Mayr Power Transmission

Videos

Loading the player ...

- Offer Profile

- mayr power transmission is the world-wide No. 1 for torque limiters and offers leading technologies in the fields shaft couplings and safety brakes. Many years of experience and competence in the development of application-optimized solutions have made our company market leaders for safety clutches. A large number of renowned machine manufacturers worldwide trust in the reliability of our high-quality drive and control components and in our complete drive solutions.

Product Portfolio

Torque limiters

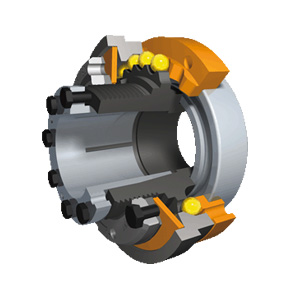

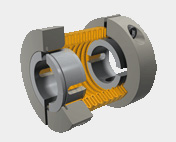

EAS-compact (standard)

- The backlash-free, load disconnecting torque limiting

clutch.

- Instant separation on overload

- Permanent backlash-free torque transmission

- Readable torque adjustment

- Synchronous, ratchetting and overload designs

- High performance density

- Favorable torque curve in the drive line on overload

- Construction type "short hub" also available in rustproof design and in sealed design

EAS-smartic (standard) - load disconnecting

- The installation space-optimised torque limiting clutch

- Simple torque adjustment, can be directly read off

- Quick installation via clamping hub

- Backlash-free torque transmission

- Good dynamic characteristics

- Cost-effective and reliable

EAS-element / EAS-element clutches (overload)

- The installation space-optimised torque limiting clutch

- Simple torque adjustment, can be directly read off

- Quick installation via clamping hub

- Backlash-free torque transmission

- Good dynamic characteristics

- Cost-effective and reliable

EAS-Sp/-Sm/-Zr

- The residual torque-free disconnecting torque limiting

clutches with switching function

- Torque is steplessly controllable and adjustable during operation

- High switch-off accuracy on overload

- Connection and disconnection of system parts during operation

EAS-axial

- Accurate limitation of tensile and pressure forces

- Reliable limitation of forces with high accuracy

- Backlash-free force transmission with high axial rigidity

- Immediate force interruption on overload

- Automatic engagement precisely at the point of disengagement

- Electrical switch-off via integrated sensor

ROBA-slip hubs

-

- Robust and reliable

- Easy installation and handling

- Suitable for high friction work and high torques

ROBA-contitorque

- the consistent-torque continuous slip clutch with

magnetic hysteresis principle

- Precise torque limitation

- Contactless torque transmission

- Wear-resistant and maintenance-free

- Load holding

- Can be used as clutch or brake

EAS-torque sensor

- The torque-actuated signal transmitter

- Signal emission on overload without disconnection of the masses (no mechanical overload protection)

- Input and output are protected against breakdowns and connected via positive locking

- For all applications on which disconnection of the input and output is not permitted

- Can also be used in hoists and vertical axes

Other torque limiters

EAS-dutytorque

- The perfect torque limiting clutch for extruders

- Instant separation on overload

- Simple, quick re-engagement

- Reliable and robust

- High switch-off and repetitive accuracies

- Can be deinstalled radially

EAS-compact-R (RA)

- Rustproof torque limiting clutches

- Stainless steel design

- Instant separation on overload

- Continuous backlash-free torque transmission

- Short delivery times

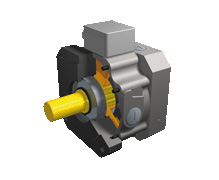

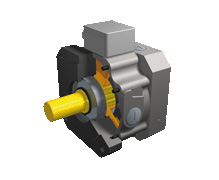

EAS-HTL

- Torque limiting clutch integrated into IEC and NEMA

housings

- Backlash-free torque limiting clutch

- Integrated limit switch

- Ratchetting, synchronous and overload designs

- Standardised connection dimensions

ROBA-Co-Pro

- The compact and high-performance overload protection for

modern constructions

- Large shaft diametres

- Extremely high torques

- Small outer dimensions

EAS-NC

- Backlash-free torque limiting clutch

- Torque settings can be read off

- Easy installation

- Hardened functional components

- Synchronous and ratchetting designs

EAS-standard

-

- Has been successfully used in all mechanical engineering applications for 45 years

