- Offer Profile

-

We have been active in the tank construction business since 1959. After the founding of businessman Erwin Henze’s sole proprietorship, Henze-Harvestore GmbH followed in 1978 and Harvestore Deutschland GmbH in 1990.

We currently have 50 employees contributing to the success of our company, 12 of whom are experts in technical project management and construction, 13 in administration and sales and 40 of whom are skilled production and assembly workers.

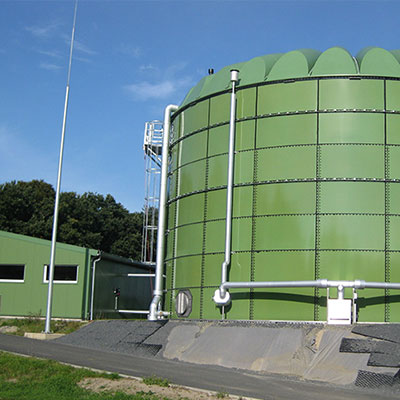

Biogas

- We have been active in the specialist field of biogas since 1980. The first biogas plant, built in Rhede-Bocholt in 1980/81, has been in continuous operation since then and has already been expanded numerous times. We build containers for biogas plants all over the world, which is precisely why individual customer requirements are our priority. We take into consideration factors relating to both company and production, adapting the container system and agitator technology accordingly. We also supplement this area of business with services, conversion as well as the dismantling and reconstruction of existing systems.

Container with attached gas depot

-

Combined storage

This design makes possible the storage of fermentation substrate and biogas in one container. The container wall is produced from normal, stainless or enamelled steel. These different materials are also distinguished by their high resistance to the corrosion usually caused by fermentation substrate and biogas.

For roof construction, gas depots made from PVC and/or EPDM foil are used – substances which have proven impermeable to methane gas. The foundation of the gas depot comprises central support made of stainless steel 1.4571 (AISI 316Ti) and a belt substructure. Concerning agitator technology, submersible agitators and/or long-shaft agitators are used. Our scope of delivery includes continuous measurement of gas levels as well as DEKRA-approved protection against overpressure and underpressure.

Central stirred digester

-

Long-term experience for optimum plant operation

This type of completely stirred fermenter is characterised by optimum gas yield with minimum energy input. Our very own roof construction with external galvanised steel girders and a V4A stainless steel membrane complete this high-quality container and ensure the best possible corrosion protection. We have been building these fermenters since 1992 and have constructed more than half a million cubic metres in volume to date. Our long-term experience ensures your optimal and hassle-free plant operation. We use coated, enamelled and stainless steel materials.

Digestate depot

-

Durable and extendible

Our digestate depots are made of glass-enamelled steel segments or stainless steel segments. Both materials are durably resistant to slurry and digestates; this also applies to covered containers. We construct our silos in a manner that facilitates subsequent extension if necessary. This gives our customers a high degree of flexibility for new developments. Individual components are just as much a part of our range as complete systems including covers and pump/agitator technology. We also offer two installation options: complete installation by our team, or joint installation by one of our expert supervisors together with a pre-agreed proportion of in-house work by the customer.

Buffer and hydrolisis container

-

Quality to meet the highest standards

Buffer or hydrolysis containers installed upstream of biogas plants place the highest demands on the container material and sealant. Our many years of experience in a wide variety of applications means we can provide you with competent advice in this area. Protection of the concrete foundation with stainless steel or plastic flooring completes our scope of delivery. Mostly V4A stainless steel materials are used.

Unpressured gas depot

-

Suspended in the container is a gas membrane, which is usually filled by the pressure of the upstream digestion tank. By means of a downstream compressor, the gas is fed for further utilisation. The membrane unfurls or contracts depending on the gas fill level.

With centrally suspended gas bags, the fill level can be measured continuously. The container is operated without pressure. An overpressure safety device activates at at 5 mm WS.

Operating instructions

If a gas network is connected directly to an unpressurised gas depot and no pressure-retaining measures (e.g. pressure-retaining valve) are in place, the prevailing condition is virtually unpressurised. Consumers can only be operated with a downstream compressor.

Pressure curve

In regular operation, the gas bubble of the container is unpressurised. Because the gas bubble unfolds, there is no significant increase in pressure when the tank is filled further. Only when the pressure bubble is full and bulging does the pressure increase.

