- Offer Profile

- Since 1946 Klaus Union is a

market leader in the development of pumps and valves that meet the most

exacting quality requirements. And this is as it should be, since our

products are used to transport aggressive, toxic and explosive substances in

the chemical and petrochemical industries.

We play a major role in ensuring that plants in these industries operate reliably and in a manor that protects both people and the environment.

Latest Products

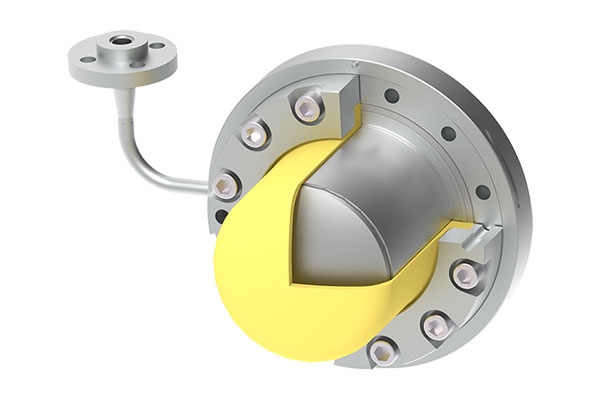

HYBRID DOUBLE CONTAINMENT SHELL

-

Without Compromising Performance

Pumping aggressive, explosive and highly toxic liquids requires the highest level of process safety. To protect people and the environment, leakage of the pumped liquid must be avoided ° including in the event of a pump failure. For these most critical applications a magnetic drive pump equipped with a monitored, double containment shell still remains the safest solution. To reduce the heat generated by a purely metallic, double containment shell and at the same time to improve the overall efficiency of the pump, Klaus Union has developed and patented a new hybrid double containment shell.

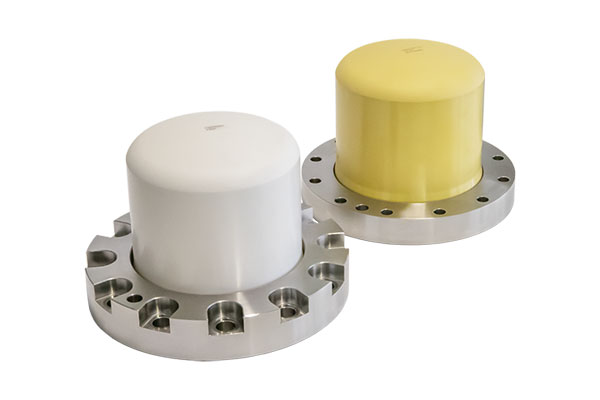

NON-METALLIC CONTAINMENT SHELLS

-

Without Compromising Performance

Through the use of non-metallic containment shells instead of the traditionally used metallic containment shells, Klaus Union eliminates eddy current losses and increases the efficiency of magnet drive pumps significantly. Thanks to the leak-free magnet drive concept, pumps with magnet drives have a huge market share in the chemical and petrochemical industry. For many years, Klaus Union has used nonmetallic containment shells and particularly those made from ceramics for various applications due to their high chemical resistance. Until recently, the operative range has been limited due to the specific material characteristics. However, pump applications increasingly demand higher operating pressures, temperatures and flow rates whilst still offering maximum efficiency.

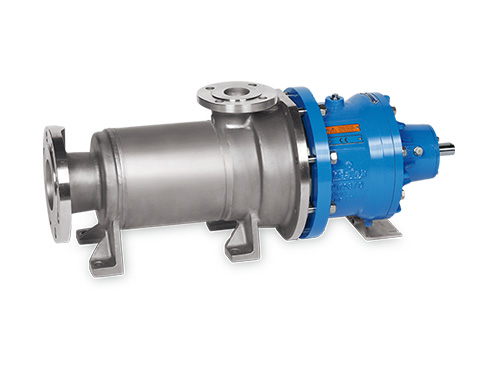

MAGNETIC DRIVE PUMPS

-

Towards A Greener, Hydrogen-Powered World

As the world seeks sustainable energy solutions, hydrogen is emerging as a key player in the transition to a greener future. At Klaus Union, we‘re proud to be at the forefront of this revolutionary journey by manufacturing state-of-the art magnetic drive pumps for hydrogen production appli cations. Magnetic drive pumps play a crucial role in the production of hydrogen. They ensure the safe and efficient pumping of fluids in processes like alkaline water (for KOH or NaOH) and PEM electrolysis, where hydrogen is generated from ultra pure water.

