- Offer Profile

-

Evolving automation since 1951. Piab is evolving automation through progressive gripping, lifting and moving solutions. We believe in an automated world where no resources are wasted, and no humans are injured.We specialise in automated process components and solutions to enable gripping, lifting and moving applications for our customers in all industries with special attention to Packaging, Food and Beverage, Pharmaceutical, Chemical, Logistics and Warehousing, Plastics and Automotive.

Gripping, lifting and moving. Evolving Automation.

-

Refined automation with vacuum technology

Piab's vacuum-driven handling systems and robotic tools are utilized in every industrial sector around the globe. Our tailored solutions support applications from raw material handling to assembly, sorting and packaging of single objects regardless of size, weight, shape or rank in the production process.

Vacuum pumps and ejectors

- Vacuum pumps and ejectors from Piab predominantly include our patented COAX® technology which provides up to three times the vacuum flow of a conventional system. This allows for safe product handling and increased cycle speeds paired with the lowest energy consumption on the market. Piab vacuum pumps and ejectors may successfully be used in both centralized and decentralized systems, i.e., one ejector to serve all suction cups in a circuit, or one ejector for each suction cup. Combinations of these are enabled in what we refer to as semi-centralized systems.

Decentralized vacuum ejectors

- piINLINE® and piSTAMP are small light-weight decentralized vacuum ejectors that use the patented COAX® technology inside or the new optional STX technology. They are ultra-lightweight decentralized vacuum generators, some of them with integrated release mechanisms in minimized packages.They can all be mounted directly on a hose close to the suction cup (or point of suction). The piINLINE®plus has, among other nice features, a patented feature, it is the first true inline (compressed air – vacuum) ejector with integrated automatic release function. Piab’s piINLINE® ejector program offers much better performance with at least 40-50% lower energy consumption and piSTAMP 25% lower energy consumption compared to competing inline single-stage ejectors in corresponding sizes. Decentralized vacuum ejectors are especially common in the automotive, electronic/semiconductor pick-and-place applications, dedicated packaging equipment, injection-molding automation and unloading/loading metal forming machines (bending, punching and laser-cutting).

Decentralized ejectors

- Decentralized ejectors mean that each suction cup is powered by an independent vacuum source, as opposed to centralized systems where one ejector serves all suction cups. Piab’s system guarantees safe product handling with best-in-class energy saving (COAX® pat.) even at fast cycles. There are no restrictions as to vacuum flow and false vacuum signals, due to dimensioning mistakes, are eliminated. Decentralized ejectors are the most flexible solution for zoning and are very easy to troubleshoot and maintain. All Piab vacuum ejectors comply with Reach and RoHS and relevant CE directives.

Vacuum cartridges (for integration)

- Vacuum cartridges are small and lightweight, suitable for integration close to the suction point in high-speed applications, preferably for the pick-and-place of small objects. Piab’s vacuum cartridges use our patented multistage COAX® technology - an advanced solution for creating vacuum with compressed air, allowing low and fluctuating air pressure common in machinery and large plants. Piab vacuum cartridges are significantly more efficient and reliable than conventional ejectors and support flexible, modular, and energy efficient vacuum systems. All Piab vacuum ejectors comply with Reach and RoHS and relevant CE directives.

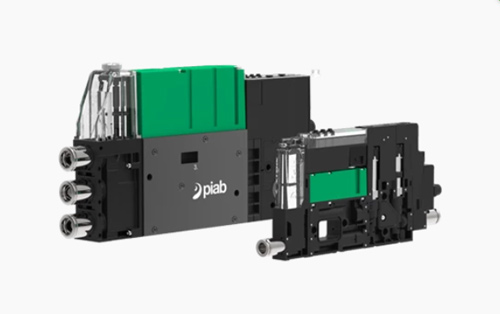

Compact and stackable ejectors

- Compact ejectors have carefully developed proportions and weight to enable stacking. A number of units can be combined in one manifold to support robot applications or other advanced machinery. Compact ejectors utilize Piab’s patented multistage COAX® technology and come with integrated controls for vacuum/blow-off activation, quick release, energy saving and supervision - from standard to the highest levels of smartness and connectivity. Use our configurator to specify the exact functions needed for the intended use. Piab vacuum ejectors comply with Reach and RoHS and relevant CE directives.

Standard ejectors

- These are vacuum pumps of a standard (classic) design and range from very small chip pumps to large capacity pumps. Most of the pumps have the COAX® cartridge inside, A vacuum system based on COAX® technology can provide you with three times more vacuum flow than conventional systems, allowing you to increase speed with high reliability while reducing energy consumption.

Special purpose ejectors

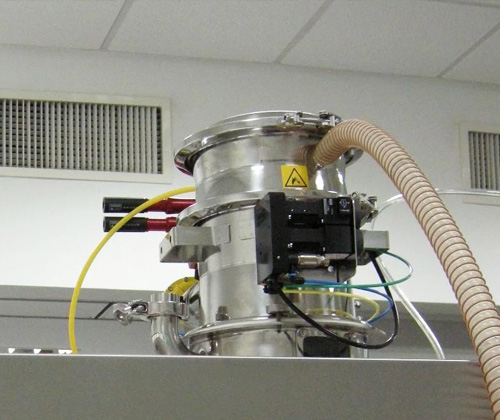

- Special purpose ejectors are the Piab term for, primarily, vacuum pumps designed to match tolerances dictated by laboratories or chemically aggressive environments. All included materials and technology have been meticulously selected and developed for applications in this field. This section also includes vacuum pumps for cramped areas and special purpose ejectors for systems where low vacuum levels are used to transport light particles in a large flow. All Piab vacuum ejectors comply with Reach and RoHS and relevant CE directives.