Beet storage

-

Durability even in extreme conditions

Due to their low pH value, beet pulp and silage leachates place formidable demands on container construction. By using high-quality enamel or, alternatively, high-quality stainless steel materials, we create the basis for a long and durable service life of your storage containers. We use enamelled or stainless steel materials.

Digester

-

An individual product through the combination of proven solutions

Digesters and anaerobic tanks built by us to date have been of dimensions between 200 m³ and 6,000 m³. We use bolted segment plates in 316 and 304 stainless steel qualities as well as enamelled or coated normal steel. The pressure-tight stainless steel roofs are designed to withstand overpressure of 25 - 50 mbar as the standard. The gas-tightness of each stainless steel roof is inspected and documented. Central agitators or gas injectors are flanged to the central crown ring. For separators provided by customers, we supply load-lifting beams in coated steel or stainless steel. We carry out static verification of the load-lifting beam as well as its design, production and assembly. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, hydraulic safety devices, staircases, walkways, insulation, special building components and double-membrane depots.

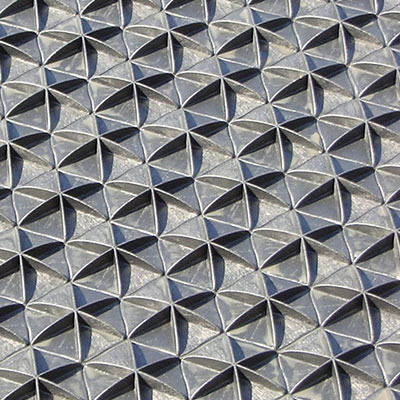

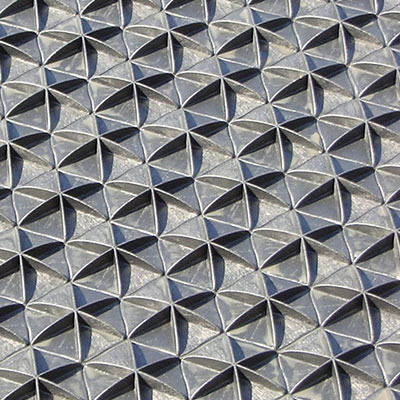

Hexa-Cover

-

Emission control with Floating Covers

We are an authorised dealer for Hexa-Cover Floating Covers. Hexa-Cover is a DLG-approved (German Agricultural Society) emission control cover which enables emission reduction of up to 95%. Hexa-Cover is impressively versatile and can be used in elevated containers as well as in lagoons. Floating Covers are delivered in Big Bags. The Covers are inserted when the container is full or empty and arrange themselves automatically when the medium is homogenised.

Refurbishment and loan gas depot

- We carry out the maintenance, conversion and refurbishment of gas depots for all manufacturers. Using our own team, we replace reverse-drawing tank jacket and renew telescopic guides and safety equipment. For the renewal of corrosion protection coatings, we work together with long-standing partners. We keep an extensive stock of spare parts for the maintenance and/or refurbishment of cable-guided dry gas depots. If desired, we can provide a rental gas depot of at least 50 m³ during implementation of refurbishment measures.

References

Energiepark Trelder Berg

-

- Place of construction: 21244 Buchholz i.d. Nordheide, Germany

- Year of construction: 2006 / 2010

- 3 Pre-storage tanks:Diameter: 11.09 m Height: 11.93 m Volume: 1,150 m³ each Tank equipment: with central agitator 6 Fermenters Diameter: 17.07 m Height: 16.87 m Volume: 3,860 m³ each Tank equipment: with central agitator

- 3 Secondary fermenters Diameter: 17.07 m Height: 8.47 m Volume: 1,940 m³ each Tank equipment: with attached gas depot, volume 1,300 m³

GreenGas Rathenow

-

- Place of construction: 14712 Rathenow, Germany

- Year of construction: 2008

- 2 Buffer tanks Diameter: 10.24 m Height: 5.67 m Volume: 470 m³ each Tank equipment: with emission control roof

- 2 Fermenters Diameter: 17.92 m Height: 19.67 m Volume: 4,960 m³ each Tank equipment: with central agitator

BGA Dorsten

-

- Place of construction: 46282 Dorsten, Germany

- Year of construction: 2010

- 8 Fermenters Diameter: 16.22 m Height: 15.47 m Volume: 3,200 m³ each Tank equipment: with central agitatorescription

Werite

-

- Place of construction:49757 Werlte, Germany

- Year of construction:2013

- Mixing and equalising tankDiameter: 9.39 m

- Height: 5.89 m

- Volume: 400 m³

- Material (wall): V4A stainless steel, material 1.4404 (AISI 316L)

- Tank equipment: PVC film membrane

Agriculture

-

With maximum impact in harvesting

HARVESTORE silos can be used for a wide range of agricultural applications: We offer gas-tight silos for storing grain, wet grain, wet maize, CCM, fermented feed/grass maize silage. Liquid manure can be stored open or covered in a HARVESTORE manure silo. Other bulk storage containers and sprinkler tanks complete our range. We supply not only individual components but also complete systems, including modern storage and retrieval technology – according to your requirements. Can’t find the product you’re looking for? Get in touch – we can find a solution for (almost) any stored goods.

CCM/Whole-grain silo

-

Gas-tightness for optimum fodder quality

For more than 40 years, we have been building gas-tight tower silos for the storage of maize and CCM. By using glass-enamelled steel segments for the silo wall in combination with stainless steel roofing, we ensure lasting resistance to corrosion. The use of polyurethane sealant ensures the silo stays gas-tight for a very long time. Whether you intend to store 100 tonnes or 10,000 – we will find the best and most operationally safe solution for you. In pig, cattle or poultry farming, dry or liquid feeding – Harvestore silos are flexible and can be adapted to suit any farm.

Grain storage

-

Airtight storage of freshly harvested and dry grain

Galvanised or glass-enamelled HARVESTORE tower silos offer you the greatest degree of flexibility in grain storage. Whether you want to preserve wet grain under airtight conditions or store dry grain – your crops are in the best hands. Adding acids for storage stability poses no problem for glass-enamelled silos, as they offer excellent corrosion protection.

Fermented fodder silo

-

Optimisation of labour

Fully automatic feeding for beef cattle – with a HARVESTORE tower silo, you can benefit from all the system’s advantages and economy of labour. For grass and maize silage, for lucerne or haylage. According to your requirements and operational conditions, various top and bottom unloading technologies are available for removal - and have been for over 50 years.

Enamelled slurry silo

-

Durable and extendible

Our enamelling is durably resistant to slurry and digestates; this also applies to covered containers. We construct our silos in a manner that facilitates subsequent extension if necessary. This gives our customers a high degree of flexibility for new developments. Individual components are just as much a part of our range as complete systems including covers and pump/agitator technology. We also offer two installation options: complete installation by our team, or joint installation by one of our expert supervisors together with a pre-agreed proportion of in-house work by the customer.

Stainless steel silo

-

Durable and extendible

Our slurry silos are generally made of V2A stainless steel segments (material 1.4301, AISI 304). On request or for special applications, we can also use V4A stainless steel (material 1.4571/AISI 316Ti or 1.4404/AISI 316L). We construct our silos in a manner that facilitates subsequent extension if necessary. This gives our customers a high degree of flexibility for new developments. Individual components are just as much a part of our range as complete systems including covers and pump/agitator technology. We also offer two installation options: complete installation by our team, or joint installation by one of our expert supervisors together with a pre-agreed proportion of in-house work by the customer.

Hexa-Cover

-

Emission control with Floating Covers

We are an authorised dealer for Hexa-Cover Floating Covers. Hexa-Cover is a DLG-approved (German Agricultural Society) emission control cover which enables emission reduction of up to 95%. Hexa-Cover is impressively versatile and can be used in elevated containers as well as in lagoons. Floating Covers are delivered in Big Bags. The Covers are inserted when the container is full or empty and arrange themselves automatically when the medium is homogenised.

Bulk storage silo

-

The best solution for every product

The most varied products, the most differing requirements and individual designs. Our silos are as flexible as your products are varied. Whether stainless steel, glass-enamelled, galvanised or powder-coated – always the best choice for you. HARVESTORE silos can be built with flat-bottom discharge system or funnel base. By using smooth sheet metal elements and countersunk bolts, we minimise the risk of residues and dust deposits in the silo, compared to, for example, corrugated sheet metal silos. The flow behaviour of heavy-flowing bulk materials is also improved. This minimises the risk of bridging.

