- Offer Profile

-

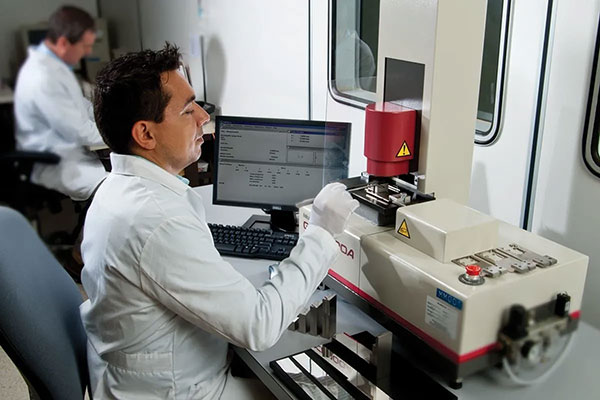

A Legacy of Quality

Precision. It’s the essence of metrology instruments and solutions, and the Mitutoyo name has come to embody trusted precision in applications of all kinds.

For over 50 years, Mitutoyo Canada Inc. has worked diligently to produce the best precision measurement instruments and solutions commercially available. We began decades ago with the era’s most accurate micrometer, and we’ve continued to evolve, developing innovative solutions that meet today’s changing requirements.

From an unmatched line of small tools to sophisticated imaging systems, 3D CNC measuring systems, world-class calibration and more, our solutions help customers achieve accuracy and excellence.

COORDINATE MEASURING MACHINES - CMM

Standard Coordinate Measuring Machines

CRYSTA-Apex V

-

The highly versatile CRYSTA-Apex V series CNC Coordinate Measuring Machines offer multi-sensor flexibility with vision, laser, surface finish and scanning probe technologies for fast and accurate measurements.

FEATURES & BENEFITS:

• SMS (Smart Measuring System) – system for on-line monitoring and operational status of a measuring machine with data visualization to enable product quality improvement

• Real-time CMM and workpiece temperature compensation (standard feature)

• High-speed optimal path scanning with high-speed active scanning

• Multi-sensor support with an array of contact and non-contact probes that includes tactile, scanning, laser, optical, surface finish measuring

CRYSTA-APEX EX 1200R

-

The CRYSTA-Apex EX 1200R series is an advanced CNC CMM equipped with the REVO 5-axis scanning probe head. The 5-axis operation allows for faster probe movements and measurements.

FEATURES & BENEFITS:

- REVO 5-axis scanning probe head delivers ultra-high speed 5-axis scanning

- Reduces time required for probe repositioning movements and allows for flexible positioning

- 3D CAD modeling offers productive on-line or off-line programming

- Automatic probe changes with an optional module changer is supported

- Supports RSP2 for 5-axis scanning probe and SP25M type RSP3 probe for use of a cranked stylus

- Temperature compensation guarantees accuracy within the range of 16 to 26°C without a temp-controlled room

High-Accurancy Coordinate Measuring Machines

STRATO-Apex 500/700/900/1600

-

The Mitutoyo state-of-the-art STRATO Apex Series of CNC Coordinate Measuring Machines delivers high-accuracy measurements with smooth, high-speed operation for top scanning performance.

FEATURES & BENEFITS:

- Temperature compensation guarantees accuracy within the range of 18 to 22°C (STRATO APEX 574 19 to 21°C), without a temp-controlled room

- Vibration-damping unit prevents floor vibrations from reaching the main unit; detects load changes caused by movement of individual axes

- Ultra-high precision glass scales combined with high-performance reflective linear encoder creates ultra-high accuracy measurement on each axis

Ultra High-Accurancy Coordinate Measuring Machines

Legex 500/700/900/1200

-

The Mitutoyo LEGEX Series ultra-high accuracy fixed-bridge CNC CMM is the ultimate in the world’s high-accuracy measurement technology. LEGEX series CMMs are suitable for complex small-to medium-sized workpieces that require dimensional accuracies with small tolerances like gears, bearings, lenses and precision dies.

FEATURES & BENEFITS:

- Air-damped spring isolators with an auto-leveling function eliminates factory floor vibrations from the machine

- Rigid, durable construction with fixed-bridge design eliminates measurement fluctuations due to axis movement

- FEM structure analysis simulation, guarantees geometric motion accuracy has minimal errors from fluctuations in the load and other variables

Shop Floor Coordinate Measuring Machines

MACH-KoGa-Me

-

The Mitutoyo MACH Ko-Ga-Me is a fast, compact, lightweight and easy-to-mount Coordinate Measuring Machine, ideal for automated cell measurement solutions. The MACH Ko-Ga-Me can be mounted on any rigid frame, including machine tools, providing full CMM capabilities without the space requirements of a full-size machine. It also offers in-process measurement without requiring setup or breakdown.

FEATURES & BENEFITS:

- Ideal for small workpiece inspection

- The MACH Ko-Ga-Me accommodates a wide choice of measuring probes including touch-trigger, optical and scanning types

- Load pieces manually or robotically for an automated closed-loop control process

- Quicker measurement feedback and compensation of the manufacturing process reduces scrap and increases throughput

- Temperature compensation guarantees accuracy within 4 different ranges: 19~21°C, 15~25°C, 10~30°C, 10~35°C

MACH-V

-

The MACH-V is the world’s fastest vertical axis near-line/in-line CNC CMM making it an optimal, flexible measuring system that replaces dedicated gauge measurement in a production line without sacrificing accuracy.

FEATURES & BENEFITS:

- The world’s fastest vertical-axis in-line CNC CMM with 8,840mm/s² acceleration

- Open access to the measuring area from the front, back, left or right increases flexibility in loading workpieces

- Improved structural design, air-free operations and improved dust resistance reduces maintenance

- Temperature compensation guarantees accuracy within the range of 41 to 95°F (5 to 35°C) without a temp-controlled room

MACH-3A

-

The Mitutoyo MACH-3A horizontal-type CNC Coordinate Measuring Machine incorporates the CMM controller and host computer in the main unit resulting in a compact, space-saving footprint on the shop floor. The unit’s all-in-one, superior structural design allows for stable around-the-clock operations with dust resistance, making the MACH-3A CMM highly reliable for measurements on the production line.

FEATURES & BENEFITS:

- World class acceleration, measuring speed and drive speed contributes to total cost reductions as an auto-measurement system

- The horizontal-axis design allows this system to use the same workpiece handling and routing as the processing machines use

- Improved structural design, air-free operation and incorporated control unit and PC reduces maintenance

- Temperature compensation guarantees accuracy within 4 different ranges: 66.2~69.8°F (19~21°C), 59~77°F (15~25°C), 50~86°F (10~30°C), 50~95°F (10~35°C)

MiSTAR

-

The Mitutoyo MiSTAR CMM revolutionizes shop floor precision measurements with exceptional versatility, simple operation, reduced footprint compact design and best-in-class drive speed and acceleration.

FEATURES & BENEFITS:

- Technologies such as a symmetric structure, uniform material, and temperature compensation gives the MiSTAR an accuracy guaranteed temperature range of 10 to 40ºC

- The MiSTAR achieves a contamination resistance more than 2 times better than conventional CMM’s by implementing the newly developed Mitutoyo absolute scale* that is highly resistant to the challenging production line environment

- The adoption of single support moving bridge provides a three-sided open architecture, significantly easing the task of moving workpieces on and off the measuring table

- With Mitutoyo clamping tools and pallet receiver designed for the MiSTAR enables quick setup and measurement of like workpieces

- The use of clamping tools and pallet receiver enables quick measurement of similar workpieces

* A scale that provides an absolute value for each measurement point. This eliminates the need for a machine initialization operation

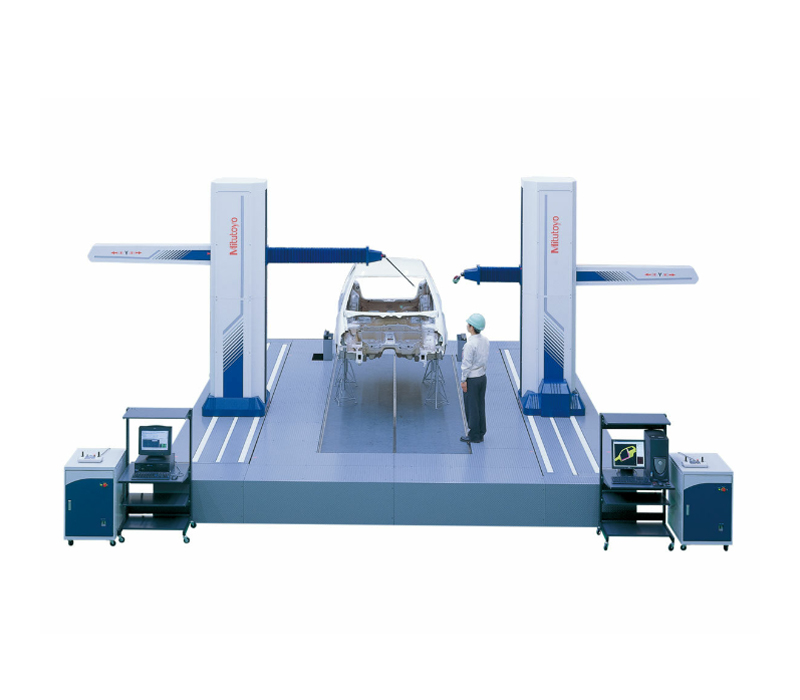

CARBstrato

CARBapex/CARBstrato Series 355

-

The Mitutoyo CARBapex/CARBstrato Series 355-Car Body Measuring System CNC CMM are a cost-effective horizontal type, large CNC CMMs, and offer the world’s largest class measurement range with capacity up to 8 meters (26 feet) that makes it possible to measure car bodies. These CMMs are capable of interchanging contact and non-contact probes, millions of measurement points can be collected in a short time.

FEATURES & BENEFITS:

- High speed, high stability, and environmentally robust durability providing around-the-clock operation while delivering reliability and high accuracy

- Backlash free mechanism X-axis drive and air bearings and a friction drive system for Y- and Z-axes minimizes vibrations during movement

- The top of the base houses the X-axis protected with diamond steel plating for operator safety and accessibility to the parts being measured

- A light-sensitive safety device installed in the Y-axis-arm bellows stops all movement immediately when the arm comes into contact with a workpiece, clamp or anything else during measurement providing optimal operator safety

- Stable measurement results are achieved with continuous scanning probes (contact or noncontact type)

- Implementation of 3-point support method maintains long-term accuracy independently of foundation deformation

- Real-time CMM and workpiece temperature compensation (standard feature)

CMM Probe and Change Rack Options

Probe Heads

-

Mitutoyo offers a wide variety of CMM probe heads that support a number of probe systems to enhance the measurements capabilities of Mitutoyo Coordinate Measurement Machines and improve measurement throughput for nearly any type of application.

FEATURES & BENEFITS:

Mitutoyo offers fixed, manually articulated and motorized CMM probe heads for both manual and CNC Coordinate Measuring Machines. The probe heads support a wide range of probes and styli to take accurate measurements for nearly any type of application.

