- Offer Profile

-

Salvatore Robuschi’s activity started back in 1935 and since then the Company generational handover has focused on making high quality products. In the last fifteen years the Company has specialized in producing pumps with innovative features in terms of construction technology, application fields and components modularity.

Through the precision casting used to build many parts (for ex. the impellers) and the special design, Salvatore Robuschi pumps guarantee great efficiency and low NPSH values.

Centrifugal pumps

RD pumps (RDB-RDL-RDM)

-

Centrifugal pumps with closed impeller built according to ISO 2858-5199 norms.

Simple and modular construction ISO 2858-5199 norms. Discharge sizes from DN 32 to DN 125. High hydraulic efficiencies and low NPSH value (investment casting impellers). Heavy duty shaft and bearings. Only 3 bearing brackets for the whole range. Only 1 casing cover fits every seal arrengement.

Use

RD pumps can handle aggressive organic and inorganic liquids in the chemical and petrochemical industries. They are also used in sea water desalination plants, absorption equipment in environmental engineering, power stations, steel industry and hot water distribution.Technical Specifications

- Maximum flow rate: 500 m3/h

- Maximum head: 140 mwc

- Maximum pressure: 16 BAR

- Maximum temperature: 220° C

Materials

- Standard: AISI 316.

- On request: Duplex, Superduplex, AISI 304, AISI 904, Hastelloy B and C.

Hydraulic

- Closed impeller

RG pumps (RGB-RGL-RGM)

-

Centrifugal pumps with open impeller built according to ISO 2858-5199 norms.

Simple and modular construction ISO 2858-5199 norms. Discharge sizes from DN 32 to DN 125. High hydraulic efficiencies and low NPSH value (investment casting impellers). Heavy duty shaft and bearings. Only 3 bearing brackets for the whole range. Only 1 casing cover fits every seal arrengement.

Use

RG pumps can handle slightly contaminated liquids or not abrasive slurries in the chemical and petrochemical industries. Well suited for handling liquids with gas contents up to 15%. They are also used in refineries, general industrial service, pulp and paper industry, foodstuffs industry, sugar industry, sea water desalination plants, absorption equipment in environmental engineering, power stations, steel industry and hot water distribution.Technical Specifications

- Maximum flow rate: 300 m3/h

- Maximum head: 95 mwc

- Maximum pressure: 16 BAR

- Maximum temperature: 220° C

Materials

- Standard: AISI 316.

- On request: Duplex, Superduplex, AISI 304, AISI 904, Hastelloy B and C.

Hydraulic

- Open impeller

RC pumps (RCB-RCL-RCM)

-

Centrifugal pump with vortex impeller in according to ISO 2858/5199 norms.

Simple and modular construction with bearing bracket in according to ISO 2858-5199 norms. Discharge sizes from DN 32 to DN 250. Large free passage clearance up to 150 mm due to the completely recessed impeller. Heavy duty shaft and bearings. Only 4 bearing brackets for the whole range. Only 1 casing cover fits every seal arrengement.

Use

RC pumps can handle chemical and crystalline suspensions, all viscous liquid, liquid with high concentrations of fibrous suspensions, municipal and industrial wastewater, every kind of sludge. They are also used in textile, tannery, refineries, general industrial service, pulp and paper industry, foodstuffs industry, sugar industry, sea water desalination plants, absorption equipment in environmental engineering, power stations and steel industry.Technical Specifications

- Maximum flow rate: 800m3/h

- Maximum head: 60 mwc

- Maximum pressure: 10 BAR

- Maximum temperature: 180° C

Materials

- Standard: AISI 316 - GJL250 Cast Iron

- On request: Duplex, Superduplex, AISI 304, AISI 904, Hastelloy.

Hydraulic

- Vortex impeller

RB pumps (RBB-RBL-RBM)

-

Centrifugal pumps with channel impeller according to ISO 2858/5199 norms.

Simple and modular construction with bearing bracket in according to ISO 2858-5199 norms. Discharge sizes from DN 65 to DN 300. Impeller with special blades geometry for low NPSH and high free passage. Heavy duty shaft and bearings. Only 5 bearing brackets for the whole range. Only 1 casing cover fits every seal arrengement.

Use

RB pumps can handle slightly contaminated liquids in waste water treatment plants, clean water for cooling towers or condensate recovery plants, viscous liquids in evaporators in food or chemical industry. They are also used in refineries, general industrial service, pulp and paper industry, foodstuffs industry, sea water desalination plants, absorption equipment in environmental engineering, power stations, steel industry and hot water distribution.Technical Specifications

- Maximum flow rate: 2400 mc/h

- Maximum head: 70 mwc

- Maximum pressure: 10 bar

- Maximum temperature: 220° C

Materials

- Standard: AISI 316 - Cast Iron GJL250.

On request: Duplex, Superduplex, AISI 304, AISI 904, Hastelloy.

