- Offer Profile

- AT – Automation Technology is a leading global technology company specializing in customizable 3D special imaging sensor technology. Located conveniently between Hamburg and Lübeck in Bad Oldesloe, Germany, we have been developing and manufacturing intelligent infrared cameras, high-precision 3D sensors, and unique sensor solutions since 1998. These solutions are widely used in industrial process automation, as well as in monitoring and inspection tasks worldwide, thanks to our team of over 50 dedicated employees.

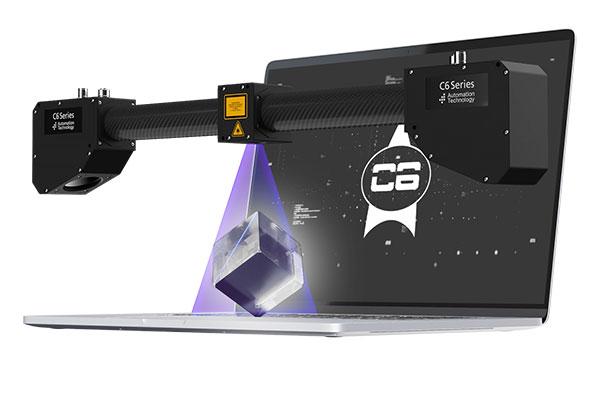

The fastest 3D sensors in the world

-

With our C6 series, we offer the fastest 3D sensors worldwide in terms of resolution and speed. The advantages include a specially developed sensor chip and WARP technology resulting in the world’s fastest 3D profiling.

- Exclusive imager design

- Latest industry standards GigE Vision / GenICam 3D

- 3D profile pixel rate of up to 128 megapixels at 29 gigapixels per second

- Unique features such as MultiPart and MultiPeak

The new 3D C6 series by AT is built on a novel sensor platform that supports the latest industrial standard GigE Vision/GenICam 3D at 1 Gbit/s. These new laser profilers offer an impressive combination of extremely fast and highly precise resolution, reaching up to 4,096 points per profile, a profile speed of up to 200 kHz, and high dynamic range 3D image capture. They are available as compact sensors, MCS, and 3D cameras.

ECS Series

-

- Integrated 3D Sensor C6 Series

- Price-performance ratio: Cost-effective 3D sensor for demanding applications

- Software standards for easy integrations: GigE Vision, GenICam and third-party software support

- Cross-industry application area: Ideal for the food industry, logistics and robot vision

The ECS series (Eco Compact Sensor) represents the latest innovation in 3D sensor technology, characterized by its economy and performance. These sensors are particularly cost-effective, thanks to the use of lower cost optics and sensors and the support of class 2M lasers with a wavelength of 660nm, while offering reliable performance at an affordable price. Designed for standard applications in the food, logistics and robot vision industries where high-end technology is not required, ECS sensors deliver fast and accurate data acquisition with an output of 2048 and 4096 points per profile and speeds up to 25 kHz. They offer various field of views and a compact design for easy integration as well as fast software connectivity through GigE-Vision / GenICam, making them ideal for cost and efficiency conscious projects.

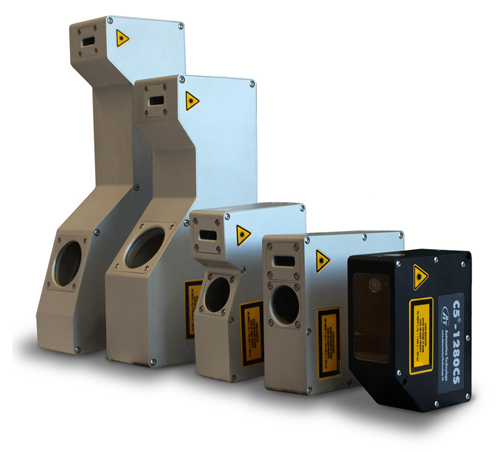

CS Series

-

- Integrated 3D Sensor C6 Series

- Factory calibrated 3D sensors

- Large selection of models with X-FOV 7 – 1290 mm

- Four different sensor resolutions available (1280, 2040, 3070, 4090)

- High industrial protection class IP67

- Available with different laser configurations

The CS sensor series sets new standards in 3D laser triangulation technology with resolutions of up to 4,096 pixels, profile frequencies of up to 204 kHz and fields of view of 7 to 1300 mm. These robust sensors with protection class IP67 and M12 connections for a reliable power supply and data transmission are available in various housing sizes. Integration is straightforward and takes place via standard interfaces such as Gigabit Ethernet or GenICam. The CS series thus offers a powerful, maintenance-free solution for OEM customers and end users in demanding industrial environments.

