- Offer Profile

-

High quality at fair prices worldwide.

VSM supplies international companies from numerous industries with quality valves: Our customers come from the chemical, pharmaceutical, refinery and natural gas sectors as well as from plant construction and mechanical engineering. Thanks to their versatility, our valves are used in a wide range of process engineering applications, in research and development, in instrumentation and control technology and in high-purity gas supply. As diverse as the areas of application are: VSM valves and services have an excellent reputation worldwide for high quality at attractive and fair prices.

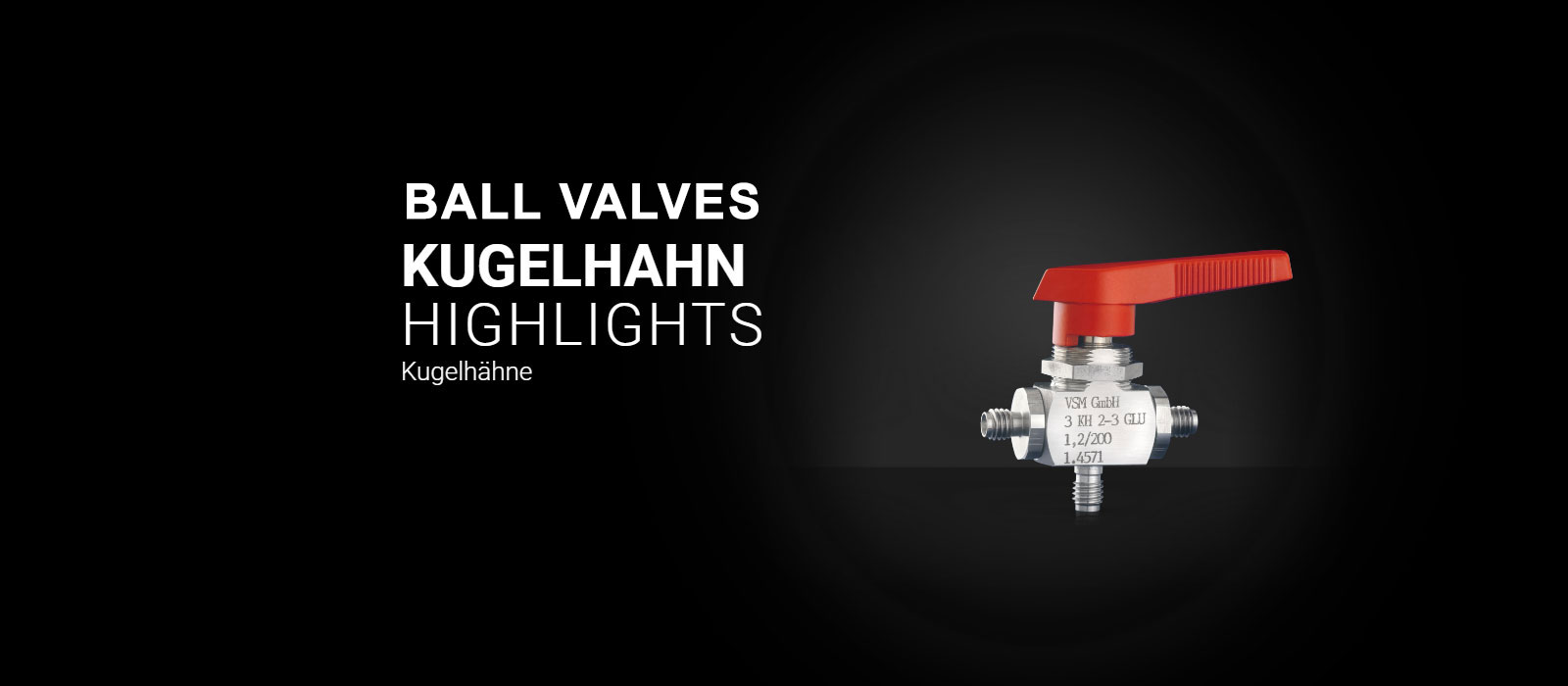

Ball valves

-

Ball valves from VSM - keep tight!