Pumps

- We are a leading worldwide specialist in the market of industrial pumps and valves. The Chemical and petrochemical industries make extensive use of our magnetic drive technology. Since our incorporation, 70 years ago, we have acquired a well deserved reputation as a leading pump and valve specialist capable of meeting the most exacting quality and safety standards.

CENTRIFUGAL PUMPS WITH MAGNET DRIVE

SLM NV

-

SINGLE-STAGE CENTRIFUGAL PUMP WITH MAGNET DRIVE

Centrifugal Pump based on DIN EN ISO 2858 / 15783- Fields of Application: Chemistry / Petrochemistry / Refrigeration and Heat Treatment / Oil & Gas / Power

- Flow Rate: max. 3.500 m3/h

- Delivery Head: max. 220 m L.C.

- Temperature Range: -120 °C to +450 °C (Hochtemp.-Pumpe SLM NHO)

- Pressure Rating: max. PN 400

KEY FACTS

- Design according DIN EN ISO 2858 / DIN EN ISO 15783

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

- Bearing Bracket with Greased-for-Life Anti-Friction Bearings as a standard

SLM AP

-

SINGLE-STAGE CENTRIFUGAL PUMP WITH MAGNET DRIVE

Centrifugal Pump acc. API 685- Fields of Application: Chemistry / Petrochemistry / Refrigeration and Heat Treatment / Oil & Gas / Power / On- & Offshore Plants

- Flow Rate: max. 3.500 m3/h

- Delivery Head: max. 220 m L.C.

- Temperature Range: -120 °C to +450 °C

- Pressure Rating: max. PN 400

KEY FACTS

- Design according to API 685 2nd Edition

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

SLM AV

-

SINGLE-STAGE CENTRIFUGAL PUMP WITH MAGNET DRIVE

Centrifugal Pump acc. to ASME 73.3- Fields of Application: Chemistry / Petrochemistry / Power / Oil & Gas / Refrigeration and Heat Treatment

- Flow Rate: max. 3.500 m3/h

- Delivery Head: max. 220 m L.C.

- Temperature Range: -120 °C to +450 °C

- Pressure Rating: max. PN 400

KEY FACTS

- Design according to ASME B73.3 M

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

SLM NHO

-

SINGLE-STAGE CENTRIFUGAL PUMP WITH MAGNET DRIVE FOR HIGH TEMPERATURE APPLICATIONS

Centrifugal Pump for High Temperature Applications (450 °C)- Design according DIN EN ISO 2858 / 15783

Fields of Application: Chemistry / Energy / Heat Treatment - Flow Rate: max. 1.200 m3/h

- Delivery Head: max. 200 m L.C.

- Temperature Range: -120 °C to +450 °C

- Pressure Rating: max. PN 40

KEY FACTS

- Design according to DIN EN ISO 2858 / DIN EN ISO 15783

- Temperature Range up to 450 °C

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

- Design according DIN EN ISO 2858 / 15783

SLM GV/HV

-

MULTI-STAGE CENTRIFUGAL PUMP WITH MAGNET DRIVE

Multi-Stage Centrifugal Pump based on DIN EN ISO 15783 / API 685- Fields of Application: Chemistry / Petrochemistry / Refrigeration and Heat Treatment / Oil & Gas / Power

- Flow Rate: max. 350 m3/h

- Delivery Head: max. 700 m L.C.

