- Offer Profile

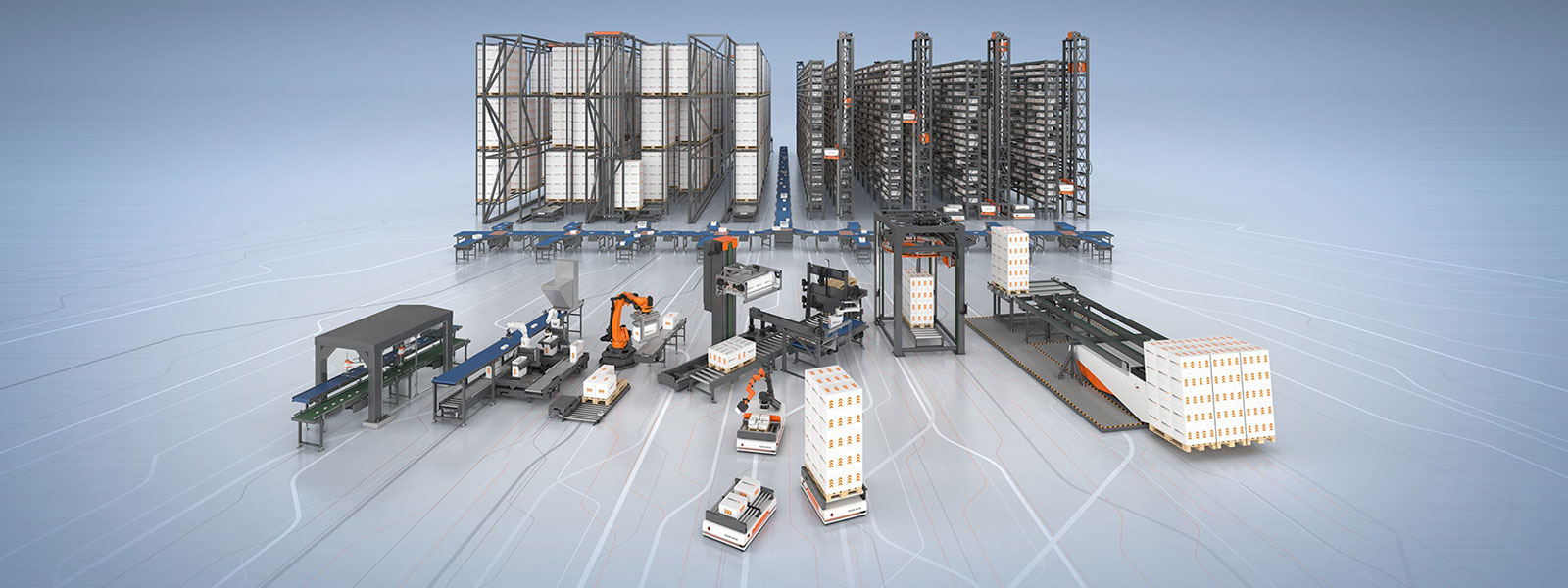

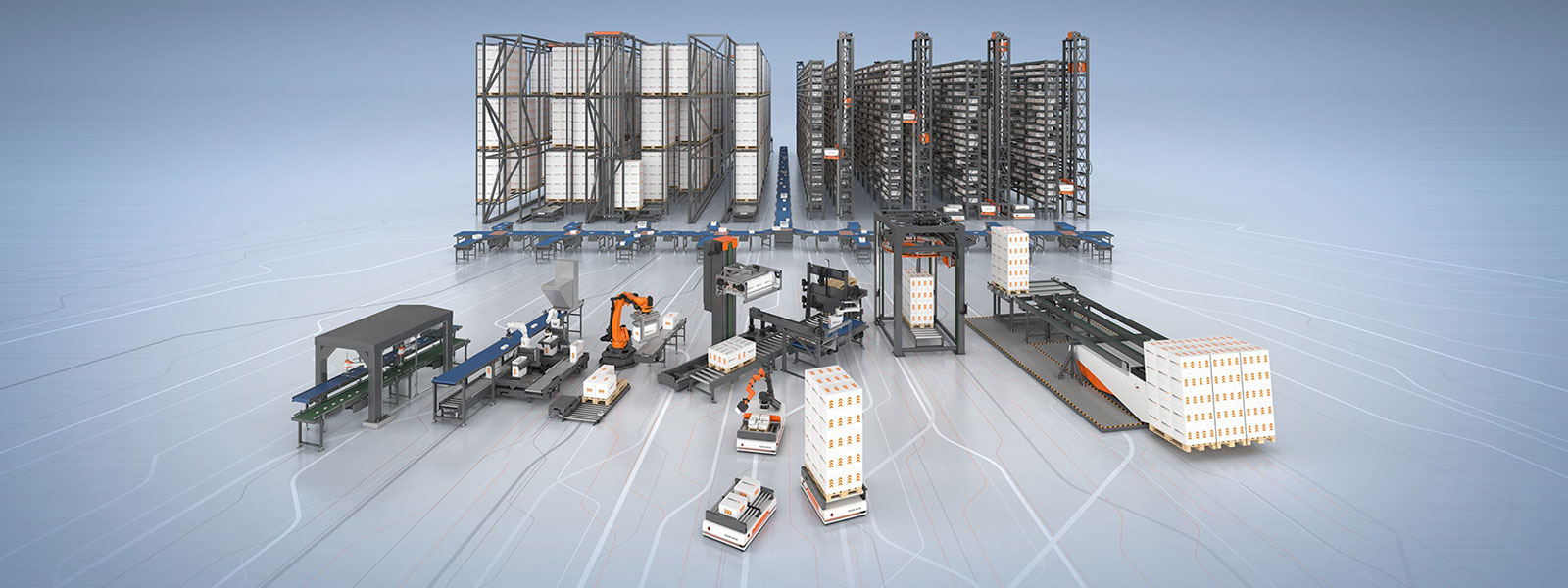

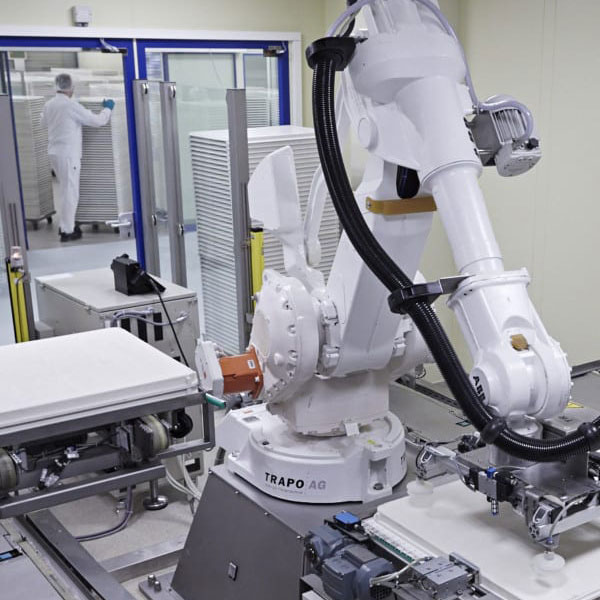

TRAPO – Your partner for automated intralogistics

TRAPO automates intralogistics processes with solutions for picking, packing, (de)palletizing, conveying, warehousing, sorting and distribution technology as well as loading and unloading. TRAPO deliberately strengthens supply-securing sectors such as the food and pharmaceutical industries, as well as the packaging and automotive industries.

1 System – 1 Control One contact for all needs: Developed in the TRAPO Technical Center, hardware and software for individual components, partial and complete lines are supplied from a single source. TIM, the TRAPO Intelligent Management System, enables all-round monitoring of 3-shift operation, control and continuous optimization of the entire line, and predictive maintenance.

TRAPO – Your partner for automated intralogistics

You have the choice: individual, partial or complete system

As a partner for automated intralogistics, TRAPO offers automation concepts for all industries. Cover your total needs in production and intralogistics via one central partner. The compact applications developed in the TRAPO technical center and installed worldwide are unique – based on a modular system. The focus is on components, partial and complete systems for every industry, especially the food industry, pet food industry and pharmaceutical industries, logistics, and the packaging and automotive industries.

Overall line concepts for new and existing systems are part of TRAPO GmbH’s self-image. Thanks to modular design, systems can be individually configured for the automation of intralogistics – and for every industry. 1 SYSTEM I 1 CONTROL: Hardware and software come from a single source. At TRAPO, customers have a fixed contact person who is responsible for the entire system project, from design to production to commissioning, and who also provides after-sales service – for the life of the machine.

