrifugal pumps are able to ventilate the suction line and to self-prim lower-lying liquids. Also gas-emitting fluids can be supplied reliably. The pumps stand out due to low suction times and high efficiency grades to guarantee reliable operation. Special characteristics are also the high air flow rate and wear resistance.

Self-priming pumps from EDUR are suitable for the supply of slightly contaminated water, cooling water, emulsions, oils and fuels such as kerosene, petrol and diesel.

Advantages

High energy efficiency

- Integrated jet pump or formation of mixture

- Low flow velocities

- Low internal friction loss

- Low NPSH (Net Positive Suction Head) values

Technical superiority

- Axial thrust-free, open or load-relieved, closed impellers

- Compensation of the radial forces due to diffuser elements in the ring housing

Process safety

- Self-priming

- Possible conveyance of gas-loaded liquids

Assembly-friendly

- Horizontal design

- Block and base plate design

Field of application

- Flow rate: max. 300 m³/h

- Head: max. 165 m

- Permissible operating pressure: up to 16 bar

- Temperature: -40° C up to +110° C

- Viscosity: up to 115 mm²/s

MULTIPHASE PUMPS

-

EDUR-multiphase pumps are designed to supply integrated liquid-gas mixtures and to generate dispersions. They enable the supply of up to 30% gas proportions.

Fields of Application and Conveyed Fluids

EDUR-multiphase pumps are used in water and wastewater technology as well as in different industrial technologies. Multiphase pumps supply liquid-gas mixtures and enrich liquids with gases, such as air, oxygen or ozone.

Functionality

The pump hydraulic differs in terms of structure and mode of operation from conventional centrifugal pumps and thus allows throttled-down operation on the suction side without cavitation arising that is critical when using standard centrifugal pumps. Gas proportions up to 30% are self-primed and safely co-supplied. In addition, dynamic mixing and an excellent gas saturation is guaranteed by those pumps.

Advantages

Innovative supply concept

- Excellent gas saturation

- Sucking and co-supplying of gas proportions up to 30%

- Dynamic mixing

- Ideal dispersion with bubble sizes between 30 and 50 ?m

- Excellent bubbles image (“white water”)

Cost saving potentials

- Significant reduction of system components (compressor, pressure tank, elaborate control unit and various valves are omitted)

- High process safety – minimum downtimes

- Low investment costs

- Reduced maintenance and service costs

- Low running costs

- Retrofit of existing systems

High energy efficiency

- Low flow velocities

- Low internal friction loss

- Low NPSH (Net Positive Suction Head) values

Assembly-friendly

- Modular design for customized solutions

- Compact close-coupled design / minimal space requirements

Technical superiority

- Direct gas entry into the suction line

- Energy-efficient motors

- Low-noise operation

Design

- Optimum pump specification by our specialised engineers

Field of application

- Flow rate: max. 60 m³/h

- Head: max. 250 m

- Permissible operating pressure: up to 40 bar

- Gas conveyance: up to 30%

- Temperature: -50° C up to +140° C

- Viscosity: up to 115 mm²/s

LIQUEFIED GAS PUMPS

-

EDUR-liquefied gas pumps are compact, high-performance pumps for the supply of liquefied gases in applications with high pressure differences. They reliably and safely fulfill the highest requirements and achieve superior efficiencies during the process.

Fields of Application and Conveyed Fluids

EDUR-liquefied gas pumps are required for unloading, refuelling, transferring and filling processes. The requirements for a liquefied gas pump are high: high pressure differences, handling of gas contents, low NPSH (Net Positive Suction Head) values, low-pulsation supply, low noise emission and ATEX conformity. Users of liquefied gas pumps expect safe supply of liquefied gas mixtures, mastering outgassing and fluctuations of the vapour pressure and high pump efficiencies. The efficiency grade of the liquefied gas pump leads to a low energy consumption, smaller drive units and relatively compact pumps.

EDUR-liquefied gas pumps are used at different positions within the transport process. Applications are found within tank plants, tank trucks, refrigerating installations, in the beverage industry and in the process technology as well as in ship building. The pumps ensure a safe distribution of liquefied gas along the entire process from production to the end consumer. EDUR-liquefied gas pumps are especially used to supply LPG gases (liquefied petroleum gas) such as butane, propane and their derivatives.