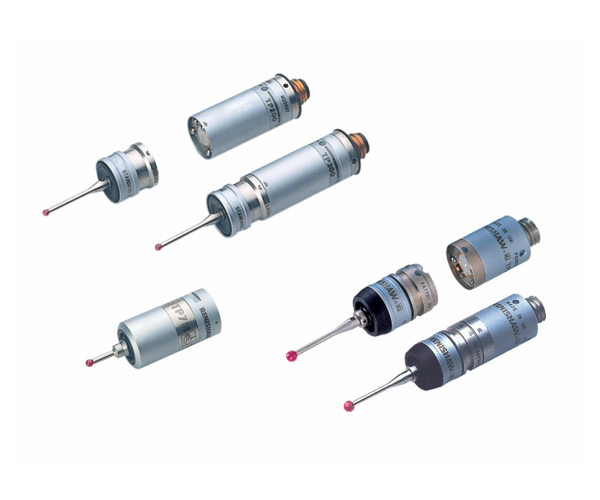

Tactile Probe Systems

-

Tactile probes (aka touch trigger probes), are probe sensors that take individual point measurements using various technologies such as strain-gage, optical transducer, kinematic switch..

FEATURES & BENEFITS:

Mitutoyo offers several different touch probes for manual and CNC Coordinate Measuring Machines. These touch probes are capable of measuring discrete points, ideal for inspecting three-dimensional parts and workpieces. The TP20 and TP200 touch probes feature detachable stylus modules giving users the ability to select the ideal measurement for any application with faster measuring time and better productivity. The TP7 probe is a high-accuracy touch-trigger probe with exceptional repeatability and ability to mount a longer stylus.

Scanning Probe Systems

-

Scanning probe are sensors that make contact with the workpieces and then slide along the workpiece surface taking measurements at specified increments, acquiring several hundred surface points each second for form measurement as well as size and position.

FEATURES & BENEFITS:

Scanning probes allow Coordinate Measuring Machines to quickly gather form and other profile data on complex workpieces and features that otherwise wouldn’t be possible. Mitutoyo offers CMM scanning probes with multiple functions and low contact force and support a variety of different styli for different applications and needs.

Surface Roughness Probe Systems

-

Mitutoyo developed a surface roughness sensor to allow a CNC CMM to be used to measure surface roughness measurements, eliminating workpiece changeover to a second measurement device.

FEATURES & BENEFITS:

- Can be attached to our CNC CMM (Retro-fitting is possible depending on the model)

- The auto joint-probe system allows probe changing automatically between scanning (SP25M) and the CMM Surftest surface analysis probe. The measurement and evaluation of size, shape androughness, is completely automated with auto joint-probe changing.*

- PH10M(Q) allows surface roughness measurement for features requiring rotation

* Requires ACR3 change rack (OPTION)

Non-Contact Probe Systems (Laser)

-

The Mitutoyo SurfaceMeasure non-contact laser measuring probe captures stable shape data on workpieces without being affected by their reflectance for highly accurate, fast and efficient measurements. The SurfaceMeasure laser measure probe automatically adjusts laser intensity and camera sensitivity to the environment and workpiece material (unlike conventional laser measure probes) for more reliable and hassle-free scanning results.

FEATURES & BENEFITS:

• Model 1110: The Mitutoyo SurfaceMeasure 1110 line laser probe, compatible with Mitutoyo CMMs, provides fast, high-precision, non-contact surface measurements. Ideal for automotive, aerospace, and medical applications, it efficiently measures complex geometries and freeform surfaces.

• Model 201FS: The Mitutoyo SurfaceMeasure 201FS is a laser probe designed for high-accuracy, non-contact form measurement using a point scanning method. The laser beam is focused on a single measurement point along the scan line, minimizing the impact of multiple reflections and ensuring precise results. This system is ideal for applications such as inspection, reverse engineering, and 3D data acquisition across a range of industries, including automotive, aerospace, and medical sectors.

Non-Contact Probe Systems (Optical)

-

Optical probes are non-contact sensors that utilizes a camera optics to do automatic focusing and edge detection tools to gather points used to generate geometry for measurement evaluation.

FEATURES & BENEFITS:

- The QVP probe automatically detects workpiece edges using dedicated VISIONPAK software

- Various calculations process, ie: dimensions and geometrical deviations are performed by general purpose GEOPAK software

- Standard adjustable co-axial light in the lens system and white light LED ring illumination eliminates the need for auxiliary illumination

- The QVO can mount on an automatic probe changer for fully automated measurement

5-Axsis Probe Systems

-

A 5-axis probe system delivers unprecedented measuring speed and flexibility without conceding any accuracy. Unlike conventional CMM measuring probes and techniques, a 5-axis probe system avoids the speed versus accuracy compromise, boosting throughput of more accurate workpieces. 5-axis probe uses an articulating head that moves in two rotary axes as it measures, reducing acceleration inertial deflections in the machine structure that leads to measurement errors.

FEATURES & BENEFITS:

- 5-axis probe motion also eliminates time spent indexing the head

- Mitutoyo offers the REVO scanning 5-axis probe and the PH20 tactile 5-axis probe for CNC CMMs

- The REVO is ideal for surface finish measurements and dimensional inspections

- The PH20 uses unique head touches to allow measurement points to be taken by moving only the head, rather than the CMM structure

Rack Changers

-

Change racks facilitate exchanging of probe sensors automatically during part inspection reducing measurement time required with the use of CMM as a single inspection tool.

FEATURES & BENEFITS:

Mitutoyo offers a wide array of probe change racks that change CMM styli and probe heads for faster, automated measurements in a single machine. There are probe change racks for manual and automated probe and styli changes at different speeds with integrated stylus safety parameters.

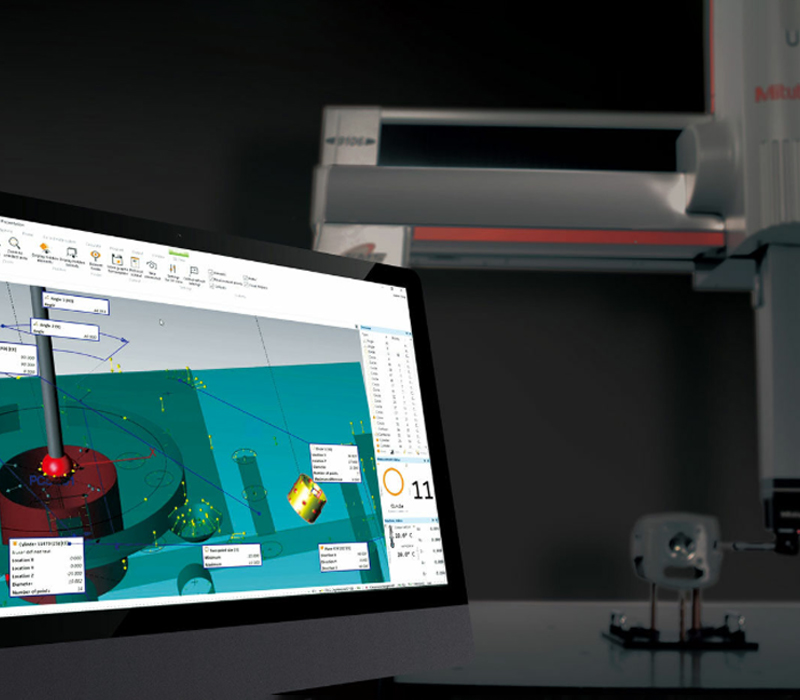

CMM Programming

-

Software modules streamline Mitutoyo CMMs with intuitive interfaces enabling fast, efficient measurements and part modeling.

FEATURES & BENEFITS:

Mitutoyo offers several software suites with a variety of features that power different Coordinate Measuring Machine applications. The software suites, when paired with the proper CMM probe, support surface measurements, vision measurements, point cloud data processing, and fully automatic measurement program generator from CAD models on CMMs

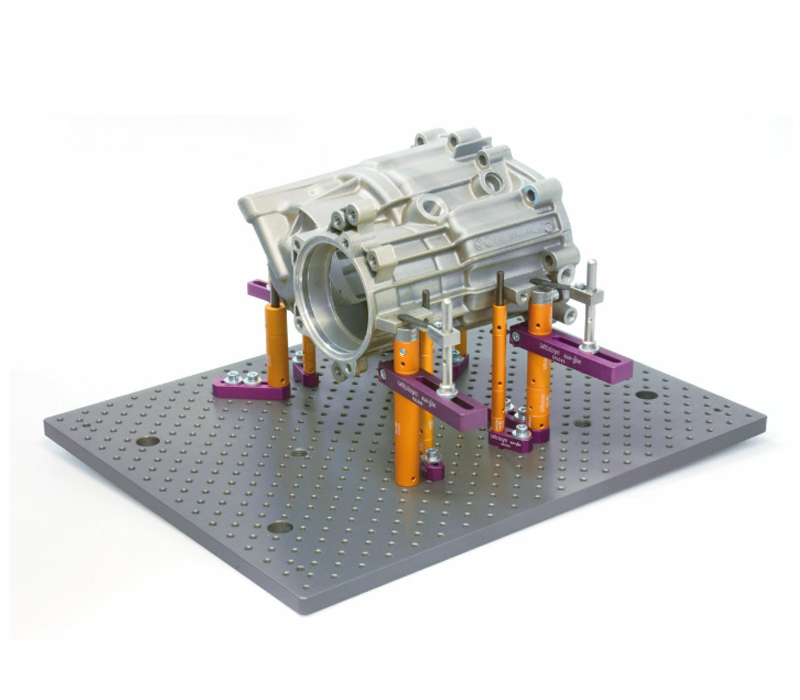

CMM Accessories

CMM Fixture Kits

-

Mitutoyo CMM modular fixture systems designed using state-of-the-art construction offering performance, versatility, systematic efficiency, and economical durability.

Mitutoyo CMM ECO-FIX fixture kits for modular CMM and Vision Measuring Systems work well for securing different part sizes and types for more accurate and efficient measurements. The fixture kit design combines operational modularity advances with lower-cost solutions including the reduction or elimination of hard fixturing costs and setup. The system is comprised of well-marked, color-coded components designed to simplify part measurement requirements.

FEATURES & BENEFITS:

- Magnetic or threaded fastening points deliver fast, plug-and-play connectivity

- First-time fixturing jobs can be established and reconfigured in a matter of minutes for quick future part measurement turnaround

- Fixtures can be built and stored to meet all common part measurement requirements as needed

- Base plates are hard coated and other components are machined for durability

CMM Probe Syli Kits

-

Industrial quality assurance requires increasing universality, flexibility and the ideal shape for absolute precision. Mitutoyo styli exemplify capabilities of: maximum precision, pioneering innovation and convincing economics.

Verification Artifacts

-

Quality control depends on constantly maintaining maximum accuracy performance of a CMM. This requires regular verification of styli as well as the CMM itself by using only Mitutoyo certified artifacts.