Suction cups and soft grippers

- Suction cups and soft grippers offer endless possibilities for your lifting and gripping needs. You can, for example, handle board materials or food, open bags, pick electronic components, label and hold objects. However, in different applications you need to fulfill different needs and requirements. Piab offers one of the market's widest ranges of suction cups so that each application will have its own solution. Tell us what your needs are, and we will together with you find the right solution and products.

Modular suction cups

- The piGRIP® is a unique modular suction cup concept with individually optimized parts for gripping, lifting and height compensation. All cups in the piGRIP® program have a round shape. You can select different types and sizes of lips (and foam), bellows, support, and fittings, making it ready to fit new machines as well as to retrofit existing cups. The fittings available are both threaded and push on fittings.

Soft grippers

- The piSOFTGRIP® is a unique lLightweight vacuum-driven soft gripper for sensitive and delicate objects with odd geometries and/or an unusual surface. piSOFTGRIP® has gripping fingers and a vacuum cavity, all made in one piece, resulting in a simple, robust product which is not sensitive to dust. Applications can be found in Food, Bin-picking, Pharmaceutical and MedTech industries. The material is food grade silicone, FDA and EU compliant, and as well as easily detectable. piSOFTGRIP® also comes with a stainless-steel wash down fitting.

Round suction cups

- Piab offers one of the market's widest ranges of suction cups so that each application will have its own solution. The largest selection of cups have a round design. Here you find cups for all industry segments, with different type of sizes, design, and material to suit your needs. There are several types of shapes and design for the round cups, making them suitable for different types of applications.

Oval suction cups

- Oval suction cups are suitable for handling long and narrow objects and surfaces when maximum lifting force is desired. Oval suction cups are especially suitable for irregular surfaces and when level compensation is desired.

Rectangular suction cups

- Rectangular suction cups are recommended for handling long and narrow objects and surfaces when maximum lifting force and grip are desired. The rectangular bellows suction cups are especially suitable for products in plastic flow packs, such as candy bars, and when level compensation is desired. The long version with an extra bellow is suitable for objects with large height differences. All rectangular cups are made of Duraflex®, a specially developed material that features the elasticity of rubber and wear resistance of polyurethane. The material is mark-free.

Accessories for suction cups

- We offer a broad program of components to support installation and usage of your suction cups. Such as mounting elements, level compensators, ball joints, suction cup valves, fittings and adaptors.

Robot End Of Arm Tooling (EOAT) components

- Piab provides an extensive offering for all types of palletizing and de-palletizing operations, no matter if you are looking for ergonomic handling equipment, components and sub-systems to build your own End of Arm Tool or ready- to- use palletizing End of Arm Tool for industrial robots or collaborative robots. We also provide demoulding and de-gating applications in the plastic industry with our modular component portfolio, custom-made parts and components from well-known brands when building your End of Arm Tools. Advanced gripping solutions are complete gripper systems for specific application areas. The ready-to-go grippers are designed to be installed directly on the robot arm or tool changer. Several mounting interface options, in accordance with ISO-9409-1, are available, making it easy to install on most robot brands. Piab’s advanced gripping solutions will simplify and even eliminate engineering time for grippers, make installation easier and secure that state-of-the-art components are used and dimensioned correctly to achieve maximum performance and productivity for the customer.

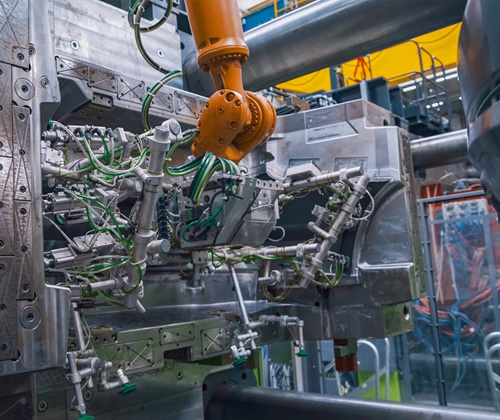

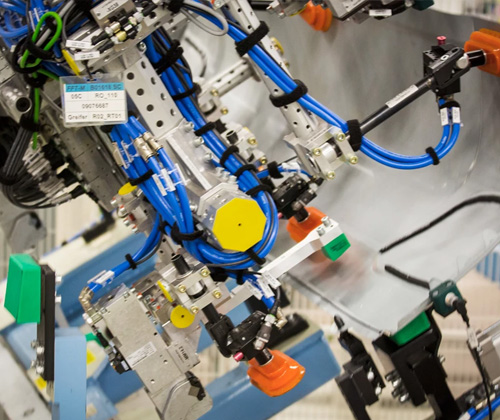

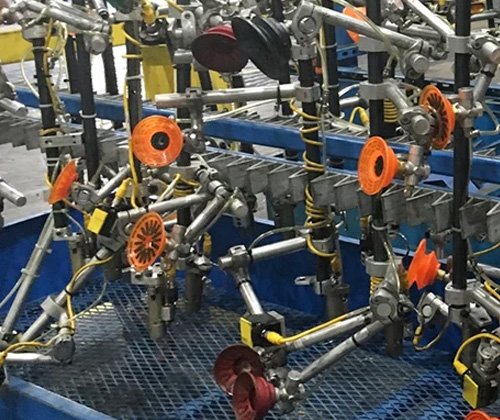

Automotive press shop, body shop and assembly

- Piab offers a selection of configurable tooling systems which allow you to design your automation tooling and construct vacuum end effector tools that require minimal design while meeting your specific needs. Components are made of hard coated anodized aluminum providing a lightweight and rigid system that can be assembled on-site without welding or any special tooling. The system utilizes Piab’s well known innovations such as vacuum safety valves, which secure that no objects are dropped if compressed air is lost and COAX technology for efficient vacuum generation and energy saving.