Pick and Place

Precision and high performance for pick and place systems

In order to pick up and move products with repeatable accuracy, the use of pick and place systems is recommended. They constantly perform the same movement 24 hours a day at maximum performance and with absolute precision, thus ensuring consistently high quality, availability and cycle rates.

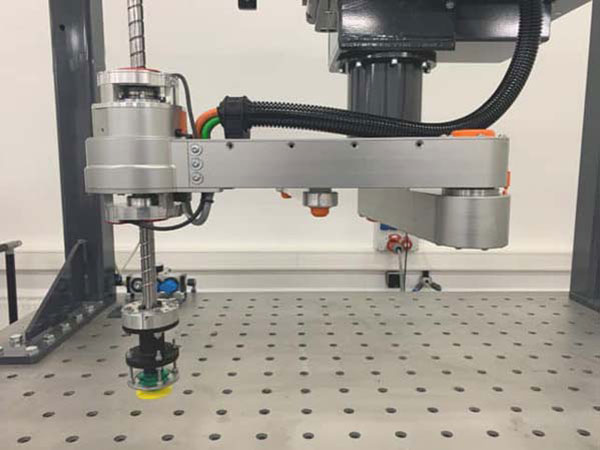

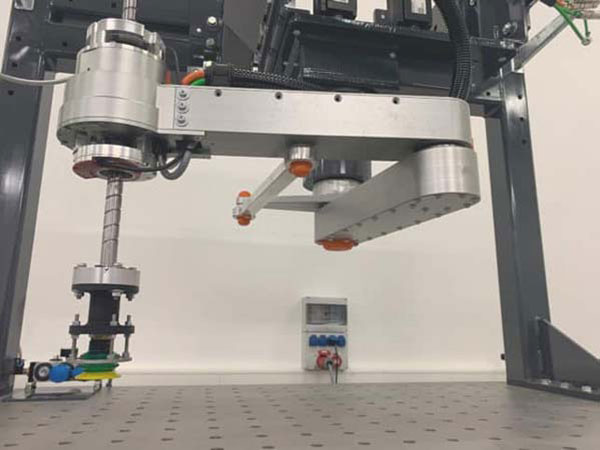

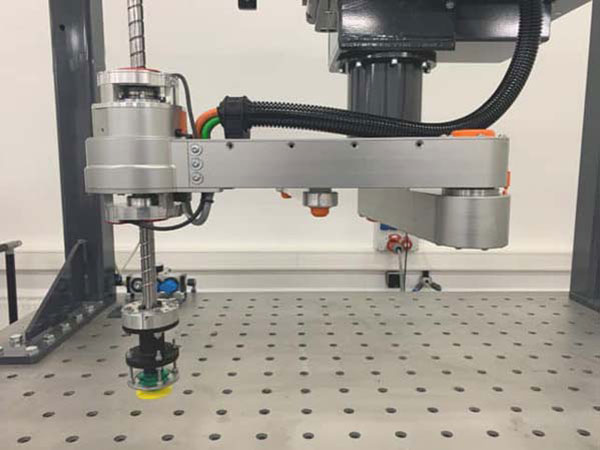

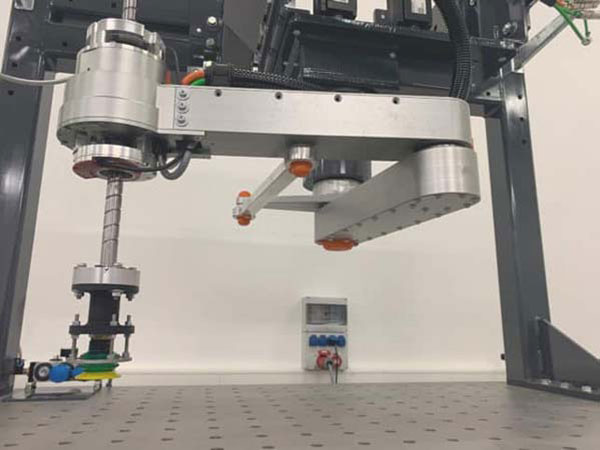

Kinematic-Picker

High-performance kinematic picker: innovative pick and place solution

Kinematics transcends limits and offers more possibilities for picker application. With enormous stroke and extended radius, the kinematics solution ensures consistently high process quality, machine availability and enormous cycle rates. The high-performance parallel kinematics consists of a five-member kinematic structure, a Z-axis and a rotary module for orientation. The modular system has an optional three or four degrees of freedom. Named for the high performance of the HPPS series, the high-speed pick-and-place system is used with up to 200 parts/min and with up to five kilograms of payload.