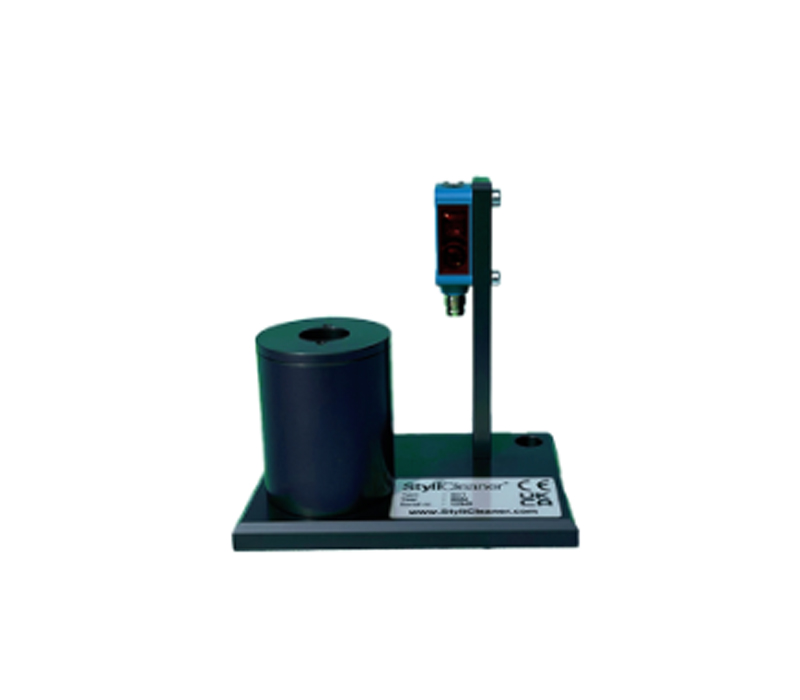

Styli Cleaner

-

A clean stylus is crucial for accurate measurements. StyliCleaner removes contaminants that can impact your CMM measurement results.

Ensure the accuracy and longevity of your CMM equipment with StyliCleaner, the specialized cleaning system designed to keep your styli in optimal condition. A clean stylus is essential for precision measurement, and StyliCleaner is engineered to remove contaminants that can affect the performance of your CMM and your measurement results.

The difference between a dirty stylus tip and a clean stylus tip can significantly affect the performance and accuracy of a Coordinate Measuring Machine (CMM).

In summary, a clean stylus tip ensures better accuracy, longer lifespan, consistency, and efficiency during CMM operations. A dirty stylus tip, on the other hand, can lead to inaccurate measurements, increased wear, and potential contamination issues, negatively impacting both the CMM machine and the workpieces being measured.

Form Measurment Machines

Surface Roughness

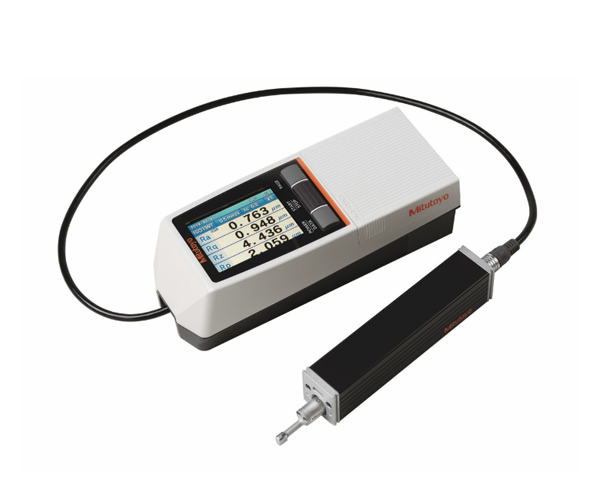

SJ-210 - Portable Surface Roughness Tester

-

The Surftest SJ-210 surface roughness measuring instrument allows users to view surface roughness waveforms on the built-in, color LCD display. The display provides operators with sectional calculation results, assessed profiles, load curves and amplitude distribution curves in addition to calculation results. This instrument is able to perform measurements in any orientation, including both vertical and upside-down. Optional accessories, such as a height gage adapter, efficiently performs measurements in various situations and setups.

FEATURES & BENEFITS:

- Built-in 2.4-inch color graphic, back-lit LCD display provides excellent readability, improved visibility and is easy-to-use in dark environments

- Operation keys are clearly defined on the front of the unit and under the sliding cover

- Internal memory stores up to 10 measurement conditions and one measured profile

- An optional memory card can be used to store large quantities of measured profiles and conditions

- Password protection prevents unintended operations and protects instrument settings

- The display interface supports 16 interchangeable languages

- LCD display mode can be freely switched between portrait and landscape as well as left-hand or right –hand direction

- The Surftest SJ-210 complies with the following standards: JIS (JIS-B0601-2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO-1997, and ANSI.

SJ-310 - Portable Surface Roughness Tester

-

The Surftest SJ-310 surface roughness measuring instrument provides accurate results in a compact, portable unit. The detector supports a variety of measurement orientations and can make measurements vertically and upside-down. The Surftest SJ-310 includes as built-in thermal printer which provides operators the ability to instantly print measurement results on site.

FEATURES & BENEFITS:

- Built-in 5.7-inch color graphic, back-lit LCD touch-panel display provides superior readability, ease-of-use and visibility in dark environments

- User interface provides intuitive, easy-to-understand operability

- Reinforced Measure-Start, and other frequently used buttons, resist wear and workshop contaminants

- Large-capacity battery allows approximately 1500 measurements when fully charged

- Built-in high speed printer prints in landscape or portfolio mode for different applications

- Internal memory stores up to 10 measurement conditions and one measured profile

- An optional memory card can be used to store large quantities of measured profiles and conditions

- Complies with the following standards: JIS (JIS-B0601-2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO- 1997, and ANSI

SJ-410 - Portable Surface Roughness Tester

-

The Surftest SJ-410 surface roughness measuring instrument provides both skidded and skidless measurements. The SJ-410 surface roughness measuring instrument is equipped with 46 roughness parameters that conform to the latest ISO, DIN, ANSI and JIS standards. The unit’s high-resolution detector and drive unit provide a wide range of highly accurate measurements and ultra-fine steps. Using the unit’s skidless measurement and curved compensation functions, straightness, waviness and evaluation of cylinder surface roughness can be easily measured and evaluated.

FEATURES & BENEFITS:

- Built-in 5.7-inch color graphic, back-lit LCD touch-panel display provides superior readability, easy-of-use and visibility in dark environments

- User interface and auto calibration function provides intuitive and easy-to-use operability

- Digital filter function delivers non-distorted roughness profiles for more accurate results

- Limited contour analysis function supports four types of measurement: step, level change, area and coordinate difference

- Password protection prevents unintended operations and protects instrument settings

- Output measured data to a PC with optional RS-232C or USB cable

- Optional column stand available (178-039) to increase operability

Surftest SJ-500 / 500P

-

The SJ-500 is a high-precision and high-performance surface roughness tester with a dedicated control unit, achieving user-friendly display and simple operation. The portable SJ-500 surface tester provides highly accurate analysis of surface roughness and fine contours.

FEATURES & BENEFITS:

- The SJ-500 is the portable version of the desktop SV-2100 surface roughness tester

- The SJ-500P is equipped with a desktop PC system

- Supports measurement in the axial direction by swiveling detector through 90° to analyze shrouded features such as crankshafts

- Vertical adjustment knob helps to safely position the stylus close to the workpiece and measure inside small holes

- Digital Adjustment Tilting (DAT) function makes leveling of workpieces ±1.5° easier and more efficient

- Highly visible, 7.5-inch TFT LCD color display and touch-operated panel provides user friendly, easy operability

- Dedicated control unit’s built-in joystick allows for quick, easy position

- Simple input function allows inputs according to drawing instruction symbols of ISO/JIS roughness standards for simple settings of surface roughness measuring conditions

- Manual column stand is optional for SJ-500 (178-085, 178-089)

SV 2100 - Dedicated Processor - Column Type

-

The Surftest SV-2100 is a high-precision and high-performance surface roughness tester with a dedicated control unit, achieving user-friendly display and simple operation. The Surftest SV-2100 surface tester provides highly accurate analysis of surface roughness and fine contours..

FEATURES & BENEFITS:

- User-friendly display and simple operation equipped with a highly visible color 7.5-inch TFT LCD

- Absolute scale system allows easy and accurate positioning for multiple measurements with high repeatability

- A built-in joy stick dedicated to the control unit allows easy and quick positioning

- Fine positioning of a small stylus, required for measuring the inner side of a small hole, can be easily made using the manual knob

- Simple input function allows inputs according to drawing instruction symbols, for ISO/JIS roughness standards, allowing for simple selection of surface roughness measuring conditions

SV-3000 CNC - Extreme Type

-

The Surftest Extreme SV-3000CNC surface roughness measuring instrument measures in both axes with high-accuracy. Each axes have the maximum drive speed of 200 mm/s, which permits high-speed positioning that will increase throughput of multiple profile/multiple workpiece measurement tasks. For models with the α-axis, it is possible to perform continuous measurement over horizontal and inclined surfaces by power tilting the drive unit. And for models with the Y-axis table, it is possible to expand the measuring range for multiple workpieces, etc., through positioning in the Y-axis direction.

FEATURES & BENEFITS:

- Incorporated anti-collision safety device on the detector unit will automatically stop the instrument, even if its main body collides with a workpiece or fixture

- Easy-to-operate remote box allows the operator to conduct movements by selecting the axis icon and then using the designated joystick

- Communication with the data processing/analysis section is via USB

- Using optional rotary table Θ1 and Θ2 designed to use with the CNC models enables it to expand the CNC measurement application range

FTA-S3000

-

The Formtracer Avant S3000 Series Surface Roughness Tester with single-sided stylus boasts best-in-class drive speed for the drive unit and column axis along with a quick stroke return speed for much faster measurements. The measuring unit’s rapid movement, combined with optional accessories to automate leveling of the measuring surface during set up, shortens measurement time while reducing operator burden. The single-sided stylus completes one-sided and bottom measurements with high accuracy, and the surface roughness detector head can be easily swapped out with an optional contour detector to make the Formtracer Avant S3000 a powerful, complex machine.

FEATURES & BENEFITS:

- Mounting an arm onto the Z1-axis contour detector with a magnet-type attachment system further improves measurement efficiency

- Hot swapping allows switching between the roughness detector and optional contour detector without powering the machine off

- The toolless replacement mechanism uses a thumb-turn clamp for much faster switching between detectors

- Stylus drop detection feature detects any sudden drop of the stylus and stops the measurement operation

- Collision monitoring for the magnet arm and detector cover ensures safe measurements even during high-speed movements

- Optional accessories for automatic measurement automate processes from the setup to the measurement

SJ-220 - Portable Surface Roughness Tester

-

The SJ-200 series of portable surface roughness measuring instruments that has contributed to industrial development and technological progress through precision measurements, has evolved further still. While maintaining excellent portability and ease of use on-site, it also provides touch screen functionality for intuitive operability. Equipped with a built-in battery, it can perform measurements in environments where power is not available and can be used approximately 1000 times on a full charge. Cableless and paperless work is made possible by using the U-WAVE-TIB, a Mitutoyo wireless data transmitter. This is a user-friendly device that provides compatibility and versatility to meet diverse manufacturing needs.