Hydraulic

- Channel impeller

HD pumps (HDM-HDA)

-

Centrifugal pumps with closed impeller. Flanges unions PN 16 or DIN 11851 (food industry).

HD pumps have the same interaxis of ISO 5199 chemical norm pumps, this means easy interchangeability. Casing and impeller manufactured with investment casting technology. Standard IEC motor (different brand available) with stub shaft design. Possibility to choose seal arrangement: single, bouble tandem, double back to back and packing gland.

Use

HD pumps can handle aggressive organic and inorganic liquids in chemical industries. They are also used in general industrial service, foodstuff industry, water/solvent recovery process, power stations, steel industry and small evaporator plants.Technical Specifications

- Maximum flow rate: 200 m3/h

- Maximum head: 60 mwc

- Maximum pressure: 8 BAR

- Maximum temperature: 120° C

Materials

- Standard: AISI 316

Hydraulic

- Closed impeller

HG pumps (HGM-HGA)

-

Centrifugal pumps with semi-open impeller. Flanges unions PN 16 or DIN 11851 (food industry).

HG pumps have the same interaxis of ISO 5199 chemical norm pumps, this means easy interchangeability. Casing and impeller manufactured with investment casting technology. Standard IEC motor (different brand available) with stub shaft design. Possibility to choose seal arrangement: single, bouble tandem, double back to back and packing gland.

Use

HG pumps can handle slightly contaminated liquids or non abrasive slurries in the chemical and petrochemical industries; well suited for handling liquids with gas contents up to 10%. They are also used in general industrial service, foodstuff industry, dissolved air flotation systems, sugar industry, water/solvent recovery process, power stations, steel industry, textile and small evaporator plants.Technical Specifications

- Maximum flow rate: 200 m3/h

- Maximum head: 60 mwc

- Maximum pressure: 8 BAR

- Maximum temperature: 120° C

Materials

- Standard: AISI 316.

Hydraulic

- Open impeller

RS pumps (RSM-RSA)

-

Centrifugal pumps with vortex impeller. Flanges unions PN 16 or DIN 11851 (food industry).

RS pumps have the same interaxis of ISO 5199 chemical norm pumps, this means easy interchangeability. Casing and impeller manufactured with investment casting technology. Large free passage clearance up to 50 mm due to the recessed impeller. Standard IEC motor (different brand available) with stub shaft design. Possibility to choose seal arrangement: single, bouble tandem, double back to back and packing gland.

Use

HD pumps can handle chemical and crystalline suspensions, all viscous liquid, liquid with high concentrations of fibrous suspensions, every kind of sludge and municipal and industrial wastewater. They are also used in general industrial service, foodstuff industry, dissolved air flotation systems, waste water treatment plant, sugar industry, water/solvent recovery process, power stations, steel industry, textile and tannery.Technical Specifications

- Maximum flow rate: 100 m3/h

- Maximum head: 60 mwc

- Maximum pressure: 8 BAR

- Maximum temperature: 120° C

Materials

- Standard: AISI 316.

Hydraulic

- Vortex impeller

RN pumps (RN-RNM-RNL)

-

Centrifugal pumps with closed impeller built in compliance with DIN 24255.

Centrifugal pumps with closed impeller according to EN 733 norms. Discharge sizes from DN 32 to DN 150.

Use

RN pumps can handle clean and non-aggressive liquids for the pump materials (contents of solids up to 0,2% max). They are also used for non aggressive industrial liquids, water supply, heating, conditioning, cooling and circulation plants, civil and industrial applications, fire-fighting plants and irrigations.Technical Specifications

- Maximum flow rate: 480 m3/h

- Maximum head: 90 mwc

- Maximum pressure: 10 BAR

- Maximum temperature: 130° C

Materials

- Standard: GJL200 Cast Iron with AISI 430 or AISI 316 shaft and Cast Iron GJL200 or BRASS according to the pump size.

Hydraulic

- Closed impeller

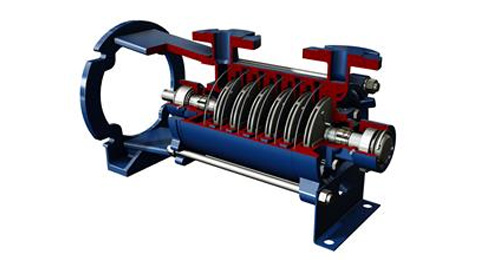

TS pumps (TS-TSK-TSL)

-

Multistage centrifugal pumps with closed impeller.

Multistage centrifugal pumps with closed impellers TS. Discharge sizes from DN 32 to DN 50. TS 31-32 range is only available with mechanical seal, TS 40-50 range is available both with mechanical seal and gland packing and cooling chambers are supplied as standard equipment.

