- Offer Profile

-

Kardex is a leading global partner for intralogistics solutions in an attractive and growing market.

The group offers premium automated products, standardized systems, and life cycle services that guarantee high availability and low total cost of ownership. With dynamic storage and retrieval systems, Kardex enables an intelligent entry into automation, offers

integrated material flow systems, small parts storage, and automated high-bay warehouses, and acts as a global AutoStore™ partner with flexible and modular storage and order processing solutions.

The group employs around 2,500 people in over 30 countries. Kardex Holding AG has been listed on the SIX Swiss Exchange since 1989.

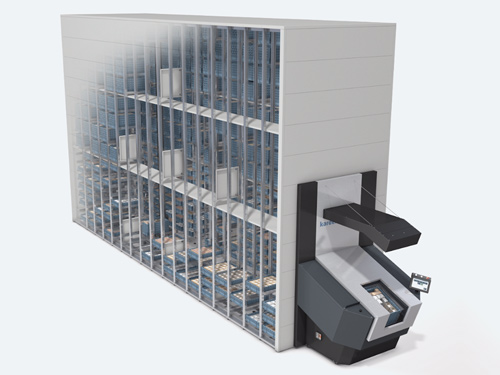

Vertical Lift Module

Kardex Shuttle

-

The Kardex Shuttle, part of the Vertical Lift Module (VLM) product family, features an enclosed shelf-based storage system designed to increase capacity in a more compact footprint.

Operating on the goods-to-person principle, the Kardex Shuttle increases productivity by delivering goods directly to an operator. These systems are modular and flexible in design enabling future adjustments for your business needs.

The new operating concept with extended features not only increases productivity, but also simplifies operation and reduces training and familiarisation requirements.

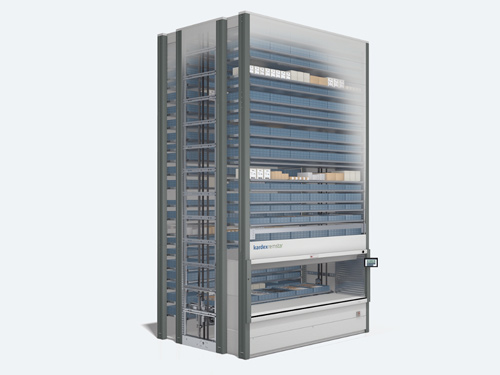

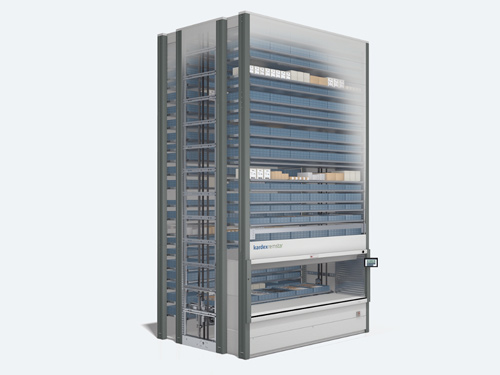

Miniload

Kardex Miniload-in-a-Box

-

The Kardex Miniload-in-a-Box, also known as the Vertical Buffer Module (VBM), is a high density storage solution suitable for small warehouses.

The Kardex Miniload-in-a-Box is an efficient solution for fast-growing product ranges with limited space. It works as a miniload system and flexibly stores, picks, and buffers small parts. Miniloads offer valuable benefits by maximising space utilisation at minimal costs.

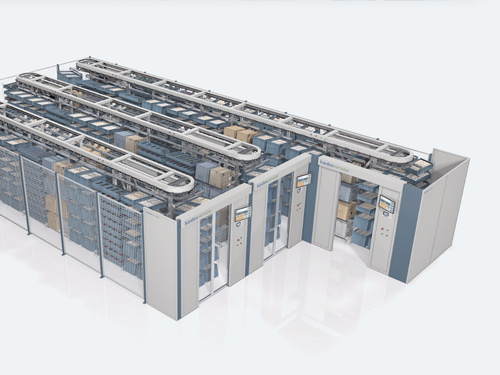

Miniload System

-

Maximise storage efficiency and reduce costs with our Miniload Systems — automated solutions designed for rapid access and high-performance storage in a compact footprint.