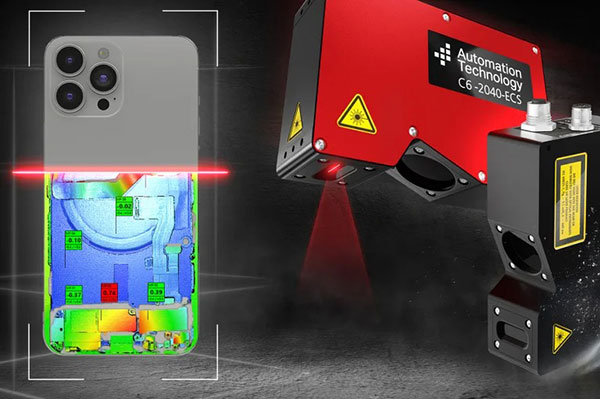

XCS Series

-

- Unique 3D scan results without occlusion due to dual-head option and extremely high resolution

- High precision and repeatability thanks to high-quality laser line projection

- Unrivaled optical resolution for electronic inspection (e.g. BGA inspection) with a field of view of up to 53 mm

- Highest inspection speed available with 3070 WARP sensor

With the new 3D sensor from the XCS series, AT – Automation Technology is launching a product that is particularly suitable for high-performance applications in the electronics industry thanks to its enormous precision and extreme speed. The sensor is characterized by an optimized laser with homogeneous thickness along the laser line, which guarantees precise detection of even the smallest structures. This enables high-precision inspection applications with high repeatability, which is ideal for the inspection of ball grid arrays (BGAs), among other things. The innovative clean beam function protects the laser from external interference and ensures a uniform intensity distribution, which further increases reliability. The sensor’s dual-head option eliminates occlusions and achieves profile speeds of up to 140 kHz with the 3070 WARP version, speeding up data analysis and increasing efficiency.

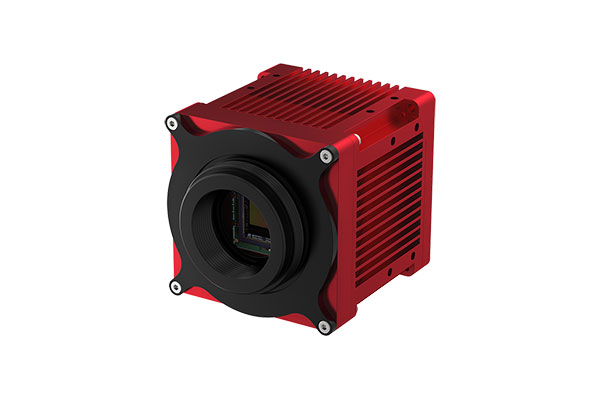

MCS Series

-

- Integrated 3D Sensor C6 Series

- Modular sensor concept for individual solutions

- Flexibly adaptable to customer requirements

- No extra costs

- No long delivery times

The Modular 3D Compact Sensor (MCS) from AT – Automation Technology is revolutionizing 3D image processing with its unique modularity, flexibility and high performance. This innovative system allows individual configuration in terms of scan width, measurement accuracy, speed, triangulation angle and working distance to perfectly match the needs of specific applications. With an unprecedented profile speed of 200 kHz and a resolution of 4096 points per profile, the MCS sets technological standards. It overcomes traditional hurdles such as high NRE costs and long development times by combining the reliability of a series product with the flexibility of a customized solution, without additional costs or minimum order quantities.

Accessories

-

- STEC Targets

- CS I/O Kit

- GigE Ethernet cable

- I/O cable

3D Camera C6 Series

-

Designed for users who want to freely configure the use of the 3D sensor and choose components such as lasers or lenses themselves.

- Compatible with custom components

- Ideal for custom application design

- Optimal for complex multi-sensor applications

- Perfect 3D imaging through integrated Scheimpflug arrangement

3D Software

-

The AT SolutionPackage bundles everything needed for setting up and configuring the AT sensor or camera, as well as for implementing the corresponding application. It includes:

- Software tools for establishing connections, sensor setup, and image data visualization