- Different flange designs for flexible mounting of various drive elements

- Different construction types for the connection of two shafts

- Different functional principles

EAS-XT

- Extruder torque limiting clutch

- High disengagement accuracy

- Simple manual re-engagement

- Compensation of shaft misalignments

- Long lifetime

ROBA-roll

- Continuous slip torque limiting clutches

- Load holding

- Plug-in installation solution

- Maintenance-free

- Mainly speed-independent slip torque

- Resistant to ambient influences

Shaft Couplings

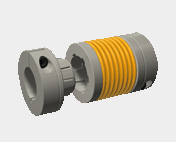

primeflex steel bellows coupling

-

- Plug-in type

- Backlash-free

- Safe disassembly without putting the steel bellows at risk, even after longer periods of operation

- Extremely compact design with high performance density

- Easy installation via clamping or shrink disk connections

- Frictional locking and positive locking shaft-hub connections

- Excellent misalignment capability

- Can be dimensioned variably from the modular construction

- Cost-effective

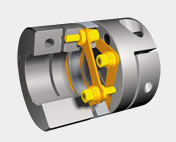

ROBA-DS servo couplings

-

- Extremely compact design due to the application of steel and high-strength aluminium alloys

- High performance density: High torques at comparably small volumes

- Backlash-free torque transmission with high torsional rigidity

- Wear-free and maintenance-free

smartflex

-

- Excellent misalignment capability (compensation of shaft misalignments)

- Minimum mass moment of inertia

- High torsional rigidity

- High availability due to flexible modular construction

- Simple and fast attachment via one screw

- Nominal torque: 16 up to 700 Nm

The torque on the clamping connection, which is transmitted via frictional locking, is dependent on the hub bore (shaft diameter).

ROBA-ES

-

- Torsionally flexible

- Vibration-damping

- Plug-in type, suitable for blind assembly

- Nominal torque: 4 up to 1040 Nm

The torque on the backlash-free shaft-hub connection, which is transmitted via frictional locking, is dependent on the hub bore (shaft diameter).

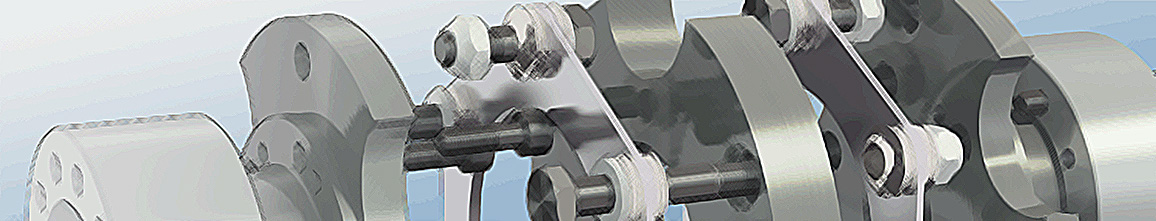

ROBA-DS all-steel couplings

-

- Very high performance density

- Very high, consistent torsional rigidity

- The full nominal torque can be transmitted, even in case of misalignments and alternating loads

- Extremely robust

- Can be used in temperatures of

up to 250 °C - Nominal torque: 190 up to 24,000 Nm

Safety brakes, Elevator Brakes & Stage Brakes

ROBA-stop-M

- The robust, cost-effective motor brake

- Maintenance-free ( no re-adjustments necessary)

- Easy installation

- Completely enclosed brake housing in Protection IP 54 or IP 65

- Insulation material class F

- Can be used for 100% duty cycle

- Short switching times

ROBA-topstop with shaft design

- Modular safety brake system for A-bearing-side servomotor

attachment

- Secure holding of the axis in any position, even with de-installed servomotor, for example during machine maintenance

- The perfect brake system for vertical axes and for handling large weights

- Long service lifetime, even with frequent EMERGENCY STOP braking actions

- Monitoring of the operating condition via integrated switch

- Short, compact design

- Low dead weight

- Low self-heating, even at 100% duty cycle

ROBA-topstop with plug-in coupling

- for mounting directly onto ball screw spindles

Modular safety brake system for A-bearing-side servomotor attachment- Secure holding of the axis in any position, even with de-installed servomotor, for example during machine maintenance