Plastic injection moulding

- Piab offers a wide selection of modular components that are suitable for the plastic injection moulding industry which handles de-molding and de-gating applications. Piabs modular components are designed to comply with market standards of both tubular and square profile systems. Product offers all needed component groups such as e.g. sprue and part grippers, gripping fingers, mounting elements, suction cups and vacuum generation, robot mounting interfaces, sensors and much more.

Other industries and accessories

- No matter what you want to pick with your End of Arm Tool or vacuum end effector, Piab can offer vital components to secure that your grip is reliable, no products are damaged and that your operations runs with the highest productivity. Component groups can be combined with each other to build sub-systems or used individually and in combination with market standard framing systems.s

Robot and Cobot gripping solutions

- Piab provides an extensive offering for all types of palletizing and de-palletizing operations, no matter if you are looking for ergonomic handling equipment, components and sub-systems to build your own End of Arm Tool or ready- to- use palletizing End of Arm Tools for industrial robots or collaborative robots. We also provide demolding and de-gating applications in the plastic industry with our modular component portfolio, custom-made parts and components from well-known brands when building your End of Arm Tools. Advanced gripping solutions are complete gripper systems for specific application areas. The ready-to-go grippers are designed to be installed directly on the robot arm or tool changer. Several mounting interface options, in accordance with ISO-9409-1, are available, making it easy to install on most robot brands. Piab’s advanced gripping solutions will simplify and even eliminate engineering time for grippers, make installation easier and secure that state-of-the-art components are used and dimensioned correctly to achieve maximum performance and productivity for the customer.

Cobots and robot grippers

- piCOBOT® is a vacuum ejector unit with integrated controls, large visual status indicators and a user-friendly display. Available with a generic electrical interface as well as several options for mechanical mounting plate dimensions in accordance with the ISO 9409-1 standard, enabling it to be configured to work with any collaborative robot and smaller industrial robots. Certified by Universal Robots, it mounts directly on the UR robot arm (ISO-9409-1-50-M6). As an option to mount a suction cup directly on the piCOBOT® thread interface, a high-end adjustable gripper with two suction cups can be seamlessly attached to the piCOBOT® unit. It is equipped with a plug-in software (URCaps) for the handheld programmable device (teach pendant) which will make it very easy to install, set up and get started.

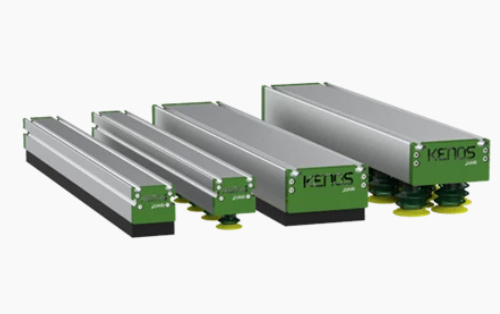

Kenos® Vacuum gripping systems

- Kenos® is a leading brand for large area vacuum grippers. It is designed and optimized to be used in various applications e.g. packaging, wood, food etc. The product group represents a flexible solution for the handling manipulation of several products with different shapes, dimensions and compactness. Most of the gripping systems can be equipped with integrated vacuum generation or suitable for separated vacuum generation (Pump or Side channel blower). The integrated vacuum generator is a modular multi-stage COAX® ejector of easy maintenance and the market's most energy efficient ejector technology. The number of ejectors can also very simply be increased even after the installation if necessary. The mat of the KVG gripping system is made of a technical foam (FDA mat approved available), with different pitch holes and thickness. As an alternative KVG120C can be equipped with suction cups, size 35-60 mm from the DURAFLEX® or Value Line® series.

Palletizing solutions

- For the typical industrial robot palletizing and de-palletizing operations Piab offers a wide range of End Of Arm Tools (EOAT) that are available both as custom made and standard configurations. All tools are designed to secure that your operations are safe, no goods are damaged, run with the highest efficiency, and that maintenance is simple and kept to a minimum. The EOAT comes with a variety of options such as pallet handling, slip sheet systems, sensors, etc. Below is the first selection of palletizing solutions we have made available on the website. We plan to release more solutions over time, so please don’t hesitate to reach out to learn more about our current and upcoming range of EOATs.

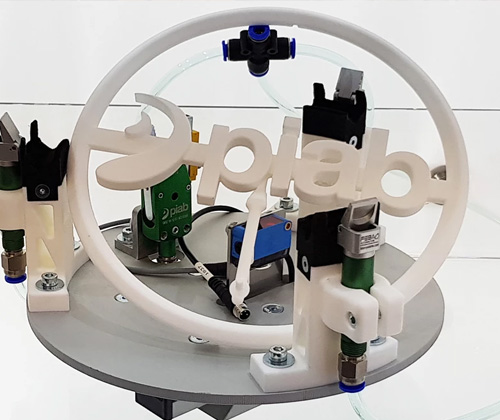

Custom line solution

- Special challenges require specific solutions. Piab’s Custom-Line Solutions – tailormade for your needs – are the answer, when you need a solution or product that is specifically designed to your needs. Solutions presented here are developed for unique customer projects. As our designs are usually modular and parametric based, they allow flexible adjustment. Hence, a Custom-Line Solution optimized to your requirements is just a click away.

System and solution accessories

- Our line of monitoring and control units for vacuum systems is unmatched when it comes to reliability. We focus on the overall solution, down to the last detail. We are fully aware that top quality components are as essential as designing vacuum pumps and suction cups that are in a class apart. You will find everything you need to monitor and control vacuum systems here. Reliability, economy and accurate control/monitoring are the common denominators.