Special tanks

-

Specialised solutions for your individual needs

Special tanks can differ vastly in their dimensions. We use bolted segment plates in 316 and 304 qualities as well as enamelled or coated normal steel. For media temperatures constantly exceeding 40°C, we combine stainless steel with a suitable sealing compound. Special tanks can be operated both uncovered and covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Different materials are also available for the concrete floor protection. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Agitators can be mounted on work platforms, for example. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

References

CCM/Whole-grain silo

-

- Place of construction: Russia

- Year of construction: 2013

- 6 Tower silos Diameter: 11.10 m Height: 23.87 m Volume: 2,350 m³ each Filling via elevator & trough chain conveyor Removal via Silohaake System with wet milling

Biogas

-

- Place of construction: 29353 Ahnsbeck, Germany

- Year of construction: 2015

- 2 Digestate depots Diameter: 26.46 m Height: 5.67 m Volume: 3,119 m³ each

Enamelled slurry silo

-

- Place of construction: 04808 Röcknitz/Thallwitz, Germany

- Year of construction: 2014

- 2 Slurry silo made of glass-enamelled steel segments Content: 4,141 m³ each

Warm water depot

-

- Place of construction:Baruth, Germany

- Year of construction: 2012

- Warm water depot

- Diameter: 7.68 m

- Height: 17.88 m

- Volume: 800 m³

- Equipment: stainless steel roof, insulation, steel construction, stainless steel floor

- Special features: medium to 60°C

- Material: V2A

Industry

-

Individual products through combination of proven solutions

HARVESTORE containers can be used in a wide variety of industrial areas. Different container systems are available for storing gaseous, liquid, semi-liquid and solid substances. We attach great importance to adapting our product to suit your needs – not the other way round. We assemble our system components according to your requirements and are therefore able to offer the greatest possible flexibility. Whether you need just one container or complete solutions with myriad extra equipment – we are your competent partner.

Wastewater tank

-

Combination of the proven system components enables individual solutions

Wastewater tanks built by us to date have been of dimensions between 30 m³ and 7,000 m³. We use bolted segment plates in 316 and 304 qualities as well as enamelled or coated normal steel. Wastewater tanks can be operated both uncovered and covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Different materials are also available for the concrete floor protection. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Agitators can be mounted on work platforms, for example. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Stainless steel tank

-

Durable and extendible

The material grades for stainless steel silos are agreed with the customer. Generally, we supply V4A stainless steel segments in grade 1.4404 (AISI 316L) or V2A stainless steel segments in grade 1.4301 (AISI 304). Alternative stainless steel grades can be investigated. We construct our silos in a manner that facilitates subsequent extension if necessary. This gives our customers a high degree of flexibility for new developments. Individual components are just as much a part of our range as complete systems including walkways, roofs, insulation and concrete floor protection. Stainless steel tanks are available in various sizes and dimensions. Detailed information can be found in our

Anaerobic tank

-

An individual product through the combination of proven solutions

Anaerobic tanks built by us to date have been of dimensions between 200 m³ and 1,200 m³. We use bolted segment plates in 316 and 304 qualities as well as enamelled plates. The pressure-tight stainless steel roofs are designed to withstand overpressure of 25 - 50 mbar as the standard. The gas-tightness of each stainless steel roof is inspected and documented. For separators provided by customers, we supply load-lifting beams in coated steel or stainless steel. We carry out static verification of the load-lifting beam as well as its design, production and assembly. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, hydraulic safety devices, staircases, walkways, insulation, special building components and double-membrane depots.

Low pressure gas depot

-

As dry gas depots, low pressure gas depots are excellently suited for the storage of sewage gas. The digester acts as a pressure generator, lifting the weighted ballast plate and storing the produced gas under constant pressure. Downstream consumers can be operated without any additional increase in pressure. Low pressure gas depots have the advantage that there is permanent pressure in the entire gas system and therefore no risk of oxygen entering the gas system when the depot is full. The linear movement of the ballast plate furthermore enables very accurate measurement of the stored volumes. We supply low pressure gas depots from 50 m³ to 7,000 m³ and at pressures ranges from 20 mbar to 65 mbar. The depots are designed as biogas containers with a weighted membrane in accordance with DWA M-376. Since all roller guides are located outside the gas compartment, the ballast plate guide is maintenance-free. Since corrosion-resistant materials are used, such as stainless steel and enamelled steel, refurbishment of the depot - as with coated black steel constructions - is unnecessary. A common feature of all our gas depots is that they are bolted together onsite from individual steel segments after careful preliminary planning and construction. The advantages of this are:

- Quality control of components still in the factory

- Precisely fitting construction elements

- Short construction time with maximum independence of weather conditions

- No work at great heights, no scaffolding, no sandblasting or coating work on the system

- Excellent corrosion protection thanks to the use of enamelled steel and stainless steel

Unpressurised gas depot

-

Suspended in the container is a gas membrane, which is usually filled by the pressure of the upstream digestion tank. By means of a downstream compressor, the gas is fed for further utilisation. The membrane unfurls or contracts depending on the gas fill level. With centrally suspended gas bags, the fill level can be measured continuously. The container is operated without pressure. An overpressure safety device activates at at 5 mm WS.

Operating instructions

If a gas network is connected directly to an unpressurised gas depot and no pressure-retaining measures (e.g. pressure-retaining valve) are in place, the prevailing condition is virtually unpressurised. Consumers can only be operated with a downstream compressor.

Pressure curve

In regular operation, the gas bubble of the container is unpressurised. Because the gas bubble unfolds, there is no significant increase in pressure when the tank is filled further. Only when the pressure bubble is full and bulging does the pressure increase.

Refurbishment and loan gas depot

-

Refurbishment and loan gas depot

We carry out the maintenance, conversion and refurbishment of gas depots for all manufacturers. Using our own team, we replace reverse-drawing tank jacket and renew telescopic guides and safety equipment. For the renewal of corrosion protection coatings, we work together with long-standing partners. We keep an extensive stock of spare parts for the maintenance and/or refurbishment of cable-guided dry gas depots. If desired, we can provide a rental gas depot of at least 50 m³ during implementation of refurbishment measures.

Thick sludge depot

-

Proven components for smooth operation

Our thick sludge depots are typically built using enamelled steel and operated with a cover. Various stainless steels are available for the cover. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Leachate depot

-

A variety of individual components enable a multitude of system solutions

Our leachate depots are typically built using enamelled steel and operated with a cover. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. For the concrete floor protection, a variety of systems is available. In addition to leakage-monitored HDPE flooring, we supply single-walled concrete floor protection in various materials. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Special tanks

-

Specialised solutions for your individual needs

Special tanks can differ vastly in their dimensions. We use bolted segment plates in 316 and 304 qualities as well as enamelled or coated normal steel. For media temperatures constantly exceeding 40°C, we combine stainless steel with a suitable sealing compound. Special tanks can be operated both uncovered and covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Different materials are also available for the concrete floor protection. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Agitators can be mounted on work platforms, for example. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Sludge thickener / sludge tank

-

Combine our components according to your needs

Our sludge tanks are typically built using enamelled steel/V4A stainless steel. Sludge tanks can be operated either uncovered or covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Thickeners can also be supplied with a conical base, e.g. 60°, in stainless steel. Machine technology, such as agitators, can be mounted on reinforced work platforms. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation, double end brackets as scraper tracks and special building components.

Grain storage

-

Airtight storage of freshly harvested and dry grain

Galvanised or glass-enamelled HARVESTORE tower silos offer you the greatest degree of flexibility in grain storage. Whether you want to preserve wet grain under airtight conditions or store dry grain – your crops are in the best hands. Adding acids for storage stability poses no problem for glass-enamelled silos, as they offer excellent corrosion protection.

Bulk storage silo

-

The best solution for every product

The most varied products, the most differing requirements and individual designs. Our silos are as flexible as your products are varied. Whether stainless steel, glass-enamelled, galvanised or powder-coated – always the best choice for you. HARVESTORE silos can be built with flat-bottom discharge system or funnel base. By using smooth sheet metal elements and countersunk bolts, we minimise the risk of residues and dust deposits in the silo, compared to, for example, corrugated sheet metal silos. The flow behaviour of heavy-flowing bulk materials is also improved. This minimises the risk of bridging.