- Compatible with new standard ISO 21920.

- Built-in 2.8-inch color graphic, back-lit display provides excellent readability, improved visibility and is easy-to-use in dark environments.

- LCD display mode can be freely switched between portrait and landscape as well as left-hand or right –hand direction

- Even if you are wearing gloves and unable to use the touch screen, you can still operate the SJ-220 using the physical buttons.

- On a full charge, it can be used to perform measurements approximately 1000 times.

- Optional U-WAVE-TIB transmitter allows for wireless displaying of measurement results, setting measurement conditions, and bidirectional communication.

- Dedicated “SJ-APP” for increased efficiency of measurement work

- The display interface supports 25 interchangeable languages

Contracer

FTA-C4000

-

The dual-sided conical stylus on the Mitutoyo FTA-C4000 allows for continuous upper and lower face contour measurement, including the effective diameter of screw threads. The selectable measuring force feature eliminates the need to set the measuring force by exchanging weights or switching orientation for faster, more efficient measurements. With an optional surface roughness detector head, the FTA-C4000 can perform both surface roughness and contour measurements quickly the machine’s unique hot swap feature.

• Mounting an arm onto the Z1-axis contour detector with a magnet-type attachment system further improves measurement efficiency

• Hot swapping allows switching between the contour detector and roughness detector without powering the machine off

• The tool-less replacement mechanism uses a thumb-turn clamp for much faster switching between detectors

• Stylus drop detection feature detects any sudden drop of the stylus and stops the measurement operation

• Collision monitoring for the magnet arm and detector cover ensures safe measurements even during high-speed movements

• Optional accessories for automatic measurement automate processes from the setup to the measurement

Contracer CV-2100 - Contour

-

The Mitutoyo Contracer CV-2100 contour measuring instrument provides highly accurate, highly efficient measurements that is easy to set up. This measuring instrument is equipped with a drive unit inclination mechanism that enables inclined-plane measurement to accurately measure difficult to measure workpiece features. The Digital ARC Scale directly tracks the arc trajectory of the stylus tip so the most accurate.

FEATURES & BENEFITS:

- Quick-release grip handle allows for rapid traverse in column Z-axis for CV-2100M4

- Key operation buttons are mounted onto the X-axis drive unit, eliminating a wired remote box

- X-axis traverse speed, up to 20mm/s, allows for quick positioning and set-up time

- Motorized stylus movement means high-volume repetitive measurements are now capable with part programming

- CV-2100N4 model can be easily mounted to optional manual column stand or custom fixture supplied by end user

FTA-C3000

-

The Mitutoyo Formtracer Avant C3000 Series Contracer boasts best-in-class drive speed for the drive unit and column axis along with a quick stroke return speed for much faster measurements. The single-sided stylus completes one-sided and bottom measurements with high accuracy, and the X-axis drive has a range of ±45° to quickly and efficiently measure inclinations without the need to adjust the measuring force. The contour detector head can be easily swapped out with an optional surface roughness detector, making the Formtracer Avant C3000 highly versatile and powerful.

FEATURES & BENEFITS:

- Mounting an arm onto the Z1-axis contour detector with a magnet-type attachment system further improves measurement efficiency

- Hot swapping allows switching between the contour detector and optional roughness detector without powering the machine off

- The tool-less replacement mechanism uses a thumb-turn clamp for much faster switching between detectors

- Stylus drop detection feature detects any sudden drop of the stylus and stops the measurement operation

- Collision monitoring for the magnet arm and detector cover ensures safe measurements even during high-speed movements

- Optional accessories for automatic measurement automate processes from the setup to the measurement

Different variant available (FTA-C4000)

Roundness

RA-120/120P

-

The Roundtest RA-120/120P roundness measuring instrument features a ±1000μm wide range detector and precision turntable to provide best-in-class rotational accuracy in compact roundness measuring instruments. A dedicated processor controls all measurements and operations via a control panel in the main unit.

FEATURES & BENEFITS:

- Digital Adjustment Table (DAT) function digitally displays the centering and leveling adjustments on the turntable to make workpiece placement much easier

- Large color backlit LCD screen shows easy-to-understand measurement results and graphs to easily check forms and set notch processing

- Notch processing excludes data by notches or scratches if desired

- Model RA-120 has a built-in high-grade thermal printer provides instant measurement analysis results, graphs and comments

- Model RA-120P is PC-based and features a Windows graphical interface for excellent usability and advanced functions

Roundtest RA-1600/RA-1600M

-

The RA-1600/RA-1600M roundness/cylindricity measuring system is PC-compliant and is equipped with extensive analysis features for both the shop floor and laboratory environment. The unit’s highly accurate and easy-to-use turntable enables simple, reliable centering and leveling on a wide variety of workpieces.

FEATURES & BENEFITS:

- The spiral-mode measurement function combines table rotation and rectilinear action allowing cylindricity, coaxiality and other measurement data to be loaded as a continuous data set

- Built-in X-axis linear scale makes measurement while tracing possible when displacement due to form variation exceeds the measuring range of the detector, and X-axis motion is necessary to maintain contact with the surface of the workpiece

- Enhanced detector safety functions, such as accidental touch and collision detection, minimizes damage to both machine and workpieces

- Analysis results such as cylindricity and coaxiality can be visually expressed in 3D graphics

- Continuous OD/ID measurement is possible without changing the detector position

- High rotational accuracy (0.03+6H/10000)μm is maintained for an entry level to mid-range model

- PC-based cylindricity capable Roundtest for both shop floor and laboratory environment

- Simple easy to use center and level function with mechanical mic heads on alignment table

- Accidental touch function disables the movement when the detector goes over range

RA-2200 - Roundness / Cylindricity Capable

-

The RA-2200 provides high accuracy, high speed and high performance in roundness measurement. The fully-automatic, or DAT (Digital Adjustment Table), function-aided manual workpiece centering and leveling offers what used to be a difficult task into one that is simple enough for even new users to perform.

FEATURES & BENEFITS:

- Programmable detector unit and holder arm greatly contributes to productivity improvement and enhanced measurement efficiency

- Offline teaching function is capable of creating part program without measurement which allows confirmation of collision-free simulations

- Available with the standard column specification or a high column specification for taller workpieces

- Highest rational accuracy in the radial direction together with high linear displacement accuracy in the axial direction offers high accuracy measurements in both roundness/cylindricity and flatness

- Comes complete with powerful data analysis software ROUNDPAK, which requires only simple manipulation using a mouse and icons, achieving enhanced functionality and ease of operation

- With extremely high rotational accuracy, both in the radial and axial directions, the turntable allows high accuracy flatness testing to be performed in addition to roundness and cylindricity measurements

- The incorporation of an automatic centering/leveling turntable (A.A.T.) with the RA-2200AS/AH models relieves the operator of the bothersome task of workpiece centering and leveling

- High repeatable measurements are achieved using Mitutoyo designed linear scales in the X/Z drive unit to guarantee the high precision positioning so vital for repetitive measurement

RA-H5200 - Roundness / Cylindricity Capable

-

The Roundtest RA-H5200 roundness/cylindricity measuring system features a rigid base and highly accurate, highly rigid turntable that achieves exceptional manufacturing accuracy of critical components, such as the rotor and stator, in addition to an air-bearing which incorporates a complex aperture that provides superior rigidity and uniform pressure distribution. As a result, the rotational accuracy (radial), which is the heart of the roundness/ cylindricity measuring system, is a world-class (0.02 +3.5H/10000)µm. A high-accuracy Z-axis column achieves ultra-high column straightness, combined with high-accuracy positioning sensors in the X- and Z-axis drive units provides highly precise and repeatable measurement capabilities. Measurement while tracing is possible through a built-in linear scale in the X-axis to maintain contact with the workpiece surface when displacement due to form variation exceeds the measuring range of the sensor.

FEATURES & BENEFITS:

- Automatic Adjustment Table (A.A.T) provides high-speed centering and leveling automatically, greatly reducing total measurement time

- Spiral-mode measurement function combines table rotation and rectilinear action allows cylindricity and coaxially for other data to be loaded as a continuous data set

- Continuous OD/ID measurement function performs internal and external diameter measurements without the need to change the detector position

- Enhanced detector safety functions, such as accidental touch and collision detection, minimizes damage to both machine and workpieces

- A surface roughness detector, compliant with the relevant International Standards, can be mounted in place of the roundness measuring detector to create a multiple sensor testing system for roundness/cylindricity and surface roughness

RA-2200 CNC - Extreme Type

-

The Roundtest Extreme RA-2200 CNC Roundness, Cylindricity and Surface Roughness Measuring System performs highly accurate roundness and cylindrical measurements at high speeds in an easy-to-use machine. Roundness and surface roughness measurements are both available from a single measuring system eliminating workpiece resetting for roughness measurement. Roughness measurement is possible in the axial and circumferential directions.

FEATURES & BENEFITS:

- Programmable detector unit and holder arm greatly contribute to productivity improvement and enhanced measurement efficiency

- Offline teaching function is capable of creating part program without measurement which allows confirmation of collision-free simulations

- Available with the standard column specification or a high column specification for taller workpieces

- Highest rational accuracy in the radial direction together with high linear displacement accuracy in the axial direction offers high accuracy measurements in both roundness/cylindricity and flatness

RA-H5200 CNC - Extreme Type

-

The Mitutoyo Roundtest Extreme RA-H5200CNC Roundness, Cyclindricity and Surface Roughness Measuring System features automatic orientation control on the detector unit to enable the system to automatically execute high-speed, operator-free measurements. The RA-H5200 Extreme CNC roundness tester incorporates a programmable detector unit orientation function to continuously and automatically measure inner and outer diameters as well as top and bottom surfaces of a workpiece. The unit’s continuous OD/ID measurement function performs internal and external diameter measurements without the need to change the detector position.

FEATURES & BENEFITS:

- High-accuracy positioning sensors in the X- and Z-axis drive units, makes highly precise, repeatable measurements

- Rigid base and highly accurate, highly rigid turntable that achieves world-class rotational accuracy

- An Automatic Adustment Table (AAT) provides high-speed centering and leveling automatically, greatly reducing total measurement time

- Measurement while tracing is possible through a built-in linear scale in the X-axis to maintain contact with the workpiece surface when displacement due to form variation exceeds the measuring range of the sensor

- Spiral-mode measurement function combines table rotation and rectilinear action allowing cylindricity, coaxiality and other data to be loaded as a continuous data set

- Enhanced detector safety functions, such as accidental touch and collision detection, minimizes damage to both machine and workpieces

- A surface roughness detector, compliant with the relevant International Standards, can be mounted in place of the roundness measuring detector to create a multiple sensor testing system for roundness/cylindricity and surface roughness

Roundtracer Extreme

-

The Mitutoyo Roundtracer Extreme delivers speed, accuracy and operability at the highest level while supporting the measurement of workpieces of various shapes such as camshafts and bearings. Its new 3-step motorized sliding axis, detector and detector holder help avoid workpiece interference without having to replace the stylus while enabling automatic measurement for better flexibility and efficiency.