Control valves

- Choose between solenoid, electrically or vacuum-controlled valves. The vacuum controlled valve (Vacustat) shuts off the flow of compressed air to the pump when the pre-set level is reached, and consequently the consumption of compressed air is minimised.

Compressed air regulators

- Different vacuum pumps need different feed pressure for optimum performance. A filter regulator can easily be manually set to a desired pressure level, and be used to eliminate particles from the compressed air. A pilot regulator can be used to automatically set the feed pressure according to your needs.

Sensors and switches

- Our product line includes inductive universal, electro-mechanical and pneumatic vacuum switches that are pre-set or adjustable. Our piSAVE® products are a group of products that has as a function to save energy in various applications. The piSAVE® products enhance an existing vacuum system; either at the suction cup or at the vacuum source.

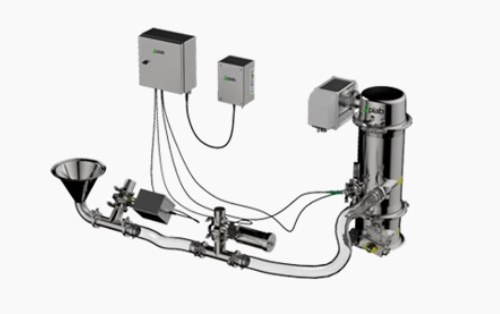

Vacuum conveyors for powder and bulk

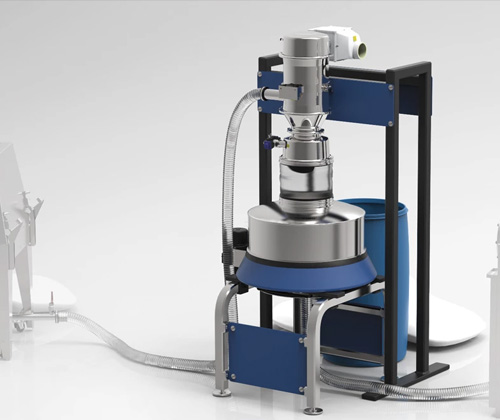

- Vacuum is used with great advantage in conveying dry powder products through dedicated pipe systems. Piab's vacuum conveying systems are built of high quality material. When producing food, pharmaceuticals and chemical products there are demands on the highest possible degree of safety as to hygiene and operation. Piab's piFLOW® conveyors have been developed as an answer to the severe requirements of operational safety and hygiene in the food, pharmaceutical and chemical industries. Piab conveyors are ATEX Dust certified. piFLOW®p and piFLOW®t are ATEX Gas certified. All conveyors are available with either an ejector driven vacuum pump or with a mechanical pump.

piFLOW®p SMART - solution for automatic vacuum conveying

- piFLOW®p SMART is a stand-alone system with machine learning software and sophisticated algorithms that run the application to reach the maximum capacity for the conveyed material. To reach the maximum material capacity an air carrying unit is integrated in the system. If there is a vertical lift higher than 8 meters in the conveying pipeline, Piab is offering a pipeline emptying unit to prevent blockage of the pipeline. All the vacuum conveying functions are controlled by the electrical control unit ECU-15S and its software.

piFLOW®p - high requirement vacuum conveying

- Our premium conveyors are designed with a Stainless Steel body (ASTM 316L) and meet the very high hygienic demands of FDA. Piab conveyors are ATEX Dust certified and piFLOW®p also has ATEX Gas certification. Typical applications are powder and granules transfer, form-fill-seal machines, big bag loading and unloading, drum/bag filling and emptying, mill/sieve/mixer/blender filling, tablet/fragile products transfer, applications in explosive atmosphere, hygienic applications or places where space is at a premium. All conveyors are available with either an ejector driven vacuum pump or with a mechanical pump.

piFLOW®t - gentle vacuum conveying

- Our premium conveyors are designed with a Stainless Steel body (ASTM 316L) and meet the very high hygienic demands of FDA. Piab conveyors are ATEX Dust certified and piFLOW®t also has ATEX Gas certification. Typical applications are transfer of tablets, capsules, coffee, granules and other fragile products. Also hygienic applications or places where space is at a premium.

piFLOW®fc - heavy duty vacuum conveying

- This is a conveyor widely used in the industry where food grade quality is a demand. It has a high throughput performance as well as a small foot print. This conveyor is often used as an alternative to mechanical conveyors when there is a requirement for dust free conveying or low maintenance. Another advantage is that the pump is based on COAX® technology which is the most energy efficient way to produce vacuum. These conveyors are designed with a Stainless Steel body (ASTM 304) and seals in direct product contact zones that are in compliance of FDA, 1935/2004 and EC No. 10/2011 to meet the demands of industrial food grade applications.

piFLOW®f - food grade vacuum conveying

- This is a conveyor widely used in the industry where food grade quality is a demand. It has a high throughput performance as well as a small foot print. This conveyor is often used as an alternative to mechanical conveyors when there is a requirement for dust free conveying or low maintenance. Another advantage is that the pump is based on COAX® technology which is the most energy efficient way to produce vacuum. Capacity up to 4 tons/h. Our food grade conveyors are designed with a Stainless Steel body (ASTM 304) and seals in direct product contact zones that are in compliance of FDA to meet the demands of industrial food grade applications. Piab conveyors are ATEX Dust certified. piFLOW®p and piFLOW®t are ATEX Gas certified. All conveyors are available with either an ejector driven vacuum pump or with a mechanical pump.

piFLOW®i - industrial vacuum conveying

- This is a conveyor widely used in the general industry and sometimes in the chemical industry. It has a high throughput performance as well as a small foot print. This conveyor is often used as an alternative to mechanical conveyors when there is a requirement for dust free conveying or low maintenance. Another advantage is that the pump is based on COAX® technology which is the most energy efficient way to produce vacuum. Capacity up to 4 tons/h. The general industry often handles abrasive powders that require specially designed equipment. Our conveyors are designed with Stainless Steel body (ASTM 304) to resist wear of parts. Piab conveyors are ATEX Dust certified. piFLOW®p and piFLOW®t are ATEX Gas certified. All conveyors are available with either an ejector driven vacuum pump or with a mechanical pump.