Our range is huge and every ball valve is beautiful. But we had to make a selection for our website: That's why you'll find a representative overview of our most important ball valves here. Our range of shut-off bodies serves a variety of industries and their specific media. Areas of application include the chemical and pharmaceutical industries, refineries and natural gas plants as well as plant and mechanical engineering.

If you have any questions about our wide range of ball valves and accessories, we will be happy to advise you at any time.

Manually operated ball valves - 2 Way-System

Series 12

- Mini ball valves Series 12 for opening/closing (TÜV-TA air)

- Pressure: PN 300 bar

- Passage: DN 1.5 mm

- Leak rate: < 10^-6 mbar · l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Series 12 in Peek

- Series 12 in Peek: Mini ball valves Series 12 for opening/closing (TÜV-TA air)

- Pressure: PN 20 bar

- Passage: DN 1.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: PEEK / HC22

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Series 16 ball valves for opening/closing (TÜV-TA air)

-

Series 16 ball valves for opening/closing (TÜV-TA air)

- Pressure: PN 20 bar

- Passage: DN 1.5 mm

- Leakage Rate: < 10-6 mbar . l/s

- Material: PEEK / HC22

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Series 18

- Series 18 ball valves for opening/closing (TÜV-TA air)

- Pressure: PN 420 bar

- Passage: DN 8.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Manually operated ball valves - 3 Way-System

Type GL: Mini ball valves Series 12 for 3-way GL / GLT switchover (TÜV – TA-Luft)

- Type GL: Mini ball valve series 12 for 3-way GL / GLT changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 1.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Type GLU: Ball valves series 12 for 3-way GLU switchover (TÜV – TA-Luft)

- Type GLU: Series 12 ball valves for 3-way GLU changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 1.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Type GL: Ball valves series 16 for 3-way GL switchover (TÜV – TA-Luft air)

- Type GL: Series 16 ball valves for 3-way GL changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 6 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Type GL: Ball valves series 16 for 3-way GL switchover (TÜV – TA-Luft air)

- Type GLU: Series 16 ball valves for 3-way GL changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 6 mm

- Leak rate: < 10^-6 mbar . l/s

- Material: 1.4571 / V4A

- Packing: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Series 18 Typ GL

- Type GL: Series 18 ball valves for 3-way GL changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 8.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Type GLU: Ball valves series 18 for 3-way GLU switchover (TÜV – TA-Luft)

- Type GLU: Series 18 ball valves for 3-way GLU changeover (TÜV-TA air)

- Pressure: PN 200 bar

- Passage: DN 8.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Manually operated ball valves - 4 way system

Series 16

- Series 16 ball valves for 4-way changeover (TÜV-TA Air)

- Pressure: PN 200 bar

- Passage: DN 8.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

Manually operated ball valves - 5 Way system

Series 16 ball valves for 5-way changeover (TÜV-TA air)

-

- Pressure: PN 300 bar

- Passage: DN 1.5 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Packing gland: Reflon, Viton (V), Kalrez (KA), PCTFE (PC)

Ball valves with heating jacket

Ball valves with heating jacket - 2-way system

Series 16 2-WAY BALL HORN WITH HEATING TUBE

-

- Pressure: PN 300 bar

- Passage: DN 6 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

- Pressure Jacket: max. 6 bar

Series 18 2-WAY BALL HORN WITH HEATING TUBE

-

- Pressure: PN 300 bar

- Passage: DN 6 mm

- Leak rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

- Pressure Jacket: max. 6 bar

Ball valves with heating jacket - 3-way system

Series 16 3-WAY BALL HORN WITH HEATING TUBE

-

- Pressure: PN 100 bar

- Passage: DN 8.5 mm

- Leak Rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Packing Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

- Pressure Jacket: max. 6 bar

Series 18 3-WAY BALL HORN WITH HEATING TUBE

-

- Pressure: PN 100 bar

- Passage: DN 8.5 mm

- Leak Rate: < 10-6 mbar . l/s

- Material: 1.4571 / V4A

- Packing Gland: Teflon, Viton (V), Kalrez (KA), PCTFE (PC)

- Pressure Jacket: max. 6 bar

Ball valves Special models

SAFETY LOCK MADE FROM 1.4571

- Type SV:

Suitable for all series 12, 16 and 18 ball valves (with or without spindle extension).