FEATURES & BENEFITS:

- Best-in-class maximum of 100 mm/sec. with improved positioning accuracy and greatly reduced positioning times dramatically increases throughput compared with conventional models

- Curvilinear measurement throughput is increased since data can now be acquired independently of the turntable 0° position

- New centering table architecture reduces positional changes of the workpiece during measurement

- Ergonomic remote box enhances the user’s experience with clearly laid out buttons and controls

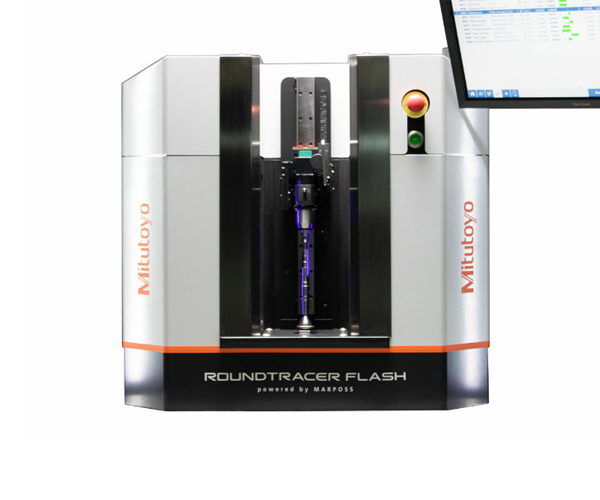

Roundtracer Flash

-

The all-in-one Mitutoyo Roundtracer Flash uses multiple image sensors integrated into fixed positions across the product structure to cover the entire measurement range. The sensors capture multiple images and generate one single image of a part with zero discontinuities and no gaps at the stitching edges. This allows the Roundtracer Flash to measure parts up to 300mm in length without any vertical movement of the sensors or part. With the absence of Z-axis motion, the optical acquisition of the complete part – which consumes time on other systems – is performed almost instantaneously on the Roundtracer Flash for impressively fast cycle times.

FEATURES & BENEFITS:

- Executes 100 static measurements in just 2 seconds irrespective of how the measurement sections are distributed along the shaft length

- Thru-holes measurement: only a few milliseconds are necessary between the image acquisition and the thru-hole measurement execution

- Fixed position sensors mean there is no mechanical stress for better durability

- Metrological performance of the Roundtracer Flash is consistent and stable over millions of cycles with minimal maintenance requirements

- Screws, pins, or rivets can be easily and quickly measured with the Roundtracer Flash

- The standard measurement toolkit includes threads analysis: maximum and minimum diameter, pitch diameter, pitch value, thread angle, thread linearity, total thread length

Formtracer

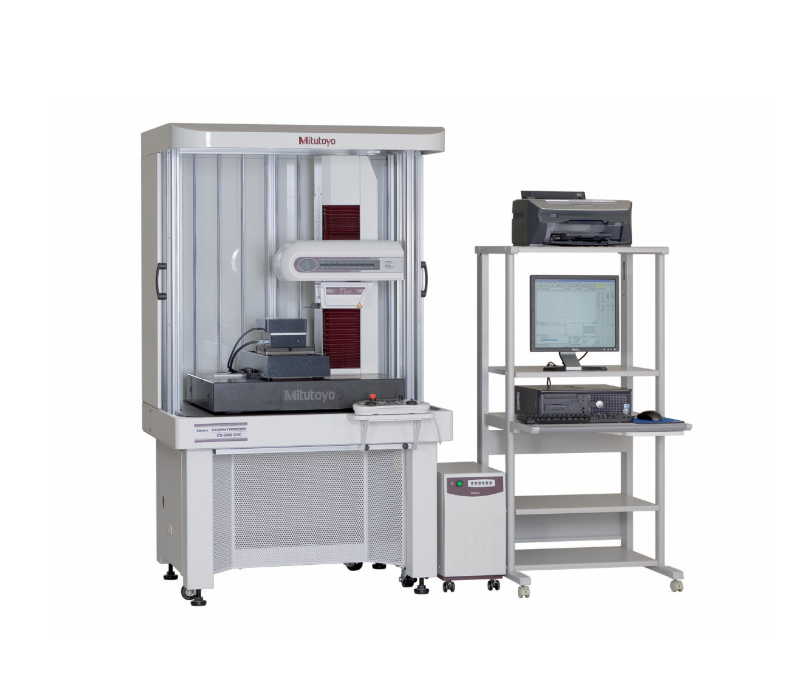

CS-3300 - Singular Detector Type

-

The Mitutoyo Formtracer CS-3300 contour form roughness measuring system provides fast, highly accurate measurements for both applications in a single unit. Its wide measuring range, high-resolution detector and simplified operation enhances the Formtracer CS-3300’s measurement efficiency and operability. This unit is able to measure inclined surfaces quickly by inclining the orientation of the drive unit by ±45°. And by incorporating an ABS scale in the Z2-axis, this unit eliminates the need for origin point re-setting conventionally required for every step of repeated measurements, over step or multiple sections.

FEATURES & BENEFITS:

- The detector unit is able to shift to the left by 2.76” (70mm) extending the unit to avoid drive unit and workpiece interference

- Internally housed detector and drive unit cables eliminate any risk of abrasion and guarantee trouble-free, high-speed operation

- Fine-feed handles and inclined X-axis drive unit measures small holes and inclined planes more efficiently

- Highly rigid ceramic guides maintain traverse linearity for longer periods of time surface quickly and is abrasion resistant

- Dramatically increased drive speed reduces total measurement time

FTA-D3000 - Dual Detector - One sided Contour Stylus Type

-

The Formtracer Avant D3000 is capable of making both contour and surface roughness measurements. The two detector heads are easily switched out without turning off the machine. The FTA-D3000 model features a single-sided stylus that is capable of measuring ID and calculate pitch diameters.

FEATURES & BENEFITS:

- Hot swapping allows switching between the contour detector and roughness detector without powering the machine off

- The tool-less replacement mechanism uses a thumb-turn clamp for much faster switching between detectors

- Stylus drop detection feature detects any sudden drop of the stylus and stops the measurement operation

- Collision monitoring for the magnet arm and detector cover ensures safe measurements even during high-speed movements

- Optional accessories for automatic measurement automate processes from the setup to the measurement

FTA-D4000 - Dual Detector - Dual-sided Contour Stylus Type

-

The all-in-one Formtracer Avant D4000 has a surface roughness and contour detector that is easily switched out without turning off the machine. The FTA-D4000 model features a dual-sided stylus that is capable of measuring ID and calculate pitch diameters. The dual-sided stylus also continuously measures upper and lower surfaces for easier, faster data analysis of difficult features such as the diameter of an internal screw thread.

FEATURES & BENEFITS:

- Hot swapping allows switching between the contour detector and roughness detector without powering the machine off

- The tool-less replacement mechanism uses a thumb-turn clamp for much faster switching between detectors

- Stylus drop detection feature detects any sudden drop of the stylus and stops the measurement operation

- Collision monitoring for the magnet arm and detector cover ensures safe measurements even during high-speed movements

- Optional accessories for automatic measurement automate processes from the setup to the measurement

Formtracer Extreme CS-5000CNC / CS-H5000CNC

-

The Formtracer Extreme CS-5000CNC/ CS-H5000CNC measuring instrument incorporates a Mitutoyo Laser Holoscale in the X1- and Z1-axes for high resolution of simultaneous surface roughness and contour measurements. Z1-Axis detector employs an active control method to implement a wide range of measurement capabilities where variation in dynamic measuring force is restricted. The unit’s high drive speeds on its X1- and Z2 axes enable high-speed positioning and increases throughput for highly accurate measurements on multiple-profile and multiple workpieces.

FEATURES & BENEFITS:

- Anti-collision safety device on Z1-axis detector automatically stops the machine if the main body collides with a workpiece

- For models with the a-axis, power tilting the detector unit enables continuous measurement over horizontal and inclined surfaces

- For models with the Y axis table, positioning in the Y-axis direction expands the measuring range for multiple workpieces

- Remote control unit enables safe, easy and fast measurements

- Icons conveniently displayed on the key top allows operators to easily identify current axis selection

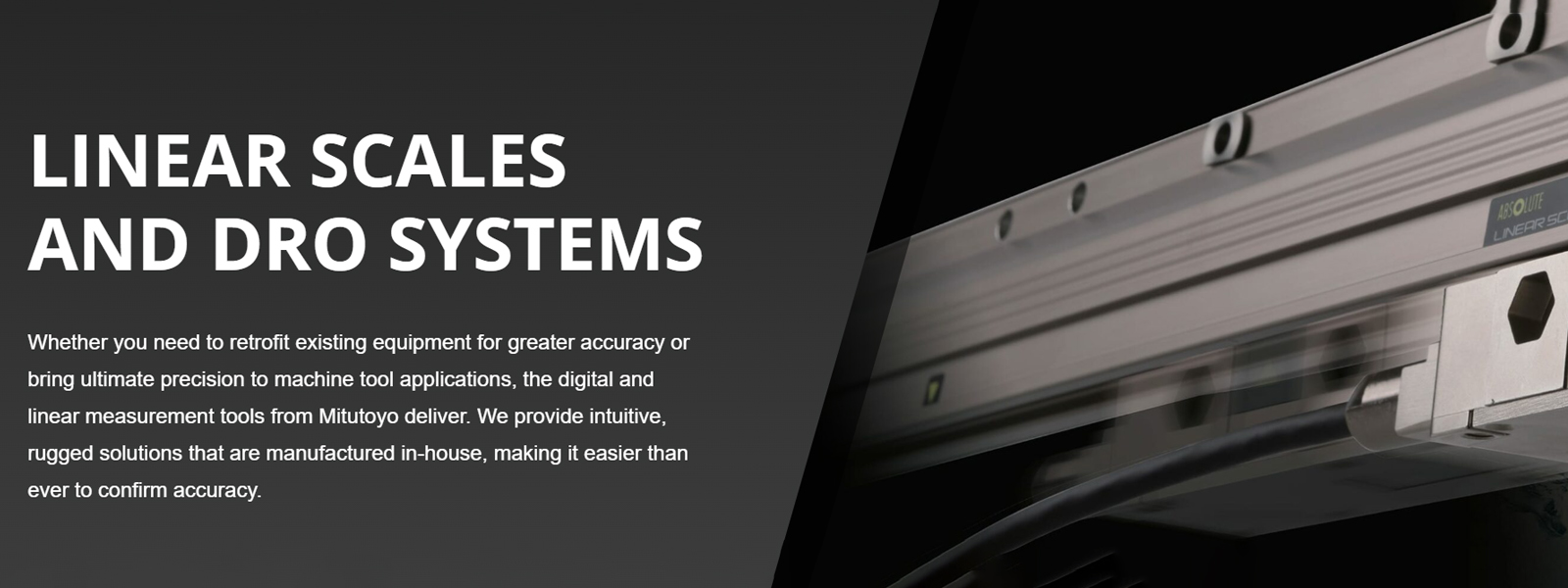

Linear Encoders and DRO Systems

Digimatic Scale Units

SD-G ABSOLUTE Digimatic Scale Units

-

The SD-G Digimatic scale facilitates mounting on jigs, tools and small machine tools to enable accurate positioning. A built-in ABSOLUTE scale is also included, using the Mitutoyo ABS point, which doesn’t require zero-set when powered on. In addition, overspeed errors have been eliminated which improves reliability.