Spare parts and Accessories

- The vacuum conveyor is reliable and requires a minimum of maintenance. It is, however, necessary to regularly change some of the parts to maintain maximum productivity. To find the best way to optimize your vacuum conveyor Piab offers a wide range of different accessories.

Industries

- We specialise in automated process components and solutions to enable gripping, lifting and moving applications for our customers in all industries with special attention to Packaging, Food and Beverage, Pharmaceutical, Chemical, Logistics and Warehousing, Plastics and Automotive.

Metall Additive Manufacturing

- Additive Manufacturing is a quickly emerging industry with a strong technology focus. As a new industry, there is a continual improvement in productivity and efficiency while maintaining health and safety standards. The raw materials used in Additive Manufacturing, such as polymers and metals, offer challenges for which we have created high quality solutions.

Metal Additive Manufacturing

-

Metal additive manufacturing is a quickly emerging industry with strong technology focus to continue improving its productivity and efficiency while maintaining high quality and adhering to health and safety standards. Raw materials used are primarily metal powders like titanium, nickel, stainless steel, cobalt, iron, tungsten carbide, all with their individual challenges.

Metal additive manufacturing, also known as metal 3D printing, is an advanced manufacturing technique that involves building three-dimensional objects layer by layer using metal powders.This process is quite different from traditional subtractive manufacturing methods, where the material is removed from a solid block to create the final product. In metal additive manufacturing, the object is created by adding the material layer by layer until the desired shape is achieved.

Automotive

- We help the Automotive Industry increase productivity and save energy with innovative and reliable products at no cost to human safety. Start to finish, we are in every stage of the production line from press shop, body shop, final assembly, and even component production.

Press shop

- Slippery panels due to oil, narrow areas to grip, reliability and speed in the press are all factors to consider in designing your vacuum system of suction cups and vacuum ejectors. Using our products created especially for the Automotive industry, press shop sheet metals are moved across the press quickly and efficiently.

APPLICATIONS- De-stacking metal sheets

- Press transfer of metal sheets

- End of line racking of metal panels

What Piab offers- Tailor-made cups: unprecedented design for handling oily sheets; our suction cups are made to keep their grip.

- Efficiency: our suction cups and vacuum ejectors are made to match the speed of the press line

- Reliability: safe and sturdy to move heavy pieces at no cost to human safety

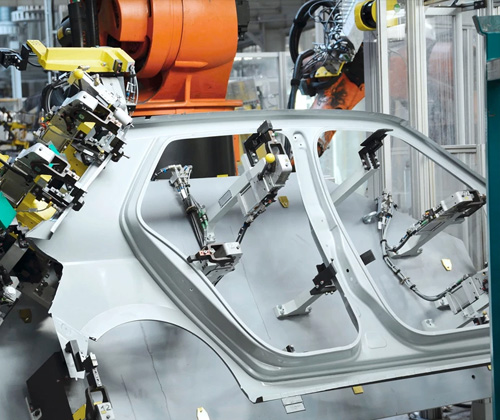

Body assembly

- In the Automotive industry, body assembly speed and safety are the first priorities. The metal sheets are heavy and oily, requiring the need of our energy efficient vacuum gripping solutions and specially designed friction cups to help lift, grip, and move products along the assembly line. Our solutions are flexible during production and are robust and reliable, offering maximum safety in case of power failure.

APPLICATIONS- Underbody, engine and trunk compartment assembly

- Bodysides and framing assembly

- Closures – hemming stations – inner and outer assembly

- Auto-racking unloading and assembly

- Kitting picking of parts

What Piab offers- Tailor-made cups: unprecedented design for handling oily sheets; our suction cups are made to keep their grip.

- Efficiency: our suction cups and vacuum ejectors are made to match the speed of the press line

- Reliability: safe and sturdy to move heavy pieces at no cost to human safety

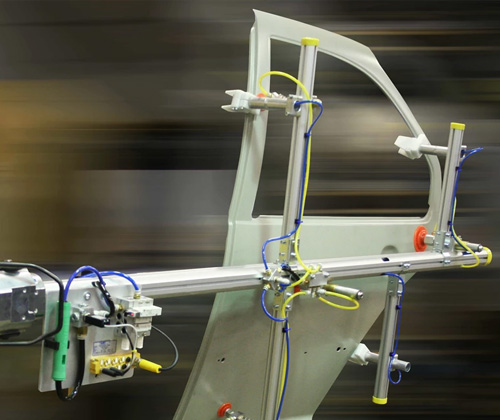

Final assembly

- In the final assembly (after paint-shop), the vehicle is equipped with heavy exterior and interior parts such as bumpers, dashboards, tires, windscreens, and even brakes and AC systems. Our vacuum products together with robots help to lift these parts safely and efficiently. And thanks to our large selection of suction cups you will find the right grip without leaving any marks.

APPLICATIONS- Door on/off ergonomic tools

- Glass assembly and installation

- Gas tank assembly and installation

- Exterior and interior trim components assembly

- Kitting picking of parts

What Piab offers- Mark free parts: our wide selection of suction cups guarantee mark free handling

- Efficiency: our suction cups and vacuum ejectors are made to optimize the speed of the assembly line

- Reliability: innovative vacuum systems and components secure handling delicate, heavy, and high value parts at no cost to human safety

Plastic moulding shops

- Automobiles consist of large amounts of plastic parts which require reliable handling both during de-moulding and part handling as well as during de-gating and cutting operations. Having a secure grip with both vacuum and mechanical gripping is essential to produce damage free, high quality plastic parts.