- Temperature Range: -120 °C to +350 °C

- Pressure Rating: max. PN 200

KEY FACTS

- Design according to DIN EN ISO 15783

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

- Barrel Design Version without Variable Seal

- Impeller Arrangement in Series; max. 6 Stages

- First Low-NPSH Stage for Improved Suction Performance

SLM SV

-

SIDE CHANNEL PUMP WITH MAGNET DRIVE

Multi-Stage Side Channel Pump based on DIN EN ISO 15783- Fields of Application: Chemistry / Petrochemistry / Refrigeration / Oil & Gas / Vacuum Technology

- Flow Rate: max. 42 m3/h

- Delivery Head: max. 470 m L.C.

- Temperature Range: -50°C to +200 °C

- Pressure Rating: max. PN 40

KEY FACTS

- Design according to DIN EN ISO 15783

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

- Barrel Design Version with only two static Seals

- Impeller Arrangement in Series; max. 8 Stages

- Self-Priming; First Low-NPSH Stage for Improved Suction Performance

SLM NVT

-

SINGLE-STAGE SUBMERSIBLE CENTRIFUGAL PUMP WITH MAGNET DRIVE

Submerged Pump based on DIN EN ISO 2858 / 15783- Fields of Application: Chemistry / Petrochemistry / Power

- Flow Rate: max. 900 m3/h

- Delivery Head: max. 200 m L.C.

- Temperature Range: -50 °C to +200 °C

- Pressure Rating: max. PN 40

- Tauchtiefen bis 10 Meter

KEY FACTS

- Design according DIN EN ISO 2858 / DIN EN ISO 15783

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- No Dynamic Seal, Separation of Liquid Chamber and Atmosphere by Means of Containment Shell

- Submerging Depth up to 10.000 mm

CENTRIFUGAL PUMPS WITH SHAFT SEAL

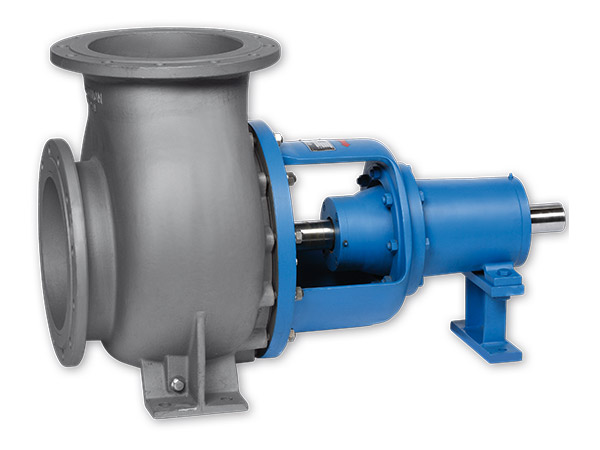

NOV

-

SINGLE-STAGE CENTRIFUGAL PUMP WITH MECHANICAL SEAL

Centrifugal pump acc. to DIN EN ISO 2858 / 5199- Industries: Chemical Industry/ Petrochemical Industry / Refrigeration and Heat Transfer / Oil & Gas / Paper and Cellulose Plants / Power / Sugar Industry / Coking Plants

- Flow Rate: max. 3.500 m3/h

- Delivery Head: max. 220 m L.C.

- Temperature Range: -120 °C to +450 °C

- Pressure Rating: max. PN 100

KEY FACTS- Design according to DIN EN ISO 2858 / 5199

- Modular System

- Shaft Seal Packing; Single or Double Mechanical Seal (also available as a Cartridge Unit)

- Heating for Casing and Casing Cover available

- Mechanical Seal-Cover available

- Design based on API 610 available on Request

GOV/H

-

MULTI-STAGE CENTRIFUGAL PUMP WITH MECHANICAL SEAL

Multi-Stage Centrifugal Pump acc. to DIN EN ISO 5199- Industries: Chemical Industry / Petrochemical Industry / Refrigeration and Heat Transfer / Oil & Gas / Power

- Flow Rate: max. 350 m3/h

- Delivery Head: max. 700 m L.C.