LOCKABLE BALL VALVE MADE OF 1.4571

- Type A: Suitable for all series 12, 16 and 18 ball valves (with or without spindle extension).

VSM SPRING CLOSING UNIT (TYPE STOP) FOR MANUALLY OPERATED VALVES (DEAD MAN'S FUNCTION)

-

- 2-Way 90°

- STOP KH 1 G

- STOP KH 2 G

- STOP KH 4 G

- STOP KH 03 G

- 3-Way 90°

- STOP 3 KH 1 GL

- STOP 3 KH 2 GL

- STOP 3 KH 4 GL

- STOP 3 KH 03 GL

- Protection Class

- IP 65

- Materials

- Housing: Zinc die-cast

- Cover Cap: Nylon

- Shaft: Stainless Steel

- Hand Lever: Stainless Steel

- 2-Way 90°

STEM EXTENSION (TYPE SPV) FOR BALL VALVES

-

Stem extensions for VSM ball valves are recommended for use with critical gaseous and liquid media and when used as a cold valve.

All stem extensions are always supplied with a 50 mm long, continuous stem.

Variant 4 enables the space between the primary and secondary stuffing box to be monitored.

The spindle extension with secondary stuffing box is suitable for use:

➔ 2-way ball valves of the 16 / 18 series

➔ 3 - Way ball valves from the 16 / 18 series

➔ 4-way and 5-way ball valves of the 16 series

➔ Ball valves with heating jacket

Stem extensions without secondary stuffing box are suitable for all ball valves.

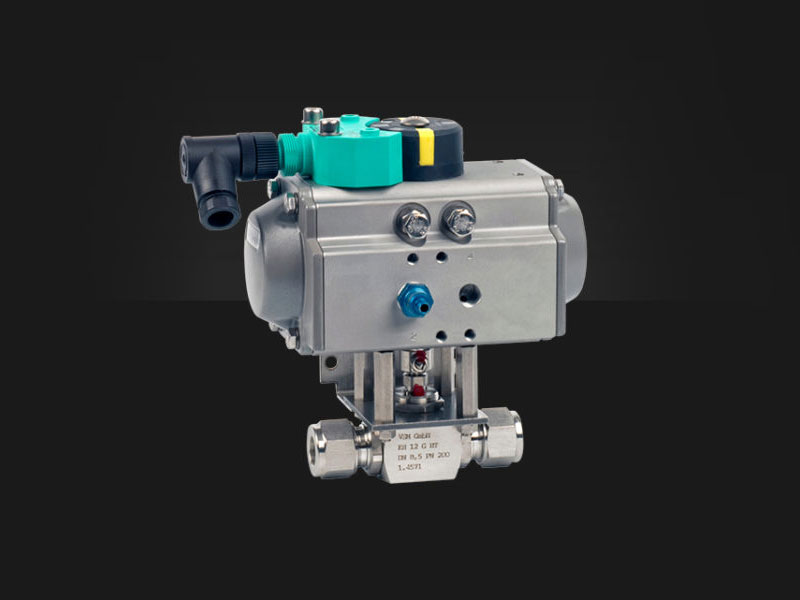

Ball valves pneumatic control heads

PNEUMATIC CONTROL HEADS TYPE-AT-F (SINGLE-ACTING)

-

- Control Pressure: min. 3.5 bar – max. 8 bar

- Angular Position:

- 90° for G and GL types

- NC (normally closed)

- NO (normally open)

- 180° for GLU types

- Temperature:

- Viton O-Rings: max. 150°C

PNEUMATIC CONTROL HEADS TYPE-AT-D (DOUBLE-ACTING)

-

- Control Pressure: Minimum 2.5 bar – Maximum 8 bar

- Actuation Angle:

- 90° for G and GL types

- 180° for GLU types

- Temperature:

- Viton O-rings: Maximum 150°C

Dosing valves

- Valves from VSM - regulate safely! Fits and keeps tight - the durable valves from VSM are recommended for a wide range of industrial applications. Here you will find our diaphragm valves for controlling gases, steam and fluids, precisely regulating needle valves, blow-off and dosing valves and our safe non-return valves, which only allow gases or liquids to flow in one direction. VSM supplies many valves for various industrial applications directly from stock. We will be happy to inform you about the high stock availability of our valves at any time.