APPLICATIONS- De-gating plastic parts

- Plastic part removal

What Piab offers- Quality: End of Arm tools, which cycle after cycle securely handles your automotive parts

- Enhanced production: innovative component systems, which allow for handling both simple and complex cuts

- Reliability: robust design of component and End of Arm tool systems

Tailor welded blanks

- Prior to stamping car panels in the press shop, large, blank metal sheets are welded together to optimize the safety and structure of the vehicle. We help to load and unload these heavy metal sheets using our innovative vacuum gripping technology. Our suction cups guarantee carrying a metal sheet without creating dents and to release the sheets safely, which leads to faster cycle times and higher productivity.

APPLICATIONS- Loading and unloading metal sheets

What Piab offers- Dent free: our suction cups are made to carry and release heavy sheets without creating dents

- Increased productivity: our vacuum systems and suction cups ensure faster cycle times

- Reliability: innovative vacuum systems and components secure handling delicate, heavy, and high value parts at no cost to human safety

Chemical

- Minimize dust exposure, save floor space, and reduce scrap with our solutions for the Chemical industry. We provide high quality technology created to ensure human safety and increase productivity. Maintenance, regular cleaning, and filter changes are easily done to minimize your production’s down time.

Desiccants

- The Desiccant manufacturing market serves global end-users in the food, pharma, consumer goods, and electronics markets. Desiccants are used to absorb moisture/water in order to keep products dry and protect from moisture/humidity. Piab’s enclosed vacuum conveying system helps to minimize dust generation and employee exposure during production.

APPLICATIONS- Feeding packaging machines

What Piab offers- Profitability: minimal product waste due to a gentle vaccum convey setting

- Human safety: our enclosed system helps to reduce exposure to hazardous dust

- Space saving: our vacuum conveyors are built to make up a minimal footprint

Detergent

- In the production of the detergents, capsulated enzymes, powders containing enzymes or other additives are transported through the process steps. Piab has developed a speed control which optimizes transfer speed without damaging the delicate enzymes. However, the enzyme dust is hazardous to human health so it’s crucial to minimize exposure. Our enclosed vacuum conveying system outfitted with state-of-the-art ULPA filters ensures the safety of employees and air cleanliness.

APPLICATIONS- Feeding blending/mixing units

- Feeding tablet press

- Reclaim of powder Feeding packaging machines

What Piab offers- Profitability: minimal product waste due to a gentle vaccum convey setting

- Human safety: our enclosed system helps to reduce exposure to hazardous dust

- Ease of use: maintenance, regular cleaning, and filter changes are easily done to minimize your production's down time

Food & Beverage

- The Food and Beverage Industry focuses on hygienic and safe production meeting the strict requirements of the FDA, EU, ATEX and other requirements with no compromise on health, safety, or product quality. Piab's innovative products and solutions are modular in design and secure the highest quality of finished goods.

Baking goods

- Typical materials conveyed with Piab vacuum conveyors in the Baking Goods market are various forms of flour, sugars, starches, seasoning, nuts, etc. Since materials change often, it’s important to have conveying equipment, which is versatile, easy to clean, and can accommodate a quick changeover. We also offer food grade suction cups and grippers for finished goods picking.

APPLICATIONS- Feeding to and from mixing and blending units

- Feeding seasoning and sprinkling units

- Feeding packaging machines

- Reclaim of product

- Direct food contact picking

What Piab offers- Made for food: hygienic and safe for direct food contact as well as easy maintenance and cleaning

- Ease of use: our vacuum conveyors are easily adjusted for a quick changeover of materials

- Human safety: our enclosed system help to reduce exposure to dust

Coffee

- Handling operations within the coffee industry is a delicate task and the industry covers everything from large scale industrial roasteries to small scale micro roasteries, but all with the same goal: to deliver a high-quality product to end consumers, where the coffee is taken care of throughout every stage of the process. Piab’s vacuum conveyors are customizable to your operation, for example, if you want to run your process with nitrogen gas instead of atmosphere, we can accommodate that. Most importantly, our vacuum conveyors will not change the characteristic of your product.

APPLICATIONS- Feeding roasted coffee beans to and from milling and grinding

- Feeding green coffee beans to roasting

- Coffee packaging

- Reclaim of coffee beans or powder

What Piab offers- Enclosed conveying: keeps oxygen sensitive beans fresh without changing any characteristics of the coffee

- Profitability: reduced waste in beans and grounds due to gentle conveying

- Human focus: easy maintenance, hygienic, and safe for human handling

Confectionary & candy

- Typical materials conveyed with vacuum conveyors in the Confectionery/Candy markets are sugar in various forms, cocoa powder, flour, and finished candy products. Since materials change often, it’s important to have conveying equipment which is versatile, easy to clean, and can accommodate a quick changeover. Piab’s SMART technology can automatically change settings to better optimize your equipment and conveying production. We also offer food grade suction cups and grippers for finished goods picking.

APPLICATIONS- Direct food contact picking

- Feeding material to and from sieving unit

- Feeding to and from mixing and blending units

- Feeding to and from tablet press Reclaim of powder

- Feeding the packaging line with finished products

What Piab offers- Profitability: reduced waste due to a gentle vacuum conveying setting

- Optimized production: vacuum conveyors tailor made for candy and confectionary

- Human focus: easy maintenance, hygienic, and safe for human interaction

Instant food

- In the production of instant food such as dry soups, noodles, sauces, etc. the materials are often dusty and can be fatty, so it’s crucial to use equipment which is easy to clean and allows for a fast changeover between products. For certain material blends dense phase conveying will help to minimize segregation. Our vacuum conveyors are designed as an enclosed system which will help to increase productivity as well as ensure employee health and safety.