Use

TS pumps can handle clean or slightly contaminated liquids. They are also used for boilers feeding, fire fighting plants, autoclaves, water supply systems, irrigation, washing plants, to pump hydrocarbons and whenever high pressures are required.Technical Specifications

- Maximum flow rate: 45 m3/h

- Maximum head: 300 mwc

- Maximum pressure: 30 BAR

- Maximum temperature: 140° C

Materials

- Standard: Casing and diffusers made in GJL250 Cast Iron, shaft in AISI 420, bearing bushes in bronze.

- On request: AISI 316 shaft and special bearing bushes.

Hydraulic

- Closed impeller

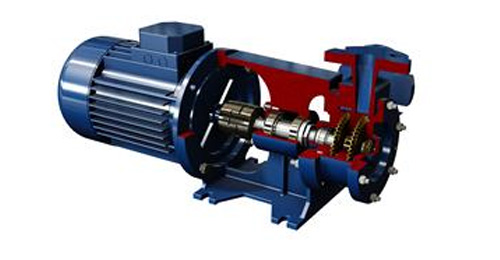

RAM pumps (RAMD-RAME)

-

Double-stage with peripheral impeller pumps.

Double-stage centrifugal pumps with peripheral impellers TS. Discharge sizes DN 25.

Use

RAM pumps can handle clean liquids without solid parts in suspension. They are also used for boilers feeding, flotation plants in waste water treatment and whenever low capacity and high pressure are required.Technical Specifications

- Maximum flow rate: 6,3 m3/h

- Maximum head: 180 mwc

- Maximum pressure: 25 BAR

- Maximum temperature: 120° C

Materials

- Standard: Casing and diffusers made in GJL250 Cast Iron, shaft in AISI 420 and impeller in BRASS or AISI 316 on request.

Hydraulic

- Peripheral impeller

RACM pumps

-

Multistage self-priming pumps.

Use

Single or Multistage side-channel self-priming pumps with radial impellers. They are fit to handle clean liquids with no suspended solid matter and can be used for boilers feeding, surge tank plants, conveying systems for liquids containing gas, condensate extraction, fuel handling, etc.Technical Specifications

- Maximum flow rate: 12 m3/h

- Maximum head: 160 mwc

- Maximum pressure: 16 bar

Materials

- Standard: Casing made in G250 Cast Iron, bronze impellers, Shaft made in AISI 420 SS

- On request: Shaft in stainless steel and special bushings.

Hydraulic

- Self-Priming

VERTICAL pumps

-

Vertical centrifugal pumps with closed, open, vortex and channel impeller according to ISO 5199 norm

Vertical immersible sump pump. The pump body is immersed into the liquid and the motor is mounted above the plate, keeping it away from the liquid. The discharge pipe is separated from the column pipe and the lubrication of the bearings is normally obtained by means of the same pumped fluid, or from an external lubricating source in abrasive services. The possibility to customize mounting plate shape and dimensions, discharge flange position and column lenght, allows designers and end-users to match sump or tank plates or flanges. Suction strainer and suction extension on request.

Use

Vertical pumps are used in all industrial applications, refining, oil and gas production, chemical, pulp and paper and water facilities. They are also used in drainage sumps, oily water sumps and tank transfer.Technical Specifications

- See curves for horizontal type RN-RD-RG-RB-RC

- Pump lenght: up to 6 meters

Materials

- Pump standard: AISI 316 - G250

- On request: special materials

- Bearing bush; Bronze, Rubber, RULON and PEEK

Hydraulic

- Closed, open, vortex and channel impeller

CANTILEVER pumps

-

Vertical cantilever centrifugal pumps with vortex and channel impeller.

The pump body is immersed into the liquid and the motor is mounted above the mounting plate out of the corrosive area. Oversize heavy duty ball bearings are supplied with grease fittings and located above the mounting plate out of the corrosive area. This means no bearing in the liquid, no seal or bearing bush and bearing assembly is sealed-off to prevent bearing's contamination by liquids or gases-vapors. This allows the pump to run dry without risk of damage and so reliable operation and reduced costs. The possibility to customize mounting plate shape and dimensions, discharge flange position and column lenght, allows designers and end-users to match sump or tank plates or flanges. Suction strainer and suction extension on request with the possibility to fit a PTFE lip seal for vapor proof construction.

Use

Cantilever pumps are used for sludges, slurries and liquids containing large or long solids. They are also used in drainage sumps, oily water sumps, tank transfer,food processing, ground water development and irrigation, heavy oil, oil sand and shale, paper stock, sewage collection and treatment, shower pumps, slurry processing and transfer.Technical Specifications

- See curves for horizontal type RB-RC

- Pump lenght: up to 1,8 meters

Materials

- Standard: AISI 316 - GJL250.

- On request: CA6NM (400HB hardness), AISI 304, AISI 904, Duplex, Superduplex.

Hydraulic

- Vortex and channel impeller