Diaphragm valve - Series MV

-

- PN: 250

- DN: 4

- Temperature: -50°C to +300°C

- Leak rate: < 10^-10 mbar l/sec

- Cv: 0.25

Needle valves

Needle valve series NV

- Specifications:

- Temperature: 200°C

- Pressure: 350 bar

Needle valve series NV G

- Specifications:

- Temperature: 370°C

- Pressure: 350 bar

Needle leakage valve series NVL

-

Nadeleckventil für Gase und Flüssigkeiten, zum Absperren und Regeln, mit geteilter Spindel.

Specifications:

- Temperature: 200°C

- Pressure: 350 bar

Needle leakage valve series NVL G

-

Description

Specifications:

- Temperature: 200°C

- Pressure: 350 bar

Non-return valve

Non-return valve

-

- Material

- 1.4404 / 1.4571 / Hastelloy C22

- Pressure

- PN 350 bar RT

- Temperature

- -40° C to 260° C

- Leak Rate

- 10-9 mbar · l/s

- Spring made of VA (Stainless Steel)

- 0.023 bar – 1

- 0.21 bar – 2

- 0.7 bar – 3

- Connections

- G – Double ferrule compression fitting

- F – Internal thread

- M – External thread

- (Mutual connection combinations are also possible)

- Material

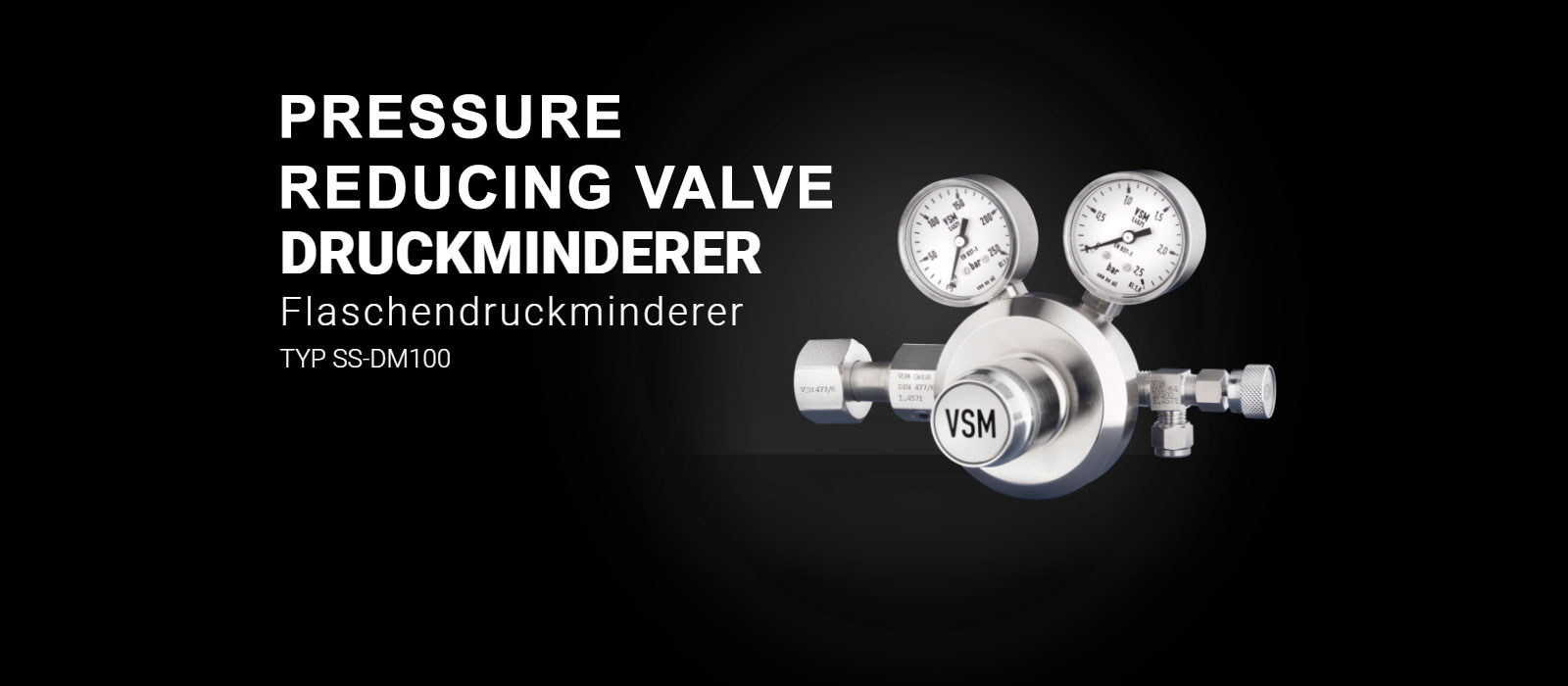

Pressure regulator

-

Pressure reducing valves from VSM - create balance!

Our reliable pressure reducers are used tirelessly to balance industrial systems. Wherever they are installed, they use valves to ensure that a predefined target outlet pressure is not exceeded in the application, regardless of the inlet pressure. This prevents damage or achieves a suitable pressure for the application.VSM supplies cylinder pressure reducers, line pressure reducers and tapping point pressure reducers for a wide range of applications. We will be happy to advise you on their properties!

Cylinder pressure reducer

-

Fine pressure reducer type FDM 100 as cylinder pressure reducer