- Powerful cxSDK tool with programming interfaces for C, C++, and Python

- Easy evaluation of metrology applications with the MetrologyPackage

3D Accessories

- Cables and Panels

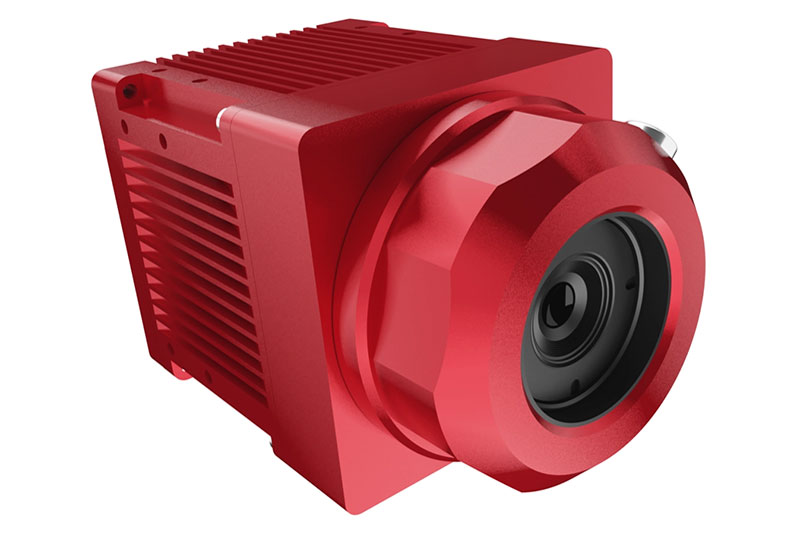

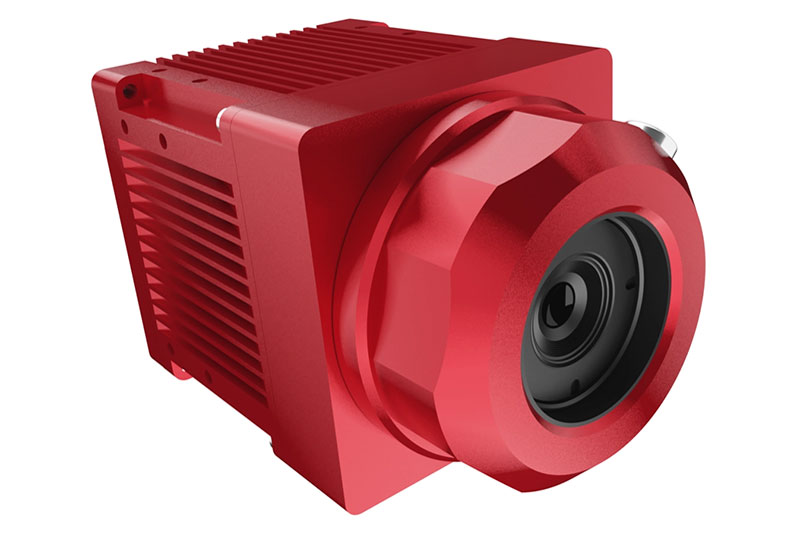

IR Thermal Imaging

-

The smart solution for temperature monitoring

The smart infrared camera IRSX by AT – Automation Technology is a multifunctional, industry-ready thermal imaging system with integrated smart functionality. Through application-specific customizations via apps, it enables cross-industry monitoring, process automation, and inspection.

- Smart stand-alone solution

- Robust industrial design (IP67)

- IoT standard interfaces for seamless integration

- Web-based configuration without programming effort

IRSX: The world’s first truly smart infrared camera

The IRSX infrared camera is an innovative solution for use in virtually any application in an industrial environment. Thanks to its intelligent platform with web-based configuration, there is no longer a need for external software or hardware. Numerous industrial IoT standard interfaces allow for direct integration into all conceivable automation environments.

Infrared camera IRSX

-

The IRSX infrared camera is an innovative solution for use in virtually any application in an industrial environment. Thanks to its intelligent platform with web-based configuration, there is no longer a need for external software or hardware. Numerous industrial IoT standard interfaces allow for direct integration into all conceivable automation environments.

Highlights:

- Plug & Play: Easy Integration

- Measurement Accuracy Up to +/-0.3°C

- Safety Fail-Safe Operation

- Communication IoT Interfaces

IRSX Software

- AT SolutionPackage – Setting up the IRSX in just a few minutes

The AT SolutionPackage bundles everything needed for the setup and configuration of the smart IRSX infrared camera and the implementation of its associated application. It includes:

- Software tools for establishing connections, camera setup, and image data visualization

- Powerful cxSDK tool with programming interfaces for C, C++, and Python

- Optimal configuration for the measurement task using IRSX Simulator software

Industries

- From A for automotive manufacturing to Z for non-destructive testing, our products ensure automation, testing and optimization of critical processes.

Aerospace

Automotive

Electronics and Semiconductors

Energy

Food and Beverage

Iron and Steel

Packaging and Logistics

Petrochemistry

Plastics

Transportation

Wood an Lumber

Industrial Automation

- Industrial automation is revolutionizing manufacturing with advanced technologies that optimize processes and increase productivity. It enhances the precision of position detection to 3D sensor-based object measurement and surface inspection, ensuring the highest quality and efficiency standards. Discover our 3D sensors and learn how they provide modern solutions for industries worldwide and transform production processes.

Robot Guidance

- Unlock the full potential of automation with advanced robot guidance using 3D sensors. Experience unparalleled precision, efficiency, and flexibility in your manufacturing processes.

Metrology

- Ensure the highest precision and quality in manufacturing with advanced metrology using 3D sensors. Verify geometric features and tolerances with unparalleled accuracy and efficiency.

Surface Inspection

- Ensure top quality with advanced 3D surface inspection. Detecting even the smallest defects, our 3D sensors guarantee every product meets the highest standards before reaching customers. Experience precision and reliability in quality control.