- The perfect brake system for vertical axes and for handling large weights

- Long service lifetime, even with frequent EMERGENCY STOP braking actions

- Monitoring of the operating condition via integrated switch

- Short, compact design

- Low dead weight

- Low self-heating, even at 100% duty cycle

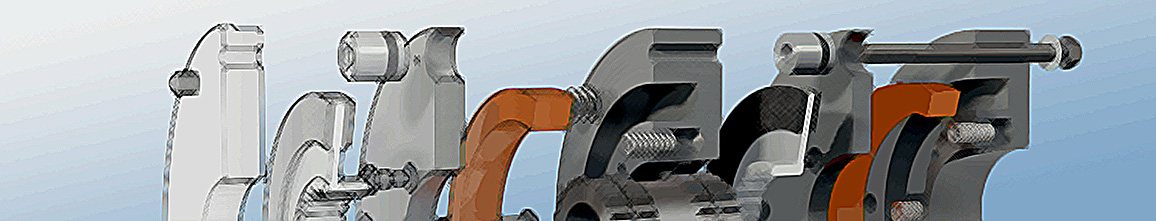

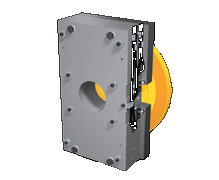

ROBA-linearstop

- Dynamic safety brake

- Reliable dynamic braking

- Tested acc. Trade Association test regulation

- TÜV certified

- Can be mounted onto standard cylinder acc. ISO 15552

- Closed spring-loaded

- Opened pneumatically

- Integrated switching condition monitoring possible

- Clearing the clamp is not necessary

- Also available as clamping unit for EMERGENCY STOP braking actions

Nominal holding force: 0.8 to 40 kN

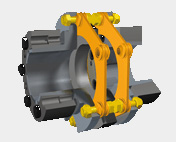

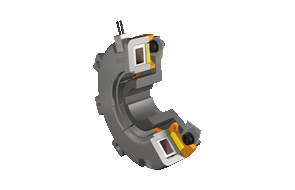

ROBA-diskstop

- Safety brake system for brake disks

- Cost-effective, patented solution for high braking torques

- Redundancy function acc. EN 81 in two-brake arrangements

- Prototype-inspected as protective equipment against excessive upward speeds (ABV 08495)

- With patented alignment mechanism to avoid sliding noise

- Patented noise damping for quiet operation

- Can be released electrically and mechanically without direct access to the drive

- Installation of microswitches for function monitoring possible

- Easy installation with no adjustment work required

- High energy absorption capability

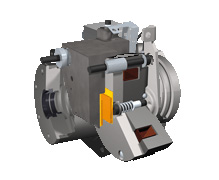

ROBA-duplostop

- Double safety brake for elevator drives

- Maximum safety due to redundancy acc. EN 81

- When fitted with release monitoring, also suitable as protective equipment against excessive upward speeds

- Exceptionally short design

- Brakes can be switched and inspected individually

- Mounting the encoder does not lengthen the construction

- Installation of microswitches for funstion monitoring possible

- Easy installation without adjustment work

- Virtually silent due to patented mayr noise damping

- Brake release via hand release available as an option

ROBA-twinstop

- The perfect elevator brake for compact drives

- The reliable double brake

acc. EN 81 - Maximum safety due to redundancy

- Extremely short design

- Virtually silent due to mayr-noise damping

- Cost-effective

- Easy installation

- The reliable double brake

ROBA-stop-silenzio

- The quietest safety brake for elevator and stage drives

- Dual-circuit brake as redundant brake system with very short constructional length

- Installation of microswitches for function monitoring possible

- Simplest possible installation

- No air gap adjustment necessary

- Consistently low noise level for several hundred thousand switching actions

Electromagnetic clutches and brakes

ROBATIC

- Electromagnetic, energise to engaged pole face clutches

- Consistent switching behaviour over the entire service lifetime

- High torque security due to optimised magnetic circuit

- High performance density

- Low magnetic leakage flux

- Minimum wear due to large friction surfaces and smooth switching behaviour

- Large permitted shaft diameter

- Short switching times

- Low-noise operation

- Safe function up to wear limit

ROBA-quick

- Electromagnetic, energise to engage pole face brakes

- Exact positioning over the entire service lifetime

- Safe function up to wear limit

- High braking torque security due to optimised magnetic circuit

- High performance density

- Low magnetic leakage flux

- Short switching times

- Low-noise operation

ROBA-takt

- Stepper module for positioning and synchronising

- Exact positioning over the entire service lifetime

- Energy-saving and environmentally-friendly

- Maintenance-free over the entire service lifetime

- High permitted switching frequency

- Sealed

DC Drives

tendo-PM

-

Permanent magnet motors and servo motors

- Extremely quiet running due to low torque ripple content and high speed consistency