FEATURES & BENEFITS:

- ORIGIN key allows setting of an absolute zero point to be used as reference in subsequent measurements

- Horizontal or vertical display according to the scale mounting direction

- Long battery life for easier maintenance

- Equipped with an output port to transfer measurement data to implement in control and gaging systems

- IP66 certified for protection against dust and water

- EC counters are available as external display units

Different variants available.

SDV-D ABSOLUTE Digimatic Scale Units

-

The Mitutoyo SDV-D Digimatic single-function vertical linear scale facilitates mounting on jigs, tools and small machine tools to enable accurate positioning. A built-in ABSOLUTE scale is also included, using the Mitutoyo ABS point, which doesn’t require zero-set when powered on. In addition, overspeed errors have been eliminated which improves reliability.

FEATURES & BENEFITS:

- ORIGIN key allows setting of an absolute zero point to be used as reference in subsequent measurements

- Vertical display according to the scale mounting direction

- Long battery life for easier maintenance

- Equipped with an output port to transfer measurement data to implement in control and gaging systems

- EC counters are available as external display units

Different variants available.

Quill Kit with ABSOLUTE Encoder

-

The Mitutoyo Quill Kit is easy to install and fits most vertical knee milling machines. Its LCD display provides high resolution positioning for a milling machine’s quill Z-axis.

FEATURES & BENEFITS:

- Push button controls for inch/mm, zero-set and on/off

- Powered by a single SR-44 battery which lasts about 1 year with normal use

- SPC Output for data transmission to data processors or a remote display

- Includes bracket and display

DRO Retrofit Package

2-Axis, KA Counter Milling Package

-

The Mitutoyo 2-axis retrofit milling package utilizes a KA-200 digital readout with slim linear scales in several different X- and Y-axis travel lengths on manual milling machines. The KA-200 features ABSOLUTE and incremental modes with nine presets each. Using electromagnetic induction, the included ABSOLUTE AT715 linear scale is not affected by contamination making it ideal for shop floors.

FEATURES & BENEFITS:

- Includes KA-200 digital counter, AT715 electro-magnetic slim ABSOLUTE linear scales, linear scale brackets and display arm kit

- KA-200 counter can output RS-232C data to a PC, printer or PLC using an optional code out unit (#09AET993)

- The ABSOLUTE scale on the AT715 linear scale eliminates the need for origin resetting for faster, more accurate displacement measurements

- Packages are available in 6 different X-axis travel lengths and 4 Y-axis travel lengths

- IP67 rating (AT715 linear scale) protects linear scale from water and oil contamination

- Comes with 5 year warranty

Different package variants available.

General Purpose Linear Scales/Counters

AT715 ABS Linear Scale

-

Utilizing an electromagnetic induction system, the ABS AT715 linear scale is highly resistant to oils, water and dust making it ideal for shop floor use. The main scale unit provides two mounting directions for easy installation on a machine tool which has difficult mounting arrangements.

FEATURES & BENEFITS:

- Abnormal calculations do not accumulate even if the calculation mistake is generated by electrical noise

- Absolute scales have eliminated the need for origin restoration and drastically reduces power consumption

- Suitable for milling machines, XY tables, jigs, etc.

- IP67 protection level offers high resistance to water, dust and other contaminants

Different variants available.

KA-200 Counter

-

The multiple features and intuitive display on the KA-200 counter provides great versatility and high performance for both two- and three-axis travel. Each axis has independent resolution readings for diverse precision measurement needs.

FEATURES & BENEFITS:

- Absolute and incremental modes are easily toggled with 10 presets each

- Non-linear and linear error compensation

- LED display is adjustable for brightness with a high refresh rate for easy readability in any light setting

- Calculator function allows distance and angle calculations to be simple and error free

- RS-232C data can output to a PC, printer or PLC using the optional code out unit (09AET993)

- Data can be sent directly to a spreadsheet using optional USB drive

Feedback Linear Scales

AT1100 Linear Scale

-

The AT1100 linear scale features unique electromagnetic induction technology to provide excellent oil, water and other contaminant resistance. The linear scale’s housing shape, detector track location and track-seal material further protect the scale and sensor in harsh environments.

FEATURES & BENEFITS:

- Electromagnetic induction principle means scales are unaffected by most contamination

- Multipoint frame mounting method provides high resistance to vibration and shock

- Absolute scales have eliminated the need for origin restoration and drastically reduces power consumption

- Improvements in signal processing technology creates approximately six times higher accuracy than that of previous scales

- Compatible with high-speed serial interface from leading machine-tool companies, allowing direct connection to an NC controller

ST700 ABS Linear Scale

-

The ABS ST700 features exposed scales and an electromagnetic induction principle to deliver highly accurate results in harsh environments. The linear scale features improved indication accuracy and outputs data digitally to help eliminate human error.

FEATURES & BENEFITS:

- The detector head is approximately 1/3 the previous model size for building space-saving systems

- Four directional cable outlets with mounting holes on the top and sides

- Compatible with servo amplifiers from numerous companies (high-speed serial interfaces)

- Signal adjustment at installation is automatically performed with dedicated software

- IP65 rating protects linear scale from water and oil contamination

ST1300 ABS Linear Scale

-

The high-speed, high-resolution capabilities offer the ability to withstand contamination which makes the ST1300 linear scale ideal for semiconductor positioning. The scale’s 12m maximum effective length with 8-m/s max response speed provides accurate positioning on large-stage applications as well.

FEATURES & BENEFITS:

- Outstanding robustness against contamination compared to earlier photoelectric types by using a new detection principle

- Choose between double-sided tape and tension mounting methods

- Signal validation PC program facilitates mounting adjustment and maintenance

- Absolute scales have eliminated the need for origin restoration and drastically reduced power consumption

- Extensive interface compatibility including FANUC, Mitsubishi Electric, Yaskawa Electric, Panasonic, Mitutoyo ENSIS standard interface

AT211 Linear Scale

-

The high-resolution, high-accuracy sealed AT211 linear scale is ideal for feedback control in positioning a semiconductor, manufacturing system, CNC machine tool, etc. The two-phase, square wave scale can be directly connected to a control unit.

FEATURES & BENEFITS:

- Scale alarm display LED allows for easy maintenance

- AT211-A model is a multiple-point installation type designed for improved resistance against vibration and shock

- AT211-B model attaches to a machine at both ends and is compatible with the AT111 slim type in size

- Linear encoder is suitable for control of semiconductor manufacturing systems and CNC machine tools

ST422 Linear Scale

-

The ultra-compact ST422 Linear Scale has an effective measurement length of 3000mm, making it ideal for use on large machines. It’s ultra-compact design allows the detector to be used in applications where space-saving is important.

FEATURES & BENEFITS:

- The maximum response speed is 5000mm/s. (When resolution is 1μm and the minimum edge interval is 125ns)

- Ultra-compact detector control unit allows use in applications where space-saving design is important

- The maximum effective measurement length of 3000mm enables use on large machines

- Simultaneous output of 2-phase square wave signals (maximum resolution: 0.2μm) and 2-phase sinusoidal wave signals (main signal: 40μm) is available

- LED display function for indicating signal errors

- Equipped with scale reference point output

ST46-EZA Linear Scale

-

The compact size and easy usability makes the ST46-EZA linear scale highly versatile for a variety of applications. The detector head is only 7.5mm thick, ideal for machines where a space-saving design is important.

FEATURES & BENEFITS:

- Effective measurement lengths for the ST46-EZA range from 10mm to 3000mm

- Detector head mounting and signal adjustment possible without oscilloscope or PC

- A setup indicator for checking signal strength is included

- I/F circuit integrated in connector shell reduces volume to 60% compared to conventional interface

- Self-diagnosis function with USB connectivity facilitates signal strength checking and parameter setup

- Glass and metal tape scales are available with the same features and functions

- The metal tape scale type offers a mounting surface area of 12.5 by 9.325 mm, allowing use in applications where a space is a premium

ST36 Linear Scale

-

The ST36 linear scale has a maximum effective measurement range of 3000mm making it ideal for use on larger machines. An LED alarm detects overspeed and sinusoidal signal anomalies to protect your machine and workpiece.

FEATURES & BENEFITS:

- Outputs two-phase sinusoidal wave signal, two-phase pulse signal and 1Vp-p at 4μm pitch for versatility

- High-accuracy type, 0.5μm class (effective range up to 300mm)

- Offers a thinner detector head (thickness 11.5mm)

- Along with the output specifications of 2-phase sinusoidal wave and 2-phase square wave, the output specification of 1Vp-p wave is available

PSU-200

-

The PSU-200 splits the sinusoidal signal output with Mitutoyo linear scales into a minimum of four and a maximum of 200 divisions. The signal is converted to a square-wave signal so that NC feedback systems, measurement control devices, etc., can be used with linear scales in order to achieve highly accurate positioning.

FEATURES & BENEFITS:

- Works with Linear Scales with the sinusoidal signal output

- Quadrature signal output conforms to EIA standard RS422-A

- Alarm function for detecting broken wires or short circuits in the detector, over-speed and fluctuation errors in the input signal from the detector

Optical Measurement

Profile Projectors and Optical Comparators

-

With a wide variety of sizes and projection lenses available, Mitutoyo’s line of profile projectors and optical comparators are ideal for almost any optical measurement application requiring high accuracy. Crystal-clear images and intuitive digital readouts make these instruments among the best in their class.

The measurement capabilities of Mitutoyo’s profile projectors, along with their digital readout protractor screens, allow for the easy measurement of a variety of workpieces without blurring, distortion or complex calculations. In addition, their day-bright surface illumination provides bright and clear images, reducing errors and operator strain.

FEATURES:

- Digital angle display

- Day-bright surface illumination

- Easy-to-read digital XY counters

- Available objective lenses with up to 100X magnification

Different projector variants available.