Advantages

Low running costs

- Very high efficiencies

Process safety

- Gas-loaded liquid conveyance

- Large operating range

- Suction and intake mode possible

- High nominal pressures

- Low NPSH (Net Positive Suction Head) values

- Full conveying capacity by cavitation-free operation

- ATEX-certification

- Explosion-protected, customised motors

- Low-pulsation supply

- Low noise emission

- Long lifetime

- Highest safety

- Easy handling

- Easy servicing

Technical superiority

- Axial thrust-free, open or load-relieved, closed impellers

- Compensation of radial forces due to combination of diffuser with blade and ring housing

- Single- and double-acting mechanical seals or optionally magnetic couplings

- Energy-efficient motors

Assembly-friendly

- Modular design for customized solutions

- Compact block or baseplate design / little space required

Design

- Optimum pump specification by our specialised engineers

Field of application

- Flow rate: max. 170 m³/h

- Head: max. 300 m

- Permissible operating pressure: up to 40 bar

- Temperature: -50° C up to +110° C

- Viscosity: up to 115 mm²/s

SUBMERSIBLE PUMPS

-

EDUR-submersible pumps are placed directly into the conveyed fluid and are best suited for the reliable transport of aggressive fluids. They stand out in terms of process safety due to a guaranteed exclusion of leakages.

Fields of Application and Conveyed Fluids

EDUR-submersible pumps are multi-purpose pumps. They are used when bad intake conditions or critical conveyed fluids inhibit a dry installation of pumps. Main application fields can be found within cleaning technology. Possible conveyed fluids of submersible pumps from EDUR are pure or slightly contaminated liquids. Typical applications of EDUR-submersible pumps are, for example, pre-treatment plants for the surface technology dealing with hot aggressive liquids circulating inside.

Advantages

High process safety

- Low NPSH (Net Positive Suction Head) values

- Optional free-flow impeller

Assembly-friendly

- Modular design for customized solutions

- Compact design / minimal space requirements

Design

- Optimum pump specification by our specialised engineers

Field of application

- Flow rate: max. 300 m³/h

- Head: max. 55 m

- Permissible operating pressure: up to 16 bar

- Temperature: -25 °C up to + 90 °C

- Viscosity: up to 200 mm²/s

- Special executions for individual conditions

MAGNETICALLY COUPLED PUMPS

-

EDUR-magnetically coupled pumps are well suited for the reliable transport of toxic, environmentally hazardous and explosive conveyed fluids. Leakages are prevented by hermetic sealing of the magnetic coupling.

Fields of Application and Conveyed Fluids

Magnetically coupled pumps from EDUR are often used within cooling technology, transport of liquefied gas, energy technology as well as other industrial technologies. They are used for the supply of pure or slightly contaminated water, but they are especially well suited for the supply of toxic, environmentally hazardous and explosive fluids as well as for high-temperature applications.

The drive torque of the motor is transferred to the pump shaft through magnetic field strength. A “can” hermetically separates the interior of the pump from the atmosphere. The bearing of the pump shaft is designed in medium-lubricated slide bearings. This prevents any amount of leakage, which would otherwise occur with conventional shaft seals.

Advantages

Process safety

- High energy efficiency due to low-loss / lossless magnetic couplings

- Comprehensive testing of entire unit

- Easy servicing

- Hermetically sealed

- Absolutely wear-free

- High operational safety

- Long lifetime

- ATEX approval on request

Assembly-friendly

- Modular design for customized solutions

- Compact design / minimal space requirements

Field of application

- Flow rate: max. 600 m³/h

- Head: max. 300 m

- Permissible operating pressure: up to 40 bar

- Temperature: -50°C up to 220°C

- Viscosity: up to 200 mm²/s

INDIVIDUAL CENTRIFUGAL PUMPS

-

Are you still looking for the right pump for your application? We would be happy to advise you and develop your best pump solution together with you!

THE RIGHT EDUR CENTRIFUGAL PUMP

EDUR pump specialists will be pleased to advise you from the planning phase onwards. Even when revising your existing systems, great potential for improvement can be achieved.