A miniload system is an automated storage and retrieval system (ASRS) designed for efficient handling and organisation of small unit loads. Our Miniload Systems are suitable for a wide range of applications, storing items in bins, cartons, or on trays. Stacker cranes manage all the storage and retrieval operations. Combining high-density storage with the ability to use full room height, these Miniload Systems provide excellent throughput and flexibility. With a height of up to 24 metres, they feature a variety of load-handling devices and provide single or multiple-deep storage.

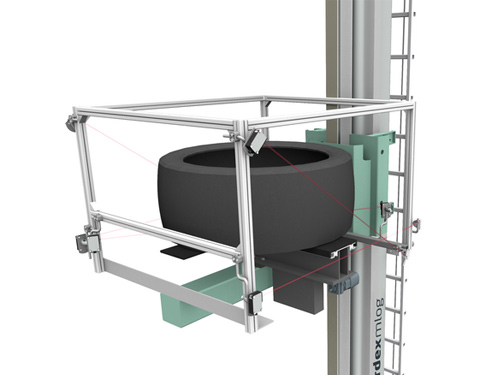

Bin Shuttle System

-

The innovative bin shuttle system offered by Kardex powered by ROCKETSOLUTION is an automated small parts warehouse designed to meet current and future needs. It dramatically increases warehouse capacity and performance while reducing costs.

Ideal for industries such as wholesale, retail, e-commerce, the manufacturing industry, and 3PL, this system delivers unmatched efficiency and scalability. Flexibly scalable in terms of dimensions and performance, the bin shuttle system is the perfect solution for automated small parts storage loads of up to 50 kg. The bin shuttle system impresses with maximum storage density, flexible scalability, enormous robustness, and simple integration.

Bin Conveyor Systems

-

Kardex offers bin conveyor systems as part of larger automated warehouse solutions. These conveyors help boost material flow, reduce manual bin handling, and optimise labour resources.

Bin conveyor systems transport all types of bins, cartons, and trays, adapting to your individual requirements to guarantee optimum performance and efficiency. Our portfolio includes both horizontal and vertical conveyor products, which perform multiple functions, including conveying, sorting, storing, and accumulating. These conveyors complement small parts solutions such as our miniload systems, the bin shuttle system, or the AutoStore system.

Carousel

Kardex Megamat

-

The Kardex Megamat, also known as a Vertical Carousel Module (VCM), is perfectly suited for goods with a high picking frequency and uniform sized inventory.

Using the paternoster principle the Kardex Megamat provides quick and precise access to stored goods. It is especially suitable for frequently accessed goods because it conveys the needed carrier to the access opening via the shortest possible path.

Kardex Horizontal Carousel

-

Maximise efficiency with the Kardex Horizontal Carousel, designed for fast, reliable, and cost-effective storage and retrieval of goods.

The Horizontal Carousel Module (HCM) works particularly well in facilities with low ceilings or double stacked to maximise capacity in facilities with taller ceilings. HCMs are ideal for managing medium and slow-moving SKUs requiring high throughput rates.

AutoStore™ Cube Storage

-

Cubic bin storage is a high-density storage solution that maximises space by using cube-shaped grids to store bins vertically. With AutoStore™ we offer a high-density cube storage solution that uses robots to store and retrieve bins. This flexible solution is suitable for companies of all sizes and industries.

As a global AutoStore partner, Kardex offers modular and flexible cubic bin storage solutions to fulfil orders quickly and efficiently. Each AutoStore solution is designed based on your operational needs and is fully validated through our simulation software. This ensures your warehouse automation solution will meet your demands and resolve operational challenges.

StoreX Calculator

-

Built for supply chain directors, operations managers, and facility planners - evaluate your AutoStore investment with data-backed cost and ROI insights.

Share your current operational metrics - such as number of operators, daily order volume, and SKU count - using the form below. This will help us better understand your operation’s performance.

Intuitive Picking Assistant

-

The Intuitive Picking Assistant (IPA) elevates picking processes of AutoStore™ solutions to the next level. By projecting all relevant picking information it guides the operator through the picking process.