- Werkstoff: 1.4404 / 1.4571 oder Ms-verchromt

- Temperatur: 20°C bis 150°C

- Leckrate: 10-8 mbar l/sec

- Membrane: Viton/Teflon, HC276

- Sitzbohrung: 2,8 Ø oder 6,5 Ø

Line pressure reducer LDM 400

-

FDA-compliant for corrosive and non-corrosive gases and liquids

- Inlet Pressure: PE 250 bar

- Outlet Pressure: PA 0 – 40 bar

- Connections:

- Inlet 1/4´´ NPT F

- Outlet 1/4´´ NPT F

- Temperature: -40°C to 140°C

- Weight: 1.4 kg

- Leak Rate: 10-9 mbar l/s

- Cv: 0.14

Tapping point pressure reducer type EDM

-

- Material: Stainless Steel 1.4571 / 1.4404 or chrome-plated steel

- Temperature: -30°C to 180°C

- Pressure: max. PN 250 bar

- Leak Rate: 10-8 mbar l/s

- Membrane: Viton, Viton & Teflon

- Seat: PVDF / PCTFE

- Filter: Sintered Metal SS 10 μm

- Backside: 2x M4 screw holes

Accessories

- We stock high-quality accessories to match our quality fittings: filters, tapping points, air jet pumps and vacuum pumps are available in various designs, for example oil and grease-free or FDA-compliant for use in food production. Please contact us for suitable accessories for your fitting requirements!

Tapping point type ES-107

-

- Temperature: -30°C to 100°C

- Pressure: max. PN 25 bar

- Leak Rate: 10-9 mbar l/s

- Seat: Viton

- Filter: Inlet Filter SS 10μm

Filter SS-Fi-F6

-

- Mutter: 1.4571

- Body Seal: Teflon / Peek / Vespel

- Deckel: 1.4571

- O-Ring: Viton / Kalrez

- Filter Housing: 1.4571

- Pressure: 250 bar

- Temperature: 200°C / 300°C

- External Filter Area: 21.11 cm²

Air jet pump / vacuum pump

-

- Connection Options:

- 6 mm

- 8 mm

- 12 mm

- Double compression ring fitting

- (others upon request)

- Body: 1.4401 (Stainless Steel)

- Nozzle: PEEK

- Connection Options: