- Offer Profile

- Vision

Provide the world with valuable solutions in all applicable applications

Business Concept

To develop, manufacture and market fastening and centering products based on hydraulic and hydro-mechanical principles. For use as hub-shaft connections, tool and work piece holders and similar applications. The ETP high precision quality products should offer quick assembly and disassembly and high levels of customer satisfaction.

Power Transmission

- The ETP-Principle gives because of the hydraulic principle:

compact design, fast assembly, easy positioning, good runout, does not damage the contact

surfaces and is easy to dismantle. These qualities are important today and will be even more

important in the future.

With increasing requirements on down sizing the machines, better runout/balance, increased machine speeds, shorter downtime for service and increased precision, ETP hydraulic hub-shaft connections are choosen for more and more designs. Hydraulic Hub-Shaft connections – Single screw mounting

- These products are, just as it sounds, designed for using only a single screw for mounting. This ensures quick and easy mounting/dismantling and easy adjustments/repositioning of the hub. Used in a variety of applications/industries such as packing, food/beverage and pharmaceutical.

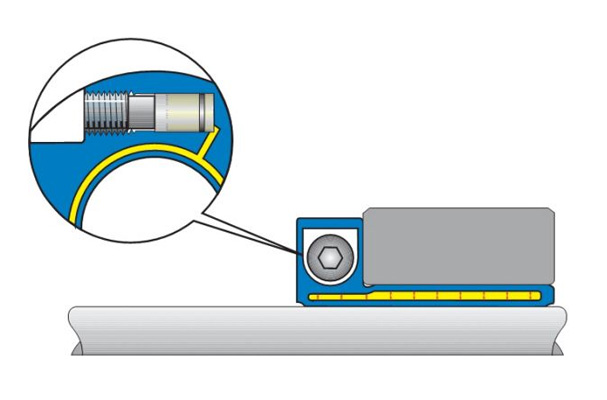

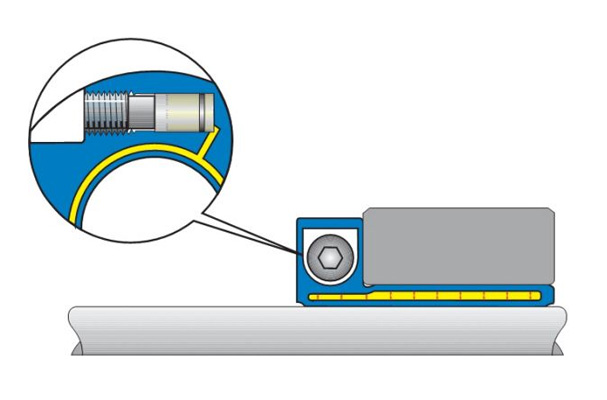

ETP-EXPRESS

-

ETP-EXPRESS has only one screw for pressurising, it is therefore suitable when there is a need for the repositioning of the hub fast and accurate. The screw is tightened in the radial direction, this means no space is used along the shaft for mounting tools. Other components can be mounted on the shaft all the way up to the flange. ETP-EXPRESS has extremely small built-in dimensions.

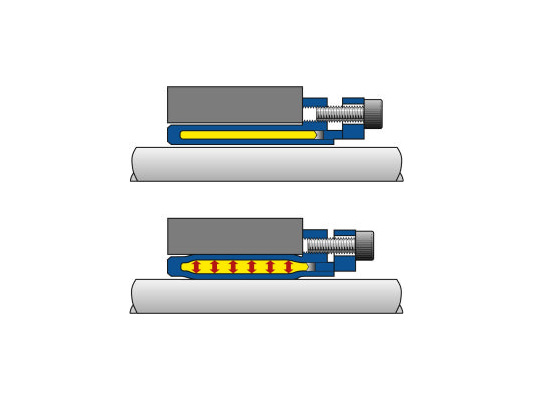

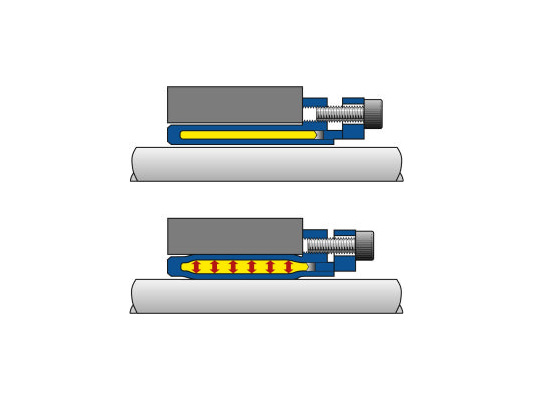

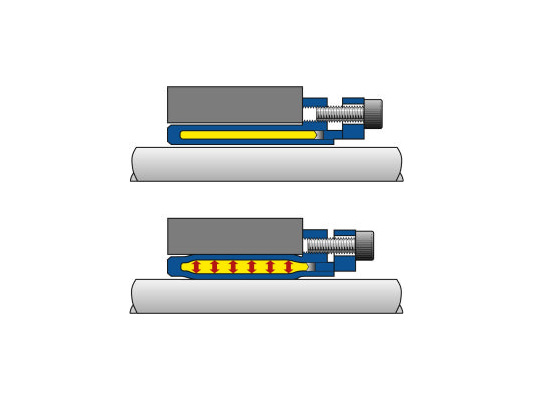

CONSTRUCTION

ETP-EXPRESS consists of a double-walled hardened steel sleeve filled with a pressure medium and a flange. The flange part contains a screw and piston with seals to maintain pressure.

OPERATION

When the pressure screw is tightened the double-walled sleeve expands uniformly against shaft and hub and creates a rigid joint. Dismantling is done by loosening the screw. ETP-EXPRESS returns to its original dimensions and can easily be dismantled.FEATURES & BENEFITS

- Extremely fast mounting/dismantling with only ONE screw.

- Radial tightening of the screw saves space along the shaft.

- Extremely small built-in dimensions.

- Accurate positioning, no axial movement when mounting.

- Good concentricity, also after several mountings.

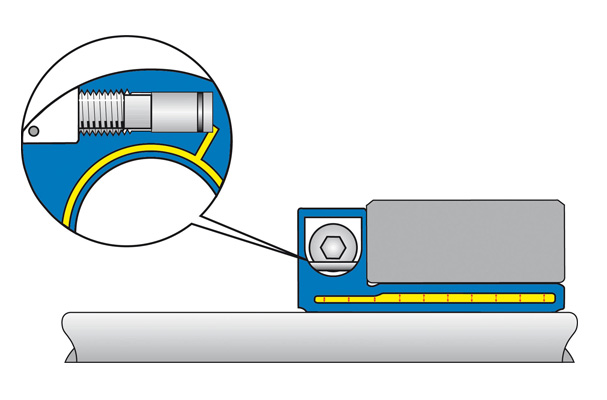

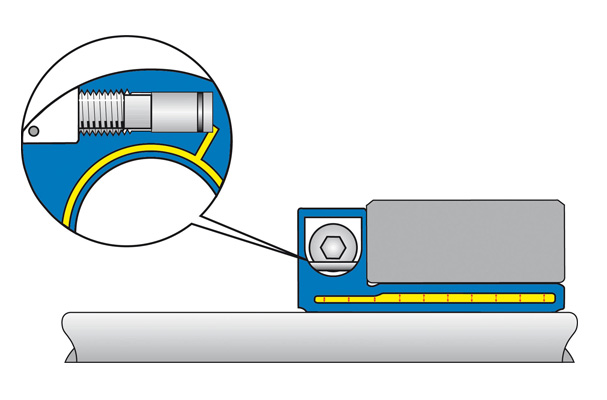

ETP-EXPRESS R

-

CONSTRUCTION

ETP-EXPRESS type R is ETP-EXPRESS made of stainless steel. The screw is also stainless.

OPERATION

ETP-EXPRESS type R works in the same way as ETP-EXPRESS.FEATURES & BENEFITS

- ETP-EXPRESS type R has the same good qualities when it comes to fast and frequent mounting with only ONE screw in the radial direction, small built-in dimensions etc. as ETP-EXPRESS.

- All parts of ETP-EXPRESS R exposed to the environment are made of stainless steel.

- Easy to clean. In food processing this meets essential requirements.

ETP-POWER

-

CONSTRUCTION

ETP-POWER is a hydraulic connection which consists of adouble-walled hardened steel sleeve filled with a speciallydeveloped pressure medium and a flange. The flange partcontains screw and piston with seals to maintain pressure.

In the flange there are two pre-machined bores which can be used for mounting location pins, screws to the hub or similar.OPERATION

When the pressure screw is tightened the double-walled sleeve expands uniformly against hub and shaft and creates a rigid joint. Dismantling is done by loosening the screw. ETP-POWER returns to its original dimensions and can easily be dismantled.FEATURES & BENEFITS

- High radial load capacity.

- Fast mounting/dismantling with only ONE screw.

- Small built-in dimensions.

- Radial tightening of the screw saves space along the shaft.

- Accurate positioning, no axial movement when mounting.

- Good concentricity, also after several mountings.

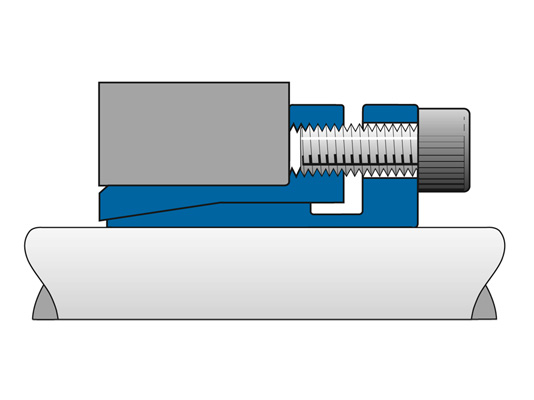

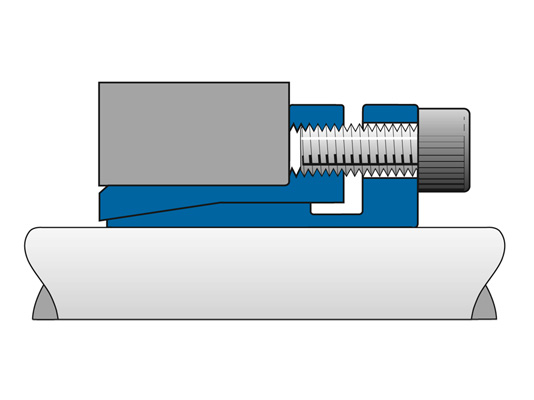

ETP-TECHNO

-

CONSTRUCTION

ETP-TECHNO consists of a double-walled hardened steel sleeve filled with a pressure medium, and a flange. The flange part contains the pressurizing mechanism, which consists of a screw and piston with double sealing function, an o-ring and a metallic seal with a steel ball, which is pressed against spherical a seating.

The outer and inner diameter and the side of the flange towards the hub are accurately machined for extremely good concentricity.

The pressurizing mechanism is designed for 1000´s of mountings.

OPERATION

When the pressure screw is tightened the double-walled sleeve expands uniformly against the shaft and the hub thus creating a rigid joint. Dismantling of the joint is done by loosening the screw. ETP-TECHNO returns to its original measurements and can easily be dismantled.FEATURES & BENEFITS

The unique hydraulic principle gives a great number of advantages:- Fast mounting/dismantling. Only one screw needs to be tightened.

- Extremely good concentricity, also after several mountings.

- Can be mounted/dismantled 1000´ s of times.

- Possible to mount in tight spaces. The pressure screw is tightened in the radial direction to the shaft.

- Small built-in dimensions.

- The hub can be adjusted easily and accurately.

Hydraulic Hub-Shaft connections – Multiple screw mounting

- Multiple screw products mean that you have to tighten two or more screws to mount the product. Used in a large variety of applications, from mounting timing belts and arms. Useful for all your normal needs.

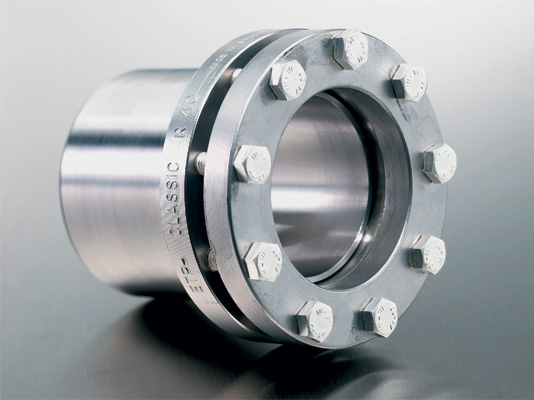

ETP-CLASSIC

-

ETP-CLASSIC is used in a large variety of applications, for mounting timing belt pulleys, cam curves and arms etc. Positioning along and around the shaft is easy and fast with high precision. Service and maintenance are also easier because of the easy dismantling. ETP-CLASSIC is recommended for all normal needs.

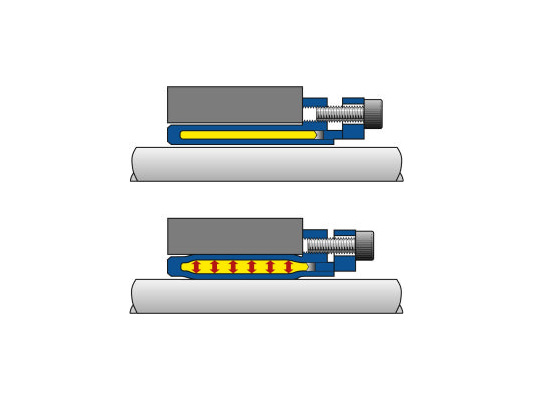

CONSTRUCTION

ETP-CLASSIC consists of a double-walled hardened steel sleeve filled with a specially adopted pressure medium, sealing ring, piston, pressure flange and clamping screws.

OPERATION

When tightening the screws the sleeve expands uniformly against hub and shaft and creates a rigid joint. When loosening the screws the sleeve returns to its original measurements and can easily be dismantledFEATURES & BENEFITS

The unique hydraulic principle gives a great number of advantages:- Small built-in dimensions and a reasonable surface pressure means small outside diameter for the hub.

- Mounting and dismantling is fast.

- Fine adjustment of the hub can be made during mounting.

- Low tightening torque and a small number of screws makes the mounting easy.

- Good concentricity also after several mountings.

- ETP-CLASSIC has cap head screws but screws with hex head are available as accessories.

ETP-CLASSIC R

-

CONSTRUCTION

ETP-CLASSIC R is the same as ETP-CLASSIC but made of hardened stainless steel.

Type R has hex head stainless steel screws, in order to facilitate easy cleaning when used for example in machines for processing food.

OPERATION

ETP-CLASSIC R works in the same way as ETP-CLASSIC with a few exceptions:- There are a few more screws as the tightening torque is lower for stainless steel screws.

- The transmissible torque is lower.

FEATURES & BENEFITS

- ETP-CLASSIC R has the same qualities as ETP-CLASSIC when it comes to fast/ backlash free mounting and positioning.

- All parts exposed to the environment are made of stainless steel. In food processing this meets essential requirements.

ETP-MINI / ETP-MINI R

-

ETP-MINI is superior to keyways or setscrews because it allows an adjustable, backlash free joint. Typical applications are mounting of hubs on small electrical motors, stepmotors and encoders. As no keyways are needed, the shaft will not be weakened and the unbalance will be lower, which is very important at high speeds, as the motor bearing is sensitive to vibrations. Also available in stainless, ETP-MINI R, suitable for the food processing industry etc.

CONSTRUCTION

ETP-MINI consists of two, partly slotted, conical steel sleeves (type R stainless) and clamping screws (type R stainless).

OPERATION

By tightening the screws the inner sleeve is pressed against the shaft and the outer sleeve against the hub thus forming a rigid joint.

When dismantling, one or if necessary, two of the screws are moved to the threaded dismantling holes in the flange. By tightening, the sleeves will separate and the joint will loosen.

ETP-MINI R has one screw more than the normal ETP-MINI in order to transmit the same torque (lower tightening torque for stainless screws). The built-in dimensions are the same.FEATURES & BENEFITS

- Easy to mount.

- Good runout.

- Allows wide tolerances.

- Available in stainless steel (type R).

- ETP-MINI R has stainless cap head screws but stainless hex head screws are available as accessories.

Hydro-mechanical connections – For large dimensions and heavy loads

- A robust and compact design with no oil leakage, ability to take high loads and quick mounting/dismantling of large dimensions, make our hydro-mechanical connections ideal to work in difficult environments and heavy operations. All those reason are examples why the steel- and marine industry very much appreciate this assortment.

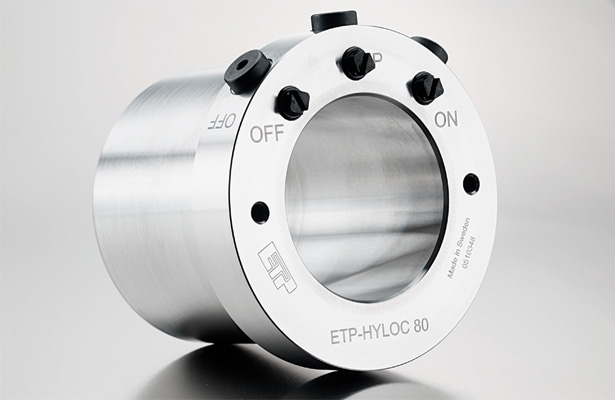

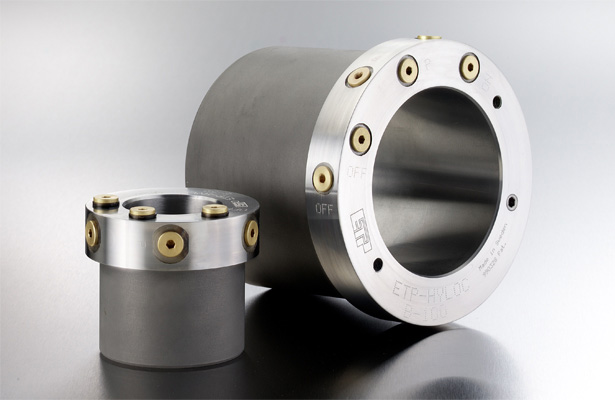

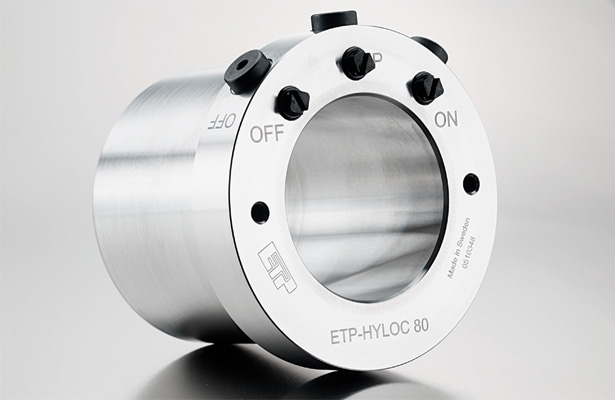

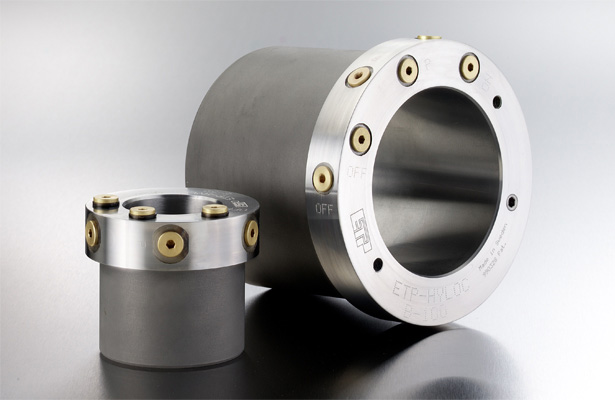

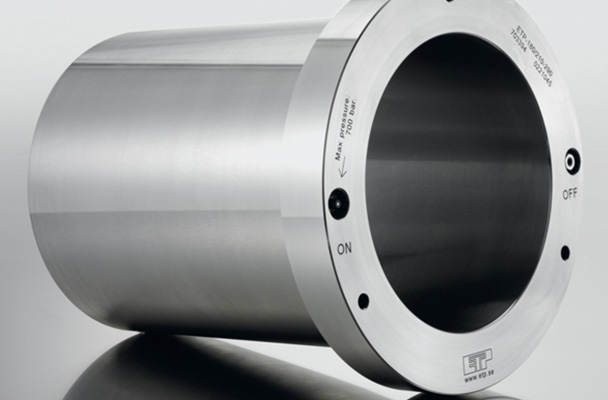

ETP-HYLOC

-

ETP-HYLOC, due to its robust design, is ideally suited to work in difficult environments and heavy operations like steel rolling mills, process industry etc. An interesting application, among many, has been fastening of rolls to shafts. ETP-HYLOC is fast to mount, has good concentricity and can take high radial loads.

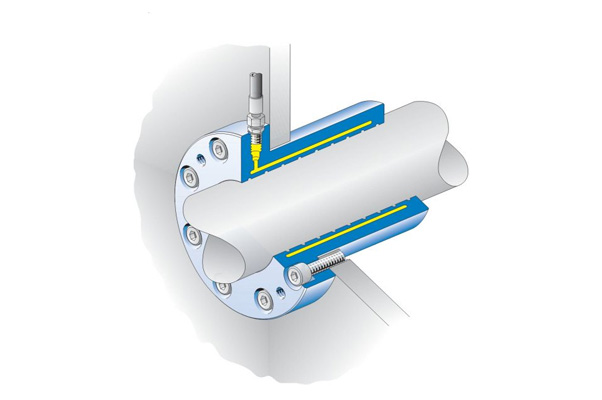

CONSTRUCTION

ETP-HYLOC is a hydromechanical joint, which consists of a double-walled steel sleeve, which encloses a conical moveable piston. In the flange there are three threaded connections (”ON”, ”P” and ”OFF”) in the radial direction and the same in the axial. This makes it possible to choose radial or axial connection of the hoses. Mounting and dismantling is carried out with a hydraulic pump with three hoses.

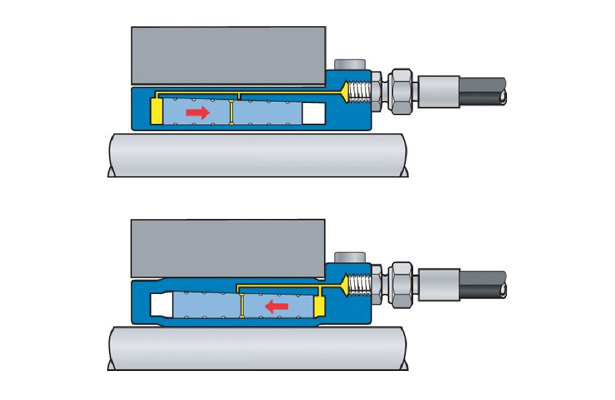

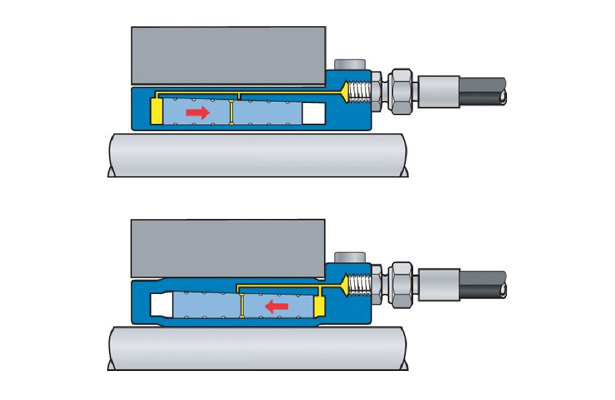

OPERATION

When the piston is moved, by the hydraulic pressure from the pump, the double-walled sleeve expands uniformly against shaft and hub and forms a rigid joint.

When dismantling, the piston is moved in the opposite direction and the joint will loosen.

A small amount of oil will be taken via spiral tracks in the piston between the surfaces, in this way making it easier for the piston to move.FEATURES & BENEFITS

- High transmittable torque, which can be varied by changing the mounting pressure.

- Fast mounting/dismantling also in tight spaces. By using a pump the time is reduced to a minimum even for large sizes.

- Radial or axial pressurizing is possible.

- Fine adjustments of the hub can be made when mounting.

- Good concentricity, also after several mountings.

- High radial load capacity.

ETP-HYCON S/SX

-

ETP-HYCON S and SX are compact rigid shaft-shaft couplings for high performance, quick mounting/dismantling and thus short downtime. Type SX is longer than S and can transmit considerably higher torque. Both types are type approved by DnV for marine applications.

CONSTRUCTION

ETP-HYCON S and SX both consists of an outer sleeve with hydraulic connections, an inner sleeve with ETP-HFC on the inside and an on the inner sleeve assembled cylindrical ring and seals.

OPERATION

When mounting two connections are pressurized simultaneously. The oil pressure lubricates the contact surfaces in the axial space between the seals. This facilitates the movement of the outer sleeve, which is forced to move because of the axial force created by the oil pressure. When the outer sleeve has been driven up a certain length, the pressure is released, the outer sleeve compresses the inner sleeve to an even surface pressure. A rigid strong joint has been created.

Dismantling is done in the same way, but with a lower pressure to get an even dismantling process.FEATURES & BENEFITS

The unique ETP-HFC treatment which increases the friction considerably, the hydro-mechanical principle and the through seals closed oil chambers together gives a great number of advantages:- High transmittable torque.

- High torsional stiffness.

- Quick mounting/dismantling.

- Low weight, low polar moment of inertia.

- No oil drainage.

- Compact design.

ETP-HYCON F/FX

-

ETP-HYCON F and FX are compact rigid shaft-flange couplings for high performance, quick mounting/dismantling and thus short downtime. Type FX is longer than F and can transmit considerably higher torque. Both types are type approved by DnV for marine applications.

CONSTRUCTION

ETP-HYCON F and FX both consists of an outer sleeve with hydraulic connections, an inner sleeve with a flange and ETP-HFC on the inside and an on the inner sleeve assembled cylindrical ring and seals.

OPERATION

When mounting both two connections are pressurized simultaneously. The oil pressure lubricates the contact surfaces in the axial space between the seals. This facilitates the movement of the outer sleeve, which is forced to move because of the axial force created by the oil pressure. When the outer sleeve has been driven up a certain length, the pressure is released and the outer sleeve compresses the inner sleeve to an even surface pressure to the shafts. A rigid strong joint has been created.

Dismantling is done in same way, but with a lower pressure to get an even dismantling process.FEATURES & BENEFITS

The unique ETP-HFC treatment which increases the friction considerably, the hydro mechanical principle and the through seals closed oil chambers together gives a great number of advantages:

- High transmittable torque.

- High torsional stiffness.

- Quick mounting/dismantling.

- Low weight, low polar moment of inertia.

- No oil drainage.

- Compact design.

- The flange does not move axially during pressurizing.

Hydraulic connections - External pressurization

- Here the pressure setting/mounting is done with the help of an external pressure source separate from the connection. This makes mounting extremely fast and it’s possible to pressurize several connections simultaneously.

ETP-OCTOPUS

-

We have, through the development of ETP-OCTOPUS, explored the many positive qualities of our hydraulic hub-shaft connections. The most important features are compact design, quick locking, accurate positioning and good runout. The joint will not damage the contact surfaces and must be easy to dismantle.

For ETP-OCTOPUS the pressure setting is done with an external pressure source separate from the clamping joint. This makes the pressure setting extremely fast and makes it possible to pressurize several joints simultaneously and remotely.

CONSTRUCTION

ETP-OCTOPUS is a double-walled hardened steel sleeve with a flange. In the flange there are bores for mounting of a hub and a scraper with a screw joint, threaded connection for hydraulic oil and an air relief screw. The inner diameter has spiral tracks in order to get an even friction and a defined locking force.

OPERATION

The assembly is done with the screw joint. When hydraulically pressurized the inner sleeve expands uniformly against the shaft and creates a rigid joint. When the pressure is released the sleeve returns to its original dimension and can easily be moved along the shaft to its new position and be repressurized.FEATURES & BENEFITS

The unique hydraulic principle, the solid and simple design of the sleeve gives a great number of advantages:

- High torsional stiffness.

- Both axial force and torque can be transmitted.

- Easy to build in, only space for the screw joint is needed.

- Can be used independent of the operating temperature.

- No axial movement during pressurizing.

- Low risk of leakage.

Customized solutions

- Continuous development with customers, where ETP

contribute with wide application knowledge and calculation assistance, has

resulted in a steady flow of new products. We offer customized solutions in

co-operation with OEM: s. Below you find some examples.

More information can be sent on request.

ETP-HYDROPRESS

-

ETP-HYDROPRESS - Quick and precise fastening for larger shafts

ETP-HYDROPRESS is available on request.

The dimensions and loads in the list below serve as guidelines to make a customized product. It can be made for both larger and smaller shafts as well as shorter or longer. Number of mountings > 1 000.

For extreme high torque applications the contact surfaces of ETP-HYDROPRESS (sizes ≥130 mm) can

be plated with ETP-HFC, High Friction Coating, which doubles the torque capacity. For frequent sliding along a shaft it can be plated on the inside with aluminium bronze.Construction

ETP-HYDROPRESS is a hydraulic joint, which consists of a double-walled steel sleeve. Mounting is easily carried out with a hydraulic grease pump. In the flange there are two connections:

a grease nipple for the pump and a pressure release valve used for dismantling, a screw which presses against a steel ball and forms a spherical seating. Radial and/or axial connections for the pump hoses are possible. The inner diameter can be made with spiral tracks in order to easier let foreign liquids or particles disappear.Operation

When the hydraulic pressure from the pump is injected, the double-walled sleeve expands uniformly against shaft and hub and along the shaft and forms a rigid joint. When dismantling, the allen screw in the pressure release valve is loosened and the grease comes out. ETP-HYDROPRESS returns to its original measurements and the joint is loose. Normal working pressure is up to 700 bar.FEATURES & BENEFITS

- Variable transmittable torque or axial force by changing the mounting pressure.

- Easy mounting/dismantling of large

- components in tight spaces.

- Quick mounting. Only a grease pump is necessary for mounting.

- Radial and axial connection is possible.

- Fine adjustments of the hub can be made when mounting.

- Good concentricity, also after several mountings.

ETP-UNIGRIP

- The axial tensioner ETP-UNIGRIP is used when workpieces or tools, for example circular knives with spacers, are going to be clamped axially against a shoulder on the shaft in an accurate position.

CONSTRUCTION

Hydraulic unit with two clamping systems consisting of a hardened steelbody with an inner sleeve, three axial pistons with seals and two pressure screws.

OPERATION

When the first screw (marked R) is tightened the inner sleeve grips the shaft, locking ETP-UNIGRIP in position. As the second screw (marked A) is tightened, the axial pistons move into contact with the component which is to be clamped. The hydraulic principle means that the axial force is evenly distributed between the three pistons, offering accurate clamping of components.

DESIGN RANGE

For standard sizes see leaflet.

ETP-UNIGRIP can also be manufactured with a threaded bore without hydraulic expansion of the thread, with more pistons, higher axial thrust force and longer piston stroke. It can also be made to other dimensions on request. Send your application details and we will offer you the solution.

ETP-KN

-

OPERATION

The Knifeholder, ETP-KN, consists of a double-walled hardened steel sleeve filled with a pressure medium. The pressurising mechanism consists of a screw and piston with double sealing function.

When the pressure screw is tightened the double-walled sleeve expands against the shaft and creates a rigid joint. Dismantling or repositioning is done by loosening the screw.

Clamping alternative: On request the holders can be equipped with a nipple. In this case pressurising is done with a grease pump.FEATURES & BENEFITS

- The hydraulic principle gives the following characteristics:

- minimal axial/radial runout

- longer lifetime for the knives

- higher feed rates

- possibility to use carbide knives

- no damages to shafts

- easy adjustments and repositioning along the shafts

CUSTOMIZED DESIGNS

-

All development starts with establishing a technical requirement specification together with the customer. The whole process will be a teamwork with the customer, the ETP-Representative and us.

As a start sometimes the “Application design assistance form” on our homepage is sent to us. You find it in the download section here next to. This is a very important process. It contains listing the loads and other surrounding factors influencing the application.

At the next stage ETP makes some principal drawings which are discussed with the customer. In house we have the latest CAD software and FEM calculation capacity. For production we have the for the quality of the final product most important machinery in house, like welding machines of different kinds: conventional, laser and electron beam welding. Other important operations are grinding – if needed, filling of pressure medium, quality control (with ultra-sound for the weld) and accurate turning.

Metalworking

- Todays modern machines working with high speeds and

feeding rates have high demand on both tool and toolholder To achieve a long

tool life three requirements have to be fulfilled:

- Low run-out

- Balanced holder

- High clamping forc

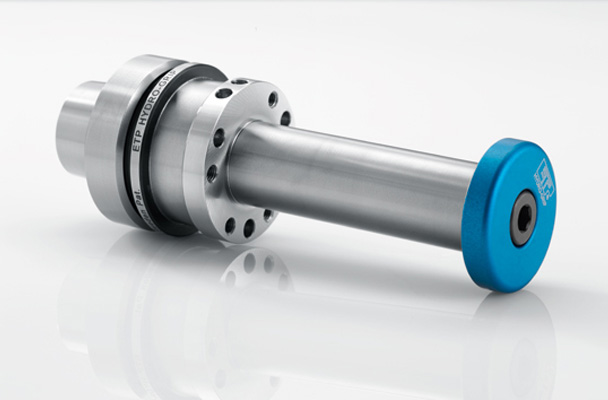

HYDRO-GRIP Hydraulic high precision tool holders

- HYDRO-GRIP high precision tool holders are your guarantee of secure clamping for milling, drilling and reaming tools. Their unique strength provides precision and rigid-tool stability to improve machining performance for the largest number of applications.

HYDRO-GRIP

- ETP HYDRO-GRIP - hydraulic high precision toolholder

HYDRO-GRIP has a very compact and tough design. Tool changes are made quickly, easily and with high levels of precision. The high clamping force guarantees a secure clamping of your milling, drilling and reaming tools. With a minimum tool runout a good surface finish is achieved along with an extended tool life. In addition to our extensive standard range, ETP HYDRO-GRIP can be made to your specific gauge line requirement, using our modular design possibility. Also versions with radial length adjustment available.FEATURES & BENEFITS

- For drilling to semi-roughing

- High clamping force

- Easy handling

- Short overhang

- Modular design possibility

HYDRO-GRIP HD (Heavy Duty)

-

ETP HYDRO-GRIP HD, Heavy duty, is the first hydraulic Power chuck available on the market. Here ETP combine all the positive benefits of hydraulic clamping, such as easy handling and precision, with an extreme high tool clamping force capability and rigid design. A high bending stiffness and the dampening properties of the hydraulic pressure media makes ETP HYDRO-GRIP HD the ideal holder for any machining, from heavy rough milling to finishing.

FEATURES & BENEFITS

- For heavy machining

- Extreme high clamping force

- Easy handling

- Rigid design

HYDRO-GRIP PENCIL

-

ETP HYDRO-GRIP PENCIL is with its extreme slim design one of the most versitile holder on the market. An extensive range of standard dimensions and lengths optimize your productivity when machining deep cavities and complex components. ETP HYDRO-GRIP PENCIL can also be made to your specific gauge line requirement, using our Special designs possibility.

FEATURES & BENEFITS

- For drilling to finishing

- Pencil design enabling machining in deepcavities and complex components

- Special designs possibility

ETP ECOGRIP

-

With the new ECOGRIP range ETP sets a new standard of hydraulic toolholders. ETP ECOGRIP has a very compact and robust design. Tool changes are made quickly, easily and with high level of precision. With the minimum tool runout a good surface quality is achieved along with extended tool life.

FEATURES & BENEFITS

- For rilling and light mchining,

- Easy handling

- Short overhang

ETP ECOGRIP ER

-

Make your ER holder hydraulic and enjoy multiple benefits

With the ETP ECOGRIP ER hydraulic sleeves you can easily turn your standard ER collet holder into a high precision hydraulic holder. Thus you can easily enjoy all the positive benefits of hydraulic clamping such as easy handling and precision, at an impressive competitive price level. This enables more users to benefit from decrease tool wear and increase productivity compared to using ER collet holders. With the use of the three axial screws an adjustability of the run-out is achieved.

FEATURES & BENEFITS

- Turning ER holders hydraulic

- Easy handling and precision

- Adjustability of run-out

Design your own hydraulic high precision toolholder - Online!

- HYDRO-GRIP can be made to your specific gauge line requirement. Combine any shank available in our assortment with any tool dimension 6 - 32 mm. These customized toolholders offer the same rigid design, dampening properties and high runout accuracy as our standard assortment.

HYDRO-GRIP CUSTOMIZED

-

Design your own hydraulic precision toolholder

ETP HYDRO-GRIP can be made to your specific gauge line length requirement, using our modular design possibility.

Combine any shank available in our assortment, with any tool dimension (12 - 32 mm). With an intermediate sleeve, ETP offers you your customized tool-holder to any required gauge lenght ( up to 400 mm).

These customized toolholders offer the same rigid design, dampening properties and high runout precision as our standard assortment.

FEATURES & BENEFITS

- Maximum flexibility in your design

- Choose your required gauge line length

- Radial length adjustment module possible

HYDRO-GRIP PENCIL CUSTOMIZED

-

Design your own hydraulic high precision toolholder - Online

ETP HYDRO-GRIP PENCIL can be made to your specific length requirement, using our online design feature.

Simply choose any machine shank available in our assortment, with any tool dimension (6 - 20 mm. Specify your required design type (1 - 3) and machining depth (L3). Our online programme will check the design possibility.

FEATURES & BENEFITS

- Maximum flexibility in your design

- Freely choose your required machining depth (L3)

- Drawings and CAD-files of your design available for download instantly

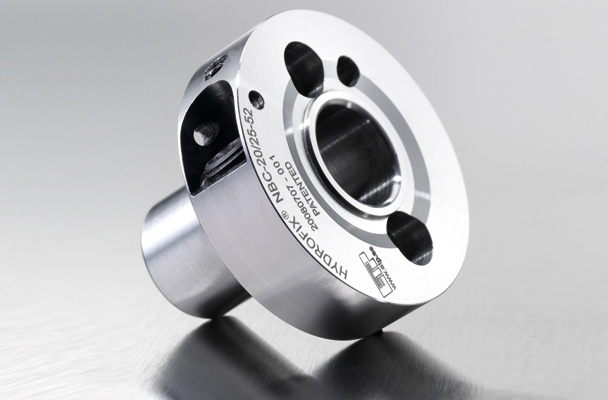

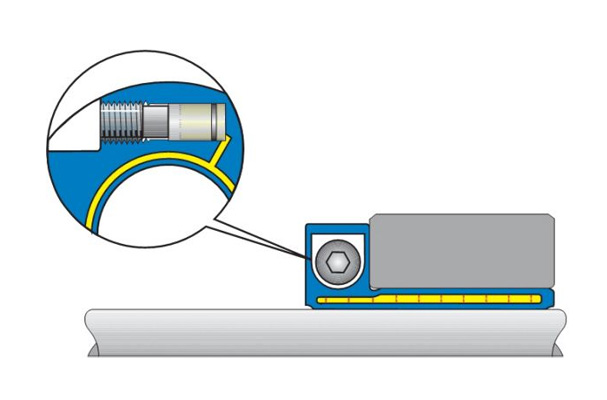

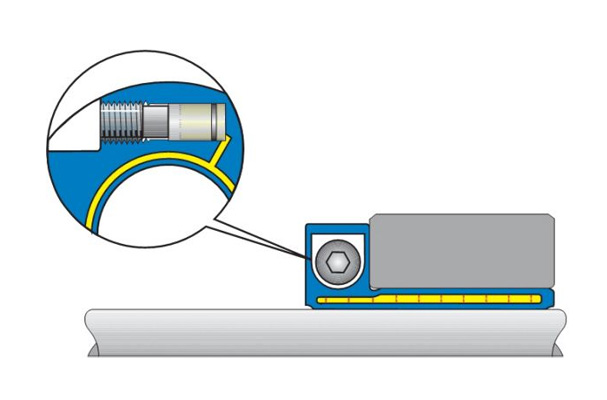

HYDRO-FIX hydraulic clamping system for boring bars and driven tools

HYDRO-FIX NBC

-

HYDRO-FIX® and ECOGRIP hydraulic clamping system has successfully been used for over 15 years.

HYDRO-FIX® and ECOGRIP are excellent for boring bars for internal and external turning, driven toolholders and fine boring heads. With the one screw fix system it is quick and easy to handle. The clamping is uniform around the tool and therefore the tool life is improved. HYDRO-FIX® /ECOGRIP absorbs and reduces vibration, improves surface quality and best of all increases your productivity!FEATURES & BENEFITS

- Reduced vibration

- Increased overhang of boring bar with 60%

- Increased speed and or/feed = Higher productivity

- Improved surface quality

- Increased tool life

- Quick and easy to handle with the one screw fix system

Woodworking

- HYDRO-GRIP is self-centered and clamped in just a few seconds. Choose between two different methods to center and clamp HYDRO-GRIP. Either with an allen T-wrench or a high pressure grease pump. Simply put, you choose the method that best suits your needs.

Sleeves for general woodworking / Sleeves for large spindle diameters

**NEW** HYDRO-GRIP CIA

-

Reduce the set up time and increase your cash flow!

You know there is no secret that quick tool changes and minimal set up time is an easy way to save money, the true challenge is to find out how to do it.

How about using a Power Tool when pressurize your hydro sleeve and tight it as much as you like, you are done in seconds and it is strong as an ox.

Safe for your precious fingers when handle a super sharp tool set and no more fiddling with a cumbersome safety collar as it is integrated.

CIA is the brand new ETP HYDRO-GRIP hydro sleeve that will make your tool changes and -set up safer, easier and quicker than ever!

FEATURES & BENEFITS

- Pressurizing is done in seconds with a Power Tool.

- Integrated safety collar with hydro sleeve.

- Ergonomic design for safe and easy handling.

HYDRO-GRIP CIR Stainless steel

-

HYDRO-GRIP CIR is manufactured instainless steel and perfect for use in demanding environments. Sleeve for interchangable tool assembly that can be used with different tools. The tool should be bolted to the sleeve´s collar. Several tools can be mounted simultaneously. Pressurizing is carried out with an allen T-wrench.

FEATURES & BENEFITS

- Fit your tools quick and easy

- Stainless steel

- Can be ultrasonically cleaned

- Practical handling with flat balance surface

HYDRO-GRIP CI

-

Sleeve for interchangeable tool assembly that can be used with different tools. The tool should be bolted to the sleeve’s collar. Several tools can be mounted simultaneously.

Pressurizing is carried out with an allen T-wrench.FEATURES & BENEFITS

- Fit your tools quick and easy

- Perfect centering and fastening with only an allen T-wrench

- Easy to operate

- Probably the most durable pressurizing mechanism on the market

HYDRO-GRIP BI

-

Sleeve for interchangeable tool assembly, the same basic construction as the CI but also has a thread and locking nut. This means the sleeve can be easily switchedbetween different tools. Several tools can be mounted to the same sleeve.

Pressurizing is carried out with an allen T-wrench.FEATURES & BENEFITS

- Fit your tools quick and easy.

Several tools can be mounted on the same sleeve - Perfect centering and fastening with only an allen T-wrench

- Same durable pressurizing mechanism as CI

- Fit your tools quick and easy.

HYDRO-GRIP AI

-

Sleeve for permanent tool assembly. Made in short lengths to allow for a light press fit. The tool and HYDRO-GRIP should be bolted together. Pressurizing is carried out with an allenT-wrench.

FEATURES & BENEFITS

- Made in short lengths

- Light press fit

- Pressurizing is carried out with an allen T-wrench

Sleeves for floor manufacturing and profiling

HYDRO-GRIP TYPE EI

-

HYDRO-GRIP EI2-40/60-92

Sleeve for interchangable tool assembly and machines with hexagonal spindle profile. The sleeve is adapted for the newest dust covers on the market. Safety disc not included.

HYDRO-GRIP EI-40/60-92

Sleeve for interchangable tool assembly and machines with hexagonal spindle profile. The sleeve is supplied with an internal hexagonal insert in the collar of the sleeve. Safety disc not included.HYDRO-GRIP EIS-40/60-92

Similar to the EI sleeve but with an internal hexagonal profile in its open side.Sleeve for interchangable tool assembly and machines with hexagonal spindle profile. The sleeve is supplied with an internal hexagonal insert in the collar of the sleeve. Safety disc not included.

HYDRO-GRIP EI 40/80-92

Sleeve for permanent tool assembly and machines with hexagonal spindle profile. The sleeve is supplied with an internal hexagonal insert that can be used in either end of the sleeve.FEATURES & BENEFITS

- Advanced hydro function

- Expands both against the tool and the machine spindle

- Probably the most durable pressurizing mechanism on the market

- Stop pin at pressurizing screw

- Adapted for the new type of dust covers

- Can be used for all applications - fixed or adjustable tools

HYDRO-GRIP AEI

-

HYDRO-GRIP TYPE AEI

Sleeve for permanent tool assembly assembly and spindles with keys.HYDRO-GRIP TYPE EI-35/80-90 and EI-40/80-90

Sleeve for permanent tool assembly and spindles with keys.

HYDRO-GRIP AEI-100/130-50

Sleeve for permanent tool assembly and spindles with keys.

Supplied with an aluminium tool ring.

HYDRO-GRIP AI 100/120-60

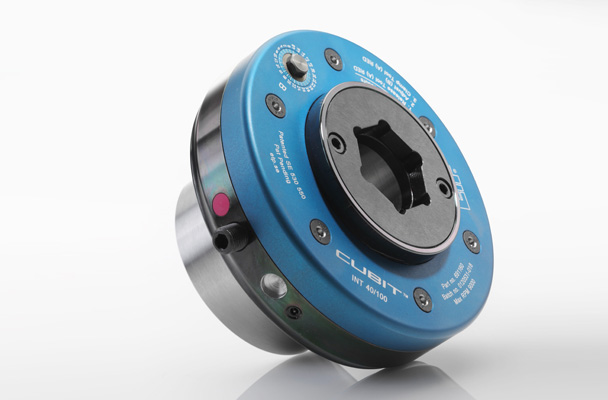

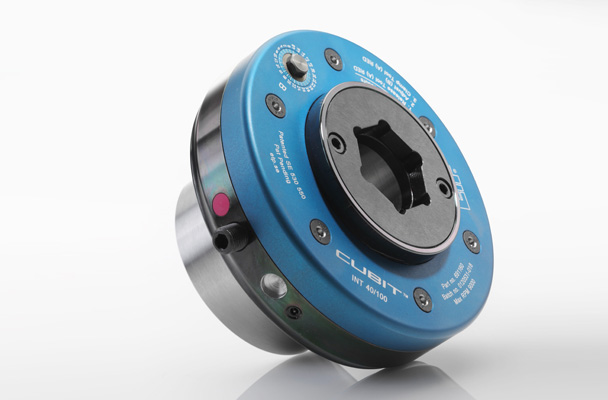

- ETP CUBIT

The ultimate way to profile precision within flooring

The new patented ETP CUBIT is a new complete concept for adjustable systems. Profiling of the tongue and groove in the flooring industry can now efficiently be done with extreme precision and repeatability. Innovative and user-friendly design together with an extraordinary performance let you in just three easy steps reach profile success.