Our centrifugal pumps cover a very wide range of products and are available in many design and material variants with different sealing systems and drive solutions. We will be pleased to implement your individual wishes and requirements and will be at your side from the inquiry to the installation and of course beyond.

REFRIGERANT PUMPS

-

EDUR refrigerant pumps are designed for high loads and extreme temperature ranges in the cooling process. They are used for the reliable transport of natural and synthetic refrigerants. Leakages are safely excluded by the hermetic sealing of the magnetic coupling.

Fields of Application and Conveyed Fluids

EDUR has been successfully developing and producing refrigerant pumps for refrigeration plants, for example, for cooling rooms and products or for creating ice surfaces, for decades. They are used for the supply of pure or slightly contaminated liquids. Natural and synthetic refrigerants are conveyed safely and reliably due to the integrated magnetic couplings.

The drive torque of the motor is transferred to the pump shaft through magnetic field strength. A “can” hermetically separates the interior of the pump from the atmosphere. The bearing of the pump shaft is designed in medium-lubricated slide bearings. This prevents any amount of leakage, which would otherwise occur with conventional shaft seals.

Variants of EDUR-Magnetically Coupled Pumps

EDUR offers refrigerant pumps with the series NMB, LBM and NHM. Also for these pumps, the EDUR-modular design enables the highest level of flexibility regarding the pump configurations. The pumps are available in a variety of construction styles and materials (grey cast iron, spheroidal graphite iron, bronze or stainless steel) as well as with various drive solutions.

As required, we deliver customer-specific configurations (such as additional containment shell monitoring). Of course, we can also provide certificates of all authorized classification societies and necessary test reports.

Advantages

As all EDUR-pumps, refrigerant pumps stand out due to their efficiency, economy and reliability. Moreover, we would like to emphasize the following product advantages and characteristics:

Process safety

- Hermetically sealed

- No heat transfer into the medium

- Low wear and tear

- Reliable handling of liquids with entrained gas

- Maintenance free

- Low NPSH values

- High operational safety

- Pulsation free operation

- Long service life

- Low noise emissions

- Closed lantern

- Icing protection

- Motors with standstill heating

- High efficiency option with plastic can

- Qmin pipe not necessarily

Low operating costs

- Very high efficiencies

Easy installation

- Modular design system for customized solutions

- Compact block construction or bedplate unit

- Low space requirements

Technical data

- Flow rate: max. 600 m³/h

- Head: max. 300 m

- Permissible operating pressure: up to 40 bar

- Temperature: -50 °C up to 220 °C

- Viscosity: up to 200 mm²/s

APPLICATIONS

- EDUR-pumps can be used in a wide range of applications and improve the operation of different industrial processes. Over time, EDUR has acquired valuable knowledge in the following applications to be a reliable partner for customers due to the optimal design of our pumps.

ENERGY TECHNOLOGY

-

Energy technology deals with different methods and procedures for the generation, distribution, storage, and usage of energy. Therefore, possible applications for centrifugal pumps in energy technology comprise a wide spectrum.

Centrifugal Pumps in Industrial Energy Technology

Energy technology deals with different methods and procedures for the generation, distribution, storage, and usage of energy. Therefore, possible applications for centrifugal pumps in energy technology comprise a wide spectrum. Apart from classical applications such as heating, heat distribution, and cooling of aggregates, this includes applications such as energy storage systems, biogas plants, heat recovery systems and fuel cells.

The technical challenges are diverse: the required volume flow rates, pressures, and the requirements for materials and sealing systems all depend on the individual application.

Application of EDUR-Centrifugal Pumps in Energy Technology

EDUR-centrifugal pumps for energy technology are characterized by a compact pump design with axial thrust-free, open or closed impellers. A large portion of the radial forces is decreased by special EDUR diffuser elements. This positively influences the lifetime of the mechanical seal, bearing, and drive motor.

Due to very low NPSH values, fluids which are close to their boiling point can be safely supplied. Centrifugal pumps from EDUR are thus able to supply steam-laden fluids and offer a high degree of operational safety. EDUR-magnetically coupled pumps are used for fluids, which are classified as environmentally hazardous or toxic. Differences in used mechanical seal systems are determined by the corresponding applications. EDUR-centrifugal pumps are constructed as close-coupled or inline pumps. The application can require both single stage or multistage design.

LIQUEFIED GAS

-

Centrifugal pumps play an important role during the production of liquefied gases as well as their transport, storage, and distribution. Liquefied gases offer the advantage that - unlike in the gaseous state of aggregation - they can be relatively easily transported and stored. Liquefaction is achieved by compression or cooling. In case of corresponding demand, the liquefied gas then undergoes regasification due to released pressure and can be fed to the consuming units via pumps.

Liquefied Gases

A distinction is made between LPG gases (liquefied petroleum gas) and LNG gases (liquid natural gas). Agents of LPG gases are, above all, butane, propane, and their derivatives, which are used as fuel gas and fuel for heat generation and arise both during oil and gas extraction as well as in crude oil refineries. LNG gas or also liquefied natural gas, mainly methane, is also used as fuel gas.

The DIN 51622 lists all other liquefied gases. For example, ammonia (NH3) is used in refrigerating systems, or carbon dioxide (CO2) is used in the process industry and in beverage production.

Application of EDUR-Liquefied Gas Pumps

EDUR offers liquefied gas pumps, which are used for production processes, transport, storage as well as for the distribution of liquefied gases. A precondition for this wide set of applications is the gas conveying capability of the centrifugal pumps guaranteed by the EDUR-design. Due to the low NPSH (Net Positive Suction Head) values, the pumps ensure an operation free of cavitation and thus full conveying capability both in suction mode and intake mode. The EDUR-liquefied gas pumps are executed according to Atex: various adjusted sealing Systems, such as double mechanical seals or hermetical magnetic couplings, ensure safe operation.

COOLING TECHNOLOGY

-

EDUR-centrifugal pumps are successfully used in industrial refrigeration systems. They are important components in the cooling process, offering a maximum degree of safety, reliability and efficiency and are designed for high loads and extreme temperature ranges. Furthermore, EDUR-pumps guarantee process safety also with critical media/fluids such as carbon dioxide (CO2) or ammonia (NH3).

Centrifugal Pumps in Cooling Technology

Cooling technology deals with methods and procedures to remove heat. The cooling processes required here are based on various physical effects dealing with the cyclical phase shift of a refrigerant in the refrigerating machine.

Application of EDUR-Pumps in Cooling Technology

Industrial refrigeration comprises a wide spectrum of different applications in cooling technology. As a rule, systems with a higher performance from about 200 m³/h compressor suction volume are required. Typical fields of application of pumps in cooling technology can be found in food processing, slaughterhouses, dairy technology, beverage industry, breweries, pharmaceutical industry, deep-freeze warehouses as well as in the chemical industry.

Centrifugal pumps in refrigerating plants are classified according to the type of conveyed fluid. Depending on the design and size of the plant, there are coolant pumps and refrigerant pumps.

EDUR-pumps for coolants stand out due to their compact pump design, axial thrust-free, open or closed and load-relieved impellers as well as diffuser elements in the ring housing, which take up a large portion of the radial forces. This overall construction has a positive influence on the lifetime of the mechanical seal as well as on the anti-friction bearings in the drive motor. In order to prevent the mechanical seal from being damaged by freezing condensation water, EDUR-pumps are executed with antifreeze protection in case of very low temperatures of the conveyed fluid.

Refrigerant pumps are often magnetically coupled pumps, which hermetically seal the refrigerant from the atmosphere. The advantage over canned motor pumps lies in the spatial separation of the drive motor from the pump, which prevents a heat intake into the conveyed fluid i.e. the refrigerant. Consequently, the separation has a positive effect on the energy balance of the whole refrigerating plant.

Furthermore, EDUR-refrigerant pumps are characterized by very low NPSH values, which have a positive effect on the refrigerant at its boiling point. Compared to volute housing pumps, EDUR-centrifugal pumps are able to transport certain gas proportions in conveyed fluid through the diffuser element. The advantage here being that the minimal amount of refrigerant evaporation is safely handled.