- 24/7 High Performance and Absolute Precision: The 3 payload classes of the HPPS series handle wet, dry or irregularly shaped food as well as primary and secondary packaging.

- Load class 1 kg: For small and very light products that can be picked up with a single suction cup.

- Load class 3 kg: For cylindrical bags or cans that can be either suctioned or gripped

- Load class 6 kg: Allrounder: for products that are either sucked or gripped (All payloads refer to gripper plus product).

High-performance parallel kinematics consists of a five-link kinematic structure, a Z-axis and a rotary module for orientation. Developed by teams from the TRAPO Technical Center.

Advantages

- Innovative gripper and kinematics from one source, one control software without internal interfaces

- Optional large radius of action (800mm) or large stroke (200mm)

- Kinematics replaces delta or articulated arm robots

- Output up to 200 picks/min.

- Payload up to 5kg

- Modular system

- In-house gripper development and production

- Picker cell can be expanded at any time

Picker with delta or articulated arm robots

Maximum freedom for pick and place applications. As a complete line provider, TRAPO designs and installs modular pick and place applications that combine components such as robots, robot grippers, frame units, camera systems and conveyor technology.

Advantages

- High flexibility and performance

- Modular system

- In-house gripper development and production

- Picker cell can be expanded at any time

- Special hygienic design

- Flexible feeding of trays

Mix tray formation with picker

Automated forming of mixed trays. Consumers take the choice on mixing trays for granted: a tray with six varieties of soup to choose from, a bar with 30 yogurts, or a tray with three varieties of instant coffee – they fulfill customer wishes at a glance. For the manufacturer, it used to be a challenge: employees manually packed mixed trays from single-variety trays according to instructions.

This is now done by the fully automated TRAPO picker line – adaptable to all industries:

- Articulated robots depalletize the single-sort trays and place them on the sorting line.

- Delta pickers pick up the cans one after the other and form them into the desired tray combination according to the specifications.

- A high-performance gantry inserts the tray combination into an existing tray.

- This is followed by palletizing of the mixing trays

Advantages

- Hardware and software for depalletizer robotics, gripper, picker line and palletizer from a single source.

- Sustainable solutions for multiple tray usage

- Flexibly adaptable to any industry

- Applicable to all performance ranges

- Modular system

- In-house gripper development and production

- Picker cell can be expanded at any time

- Automated forming of mixed trays

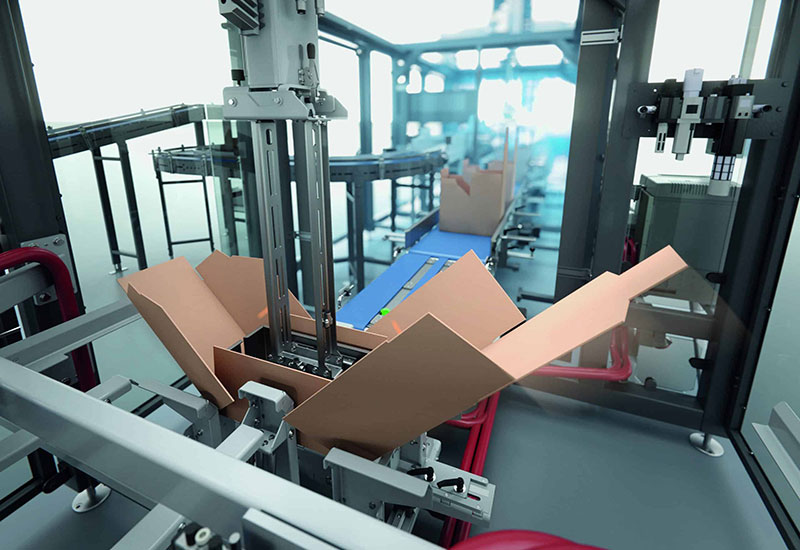

Carton Filling

Automated task: Pack primary-packed goods in carton

TRAPO GmbH also automates carton filling and the packaging process here: primary-packed goods are gently placed back into cartons at high-throughput – and thus optimally prepared for transport. The choice is yours: opt for conventional packing or the top performance of the TRAPO Packing System (TPS series).