- Temperature Range: -120 °C to +350 °C

- Pressure Rating: max. PN 100

KEY FACTS- Design according to DIN EN ISO 5199

- Modular System

- Shaft Seal Packing; Single or Double GLRD (also available as a Cartridge Unit)

- Heating for Casing and Casing Cover available, GLRD-Cover available

- Design based on API 610 available on Request

TP NO

-

SUBMERSIBLE CENTRIFUGAL PUMP

Submerged Centrifugal Pump acc. to DIN EN ISO 2858 / 5199-

Industries: Chemical Industry / Petrochemical Industry / Refrigeration and

Heat Transfer / Power

Flow Rate: max. 1.600 m3/h - Delivery Head: max. 200 m L.C.

- Temperature Range: -50 °C to +250 °C

- Pressure Rating: max. PN 40

KEY FACTS

- Design according to DIN EN ISO 2858 / 5199

- Submerging Depth up to 10.000 mm

- Design based on API 610 available on Request

-

Industries: Chemical Industry / Petrochemical Industry / Refrigeration and

Heat Transfer / Power

P

-

PIPE-BEND PROPELLER PUMP

Horizontally Mounted Propeller Pump- Industries: Power / Chemical Industry / Petrochemical Industry / Paper and Cellulose Industry / Cooling Water Plants/ Sea Water Treatments

- Flow Rate: max. 12.000 m3/h

- Delivery Head: max. 12 m L.C

- Temperature Range: -120 °C to +250 °C

- Pressure Rating: max. PN 100

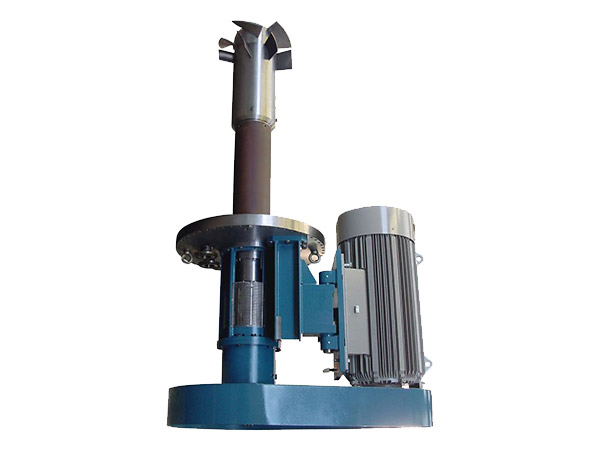

UP

-

VERTICAL PROPELLER PUMP WITH SHAFT SEAL

Vertically Mounted Propeller Pump for Integration into a Tank- Industries: Power / Chemical Industry / Petrochemical Industry / Paper and Cellulose Industry / Cooling Water Plants/ Sea Water Treatments

- Flow Rate: max. 21.500 m3/h

- Delivery Head: max. 8,5 m L.C

- Temperature Range: -50 °C bis +400 °C

- Pressure Rating: max. PN 10

KEY FACTS

- Vertically Mounted Pump for Integration into a Tank

- Adjustable Propeller Blades screwed to the Hub

- Flow Direction can be reversed by Repositioning the Propeller Blades

TWIN SCREW PUMPS WITH MAGNET DRIVE

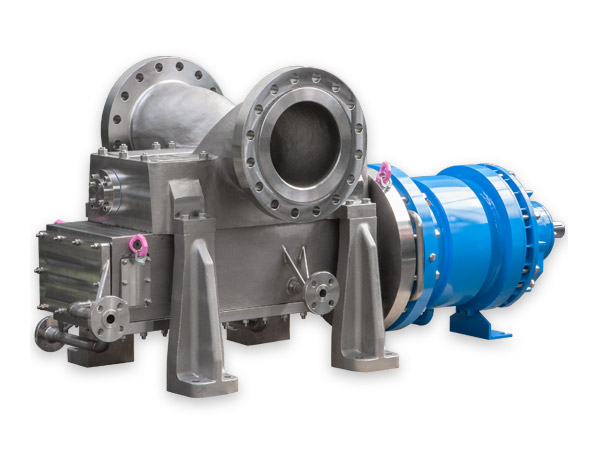

SLM DSP-2C

-

SINGLE VOLUTE TWIN SCREW PUMP WITH MAGNET DRIVE

Single Volute Twin Screw Pump acc. to API 676- Industries: Chemical Industry / Petrochemical Industry / Oil & Gas / Power / Sugar Industry / Paint