APPLICATIONS- Feeding to and from mixing and blending units

- Reclaim of product

- Powder filling and packaging

What Piab offers- Profitability: reduced waste due to a gentle vacuum conveying setting

- Innovative design: made with food grade materials that meet industry regulations

- Hygiene and health: easy to clean and maintain

Nutraceuticals

- For many of the nutraceutical products, the requirements are as high as in the pharmaceuticals industry with similar challenges such as cross contamination and dust generation. Piab’s vacuum conveyors are design to resolve these challenges. Since materials change often, it’s important to have conveying equipment which is versatile, easy to clean, and can accommodate a quick changeover. We also offer food grade suction cups and grippers for finished goods picking.

APPLICATIONS- Nutraceutical direct picking

- Fiber drum and barrel pick-up

- Feeding material to and from blender/mixer

- Feeding material to and from milling and grinding

- Feeding material to and from sieving unit

- Conveying through/to and from metal detection equipment

- Feeding to and from capsule filling

- Feeding to and from tablet coating

- Feeding to and from tablet press

- Reclaim of powder Powder packaging

What Piab offers- Small footprint: our vacuum conveyors will not compromise on limited space

- Profitability: reduced waste due to a gentle vacuum conveying setting

- Hygiene and health: easy to clean and built to meet industry requirements

Pet food

- Typical materials conveyed with vacuum conveyors in the Pet Food market are finished products (pellets, kibble, and treats) or ingredients. Customers in this industry change materials quite often, and consequently need conveying equipment which is versatile, easy to clean, and allows for quick changeovers. Our vacuum conveyors increase productivity and save space when conveying pet food.

APPLICATIONS- Feeding to and from mixing and blending units

- Feeding to and from extruder

- Feeding packaging machine Reclaim

What Piab offers- Profitability: reduced waste due to gentle vacuum conveying

- Hygiene and health: easy to clean and maintain

- Small footprint: our vacuum conveyors will not compromise on limited space

Logistics & Warehousing

- Piab manufactures highly efficient products that span all aspects of material handling in fulfillment and distribution centers. Our automated solutions help to optimize bin picking, parcel and package handling, palletizing and de-palletizing.

E-commerce and automated warehouses

- Within fast-moving e-commerce, automatic shuttles or automatic guided vehicles bring the goods to the order picking station, where objects are either placed in standard cases/boxes or the objects are kept in their original packaging. Piab offers tailor-made vacuum grippers, vacuum systems and components to help increase your automation efficiency within your operations.

APPLICATIONS- Order picking /bin picking/ random bin picking

What Piab offers- Reliability: innovative grippers with an exceptional grip on thousands of combinations of products and parts

- Optimized operations: all our solutions are made to increase your automation and improve your energy efficiency

- Speed: with Piab's vacuum systems we enable you to improve your operation's speed due to our responsive gripping technology

Palletizing and de-palletizing

-

Almost anything in the world that is being shipped will at some point sit on a pallet. We have an immense offering of products that fit your palletizing and de-palletizing needs, whether it’s to place an object on the pallet or remove an object. All tools are designed to secure that your operations run with the highest efficiency, are low maintenance, safe, and that no goods or humans are injured in the process.

APPLICATIONS- Pallet handling and positioning

- Slip sheet feeding

- Trays and open top containers

- Boxes and containers Bags, sacks and bundles

What Piab offers- Reliability: our End Of Arm Tools are created to ensure safe operations pallet after pallet

- Speed: with Piab's palletizing solutions we enable you to improve your operation's speed due to our responsive gripping technology

- Improved uptime: maintenance is simple and kept to a minimum, giving you time back

Intralogistics

- Right time, right place. This motto is key when securing that your material, components, and parts are ready for the next process step. All your intralogistics can be fully automated thanks to vacuum automation, conveyor systems, automated guided vehicle solutions, kitting robots, pick and place stations, and sorting stations. Piab offers a large variety of solutions to enable efficient and reliable vacuum automation within intralogistics.

APPLICATIONS- Order picking /bin picking/ random bin picking

- Robot pick and place and packing SMD roll handling

- Kitting

What Piab offers- Innovation: utilizing best in class components, ergonomic lifters, and End Of Arm Tooling we can help you optimize any production line

- Reliability: our solutions will help you secure that the right products are at the right place in your plant

- Customization: our wide offering of modular components can be adapted for your operation's needs

Packaging

- Piab has a long history of setting the standards for the Packaging industry and over the years we have developed a wide variety of high quality components and solutions to help increase your process performance and secure minimum downtime. Packaging plays a key role in nearly every industry worldwide and our legacy has created best in class solutions for fast, safe, and efficient handling of individual and packaged products.

Palletizing/de-palletizing

- Almost anything in the world that is being shipped will at some point sit on a pallet. We have an immense offering of products that fit your palletizing and de-palletizing needs, whether it’s to place an object on the pallet or remove an object. All tools are designed to secure that your operations run with the highest efficiency, are low maintenance, safe, and that no goods or humans are injured in the process.

APPLICATIONS- Pallet handling and positioning

- Slip sheet feeding

- Trays and open top containers

- Boxes and containers

- Bags, sacks and bundles

What Piab offers- Reliability: our End Of Arm Tools are created to ensure safe operations pallet after pallet

- Speed: with Piab's palletizing solutions we enable you to improve your operation's speed due to our responsive gripping technology

- Improved uptime: maintenance is simple and kept to a minimum, giving you time back

Cartons and trays, erecting and forming

- Increasing speed and cycle rates are something we take into consideration when developing products to improve the efficiency of your packaging line. Consideration for multiple aspects such as carton material, erecting processes, cycle speed, energy saving and intelligent monitoring are all considered to help ensure maximum reliability with no missed picks.