MBM silo

-

Enamelling and removal technology guarantee a long service life

One of our company’s specialities is the construction of silos and removal technology for the storage of MBM and/or blood meal. This has now been the case for over 30 years. Due to the difficult nature of discharge from the container, the advantages of glass-enamelled steel segments become especially clear here. By using bottom unloaders in combination with stainless steel discharge augers, we guarantee a long service life and high operational reliability of the removal technology.

Reference

Wastewater tank

-

- Place of construction: KA Stahnsdorf, Germany

- Year of construction: 2018

- Centrate water depot Diameter: 12.81 m Height: 8.77 m Volume: c. 1,066 m³ Equipment: Jacket, roof insulation, nozzles, hatches Special features: all-round platform with connection to jacket staircase Material: jacket & roof V4A

Unpressurised gas depot

-

- Place of construction: Edenkoben biogas plant

- Year of construction: 2014

- Unpressurised gas depot Diameter: 12.51 m Height: 11.01 m Volume: 1,200 m³ with corrugated iron enclosure Scope: planning, statics, delivery, assembly and commissioningption

Leachate depot

-

- Place of construction: Schwaiganger, Germany

- Year of construction: 2011

- Leachate depot Diameter: 10.24 m Height: 11.27 m Volume: 890 m³ Equipment: V4A roof, insulation, steel construction Special features: leakage monitor, HDPE floor Material: enamelled steel, V4A Colour: RAL 6006

Thick sludge depot

-

- Place of construction: Mettingen, Germany

- Year of construction: 2009

- Thick sludge depot

- Diameter: 8.54 m

- Height: 4.27 m

- Volume: 230 m³

- Equipment: V4A roof, steel construction

- Special features: 25° roof

- Material: enamelled steel, V4A

- Colour: RAL 5013

Municipality

-

A variety of individual components enable a multitude of system solutions

In the municipal wastewater sector, we offer a wide range of container types for wastewater, sludge, leachate and much more. We also offer numerous gas depots. Storing solids? We can help with this too – our bulk silos should do the trick. We have a diverse variety of accessories on offer for every type of container. This means you can choose the right components for your specific application, individually and tailored to your needs.

Wastewater tank

-

Combination of the proven system components enables individual solutions

Wastewater tanks built by us to date have been of dimensions between 30 m³ and 7,000 m³. We use bolted segment plates in 316 and 304 qualities as well as enamelled or coated normal steel. Wastewater tanks can be operated both uncovered and covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Different materials are also available for the concrete floor protection. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Agitators can be mounted on work platforms, for example. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Sludge thickener / sludge tank

-

Combine our components according to your needs

Our sludge tanks are typically built using enamelled steel/V4A stainless steel. Sludge tanks can be operated either uncovered or covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Thickeners can also be supplied with a conical base, e.g. 60°, in stainless steel. Machine technology, such as agitators, can be mounted on reinforced work platforms. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation, double end brackets as scraper tracks and special building components.

Thick sludge depot

-

Proven components for smooth operation

Our thick sludge depots are typically built using enamelled steel and operated with a cover. Various stainless steels are available for the cover. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Leachate depot

-

A variety of individual components enable a multitude of system solutions

Our leachate depots are typically built using enamelled steel and operated with a cover. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. For the concrete floor protection, a variety of systems is available. In addition to leakage-monitored HDPE flooring, we supply single-walled concrete floor protection in various materials. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Special tanks

-

Specialised solutions for your individual needs

Special tanks can differ vastly in their dimensions. We use bolted segment plates in 316 and 304 qualities as well as enamelled or coated normal steel. For media temperatures constantly exceeding 40°C, we combine stainless steel with a suitable sealing compound. Special tanks can be operated both uncovered and covered. Different materials are available for the cover. In addition to stainless steel, there is also a choice of aluminium, fibreglass (GFK) or tarpaulin. Different materials are also available for the concrete floor protection. You may choose between HDPE, stainless steel, fibreglass (GFK) or epoxy. Agitators can be mounted on work platforms, for example. Tank construction is rounded off with a wide range of individual components such as manholes, nozzles, staircases, walkways, insulation and special building components.

