IEF Werner

Videos

Loading the player ...

- Offer Profile

- Ideas are our core

competency

To create sophisticated ideas is not a pure chance at IEF-Werner. It is the result of over 35 years of experience in the creation of modular components and applications. This creative process is daily ensured by more than 130 employees. Our modular components enable the realisation of customised machines in a very short time. From components arise positioning systems. From positioning systems arise customised applications - up to fully automated production lines. Through foresight and consistent modularisation IEF disposes of a product portfolio that is unique in the world

Product Portfolio

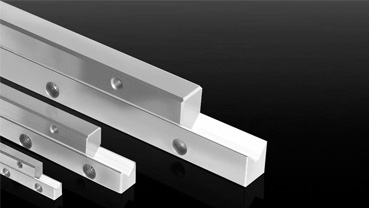

Components

Guide rails

- The IEF-Werner longitudinal guides are available as sliding or roller guide and characterised by high stiffness.

Type M/V

- Plastic-coated sliding guides

- friction value 0.06 - 0.1 at an area pressure of 0.5 N/mm

- speed up to 15 m/min

- at high transverse forces or transverse accelerations, vibrations and impacts

- for high-frequency, extremely short strokes

- V-rail of tool steel, hardened and ground

- M-rail coated with sliding lining, not hardened

Type R+K

- Cross-roller guide rails

- low friction coefficient (M = 0.003)

- speed of up to 50 m/min

- Type R (roller guide) is used in large load and highest precision requirements

- Type K (ball guide) is less dirt sensitive and suitable for easy movements and lower load requirements

Type N/O

- Needle roller guide rails

- low friction coefficient (M = 0.003)

- speed up to 50 m/min

- highest precision and stiffness

- nearly wear-free due to the "roller friction"

- at very high loads

- sealing required for protection against dirt effects

Manual adjusters

- IEF-Werner offers a wide range of accurate, manual adjusters for linear and rotary positioning tasks.

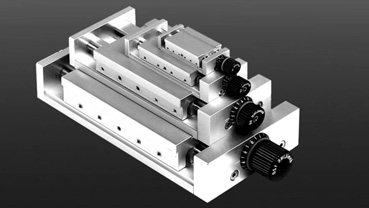

Linear adjusters: Standard adjusters

- Diversity without end! The screw driven slide system

domiLINE aluminum.

domiLINE series:- domiLINE 30

- width 30 mm

- stroke 5...20 mm

- domiLINE 50

- width 50 mm

- stroke 25...100 mm

- domiLINE 80

- width 80 mm

- stroke 25...100 mm

- domiLINE 120

- width 120 mm

- stroke 25...100 mm

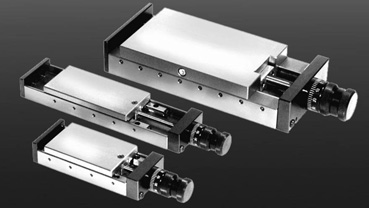

Linear adjusters: High-precision adjusters

- The high-precision carriages are made of high-quality

cast iron GG 25. On request, they can also be made chemically nickel-plated

or in anodised aluminium.

- Type M 30 - is a miniarure slides with a micrometer knob and dovetail guides or cross roll guides. The guide is especially made for small areas.

- Slides of Type M - are complete guide units with a micrometer knob which allows sensitive positioning of the guide unit.

- The slides Type H - are complete guide units with a hand crank or hand wheel which allows rapid adjustment of longer strokes.

- Type O

Without end plates :

- carriage outer and inner part of the same length

- high stroke from running over the basic carriage length into the respective direction

- Type E With end plates installed - end plates permit subsequent installation of shock absorbers, cylinders, measuring systems, proximity switches, etc.

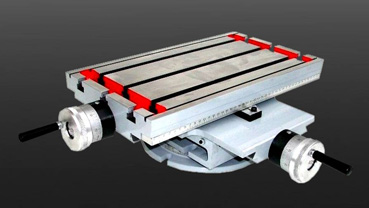

Linear adjusters: Coordinate tables

- Coordinate tables - particularly robust! They are

particularly suitable for drilling or milling applications.

