- Offer Profile

- Robotiq offers Plug + Play components for collaborative robots that are easy to use even if you don’t have any background in robotics.

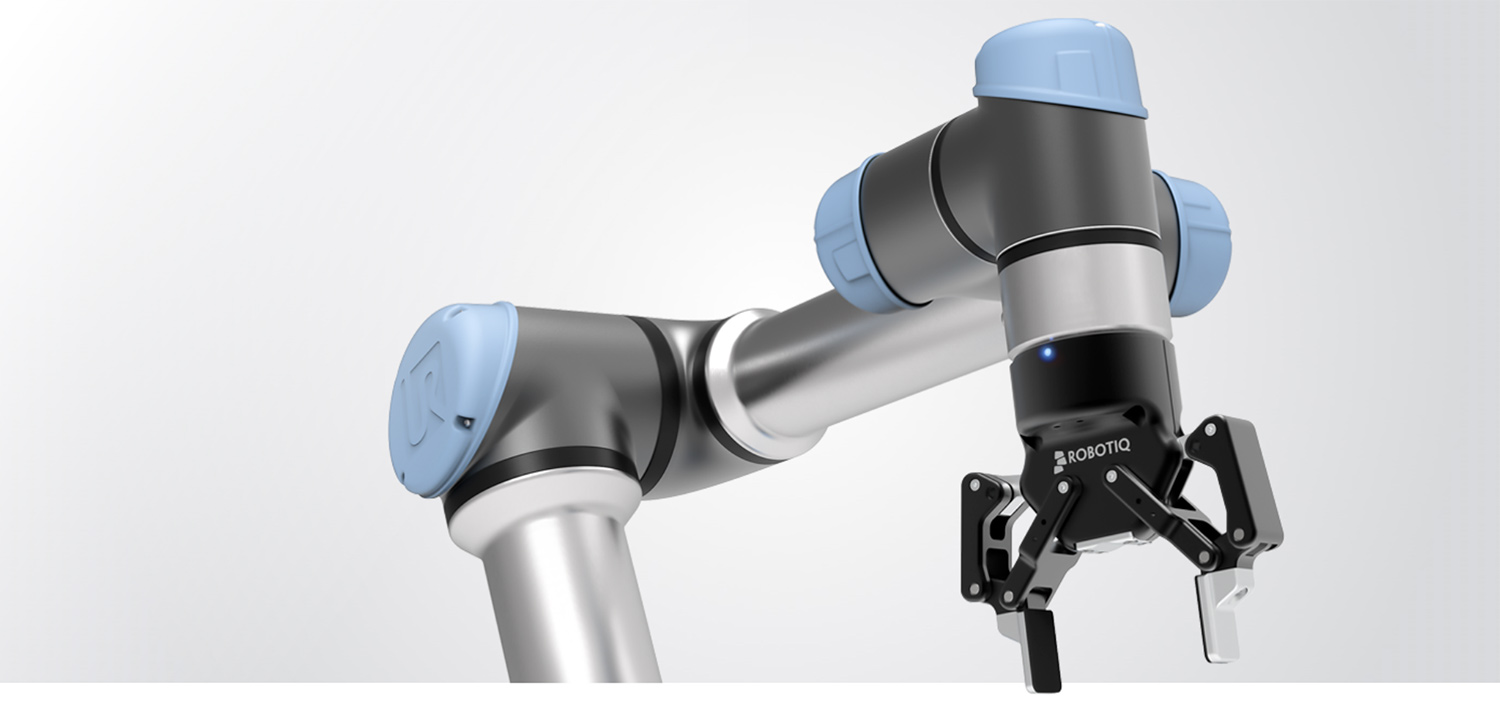

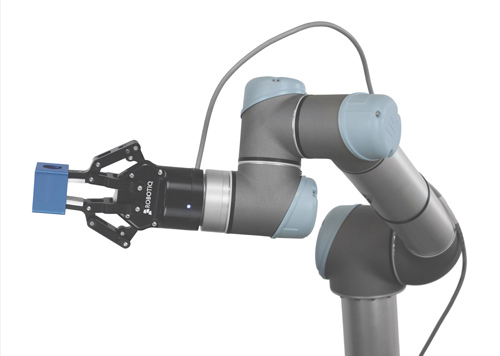

Plug + Play components for collaborative robots

- Robotiq offers Plug + Play components for collaborative robots that are easy to use even if you don’t have any background in robotics.

Plug + Play Components

-

Your favorite gripper just got better! We kept the form factor and improved the internal components. Result? A stronger Hand-E, increased payload and better warranty.The gripper for collaborative robots

Plug + Play and easy to program

High accuracy and wide stroke

Ideal for precision assembly tasks

Built for industrial applications and harsh environments

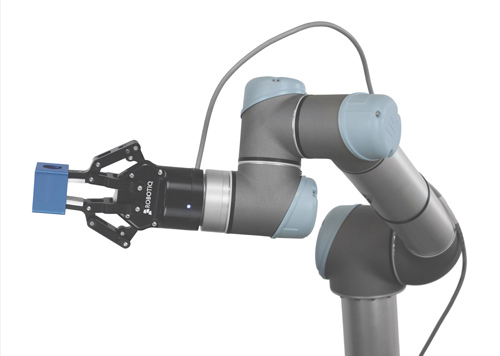

2F-85 and 2F-140 Grippers

-

- Plug + Play on collaborative robots

- Eliminate changeovers & reduce tooling costs

- Pick parts of different size and shapes

- Automate all your applications with one gripper

- Program your application in minutes

Applications

The 2F-85 and 2F-140 Adaptive Grippers are the grippers for collaborative robots. Use them to accomplish a complete lineup of applications with a fast time-to-production—no robotics expertise required. They’re key to a highly flexible and reliable robotic cell.

- Quality Testing

- Machine Tending

- Assembly

- Pick & Place

Gripper Features

Built for collaborative robots

- Two wide stroke options: 85 mm and 140 mm

- Patented finger design enables both internal and external parallel gripping, as well as a unique encompassing grip mode

Simple to program

- One easy-to-use software interface for all Adaptive Gripper models

- Built-in grip and dimension validation

- Automatic part detection and position feedback

Suit industrial needs

- Robust, factory-proven hardware

- High pinch force and payload

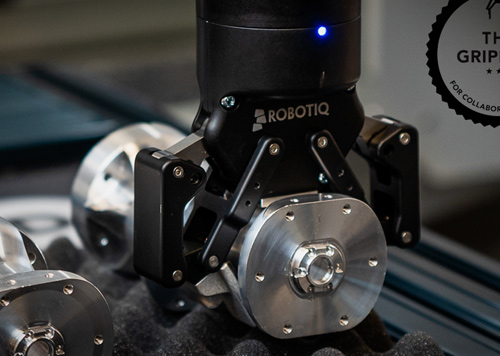

Hand-E Adaptive Gripper

-

Your favorite gripper just got better! We kept the form factor and improved the internal components. Result? A stronger Hand-E, increased payload and better warranty.

- The gripper for collaborative robots

- Plug + Play and easy to program

- High accuracy and wide stroke

- Ideal for precision assembly tasks

- Built for industrial applications and harsh environments

Applications

Hand-E’s high accuracy and 50 mm parallel stroke make it perfect for precision assembly tasks, while its sealed design ensures reliability in the toughest manufacturing conditions—including CNC machining. Hand-E’s design adheres to ISO/TS 15066 standard best practices, with maximum force, rounded edges, self-locking functionalities, and other features making it the gripper for collaborative robots.

- Quality Testing

- Assembly

- Pick & Place

- Machine Tending

Hand-E features

Built for collaborative robots

- 50-mm stroke gripper model is suited to collaborative robots

- Integrates seamlessly with Robotiq’s Wrist Camera and FT 300 Force Torque Sensor

- Ergonomic shape for hand-guiding

Easy to program

- Intuitive interface for quick onboarding and use

- No training required

- Automatic part detection, position feedback, and part validation

Designed for industrial needs

- Precise and durable

- High force and payload

- Withstands harsh manufacturing conditions

Wrist Camera

-

- Easiest vision hardware and software made for Universal Robots

- Locate different parts in a structured or unstructured environments

- Adapt quickly to workplane and task changeovers

- Create a visual model based on the CAD file of any part

- Barcode and 2D code reading

- Operate with any expertise level

Applications

The Robotiq Wrist Camera is designed to perform industrial applications with Universal Robots. Teach new parts and detect features quickly to ensure repeatable picking.

- Machine Tending

- Assembly

- Pick & Place

Wrist Camera Features

- Slim, compact aluminum body with sealed hardware for industrial needs.

- Seamless integration with the Universal Robots wrist.

- Programming software that runs directly on the teach pendant.

- Three flexible multi-object teaching methods.

- Teach parts using their CAD model.

- Automatic and manual adjustment of lighting, focus, exposition, and more.

- Customizable color validation.

- Add traceability to your assembly line with the barcode and 2D code reading function

- Install a Robotiq tag to locate equipment, trays or jigs with the Visual Offset function

- Multi-language software (ENG, FR, ES, DE, ZH, JP).

FT 300-S Force Torque Sensor

-

- NEW: IP65 Rating

- Program complex tasks the easy way

- Unlock force-sensitive applications

- Increase robot-cell reliability and flexibility

- Master force control in no time

Applications

Transform your production process by automating the most advanced force-sensitive applications on the market. Program complex robot movements in minutes—no robotics expertise needed. The result is a strong and flexible robot cell.

- Pick & Place

- Machine Tending

- Finishing

- Quality Testing

- Assembly

FT 300-S features

- IP65 Rating

- Built for compatibility with Universal Robots CB series

- Includes Force Copilot intuitive programming interface

- Adjustable tool weight based on center of gravity

- Sensor value resetting

- Hand-guided robot movement

- Precise object placement

- Alignment

- Indexing

- Insertion

- Complex trajectories

- Constant force and stiffness for each axis

- Takes precise, repeatable, and high-resolution measurements

- Stiff metal composition ensures high accuracy

3-Finger Adaptive Robot Gripper

-

The 3-Finger Gripper is the best option for maximum versatility and flexibility. It picks up any object of any shape.

Applications

The 3-Finger Adaptive Gripper is ideal for advanced manufacturing and robotic research. It adapts to the object’s shape for a solid grip, so you can focus on the task and not the grasping.

- Quality Testing

- Machine Tending

- Assembly

- Pick & Place

Gripper Features

- 4 grip types

Pinch Mode

Wide Mode

Scissor Mode

Basic Mode - Control fingers separately

Get feedback from each finger - Plug + Play

Install and program your robot in a few minutes with our Gripper URCap

Vacuum Grippers

-

- Plug + Play

- Easy programming

- Fast installation

- Full customization

- Low noise

- Efficient and easy automation

- Quick response time

Applications

Robotiq Vacuum Grippers can handle a wide range of applications and are ideal for picking up uneven and even workpieces made of different materials, such as cardboard, glass, sheet metal (dry) and plastic. Because of the customizable bracket and unique air nodes, Robotiq Vacuum Grippers provide manufacturers full control over their Gripper to make sure it’s a perfect fit for their applications.

- Pick & Place

- Assembly

- Machine Tending

Features

- EPick

Connected to the cobot wrist

No air supply

Easy to handle - AirPick

Powerful vacuum flow

Compact design for cobots

Low noise - Built for collaborative robot

Easy programming

Fast installation

No training required

Seamless integration with the Robotiq Wrist Camera and FT 300 Force Torque Sensor - Designed for industrial needs

Industrial grade components

Low maintenance

Payload up to cobot capacity

Application Kits

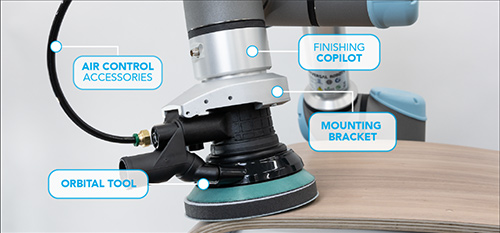

Sanding Kit

-

- Reduce programming time from hours to minutes

- Automate sanding tasks the easy way

- The only hardware and software sanding solution for Universal Robots

- Increase quality and productivity

- Reduce worker injuries

Kit includes:

- Orbital Tool

- Bracket

- Sanding Media

- Finishing Copilot

- Quick Start Guide

- Air control Accessories

CNC Machine Tending Kit

-

Here is a good sign of a productive machining process: chips are flying off! Robotiq uses its best off-the-shelf components to bring you an optimized kit for CNC machine tending applications.

- Dual Hand-E grippers with an angled bracket (90°)

- Fingertips starter kit, including a fingertip extender for larger parts

- Machine Tending Copilot software, including Force Copilot and Contact Offset

- Robotiq Wrist Camera (optional), including the new Visual Offset function

- eLearning course on how to best use your kit

Loading and unloading a CNC machine with a collaborative robot

eLearning Program

The extensive eLearning program includes:

- An introduction to robotic machine tending

- How to choose your first target cell to guarantee your success

- Building your complete robotic cell using the lean robotics methodology

- Off-the-production-line cell preparation

- Installation guidelines and best practices

- Project management tools, templates, case studies, and more

External Tool Finishing Kit

-

Automate finishing tasks the easy way by combining Hand-E’s strong grip and IP 67 rating to Finishing Copilot’s powerful software tools. Make sure the robot offers a flawless finish over the whole part’s surface by operating with constant speed and force.

- Save hours of programming

- Compensate for external tool wear

- Program on an intuitive interface

- Operate with any expertise level

- Automate one of the toughest, dirtiest jobs

About the Kit

- Hand-E Adaptive Gripper

IP 67

Plug + Play and easy to program

High accuracy and wide stroke - Finishing Copilot

Set External Tool center point in minutes

Compensate for tool wear

Generate finishing trajectories in minutes

0.2 mm precision

Surface Finishing Kit

-

- Automate one of the toughest, dirtiest jobs

- Save hours of programming

- Increase quality and productivity

- Connect with the world’s leading finishing tools

Kit includes:

- Finishing Copilot

- Bracket

- Air control Accessories

Bin Picking kit

-

Robotiq.Pickit.

Better together

Aligned with our core value of democratizing automation, the Bin Picking Kit sets a clear path for locating, picking, handling and placing flat and cylindrical parts. It’s not just about the combination of great products, it’s also about the extensive knowledge we make available to you.Try Bin Picking with a «Robotiq touch» to it.

Kit includes:

- EPick

- Extension kit

- Pickit M-HD camera

- Machine Tending Copilot