ETP CUBIT INT

Maximum Productivity

The new model CUBIT INT is developed and specially designed for combination tools placed on a horizontal or tilted motor spindle. CUBIT INT has an extremely high precision and unrivalled repeatability. The adjustment is easily accessible through the dust cover adapter, DCA, and there is no need to dismount or open the DCA. CUBIT INT brings the set-up and down time down to an absolute minimum and assure maximum productivity.Sleeve for permanent tool assembly. Supplied with safety ring and tool ring in aluminium.

Sleeves for general woodworking - pressurizing with high pressure pump

HYDRO-GRIP A

-

Sleeve for permanent tool assembly. Made in short lengths to allow for a light press fit. The tool and sleeve should be bolted together. Pressurizing is carried out with a high pressure grease pump.

FEATURES & BENEFITS

- Made in short lengths

- Light press fit

- Pressurizing is carried out with a high pressure grease pump

HYDRO-GRIP B

-

Sleeve for interchangeable tool assembly, the same basic construction as the BI with a thread and locking nut. This means the sleeve can be easily switched between different tools.

Several tools can be mounted to the same sleeve.

Pressurizing is carried out with a high pressure grease pump. This allows the use of longer sleeves.FEATURES & BENEFITS

- Well establish design with thread and locking nut

- Several tools can be mounted on the same sleeve

- Perfect centering and fastening

- Pressurizing is carried out with a high pressure pump

HYDRO-GRIP C

-

Sleeve for interchangeable tool assembly which can easily be switched between different tools.

The tool is fastened to the sleeve by bolts through the collar. Several tools can be mounted simultaneously on the same sleeve.

Pressurizing is carried out with a high pressure grease pump. This allows the use of longer sleeves.FEATURES & BENEFITS

- Several tools can be mounted on the same sleeve

- Reduces set up time

- Pressurizing is carried out with a high pressure pump

- Allows design with longer sleeves

HYDRO-GRIP AH

-

A complete and totally sealed system for existing or new cutter tools. A hydraulic sleeve with an easy press fit in each end of the tool are connected by a small channel in the body of the cuter. Pressurization of the entire unit is carried out either axially or radially using a high pressure grease pump.

FEATURES & BENEFITS

- Minimizing grease volume and leakage

- Axially or radially pressurizing

- Improved performance - minimal runout

- Pressurizing with a high pressure pump

HYDRO-GRIP TYPE CL, BL & AL

- CL is a sleeve for interchangeable tool assembly. This means the sleeve can be easily switched between different tools. Pressurizing is carried out with a high pressure grease pump, axially in the sleeve’s flange.

BL is a sleeve for interchangeable tool assembly which has a thread and locking nut. This means the sleeve can be easily switched between different tools. Pressurizing is carried out with a high pressure grease pump, axially in the sleeve’s flange.

AL is for permanent assembly. Made to allow for a light press fit. The tool and HYDRO-GRIP should be bolted together. Pressurizing is carried out with a high pressure grease pump, axially in the sleeve’s flange.

Sleeves for support bearings

HYDRO-GRIP TYPE D AND DI

- HYDRO-GRIP D

Sleeves for quick and precise assembly of support bearings for machines with bearings at both ends of the spindle. Pressurizing is carried out with a high pressure greas pump.

HYDRO-GRIP DI

Sleeves for quick and precise assembly of support bearings for machines with bearings at both ends of the spindle. Pressurizing is carried out with an allen T-wrench.

Hydraulic chucks

HYDRO-GRIP G2

-

HYDRO-GRIP type G2 is extremely user-friendly which means quick and easy tool changes. It has a tough and compact design and it is the most slender chuck in our range. A safety feature prevents the tool from falling out when the chuck is not pressurized. The tool shank must be equipped with a thread corresponding to the safety screw size.

FEATURES & BENEFITS

- Quick and easy tool change

- High performance

- Slender design

- Excellent runout

HYDRO-GRIP G3

-

HYDRO-GRIP G3 is historically very tough but the new generation has an even more compact design. The hydraulic chuck is equipped with our well known built in safety device. The safety device prevents the tool from falling out when the chuck is not pressurized. Pressurizing is carried out with an allen T-wrench. The G3 chuck allows quick, safe and easy tool changes and perfect runout and repeatability.

FEATURES & BENEFITS

- World famous safety device

- Compact design

- Quick, safe and easy tool change

- Perfect runout and repeatability

***NEW*** HYDRO-GRIP PENCIL

-

Hydraulic high precision toolholder – Pencil version

ETP HYDRO-GRIP® PENCIL is with its extreme slim design one of the most versatile holder on the market.

An extensive range of standard dimensions and lengths optimizes your productivity when machining deep cavities and complex components.

- Runout accuracy < 0.004 mm at 2.5 x dmt (max. 50 mm)

- < 0.007 mm at 2.5 x dmt at length l1 > 125 mm

- Balancing grade: G 2.5 at 25 000 rpm

- Tool shank h6 or h7 can be used

- Can be used with reducing sleeve

FEATURES & BENEFITS

- For drilling to finishing

- Pencil design enabling machining in deep cavities and complex components

- High clamping force

Hydraulic arbors

HYDRO-GRIP GEW2

-

The ETP HYDRO-GRIP type GEW2 is our hydraulic precision arbor for the Power Lock system. This combination will give you all the benefits from both the hydraulic centering function and the Power Lock system. The GEW2 arbor expands uniformly and is the ultimate centring and fastening solution for your tools.

The pressurizing is carried out by using an allen T-wrench and the mechanism is well protected from dust behind a sealed plug. Furthermore the arbor has a thread and a locking nut that makes the tool assembly extremely quick and easy.FEATURES & BENEFITS

- Multiple tool assembly

- Easy to pressurize with an allen T-wrench

- Sealed dust plug

- Ultimate centering and fastening

- Accessorie handle for quick and safe tool change at the machine

HYDRO-GRIP GE2

-

High performance units with perfect balance and runout for the tool. It can even be used in vertical mills, with or wothout toolchangers.

The GE2 arbor allows quick and precise tool assembly and a high degree of flexibility. The arbor is adapted for easy attachment of three wing tools.

FEATURES & BENEFITS

- Quick and precise tool assembly

- High performance and balance

- Redesigned safety ring in light metal

- Multiple tool attachment

- Adapted for three wing tools