High-performance packaging with perfect gripper

Goods are fed in an automated task via conveyor technology in series, pre-grouped or unsorted and packed 24/7 at high-throughput in the top-loading process. Key to the success of any robot application is the individual robot gripper technology: it influences the performance of the automated application; crucial when it comes to sustainably increasing and ensuring performance and quality. The picker application is oriented to the specified packing pattern. Individual gripper technology supports the respective packaging job. From its history, TRAPO GmbH is a partner of supply-securing industries such as the food, pharmaceutical and medical technology industries. Industry partners that require competencies in hygienic design. Picker cells, palletizing components and robot grippers can be designed by TRAPO in such a way that they can be easily cleaned during the daily cleaning processes. Thanks to in-house stainless steel production and more than 50 years of expertise, all components are supplied from his hand here as well.

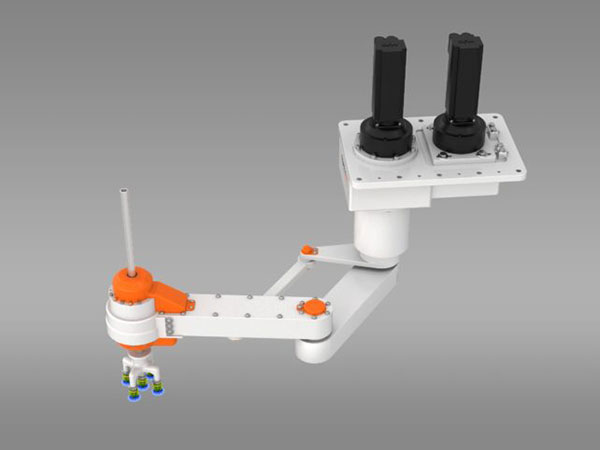

Carton Filling tith Kinematic

Parallel kinematics: Z-axis optimizes packing tasks. Carton filling with Kinematic: With individually-designed multifunctional grippers or vacuum cups, the kinematic picker of the TPS series (TRAPO Packing System) can pick up any products weighing up to 10kg to place them in cartons, trays or other containers.

TRAPO uses innovative high-performance kinematics for the further packaging of primary packaging. In the variant with a large radius of action, the picker has a rotationally symmetrical working space thanks to the parallel kinematic design and can reach far behind itself. The modular system can be used as a high-speed kinematic system with up to 60 parts/minute and payload up to 10kg. At high speed, it offers an enormous working space: optionally available with two strokes (200mm and 400mm).

Unique worldwide: Packaging with parallel kinematics. The high-performance parallel kinematics of the TPS series consist of a five-link kinematic structure, a Z-axis and a rotary module for orientation. With the help of a camera, the parallel kinematics detects the position of the parts. These are gripped or discharged in the NIO case.

Advantages

- Kinematics replaces the conventional application with articulated arm robots

- Up to 60 picks/min

- Payload up to 10kg

- Modular system

- In-house gripper development and production

- Axis drive by torque motors

- Picker cell can be expanded at any time

- Z-axis optimizes packing tasks

Standard options for carton filling

Picker application for high performance packing. TRAPO GmbH automates the packaging process: products are packaged at a consistently high speed without any loss of quality. Primary packed goods are handled gently and packed. Fully-automatic carton erectors and other accessories complement and optimize the automated loading of cartons.

On offer: models with varying outputs, for different carton formats, with side flap spreader as well as glue-closure of the carton bottom or adhesive tape dispenser.

Advantages

- Kinematics replaces the conventional application with delta or articulated-arm robots

- High flexibility and performance

- In-house gripper development and production

- Picker cell can be expanded at any time

- Special hygienic design

- Flexible feeding of trays

ECO-Box Packaging System

Shelf-Ready Packaging: A Trend with Many Advantages for Attractive Product Presentation

More and more single-family households are turning to the handy pouches – for convenience products or pet food, for example. Retailers also appreciate the advantages: the goods are quickly opened and ready to be presented in a clearly arranged box – there is no need for cumbersome storage of individual goods. TRAPO engineers put the idea to the test. The result is an innovative, highly flexible generation of machines that is particularly convincing in the area of sustainability.