High picking performance and quality are essential for efficient warehouse operations. The Intuitive Picking Assistant, compatible with various AutoStore™ Ports, enhances AutoStore™ solutions by streamlining workflows and minimising errors. This scalable solution meets evolving warehouse needs, optimising picking efficiency and accuracy while addressing labor shortages.

Kardex FulfillX Software

-

Simplify the operator experience and optimise AutoStore™ performance with Kardex FulfillX, the only purpose-built AutoStore software that extends your WMS without modification.

Kardex FulfillX is a warehouse execution system (WES) specifically designed to streamline operations and enhance performance for AutoStore, a leading automated storage and retrieval system. It is a purpose-built software solution offered by Kardex to enhance the utilisation of AutoStore robots, operators, inventory accuracy, and flexibility in the warehouse environment.

Software

Kardex Power Pick System

-

The Kardex Power Pick System optimises storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies.

Each year, hundreds of installations worldwide demonstrate the effectiveness of configuring and customising the Kardex Power Pick System. The basic package offers a comprehensive warehouse management solution, including user and account management, material handling, storage locations, bins, reports, and logs. For enhanced performance, users can expand functionality by selecting from a range of optional modules.

Kardex Control Center

-

Kardex Mlog’s modular software solution Kardex Control Center manages material flow and warehouse management processes faster and more efficiently.

From manual block warehouse and interface networking with intelligent partner systems to an automated intralogistics system connected to production lines and driverless vehicles, intelligent energy management for the automated stacker cranes and modern system visualisation, the Kardex Control Center modules offer flexible solutions for your warehouse management.

Optimise Warehouse Efficiency with Kardex Analytics

-

Your warehouse generates valuable data and Kardex Analytics helps you make good use of it. Get real-time monitoring, automated reports, and historical analytics to improve efficiency, balance machine loads, plan for peak demand, and optimise storage space. Eliminate manual reporting and make smarter decisions, faster.

By integrating with the Kardex Power Pick System, Kardex Analytics eliminates manual reporting and enables data-driven decision-making. Track order fulfilment times, machine utilisation rates, and inventory turnover trends to optimise picking performance, prevent bottlenecks, and reduce stockouts. Gain real-time visibility into warehouse activity and receive proactive alerts to minimise downtime and improve productivity.

Interface

Kardex Drive

-

Kardex Drive is a machine interface software solution designed specifically for organisations currently using SAP® solutions to manage their warehouse.

It allows an organisation to use their existing SAP® system to control their Kardex Remstar solution directly from SAP®. Kardex Drive is a plug-in for SAP® WM (warehouse management), SAP® IM (investment management) or SAP® EWM (extended warehouse management) modules.

Kardex JMIF

-

The Kardex JMIF (Java Machine Interface) is a powerful software solution designed to integrate our automated storage and retrieval systems with external systems.

The Kardex JMIF is a middleware layer that enables seamless communication between our ASRS solutions and other warehouse management systems, ERPs, or WCSs. This allows customers to control the locations, inventory, and workflows within their Kardex Remstar solution from an external system. With the Kardex JMIF, organisations can automate order consolidation, track inventory levels in real-time, and optimise their supply chain operations. By integrating our ASRS solutions with other systems, customers can reduce manual errors, improve accuracy, and increase efficiency.

Add On Technology

Mobile Data Entry (MDE)

-

Boost efficiency and mobility in your warehouse with the Mobile Data Entry (MDE) device, enabling real-time data entry and seamless integration with systems like the Kardex Shuttle and Kardex Megamat.

The MDE device replaces the stationary Kardex Power Pick System workstation. With the MDE, warehouse operators can use handheld devices to scan bar codes or enter product data. This information is transmitted wirelessly to a central database, enabling real-time inventory tracking, order monitoring and optimisation of logistics operations.

Wearable Task Assistant

-

The Wearable Task Assistant enhances the efficiency of your picking process by guiding the operator through each task.

This portable device makes the picking process even more efficient. Featuring a hands-free scanner, pick-and-place support, and a colour-coded wrist display it reduces errors, and enhances the overall quality of the picking operation.