- Flow Rate: max. 1.800 m3/h

- Differential Pressure: max. 40 bar

- Temperature Range: -120°C to +350 °C

- Viscosity: max. 100.000 mm°/s (cSt)

KEY FACTS

- According to API 676, 3rd Edition

- Maintenance-Free Permanent Magnet Drive

- Modular Design

- Cartridge Design

- Modular Construction (Multi-Part-Casing)

- Adaptive Feet with Centerline Mounting

TWIN SCREW PUMPS WITH MECHANICAL SEAL

DSP-2C

-

SINGLE VOLUTE TWIN SCREW PUMP WITH MECHANICAL SEAL

Single Volute Twin Screw Pump acc. to API 676, 3rd Edition- ‘Plug & Pump’ – Cartridge Design

- Industries: Chemical Industry / Petrochemical Industry / Oil & Gas / Power / Sugar Industry / Paint

- Flow Rate: max. 1.800 m3/h

- Differential Pressure: max. 40 bar

- Temperature Range: -120°C to +350 °C

- Viscosity: max. 100.000 mm°/s (cSt)

KEY FACTS

- Design according to API 676, 3rd Edition

- Wellenabdichtung über Gleitringdichtung, Wellendichtringe oder Stopfbuchspackung

- Shaft Seal: Face Seal or Gland Packing

- Mechanical Seals according API 610/682

- Modular Construction (Multi-Part-Casing)

- Adaptive Feet with Centerline Mounting

DSP-4CL

-

DOUBLE VOLUTE TWIN SCREW PUMP WITH SHAFT SEAL

Double Volute Twin Screw Pump acc. to API 676, 3rd Edition- ‘Plug & Pump’ – Cartridge Design

- Industries: Oil & Gas / Shipbuilding / Chemical Industry / Power / Sugar Industry / Paint

- Flow Rate: max. 5.000 m3/h

- Differential Pressure: max. 100 bar

- Temperature Range: max. +350 °C

- Viscosity: max. 100.000 mm°/s (cSt)