Gentle product handling with suction pads

- While in competitor machines a fork gripper pushes several product bags into the box at the same time, with TRAPO each product is sucked in individually using a pick and place solution and gently placed in the box.

- The type of packaging itself forms the advantage: with standard two-part packaging, the lid ends up directly in the waste – the layout of the Eco-Box does without the lid and has low waste – at this point, up to 25% cardboard material can be saved!

- Alternative wrap-around formats have a tear-open perforation that leaves a messy cut when opened. The Eco-Box is different: the tear area is clean, the perforation is not visible and is turned away from the customer’s view.

Advantages

- Savings of 25 % resources / cardboard packaging

- More flexibility, fewer format changes

- For shelf-ready cartons and other carton packages

- Short changeover times

- Higher pallet utilization

- Low maintenance costs

- Camera-assisted troubleshooting

- Instructions for format changeover via video tutorial

- Preventive maintenance with tim (trapo intelligent management system)

Palletizer

TRAPO palletizers: high efficiency and transport safety

Our robotic applications and palletizers optimise your palletizing and depalletizing processes in the long term, secure your products for intermodal transport and are adapted to the specified production environment in terms of mechanical and control technology. Depending on your product, you decide which palletiser is right for you: layer palletizer, robot palletizer or a gantry with which you can lift even the heaviest goods. With the help of individual robot grippers, the palletizing performance is optimally adapted to different packages and load carriers of all industries – regardless of shape, dimensions and surface condition. It goes without saying that palletizers feature a high degree of automation and simple operation, which ensure trouble-free operation. Flexible, reliable and efficient, TRAPO’s high-performance palletizing systems also adapt to frequently changing products and packing patterns.

What tasks does a palletizer perform?

Optimal palletizing technology forms the reliable basis for safe goods dispatch. After layer formation, TRAPO palletizers offer a solution for every industry: precise handling, gentle on the product and always with exact stack formation. The flexible palletising technology of the TRAPO layer palletiser is not only recommended for every product, but also for every working environment. Our palletizers operate in an energy-saving and low-noise manner. TRAPO palletising technology is appreciated by operators for its easy handling and high performance.

What is a layer palletizer?

Automatically controlled layer palletizers can palletize large volumes of cartons, sacks or totes at maximum performance – the TRAPO sales team will be happy to advise you! A layer palletizer is easy to operate and highly flexible. With the layer palletizer, the complete layer is prepared according to the specifications and placed on the pallet in one step – layer by layer, until the desired stacking height is reached.

What is a palletizing robot?

Fast cycle times and consistently high quality: palletizing robots are part of everyday production in automated environments. With gantries, high payloads can be palletised, while the jointed-arm robot can be used flexibly at any position. They are completed with robotic grippers – especially efficient multifunctional grippers that eliminate the need to change grippers and thus save additional time.

Automated guided vehicles plus palletizers

Our automated guided vehicles of the TTS series can be equipped with attachments depending on the order. For example, with MRK robots for palletizing. MRK stands for human-robot collaboration and means that man and machine work together and side by side without a safety fence. In this way, we combine two requirements in one system: spatial flexibility and high palletizing performance.