APPLICATIONS- Tray forming, tray unloading and loading

- Rotary carton feeding

- Case/carton erecting, case/carton opening closing

What Piab offers- Reliability: our vacuum cups comes in a large variety of designs and material to enable a reliable seal on the material being picked

- Increased performance: products created for high speed automation and low energy consumption

- Smart technology: monitor vacuum to your operation’s specifications

Picking, placing and packaging box, trays and cases

- Piab's suction cups and vacuum systems are made especially for varying needs within the Packaging industry at no cost to performance or reliability. Our food grade cups are made for direct food contact or if you’re looking to handle liquid filled bags, we have the world’s leading bag cup for you. Our vacuum solutions offer an optimal and responsive solution for picking and placing objects.

APPLICATIONS- Direct food contact

- Robot pick and place and packing

What Piab offers- Reliability: our vacuum cups comes in a large variety of designs and material to enable a reliable seal on the material being picked

- Increased performance: products created for high speed automation and low energy consumption

- Smart technology: monitor vacuum to your operation’s specifications

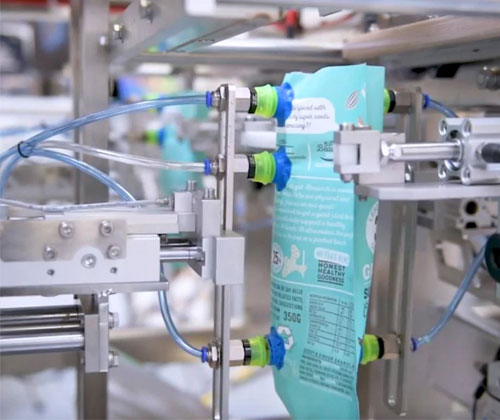

Bag, pouch and flexible packaging handling

- Flexible packaging material is the generic term for soft packages made of film, foil or paper sheeting. Popular forms are stand-up pouches, bags, sachets and envelopes. These packages are often formed, filled and sealed in a vertical or horizontal form-fill-seal machine. Our innovative vacuum systems will help you to fill and seal the bag as well handle the bag without damaging the product.

APPLICATIONS- Bag and pouch handling

- Bag and pouch opening

- Powder filling and packaging

Did you know that...- We have the world's market leading bag, pouch, and flexible packing cups!

- We offer: reliability our vacuum cups comes in a large variety of designs and material to enable a reliable seal on the material being picked

- We have: smart technology that monitors the vacuum to your operation’s specifications

Pharmaceuticals

- The Pharmaceutical industry requires the highest safety, hygienic, and quality equipment to meet industry standards and regulations. Our products exceed these requirements allowing for optimized productivity at no cost to human safety.

Powder

- In the production of pharmaceuticals, powder is transported through the process steps either through manual handling or an automated solution. Challenges to address are many such as health and safety of the staff, contamination, material segregation, product waste, as well as compliance and quality. Our solutions are customized to your needs, enabling a safe and enclosed system between your process steps. Piab offers intelligently designed solutions that efficiently connects the flow from start to finish.

APPLICATIONS- Capsule filling

- Feeding material to and from sieving unit

- Feeding material to and from milling and grinding

- Feeding material to and from blender/mixer

- Feeding material to and from fluid bed drying

- Reactor filling

- Conveying powder to and from fiber drum or barrel

- Reclaim of powder

- Packaging of powder

What Piab offers- Health and safety: we build vacuum conveyors that provide dust free production

- Efficiency: our vacuum conveyors are made to quickly transfer powder without any material segregation

- Ahead of the game: we set and exceed industry standards without compromising on safety

Tablets and capsules

- In the production of pharmaceuticals, tablets and capsules are transported through the process steps either through manual handling or an automated solution. Challenges to address are many such as health and safety of the staff, contamination, material segregation, product waste, as well as compliance and quality. Our solutions are customized to your needs, enabling a safe and enclosed system between your process steps. Piab offers intelligently designed solutions that efficiently connects the flow from start to finish.

APPLICATIONS- Feeding to and from tablet press

- Feeding to and from tablet coating

- Feeding to and from capsule filling Feeding packaging machines

- Conveying through/to and from metal detection equipment

- Reclaim of material, tablets and capsules

What Piab offers- Profitability: reduced waste due to gentle a vacuum conveying setting

- Efficiency: our vacuum conveyors are made to quickly transfer powder without any material segregation

- Human focus: easy maintenance, hygienic, and safe for human handling

Plastics

- Increase productivity and efficiency with our innovative products and solutions for the Plastics Industry. Remove ready-made plastic parts from the mould all while ensuring quality and optimal production rates.

Injection moulding

- A very common production process for plastic part production is through injection molding, producing high quality requirements that requires reliability and performance of the handling both during de-molding/part removal as well as during de-gating cutting operations. Having a secure grip with both vacuum and mechanical gripping is essential to avoid damaging the parts. To enable high productivity combination of parts removal and de-gating can be done with the same End of Arm Tool.

What Piab offers- Quality: End of Arm tools, which cycle after cycle securely de-mold your automotive parts

- Enhanced production: innovative component systems, which allow for handling both simple and complex cuts

- Reliability: robust design of component and End of Arm tool systems

What Piab offers- Quality: End of Arm tools, which cycle after cycle securely de-mold your automotive parts

- Enhanced production: innovative component systems, which allow for handling both simple and complex cuts

- Reliability: robust design of component and End of Arm tool systems