- Custom-designed for your application

- Carbon lifetime of 5000 to 6000 hours

- High-performance, low-backlash gearbox

- Protection IP 54 or IP 65 (Protection IP 68 available on request)

- Low-noise

Accessories for Safety Clutches & Safety Brakes

Limit Switch (Mechanical)

-

- This device is used to monitor mechanical movements and end positions.

- It is a controlling sensor for electronic and mechanical sequences.

- It also registers axial disengaging movements, e.g. on EAS-clutches.

Limit Switch (Contactless)

-

- This device is used for measuring and monitoring axial and radial disengaging movements, e.g. on EAS-clutches.

- It acts as a control sensor for electronic and mechanical sequences.

Limit Switch (Contactless, Magnetic Field-resistant)

-

- The magnetic field-resistant limit switch is used for monitoring and measuring axial or radial mechanical movements and adjustments e.g. on EAS-clutches.

- Magnetic field-resistant or welding-resistant proximity switches are used where strong magnetic fields can influence the function of the proximity switch.

- For example, they can be used in the field of strong magnetic coils as well as welding guns or welding electrodes with high welding currents.

Limit Switch (Contactless, with Mounting Flange)

-

- The inductive proximity switch monitors and detects operating conditions on EAS overload clutches.

- Axial movements caused by overload or switching procedures are registered by the proximity switch.

- The signal can be used for further process controlling e.g. for drive switch-off.

Limit Switch (Mechanical, Multi-directional)

-

- The limit switch is used to monitor and measure axial or radial mechanical movements and adjustments e.g. on EAS-clutches.

- The device is suitable for clutches with a minimum stroke of 1.1 mm with radial actuation and 0.9 mm with axial actuation.

EAS-Sm/Zr Control Unit -

-

- This unit is used to switch, control, monitor and to indicate overload for adjustable EAS-Sm synchronous clutches and EAS-Zr overload clutches.

EAS-Sp Control Unit -

-

- This unit is used to monitor, control and to signal overload on pneumatically adjustable overload clutches with switching functions.

Half-wave Rectifiers and Bridge Rectifiers

-

- Rectifiers are used to connect DC units to alternating voltage supplies, for example electromagnetic brakes and clutches (ROBA-stop, ROBA-quick, ROBATIC), electromagnets, electrovalves, contactors, switch-on safe DC motors, etc.

Phase Demodulator

-

- Phase demodulators are used to connect DC units to alternating voltage supplies.

- Due to automatic switching from the applied over excitation voltage to the holding voltage, it is possible to energise brakes for shorter switching times with over excitation and to reduce power dissipation after the armature disk has attracted.

ROBA-multiswitch

-

- Fast acting

- Consistently controlled output voltage in the entire input voltage range

- Consumer operation with over excitation or power reduction

- Input voltage: 100 - 500 VAC

- Max. output current: 2 A

ROBA-switch

-

Fast acting rectifier ROBA-switch 017._00.2

- load operation with overexcitation or power reduction

- Input voltage: 100 - 500 VAC

- Maximum output current IRMS: 3 A at 250 VAC

- UL-approved

ROBA-switch 24V

-

Fast switching module ROBA-switch 018.100.2

- load operation with overexcitation or power reduction

- integrated DC-side switch-off (shorter connection time)

- input voltage: 24 VDC

- max. output current: 5A

Spark Quenching Unit

-

Reduces spark production on the switching contacts

occurring during VDC inductive load switching

- Voltage limitation according to VDE0580 2000-07, Item 4.6

- Reduction of EMC-disturbance by voltage rise limitation, suppression of switching sparks

- Reduction of brake engagement times by a factor of 2-4 compared to freewheel diodes

ROBA-takt switch gear

-

- This unit is used to start, stop and to position by switching and controlling the mayr-clutch-brake units

ROBA-takt Circuit Module

-

- This device is used to start and stop mayr ROBA-takt circuit modules and mayr-clutch brake combinations.

- It can be used for alternating 24 VDC coil switching, if a 24 VDC power supply is available.