INDUSTRIAL CLEANING TECHNOLOGY

-

The cleaning and degreasing of components mainly relates to removing dirt, grease and other residues. Over time, EDUR-centrifugal pumps have proven themselves as an important component of such cleaning systems.

Centrifugal Pumps in Cleaning Technology

Apart from daily washing of laundry in private households, highly-complex machines in modified forms can be found in almost every industry for cleaning different surfaces and objects. Classic applications of cleaning technology can be found, for example, in component cleaning, metal cleaning, crate and bottle cleaning or in medical technology. In order to efficiently transport the cleaning medium to the surfaces and objects to be treated, centrifugal pumps are an important component of these cleaning systems. Through the hydraulic implementation of centrifugal pumps, certain components are cleaned from contamination by means of rinsing, immersing, or high-pressure spraying.

Application of EDUR-Centrifugal Pumps in Cleaning Technology

EDUR-centrifugal pumps have become key system components for leading cleaning plant manufacturers in order to transport the cleaning medium efficiently and reliably to surfaces and objects. Due to fulfilling complex, application-specific tasks in industrial cleaning processes, EDUR has been a valuable partner in development and implementation for years.

The various conveyed fluids and cleaning procedures require the careful selection of all pump components in terms of design. Ensuring the compatibility of the conveyed fluid with the pump materials, as well as implementing the necessary flow requirements are of the utmost importance. The different requirements for wet-mixed cleaning with high component volume or cleaning with solvents containing hydrocarbon or chlorinated hydrocarbon in batch or single part cleaning are key for the EDUR-pump selection. Adverse conveying conditions such as dry run, vacuum operation, gap-passing particles in the flow rate or slurping mode are examined and considered, for example, by means of special sealing systems and specially adjusted impellers. Depending on the cleaning system and process conditions, close-coupled pumps, inline pumps or torque flow pumps from EDUR are used. Additionally, EDUR-multiphase pumps are used for downstream recovery of substances used and for wastewater treatment.

WATER- AND WASTEWATER TECHNOLOGY

-

EDUR-pumps guarantee the efficient operation of applied water and wastewater technologies. The requirement to not only conserve water, but also return it to natural water recources in cleaned quality after use, holds enormous innovation potential for reducing the impact on the environment.

Application of EDUR-Centrifugal Pumps in Water and Wastewater Technology

EDUR-centrifugal pumps are used in various areas within water and wastewater technology. The advantages of EDUR-centrifugal pumps lie in the robustness and durability of the pumps as well as in the special capability of the multiphase pumps to supply fluid-gas mixtures. At the same time EDUR offers a wide range of torque flow pumps for the supply of contaminated water, which is pervaded with large particles.

Typical applications of EDUR-pumps range from water supply to treatment and disinfection for process water. Due to special properties of the gas conveying capability and the self-priming behaviour, the pumps are also used in critical areas, for example, in the food and pharmaceutical industries.

Multiphase Pumps in Flotation Plants

Efficient wastewater treatment comprises the recovery and reuse of nutrients and valuable substances. This is achieved by various cleaning steps by means of mechanical, biological and physical-chemical processes. In wastewater technology, flotation as a physical-chemical process is a proven efficient method worldwide.

Our multiphase pumps are used in flotation plants all over the world. With dissolved air flotation, a return flow of the clear water is saturated with air under pressure and then reduced to atmospheric pressure again. The micro bubbles that become free during the pressure release accumulate on the suspended solids and carry them to the surface, from where they are skimmed or skimmed off. Typical fields of application include the treatment of liquids with suspended solids such as oil-water emulsions, fat separations, phosphate and heavy metal precipitations, biological wastewater treatment plants and many more. In this context hazardous wastes are treated within multistage flotation plants. The pump hydraulics of EDUR-multiphase pumps are specially developed for this process allowing throttled operation on the suction side without sucking additional compressed air gas from the environment. These special pumps ensure a reliable supply of liquids with gas proportions of up to 30% at a pressure of usually 4 to 7 bar. When using the EDUR-multiphase pump in a flotation plant according to VDMA standard sheet 24430, direct addition of the gas into the suction line takes place thus allowing a reduction of plant components compared with systems of conventional type: Compressor, pressure tank, elaborate control unit and various valves are omitted.