Features- finely ground dovetail guides

- table areas accordingly plane-parallel and with accurate angles

- spindle hardened + ground, pitch accuracy 0.01 to 300 mm

- slotted bronze nut

- millimetre rids with pointers

- large scale rings, adjustable and hard-chrome-plated

- determination by clamping screw

- high resilience

- material GG

- spindle with axial and radial bearing

- parallel supply strips for secure guides

Compact cross tables:

- Type X is a simple coordinate table.

- Type XG is a simple coordinate table with base plate.

- Type XY is a double coordinate table in X- and Y-direction.

- Type XYG is a double coordinate table in X- and Y-direction with base plate.

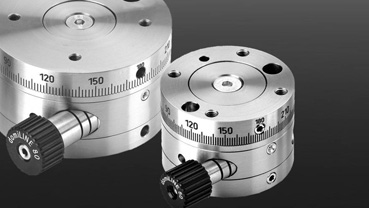

Rotary adjusters: Standard

- The rotary adjuster has a quick adjustment. For this,

loosen the screw that can be accessed at the side of the rotary tray. This

is also where the fastening screw is located. Other properties are:

MDV 55 ... 80- Quick adjustment

- Clamping with high clamping force

- Fine adjustment

- High reproducibility of the position

- Hollow shaft

- Possibility of reverse play setting

- Reading accuracy 0.5°

- High reproducibility of the position

- Compact build

The rotating unit was essentially made of stainless steel. The adjustment button is made of black anodised aluminium, the screw bearing of sinter bronze.

Rotary adjusters: with hollow shaft

- The rotary adjusters of the MDV series 80/100 and 100/140

have a hollow shaft, e.g. to place the hoses and cables. They are made of

aluminium and stainless steel.

MDV 100/140 - Rotary adjusters for manual operation with high-quality screw gear, with a reverse play that can be minimised by supplying the screw wheel.

Features- max. input torque: 2 Nm

- max. output torque: 40 Nm

- main dimensions (W x H x D): 100 x 140 x 80 mm

- weight: 4200 g

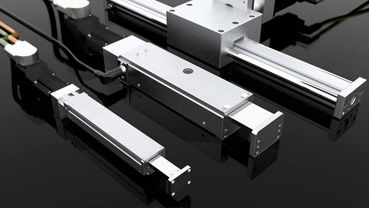

Linear drives

- Different linear drives for dynamic movement, precision or powerful movement offer the right technology for any need.

Spindle drives

-

Maximum load

Spindle drives combined large strokes with high precision at high strain.- strokes up to 1700 mm

- load up to 5000 N

- speed up to 1,2 m/s

- up to +/- 0.003 mm repeat accuracy

Types:- MS 60

- profiLINE 50

- profiLINE 70

- profiLINE 115

- profiLINE 140

- profiLINE 200

- LINE 200 GG

- standard strokes: 190 and 350 mm

- repeat accuracy: +/- 0.003 mm

- max. load: 3000 N

- spindle diameter: 20 mm

- ground slide parts of GG 25 ensure high system accuracy and good damping features

- LINE 250 GG

- standard strokes: 230, 350 & 360 mm

- repeat accuracy: +/- 0.003 mm

- max. load: 5000 N

- spindle diameter: 25 mm

- ground slide parts of GG 25 ensure high system accuracy and good damping features

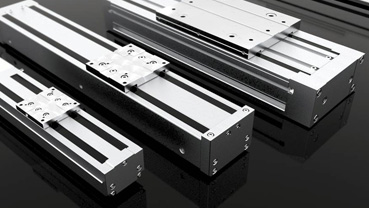

Toothed belt drives

- Maximum distance

IEF-Werner offers the complete product range for all imaginable "Pick & Place" applications from simple linear units prepared to attach your own motors to multiple-axis completely installed positioning systems.

Toothed belt drives are ideal for handling of light-weight to heavy components across large distances.- strokes up to 5500 mm

- load up to 800 N

- speed up to 5 m/s

- up to +/- 0,04 mm repeat accuracy

Other benefits- comprehensive accessories such as motors, energy control system, cable set, amplifier and controls

- can be flexibly combined

- standardised connection elements

- comprehensive consulting service with motor design

- free provision of drawing data in 2D- and 3D

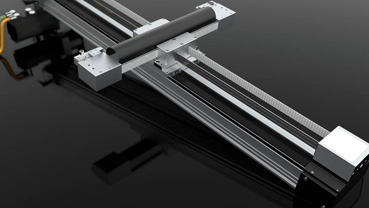

Direct drives

- Maximum dynamics

Direct drives are suitable for quick handling at the highest precision.- strokes up to 3700 mm

- load up to 500 N

- speed up to 5 m/s

- accelerations up to 70 m/s²

- up to +/- 0.003 mm repeat accuracy

The linear drives of the euroLINE series with integrated linear motor, path measuring system and guide are a system ready for installation with low construction effort. Even several independent motors on one guide are possible.

Features euroLINE 32 KLA- iron-free linear motor drive and incremental measuring system

- quick reaction for fast movements

- clam and extremely silent operation

- reverse-play-free system

Features euroLINE 120 & 170- iron-applied linear motor drive and absolute path measuring system

- extended maintenance intervals from guide carriage with ball chain and attachment lubrication elements

- electrical connection by swivelling quick-coupling system

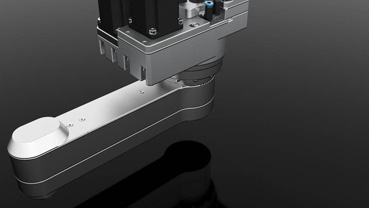

Cantilever axes

- The modules are powered using toothed belts or spindle

drive. Depending on design, they are also suitable for higher loads in

vertical drive.

Cantilever axes with toothed belt drive- Module 68

- Module 55 ZOM

- Module 90/15

- Module 90/15 telescope

- Module 160/20 ZR10

- Module 60/33

Cantilever axes with spindle drive : profiLINE 37/50/70 AL

- max. stroke: up to 185 mm

- repeat accuracy: up to +/- 0.005 mm

- max. load: 10 N ~ 50 N

- prepared for attachment of IEF standard motors / customer-specific motors possible

Multiple axis combinations

- Our multiple axis combinations allow cartesian movements

in at least two directions. Multiple axis combinations usually are faster

and lighter than conventionally combined axes.

Features- neither motor nor cable have to be moved to drive the Z-axis

- lower mass to be moved

- up to 15% shorter cycle times

- no cable wearout

- time and thus cost saving installation due to waiving of complex energy chain system

- open for the assembly of any servo motors

- simple controlling without complex interpolation

- large strokes and free-carrying installation possible

Swivel drives

- rotaryARM

The swivel arm module rotaryARM in connection with linear units is a very fast pick-&-place system for all tasks that require quick and precise automation solutions. It has a range of 297, 399 or 537 mm. The main features are:- NC-swivel arm module with optional gripper turning

- endless turning at swivel axis and gripper turning

- short cycle time from overlaying speed of swivel arm and linear axis

- rotary feed through for pneumatics and electrics integrated in swivel arm and gripper turning, thus no external energy guiding necessary

- servo motors with high-resolution absolute value encoders

- large stiffness and low net weight

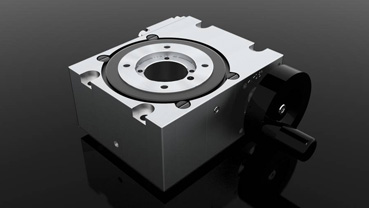

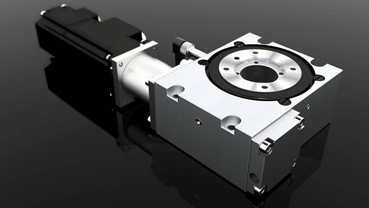

Rotary tables

- The rotary tables differ in build, accuracies and stiffness according to use.

DT-series

- IEF rotating units of the DT series comprise of stainless

steel and aluminium. They are available in many different designs. The

rotary tables DT 80/100 or DT 100/140 are designed for motor-powered

operation. They work with a high-quality screw gear the reverse play of

which can be minimised by supply of the screw wheel. The hollow shaft gives

the constructor additional space for putting hoses and cables.

DT- motor-powered

- inductive reference point switch

- high axial load resilience

- drive torque up to 40 Nm

There are the corresponding motor flanges incl. pluggable coupling systems for the attachment of step or servo drives. A pluggable reference point switch is used for motors with a resolver system.

Servo drive:- flange size: 40 x 40

- motor shaft: Ã 8 mm

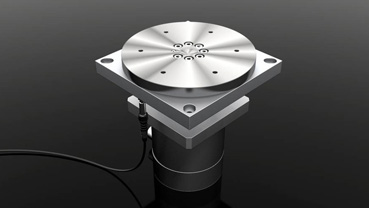

TP-series

- The rotary table TP 004 is a simply designed turning unit

of high-quality gear and drive motor as a main component. It is equipped

with an inductive reference switch by default. It can be delivered with

different transmissions.

Features- best adjustment to required torques or rotating speeds

- simple assembly of motors

- high resilience

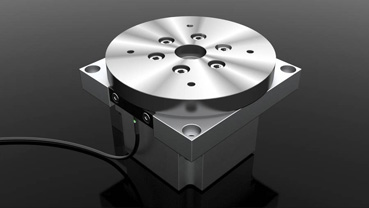

miniTURN - series

- The miniTURN-series is a compact rotating unit with low

weight. It was specifically developed for quick and precise positioning of

small parts. The unit can be used both alone and in combination with linear

units. Typical areas of use are micro-assembly, the semi-conductor industry

and measuring technology.

Features- flexible assembly options

- high-performance, precise system

- freely programmable

- central hollow shaft

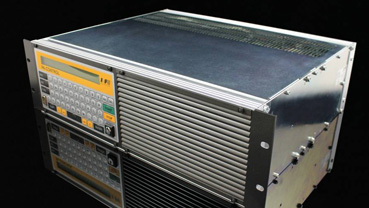

Control technology

- Controls with freely programmable graphical user interfaces and power electronics for servo or step motor technology.

Controls: PA-CONTROL Touch

- Positioning and sequential control

- for servo or stepper motors

- for up to 16 axes

- touch panel and NC-control in one device

- 47 parallel programmes with subprogramme technology

Controls: PA-CONTROL Smart

- Positioning and sequential control

- for servo or step motors

- for up to 16 axes

- Control cabinet installation device

- 31 parallel programmes with subprogramme technology

Controls: PA-CONTROL Unit

- Positioning and sequential control

- for servo or step motors

- for up to 16 axes

- 19"- and 19"/2-housings

- interpolation

- 31 parallel programmes with subprogramme technology

Controls: PA-CONTROL Single

- Positioning and sequential control

- for one step motor axis

- 19"-insertion

- 31 parallel programmes with subprogramme technology

Controls: PA-CONTROL Compact

- Positioning and sequential control

- for two step motor axes

- 19"-insertion

- 31 parallel programmes with subprogramme technology

Controls: stepTEC

- Stepper motor control

- for up to five stepper motor axes

- control cabinet installation device

- connection to superordinate controls via Ethernet

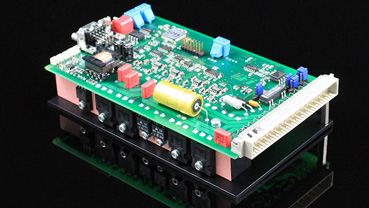

Amplifiers: LV-servoTEC S2

- Digital AC servo amplifier

- integrated positioning control

- power range of 0.5 to 5.0 kW

- connection to superordinate controls via analogue, digital or serial interfaces and field buses

- control via digital I/Os

- integrated CAN interface

- Profibus DP optionally

- safe torque off (STO)

Amplifiers: LV-flexmoTEC

- Digital servo amplifier

- for small servo motors

- connection to superordinate controls via analogue, digital or serial interfaces, field buses or ETHERNET

Power output stages: LE 12-160

- for 2-phase stepper motors

- operating voltage 50 - 160 VDC

- motor current up to 12 A

- euro insert

Power output stages: LE 3-80

- for 2-phase stepper motors

- operating voltage 22 - 80 VDC

- motor current up to 3.5 A

- control cabinet installation device

- separate system and motor supply

Power output stages: LE 8-80

- for 2-phase stepper motors

- operating voltage 22 - 80 VDC

- motor current up to 8.4 A

- control cabinet installation device

- separate system and motor supply

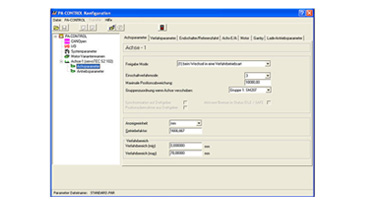

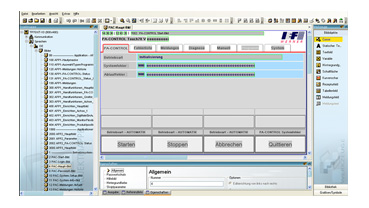

Software: WINPAC

- Programme development system

- settings of the PA-CONTROL

- programme diagnosis in automatic mode

- up- and download of all programme

- menu is perfectly designed for efficient programme generation

- remote diagnosis

- for Windows 7/8 | Vista | XP

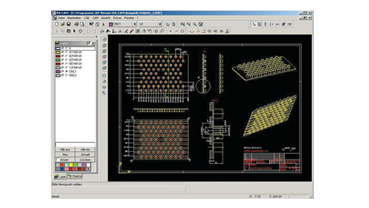

Software: PA-CAM

- 2D-/3D software for generation of CNC programmes

- CAD/CAM for flexible CNC processing

- CAD data assumption with CNC-compatible preparation of the geometry information

- well-structured window technology

- visualisation of the tool paths

- for Windows 7/8 | Vista | XP

Software: TSwin

- Project planning system for production of visualisation

solutions for PA-Control Touch

- generation of projects for text and graphics panels and devices with a Windows CE operating system

- high flexibility from functional expandability

- for Windows 7/8 | Vista | XP

Pneumatic modules

- The pneumatic gripping, turning and sliding modules permit easy combination with the construction kit system and thus best diversity of solutions.

Gripper modules

- Features

- available in three sizes

- both outer and inner clamping

- gripping force protection

- precise attachment of the gripper fingers by indexing at the finger receptacles

- combination of gripper and drive possible

Turning modules

- Features

- adjustable swivel angle

- confirmable end stops

- hydraulic shock absorbers

- high absorption forces of the bearings

- dampening and confirmation of interim positions

Sliding modules

- Features

- sophisticated linear elements

- stable guides

- standardised attachment bores with highly accurate centrings

- unlimited combination options

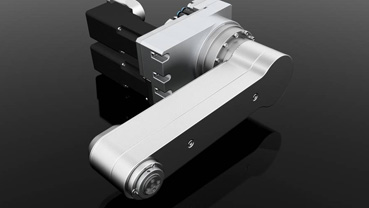

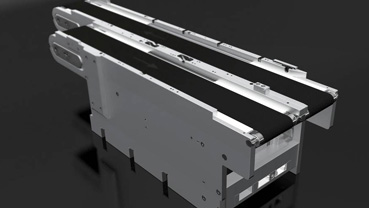

Transport belts

- Our wide range of conveyor belts permits solving diverse transport tasks.

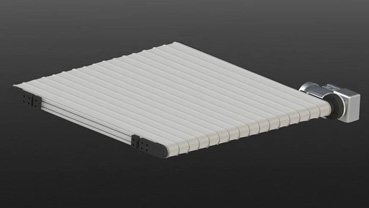

MINITRANS XS

- Extra flat build with small handover radius.

- height 10 mm

- max. length 2000 mm

- max. width 250 mm

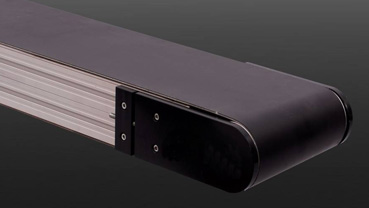

MINITRANS H23

- Compact and flat build with special aluminium profile.

- height 23 mm

- max. length 3000 mm

- max. width 300 mm

MINITRANS H33

- From this size onwards, special belts, e.g. with cross

cuts, are possible.

- height 33 mm

- max. length 5000 mm

- max. width 500 mm

MINITRANS H40

- Guide wedges for reversing can be used from this size

onwards.

- height 40 mm

- max. length 5000 mm

- max. width 500 mm

MINITRANS H50

- A very robust and rigid design.

- height 52 mm

- max. length 5000 mm

- max. width 700 mm

MINITRANS H65

- This Model can also be provided with a plastic chain

(belt).