Stainless steel tank

-

Durable and extendible

The material grades for stainless steel silos are agreed with the customer. Generally, we supply V4A stainless steel segments in grade 1.4404 (AISI 316L) or V2A stainless steel segments in grade 1.4301 (AISI 304). Alternative stainless steel grades can be investigated. We construct our silos in a manner that facilitates subsequent extension if necessary. This gives our customers a high degree of flexibility for new developments. Individual components are just as much a part of our range as complete systems including walkways, roofs, insulation and concrete floor protection. Stainless steel tanks are available in various sizes and dimensions. Detailed information can be found in our

Low pressure gas depot

-

As dry gas depots, low pressure gas depots are excellently suited for the storage of sewage gas. The digester acts as a pressure generator, lifting the weighted ballast plate and storing the produced gas under constant pressure. Downstream consumers can be operated without any additional increase in pressure. Low pressure gas depots have the advantage that there is permanent pressure in the entire gas system and therefore no risk of oxygen entering the gas system when the depot is full. The linear movement of the ballast plate furthermore enables very accurate measurement of the stored volumes. We supply low pressure gas depots from 50 m³ to 7,000 m³ and at pressures ranges from 20 mbar to 65 mbar. The depots are designed as biogas containers with a weighted membrane in accordance with DWA M-376. Since all roller guides are located outside the gas compartment, the ballast plate guide is maintenance-free. Since corrosion-resistant materials are used, such as stainless steel and enamelled steel, refurbishment of the depot - as with coated black steel constructions - is unnecessary. A common feature of all our gas depots is that they are bolted together onsite from individual steel segments after careful preliminary planning and construction. The advantages of this are:

- Quality control of components still in the factory

- Precisely fitting construction elements

- Short construction time with maximum independence of weather conditions

- No work at great heights, no scaffolding, no sandblasting or coating work on the system

- Excellent corrosion protection thanks to the use of enamelled steel and stainless steel

Unpressurised gas depot

-

Suspended in the container is a gas membrane, which is usually filled by the pressure of the upstream digestion tank. By means of a downstream compressor, the gas is fed for further utilisation. The membrane unfurls or contracts depending on the gas fill level. With centrally suspended gas bags, the fill level can be measured continuously. The container is operated without pressure. An overpressure safety device activates at at 5 mm WS.

Operating instructions

If a gas network is connected directly to an unpressurised gas depot and no pressure-retaining measures (e.g. pressure-retaining valve) are in place, the prevailing condition is virtually unpressurised. Consumers can only be operated with a downstream compressor.

Pressure curve

In regular operation, the gas bubble of the container is unpressurised. Because the gas bubble unfolds, there is no significant increase in pressure when the tank is filled further. Only when the pressure bubble is full and bulging does the pressure increase.

Refurbishment and loan gas depot

-

Refurbishment and loan gas depot

We carry out the maintenance, conversion and refurbishment of gas depots for all manufacturers. Using our own team, we replace reverse-drawing tank jacket and renew telescopic guides and safety equipment. For the renewal of corrosion protection coatings, we work together with long-standing partners. We keep an extensive stock of spare parts for the maintenance and/or refurbishment of cable-guided dry gas depots. If desired, we can provide a rental gas depot of at least 50 m³ during implementation of refurbishment measures.

Reference

Sludge thickener / sludge tank

-

- Place of construction: Groß Gerau, Germany

- Year of construction: 1998

- Secondary clarifier Diameter: 29.89 m Height: 3.53 m Volume: 2,100 m³ Equipment: drainage channel Special features: special colour Material: enamelled steel Colour: RAL 9002

Stainless steel tank

-

- Place of construction: Rastatt, Germany

- Year of construction: 2015

- Centrate water depot Diameter: 11.95 m Height: 7.31 m Volume: 709 m³ Equipment: V4A roof, steel construction, stainless steel floor, piping, fittings Material: V4A, 1.4404 (AISI 316L)

Low pressure gas depot

-

- Place of construction: Rotenburg (Wümme), Germany

- Year of construction: 2023

- Low pressure gas depot: Diameter: 7.69 m Height: 7.72 m Volume: 250 m³ Design pressure: 50 mbar Scope: planning, structural analysis, delivery, installation and commissioning Special features: Pre-shaft works

Unpressurised gas depot

-

- Place of construction: Übach-Palenberg treatment plant

- Year of construction: 2016

- Unpressurised gas depot

- Diameter: 8.04 m

- Height: 11.85 m

- Volume: 250 m³

- with corrugated iron enclosure

- Scope: planning, statics, delivery, assembly and commissioning