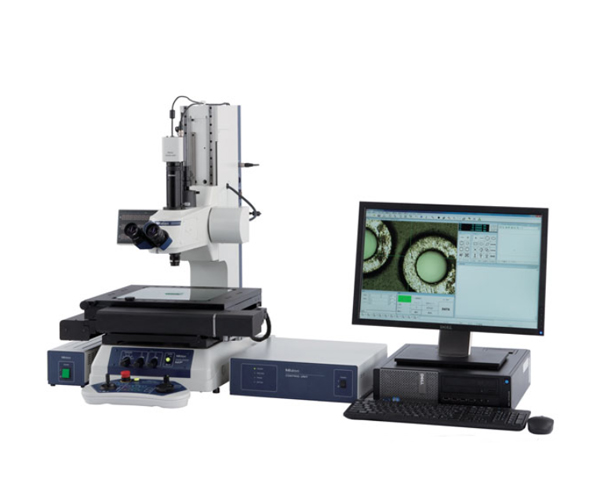

Microscopes

-

The measuring and toolmaker’s microscopes from Mitutoyo deliver the highest performance and accuracy in their class, enabling reduced part variation and measurement time. With automated focus capabilities and a wide range of available objectives, these instruments enhance practically any manufacturing quality control process.

Our industry-leading microscopes bring greater measuring speed, accuracy and reliability to a wide variety of optical measurement applications. Use our standard and universal measuring microscopes to harness one-click edge measurement and high-speed autofocus, or choose our toolmaker’s microscopes for powerful angle measurement with adjustable magnification levels.

FEATURES & BENEFITS:

- High-speed automated focus function

- Vision unit for one-click edge measurement

- Quick-release function

- Adjustable magnification and wide range of available objectives

Different microscope variants available.

Vision Unit

-

Retrofit your MF or MF-U microscopes with Mitutoyo’s vision unit. This system enables automatic edge-detection tools and graphics and measurement navigation functions. Using our vision unit, it’s possible to complete measurements in one simple step — and perform a series of measurement operations with a single screen display.

When you retrofit your microscopes with Mitutoyo’s vision unit, you can complete measurements of workpiece dimensions in one easy step. Operators can verify that measurement results are within the tolerance zones and perform a range of statistical analyses for each item. Results are output to a spreadsheet that functions as an inspection table on the same computer.

FEATURES & BENEFITS:

- Simple graphics and measurement navigation

- Verification of measurement results within tolerance zones

- Automatic edge-detection tools for one-step measurement

FS70 Microscope Head

-

The Mitutoyo series of FS70 microscope heads for semiconductor inspection function as optimum compact microscope units for semiconductor probe stations. Capable of magnifications up to 8,000x and working distances up to 34mm, our microscope heads are ideal for inspection and quality assurance applications.

Our FS70 finescope unit is compatible with YAG lasers and infrared optical systems. With an inward turret design and long working-distance objectives, our compact microscope units yield high magnifications for a wide range of semiconductor inspection applications.

FEATURES & BENEFITS:

- Ergonomic high-power units for semiconductor observation

- Available for a wide range of observations

- Compatible with infrared optical systems

Different Variants available.

Transmitted Light Video Microscope Unit

-

Mitutoyo video microscope units are lightweight, easy-to-install devices for CCD camera monitoring of semiconductor fabrications. With both standard and wide-field units available, as well as support for brightfield and darkfield observation, our VMU instruments take transmitted light video microscopy to the next level.

Mitutoyo transmitted light video microscope units are designed to connect infinity-corrected objectives to a C-mount camera for quick and easy setup of high-powered microscopy systems. They feature an in-line illumination port for maximum contrast and simple illumination compared to epi-illumination techniques.

FEATURES & BENEFITS:

- Compact, lightweight and easy-to-install units

- Ultra-long working distance objectives and correction

- Protection from thermal expansion

Different Variants available.

Infinity Corrected Microscope Objective Lenses

-

Mitutoyo infinity corrected microscope objectives provide flexible observation at high magnifications for observing even the most difficult-to-focus workpieces. Ideal for research laboratories and industrial metallurgical settings, a Mitutoyo objective lens has an image distance set for infinity, simplifying focus even with auxiliary components between the objective and the lens.

Mitutoyo infinity corrected microscope objective lenses have set the standard of excellence for long working distance microscope optics. Our objectives implement an innovative approach and plan-apochromat lenses that provide long working distance capabilities. Optimized for brightfield illumination, these objective lenses are ideal for in-line illumination applications.

FEATURES & BENEFITS:

- Longest working distances in the industry

- High-quality plan-apochromat design

- Brightfield inspection

Portable Optical Inspection

-

With a wide range of models and magnification options, the Mitutoyo portable optical inspection devices offer broad functionality and functions for fast, accurate measurement no matter where you need it — on the shop floor, in the field and anywhere you need the utmost precision.

From pocket magnifiers and pocket comparators to zoom and clear loupe tools, Mitutoyo portable optical inspection devices deliver exceptionally accurate measurements for many types of workpieces. Each unit is designed for maximum performance, and is manufactured from durable materials for reliable longevity.

FEATURES & BENEFITS:

- Lightweight optical tools for inspection

- Advanced functions for easy operation

Different variants available.

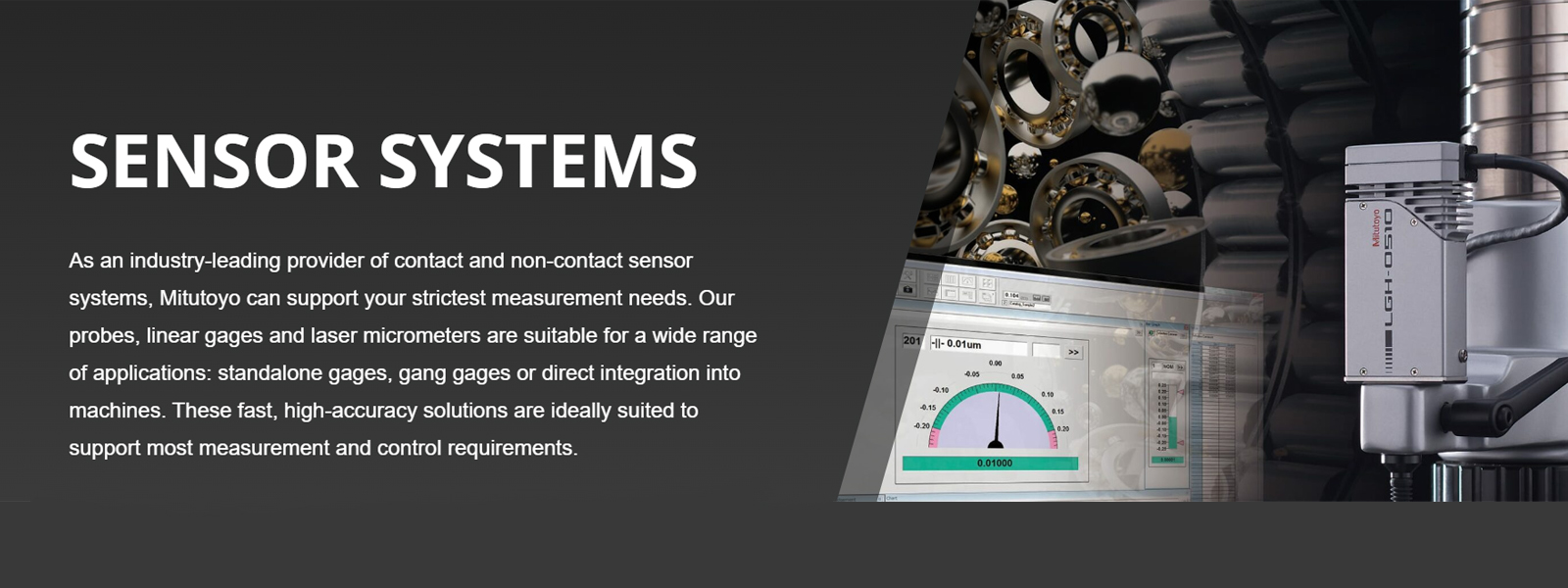

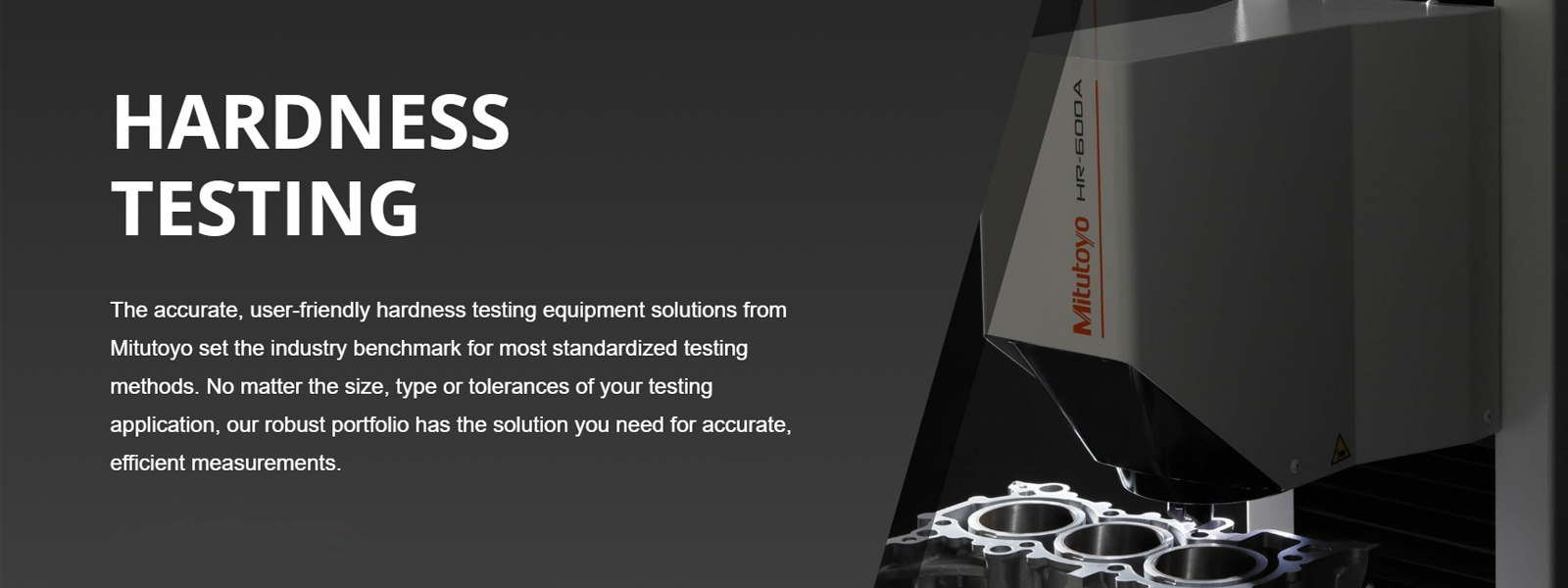

Sensor Systems

Surface Measure 0303S

-

The Surface Measure 0303S is a high accuracy and environment-resistant for inline measurement with high resolution (13 to 17 µm in X direction) and high measuring accuracy (1 σ = 9 µm). As with the SM1008S, the sensor itself is guaranteed for traceability and measurement accuracy.