KEY FACTS

- Design according to API 676, 3rd Edition

- Maintenance-friendly „PLUG & PUMP“ Cartridge Design

- Dry-Run-Capable with double-acting Seals

- Suitable for nearly every Liquids, incl. Multiphase Fluids and Polymers

Valves - pressure seal type

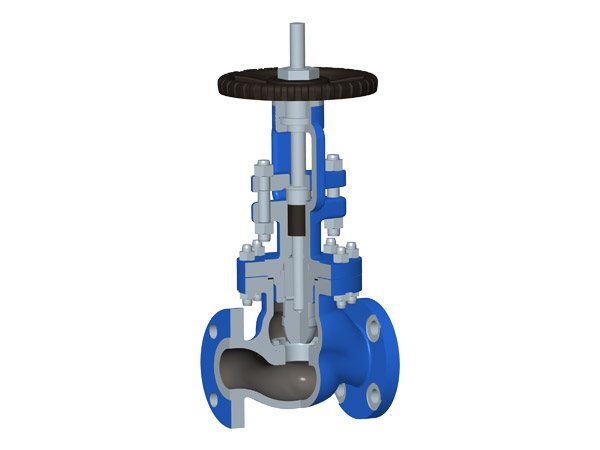

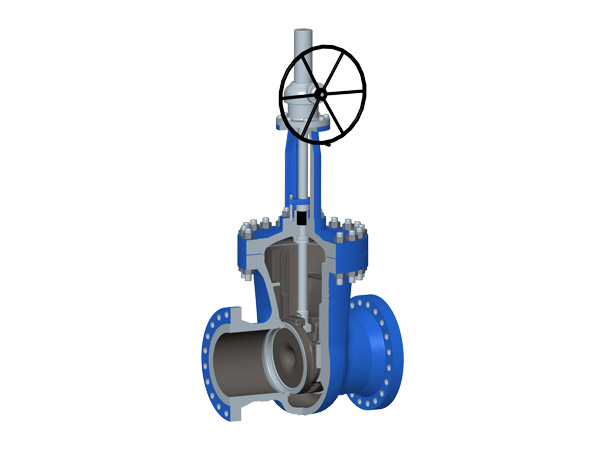

GATE VALVES

-

- Nominal Size Range: DN 80 to DN 600 / 3" to 24"

- Pressure Range: up to 600 bar

- Temperature Range: up to +650 °C / +1,202 °F

- Obturator: Double Disc Type (hardfaced)

GLOBE VALVES

- Nominal Size Range: DN 80 to DN 300 / 3" to 12"

- Pressure Range: up to 600 bar

- Temperature Range: up to +650 °C / +1,202 °F

- Sealing: Parabolic Disc

CONTROL VALVES

- Nominal Size Range: DN 80 to DN 600 / 3" to 24"

- Pressure Range: up to 600 bar

- Temperature Range: up to +650 °C / +1,202 °F

- Sealing: Parabolic Disc / Perforated Disc

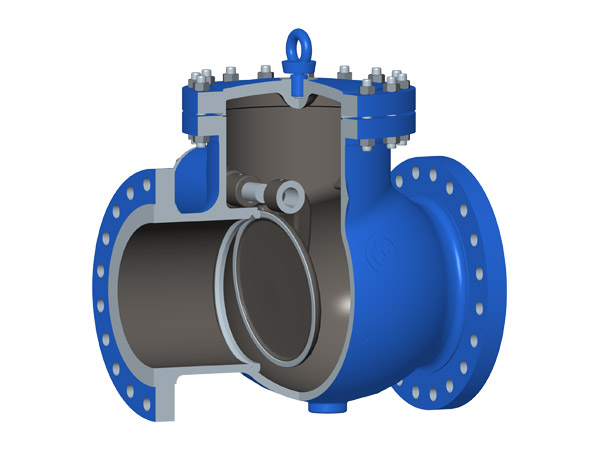

SWING CHECK VALVES

- Nominal Size Range: DN 80 to DN 600 / 3" to 24"

- Pressure Range: up to 600 bar

- Temperature Range: up to +650 °C / +1,202 °F

- Obturator: Check Valve

VALVES - BOLTED BONNET

Gate Valves - Bolted Bonnet

-

- Nom. Size Range: DN 50 – DN 600

- Pressure Rating: PN 2,5 – PN 160

- Temperature Range: -200 °C – +550 °C

- Materials: 1.4308, 1.4552, 1.4408, 1.4581, 1.0619, 1.5419, 1.7357, 1.7363

- Other materials on request

GLOBE VALVES

- Nom. Size Range: 2″ – 12″

- Nom. Pressure Range: Class 150 – 600

- Temperature Range: -200 °C – +595 °C / -325 °F bis +1,103 °F

- Materials: ASTM A351 CF8, ASTM A351 CF8C, ASTM A351 CF8M, ASTM A351

CF8MC,

ASTM 216 WCB, ASTM A217 WC1, ASTM A217 WC6, ASTM A217 C5 - Further Materials upon Request