- height 65 mm

- max. length 6000 mm

- max. width 1000 mm

Systems

Servo presses

-

aiPRESS servo presses are used to produce accurate and reproduceable joinings. They offer optimal possibilities in customising the joining process to your needs. Process factors such as feed force, running speed, positioning time and accuracy can be adapted precisely by using a large number of optional components.

aiPRESS servo presses are serially equipped with a monitor, a keyboard with mouse as well as a compact control cabinet with pluggable cable set. Optional the system can be amended with a high-quality multitouch user panel inclusive holder.

A concept that has been proven: More than 500 IEF servo presses work reliably around the world - in rough industrial environments.

aiPRESS 02 | 05 | 1 | 3 - stroke 50 mm

-

- orce range: 3000 N

- repeat accuracy: +/- 0,002 mm

- measurement accuracy: up to +/- 30 N

- ready for installation for automation

- special workspaces for an additional charge

- press width: 60 mm

aiPRESS 6 | 12 - stroke 100 mm

-

- force range: 12000 N

- repeat accuracy: +/- 0,002 mm

- measurement accuracy: up to +/- 120 N

- ready for installation for automation

- special workspaces for an additional charge

- press width: 100 mm

aiPRESS 6 | 12 | 30 - stroke 150 mm

-

- force range: 30000 N

- repeat accuracy: +/- 0,002 mm

- measurement accuracy: up to +/- 300 N

- ready for installation for automation

- special workspaces for an additional charge

- press width: 120 mm

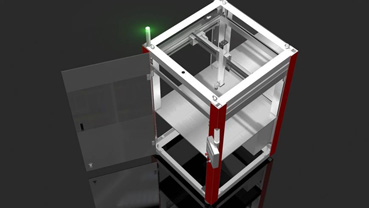

Standard cells

-

roboCELL

The standard cell roboCELL is the starting point for automated production processes. The modular concept allows the adaption to your individual applications.

By the use of standardised modules the costs are clearly calculable at any time. A variety of optional components completes the roboCELL according to your conceptions. For the flexible and reliable implementation of your automation process for example the transport system posyART, the conveyor belts MINITRANS or the palletising system smallSTACK are available for integration. Palletisers

- In state-of-the-art assembly plants, orderly and gentle handover of the workpieces is required. Interim buffering is required often as well. The IEF palletising systems are aligned with flexible factory automation and demand-oriented material flow. All versions are particularly suitable for integration at processing centres, Scara robots and transport routes. Servo motors with absolute value technology are used for the drive, which makes reference runs - e.g. at restart or opening of doors - unnecessary. In addition to the standard pallets named, special sizes can be processed as well, of course.

varioSTACK

-

pallet size

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 10 kg

varioSTACK Trayhandling

-

pallet size

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 10 kg

varioSTACK-T

-

pallet size

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 10 kg

ecoSTACK

-

pallet size

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 60 kg

smallSTACK

-

pallet size

- JEDEC (322.6 x 136 x 6.35 | 10.16 mm)

- max. 500 g

euroSTACK

-

pallet size

- Euro/1 (1200 x 800 mm)

- Euro/2 (800 x 600 mm)

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 30 kg

- 0 - 6 seconds

PSU

-

pallet size

- Euro/2 (800 x 600 mm)

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 30 kg

PSO

-

pallet size

- Euro/4 (600 x 400 mm)

- Euro/8 (400 x 300 mm)

- max. 5 kg

- 0 seconds

Wheel gauging machines

- The patented IEF wheel gauging machines were developed to measure geometric features at car wheels. They combined the function of measuring value recording, measuring process, calculation and illustration of the measured features in a single device.

Passenger car wheel gauging machine

- The wheel gauging machine R2010 for 100% inspection is a fully automatic system for integration into production lines.

Lab wheel gauging machine

- The wheel gauging machine R2010 in the design as a SPR system (static process regulation) for the measuring lab is suitable for wheels, rims and dishes.

Transport systems

- Use the transport & positioning systems by IEF-Werner to implement your individual process chains. Everything from the straight transfer route between automatic stations or manual workplaces to branched transport systems is possible.

posyART

- With posyART you will easily realise individual production processes. For this, IEF-Werner offers a clearly structured modular concept for project planning which is tailored to your requirements.

smallFLEX

- An automated assembly of products requires special specifications of the used production technology. The modular and flexibly customisable goods carrier transport system smallFLEX allows modification, maintenance and even module exchange during running operation.