Kardex Boxes

-

"Kardex Boxes" are customisable plastic bins designed to store and transport goods for a variety of industries; they keep items and available storage space structured and organised in your warehouse.

We have developed a wide range of special storage and transport boxes to match our systems to meet every customer's needs. Our dynamic box system gives you maximum flexibility to use the space available.

Kardex VLM Box

-

For the Vertical Lift Module Kardex Shuttle, we offer two box sizes, the Kardex VLM Box 800 and the Kardex VLM Box 850. Discover which best suits your needs.

The two Kardex VLM Boxes are designed to match specific VLM Kardex Shuttle tray sizes, making tray compatibility the primary factor when choosing between them. The Kardex VLM Box 850 is suitable for larger trays and is made from slightly stronger material, offering added durability. The Kardex VLM Box 800 is the right fit for smaller trays and is made from lighter material. Both versions offer modular flexibility in height, width, and depth and can be customised with a compatible base, frame, and up to eight dividers in various sizes.

Pallet Storage

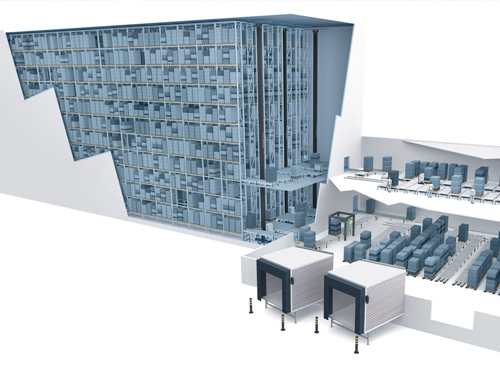

High-Bay Warehouse

-

With a height of up to 50 metres and providing single - or multi-deep storage, Kardex Mlog high-bay warehouses offer maximum flexibility and optimal use of available space.

Storage and retrieval, as well as material flow, are carried out via partially or fully automated processes. Depending on your requirements, our high-bay warehouses store pallets, cage boxes, and special load carriers.

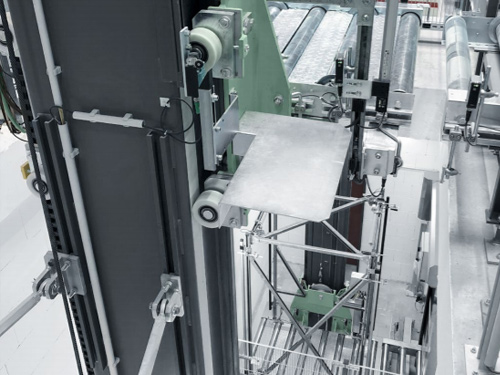

Stacker Cranes for Pallets and Miniloads

-

Stacker cranes take over the automated storage and retrieval of pallets and miniloads in the warehouse. Their high and compact design ensures efficient space utilisation in a high-bay warehouse and in a miniload system.

The overall performance of the warehouse logistics depends on the storage and retrieval machine. Therefore, when choosing stacker cranes, high quality and performance must be a top priority. The innovative stacker cranes from Kardex Mlog meet these requirements.

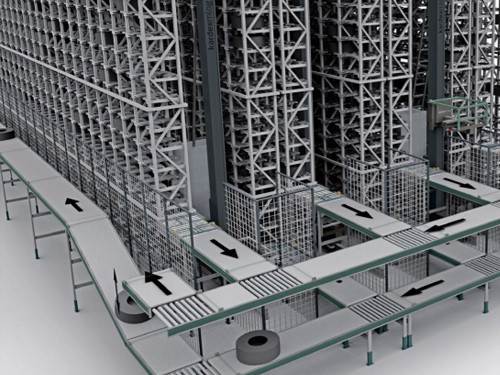

Pallet Conveyor Systems

-

Produced by Kardex Mlog, our pallet conveyors make up a customisable part of our flexible high-bay warehouse solutions. Made in-house by our experienced team, pallet conveyors ensure optimal material flow in large-scale warehouse environments.

Our pallet conveyors make up an essential part of our high-bay warehouse solutions ensuring the smooth movement of pallets, cages, and custom load units such as frames or panels.