FEATURES:

- High accuracy and environment-resistant sensor

- Supporting automated measurement

- Excellent operability simply by using a mouse

- Simple and intuitive interface

- Web-browser based, no need to install software

- Various built-in measurement

- 2D and 3D data can be obtained

Surface Measure 1008S

-

The Mitutoyo SM1008S is a high-accuracy, environment-resistant sensor designed for precise and efficient automated measurements. The sensor’s advanced capabilities include high-speed profiling and 3D shape measurement, with a maximum frame rate of 10 kHz, and an automatic judgement function that eliminates the need for alignment. Its built-in, user-friendly software allows for immediate use without installation, ensuring seamless operation right out of the box.

FEATURES & BENEFITS:

- High accuracy and environment-resistant sensor

- Supporting automated measurement

- Excellent operability simply by using a mouse

- Simple and intuitive interface

- Web-browser based, no need to install software

- Various built-in measurement

- 2D and 3D data can be obtained

Linear Gage / MU Checker Probes

-

Linear gages from Mitutoyo bring durable, reliable measurement to countless quality control applications. Whether you require one gage to measure linear displacement or several gages for multi-point contour measurement, our solutions offer exceptional accuracy and versatility.

FEATURES & BENEFITS:

- High-speed output, ideal for in-line or automated applications

- Longer measuring ranges than traditional probes and indicators: from .2" to 4"

- Resolutions from .001" to 1 nanometer

- High IP-rated protection against dust and fluid ingress

Different variants available.

Linear Gage Counters

-

With Mitutoyo’s linear gage counters, deriving accurate and usable data from linear gages couldn’t be simpler. Our counters support diverse output formats and measurement functions, providing clear readouts from either single gages or full multipoint measuring systems.

Our linear gage counters can provide reliable measurement readouts in a variety of output formats: digimatic, simplified analog for dynamic measurement or serial BCD for easy exporting to a PC. Suitable for normal measurement, peak measurement and differential measurement between multiple gages, our linear gage counters are flexible enough to serve a vast variety of applications.

FEATURES & BENEFITS:

- Zerosetting and presetting functions

- Fully compatible with SENSORPAK data indication and monitoring software

- Seven kinds of tolerance and limit value outputs

- 3-step/5-step limit output

Different Variants available.

Laser Scan Micrometers

-

Exceptional repeatability, accuracy, resolution and durability make these the ideal non-contact measurement solution for a wide variety of machined workpieces, including those that are too small or delicate for conventional contact measurement.

Our laser scan micrometer portfolio includes a rich assortment of models that measure a vast array of materials with ease. Our solutions are capable of measuring ultra-fine wires down to .0002″ / 5 microns in diameter, as well as larger cylindrical objects up to 6.3″ or 160mm (larger sizes possible with other accessories). Each model delivers high scanning rates and complete traceability, resulting in an exceptional level of accuracy and repeatability.

FEATURES & BENEFITS:

- High accuracy and resolution: accuracies down to .000012" / 0.3 microns

- High scanning rate up to 3200 scans/second

- Excellent durability and IP64 rated protection enclosures

- Improve gage R&R results between operators

Different Variants available.

Laser Scan Micrometer Display Units

-

Mitutoyo’s laser scan micrometer display units are versatile tools that provide statistical analytics supporting the precise measurements of our advanced laser scan micrometers. Whatever your application, we offer a display unit to make accurate measurements practically effortless.

Our versatile display units feature a dual-display design to make continuous monitoring of setup values quick and easy. In both standard and compact display units, two measurement value items can be displayed with a simultaneous measurement function, helping to streamline and optimize the entire measurement process.

FEATURES & BENEFITS:

- Dual-display design for easy monitoring of setup values

- Simultaneous readout of two measurement values

- Panel-mount and multifunction units

Different Variants available.

Small Tool Instruments and Data Management

Data Management

-

To achieve the full benefits of statistical process control (SPC) and maintain an accurate measurement database, you need a data management process that integrates with your network. By leveraging Mitutoyo’s data management hardware, software and advisory expertise, you can achieve a data management system that improves accuracy, production quality and your bottom line.

The data management hardware and software solutions from Mitutoyo are compatible with virtually any of our Digimatic solutions, from calipers, height gages, indicators and micrometers to Vision Measurement Systems and Coordinate Measuring Machines. Whatever your application, these solutions help ensure that each piece of measurement data is accurate and accounted for.

BENEFITS:

- Integrated data management

- Improved accuracy

- Greater Flexibility

- Easy Deployment

- Proven Reliaby

Explore our line of data management solutions, from our MeasurLink® and ITPAK® software platforms to our innovative U-WAVE wireless electronic data collection solutions.

Different variants available.

Micrometers

-

Since 1938, Mitutoyo has brought superior innovation and precision to the manufacturing of commercial micrometers. The first mechanical micrometer produced by our founder set the industry’s performance standards. Today, our latest developments continue to push the limits of speed, quality, resolution and accuracy — redefining what micrometers can achieve.

Our micrometer portfolio uses the latest advancements and proprietary technologies to increase speed, quality and stability of measurement. Thanks to these innovations, no other manufacturer can produce mics of our caliber.

BENEFITS:

- Faster measurement

- Unmatched resolution

- Greater repeatability

- Improved efficiency

- Powerful durability

Different variants available.

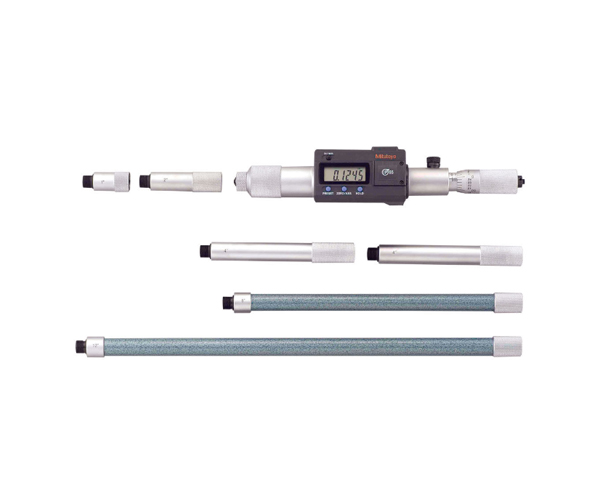

Inside Measurement

-

The inside micrometers and bore gages from Mitutoyo allow you to determine inside measurements with greater accuracy and less effort. With a full range of digital and mechanical models available, we offer the ideal solution for practically any application, including exceptionally small bores, long workpieces and blind holes.

With measurement ranges spanning from 2,000 mm to 2 mm — including difficult-to-access locations like blind holes — our solutions are highly effective and adaptive.

BENEFITS:

- Heightened accuracy

- Greater impact Resistance

- Flexible Measurement capabilities

- Simple operation

- Effective measurement for complex workpieces

Different variants available.

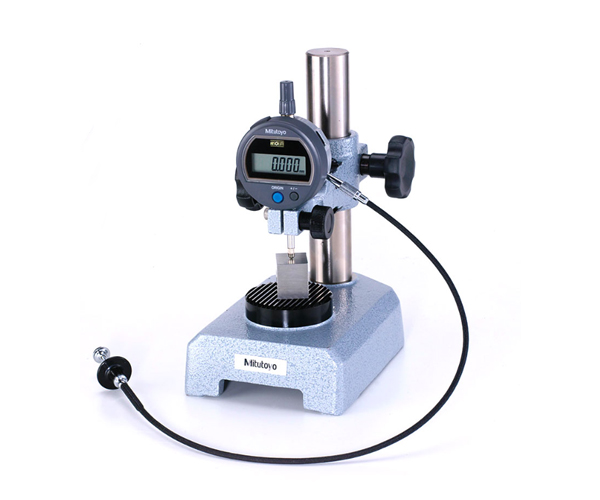

Height Gages

-

Mitutoyo is a leading developer in the field of height gages for the manufacturing industry. Our portfolio includes linear, digital, and mechanical options, all of which achieve unparalleled accuracy and precision for measurements in a wide range of manufacturing applications.

Digital and dial height gages from Mitutoyo are made to measure in a manufacturing environment. Designed to help with everything from first piece and layout inspection to tool setup and incoming inspection, they make two-dimensional measurements fast and easy with a single axis height gage.

BENEFITS:

- Exceptional accuracy

- Flexibility for a wide range of applications

- User-friendly Handling

Different variants available.

Depth Gages

-

Mitutoyo depth gages perform measurements of slots, steps, holes, and projections with a spindle that adjusts by rotating a thimble until the rod/beam connects with the bottom of the hole. When it contacts the bottom of a hole, a reading is shown either digitally or manually. The Mitutoyo depth gages have a fixed beam that can coincide with a dial indicator or digital display. Mitutoyo offers many different types and sizes of depth gages.

Every Mitutoyo depth gage and instrument capable of depth measurements are made with high-quality components to exact tolerances to provide highly accurate measurements. Data output with digital depth gages further promotes accuracy by inputting measurements directly into a computer or other processor.

BENEFITS:

- Versatility

- User friendly

- Exceptional accuracy

Different variants available.

Instruments & Reference Gages

-

Our reference gages are designed to help your metrology instruments maintain the industry-leading level of precision you expect from Mitutoyo. These solutions provide reliable, fully traceable accuracy checking and calibration across a number of requirements: length, height, straightness, thickness and many more.

Reliable accuracy checking is an essential part of the dimensional quality control process, and our fully traceable reference gages are the ideal solution. No matter which reference gage you select, your inspections and calibrations can meet the highest quality standards.

BENEFITS:

- Full traceability

- High accuracy

- Durable design

- Versatile Applications

Different variants available.

Calipers

-

Since 1938, Mitutoyo has been committed to producing high-quality, affordable measurement tools for manufacturing applications of all types. Today, Mitutoyo is the benchmark brand for calipers and other measuring tools.

Mitutoyo calipers provide the precise measurements needed for accurate machining and quality control. Our digital calipers are especially useful for quick and accurate measurements in a wide range of industrial applications, particularly in difficult-to-reach locations

BENEFITS:

- Accurate measurements

- Reliable operation in many environments

- Versatile values

Different Variants available.

Indicators

-

Mitutoyo develops digital, analog and test indicators that enable accurate, highly sensitive measurements of even difficult-to-measure features. With new usability enhancements and versatile models for a wide range of applications and measurement functions, our indicators are the natural choice for those requiring the greatest accuracy and reliability.

Our portfolio of digital and dial indicators offers maximum readability, even in adverse environments, and low-force and high-IP-rated models are available. Our dedicated indicators are ideally suited for calculation, peak-value and bore-gage applications, as well as detecting even the smallest changes in displacement.

Our test indicators feature one-piece movements for high impact resistance and durability, scratch and smudge resistance, anti-glare crystals and optional ruby tips for wear resistance. Dial indicators offer tough O-ring seals and bonded bezel and crystal, protecting from dust and oil ingress.

BENEFITS:

- Exceptional percision