PISTON CHECK VALVES

-

- Nom. Size Range: DN 15 – DN 300

- Pressure Rating: PN 10 – PN 160

- Temperature Range: -200 °C – +550 °C

- Materials: 1.4308, 1.4552, 1.4408, 1.4581, 1.0619, 1.5419, 1.7357, 1.7363

- Other materials on request

SWING CHECK VALVES

-

- Nom. Size Range: DN 15 – DN 200

- Pressure Rating: PN 10 – PN 160

- Temperature Range: -200 °C – +550 °C

- Materials: 1.4308, 1.4552, 1.4408, 1.4581, 1.0619, 1.5419, 1.7357, 1.7363

- Other materials on request

BUTTERFLY VALVES

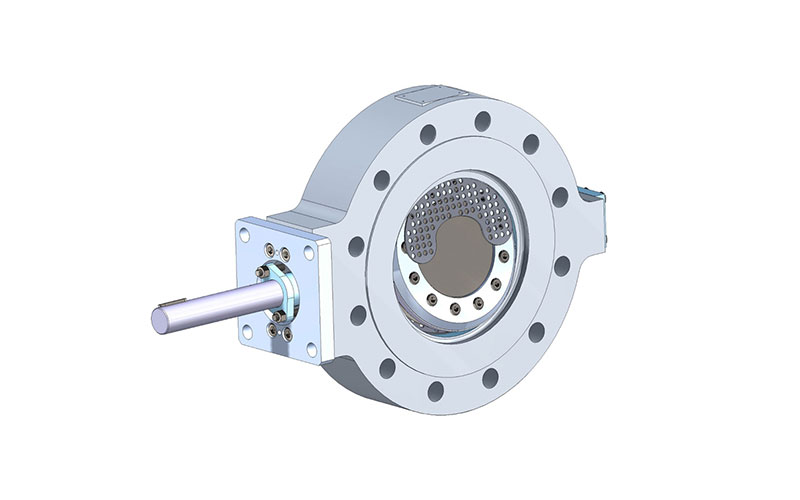

V-AXX ORCA

-

ELIMINATING THE RISKOF CAVITATION

The new ORCA® trim provides huge advantages against other solutions. Plates mounted on both sides of the disc allow the pressure to drop in several stages and prevent supersonic speed in gases and prevent the cavitation in liquids. One or more sets of plates can be mounted in accordance to the customer needs, allowing an excellent flow control when the valve is partially open.

Since the plates are mounted parallel to the disc and moved together with the disc, they do not interfere with the flow when the valve is fully open. This ensures the maximum Kv / Cv value remains as this of a standard valve.

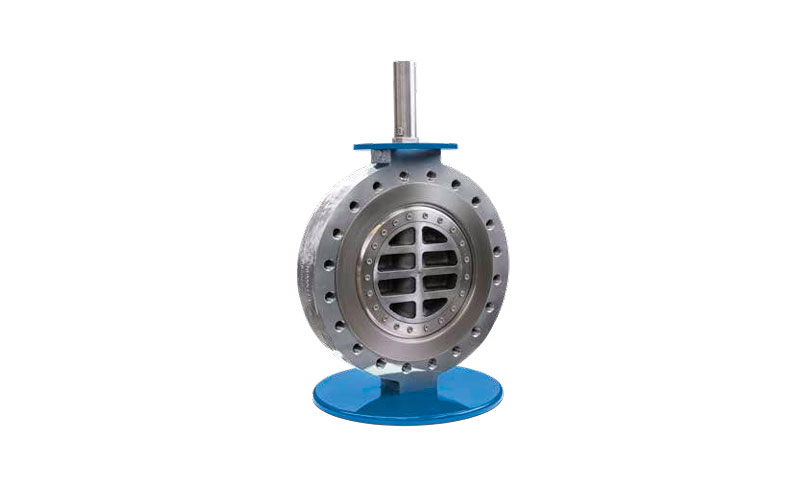

Klaus Union V-AXX

-

BUTTERFLY VALVES

The same designer who invented and patented the four offset butterfly valve in 2008 is introducing now the newest evolution in butterfly valve design. The first butterfly valve in the world which is not using a regular cone for it´s seat design. In the newly designed V-AXX® valve, the seat shape can be changed around the whole seat without restrictions. If necessary, the angle of the seat, even in the shaft area, can be 25° or more, without changing the angle in other areas. This is only possible due to the unique seat design, which is not formed by a simple cone but by a much more complex figure, not yet named in geometry.