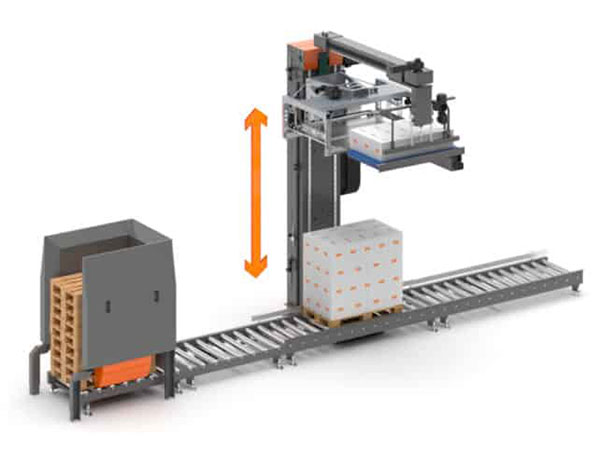

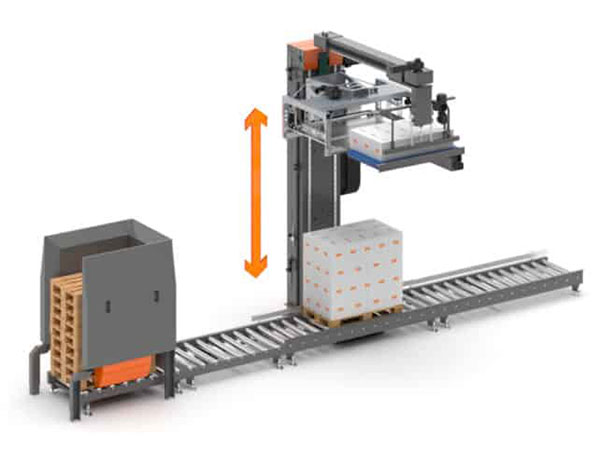

Layer palletizer

High-performance layer palletizer impresses in the tightest of spaces. With the HLP 6000 high-performance layer palletizer, TRAPO is presenting a modular system that can be adapted to any space situation and that acts flexibly in terms of product and industry at any position within production. The compact layer palletizer deposits perfectly and realizes any layer patterns of different formats – up to ten layers per minute.

The HLP 6000 serves an almost unlimited product range: highly flexible, as it can be adjusted to any product. This means that perfect, clean layers and piles can be formed under maximum performance with a wide product variety from the customer and different formats. With this considerable advantage, the HLP shows off its unique selling point, absolute flexibility: Until now, a great deal of modification work was required to implement complex layer patterns. The basic modules of the HLP 6000 are the lifting column, the layer gripper and the infeed section. The HLP 6000 is available in three variants:

Advantages

- Small footprint

- Extremely compact palletizer

- Modular system

- Multiple infeeds

- Bottom/top infeed

- Wide range of layer pad designs

- High speeds

- Possibility of palletizing on several palletizing stations

- Palletizing capacity of up to ten layers per minute

- Clean pallet image due to centering of the products in the gripper

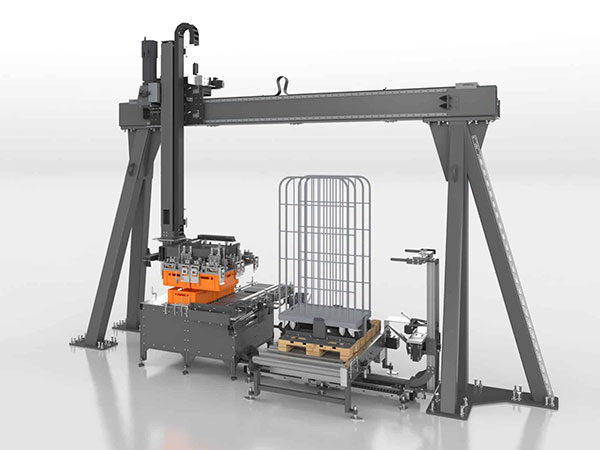

Gantry robots

Powerful robots: high-performance portal systems. High-performance portal systems from operate on two or three linear axes in cubic space. The gantry robots are designed and manufactured in the company’s own production facility in Gescher-Hochmoor.

Portals show their strength, for example, when heavy parts within a line are lifted across the entire work area in a way that is gentle on the product and material, in order to pass several machining centers. TRAPO is a specialist in portal robots from its own stainless steel production, developed and produced for special applications in areas with special requirements for hygiene and corrosion resistance.

Portal palletizers operate over production lines Powerful portals lift the heaviest workpieces. As a result, no additional space is taken up for industrial palletizers within given production. TRAPO portals reliably perform palletizing and depalletizing tasks for various stackable workpieces. Their height is adapted to the spatial conditions. The portal palletizers move at dynamic speeds that are gentle on the product when picking up and placing high payloads from the conveyor line. Different, individual robot grippers are possible in combinations for the portal palletizer – developed by TRAPO for the respective task.

- gentle product handling

- suitable for various packages and load carriers

- large working space due to cartesian axes

- flexible in length, height and width

- on request: suitable for clean rooms

- higher weights can be realized as special design on request

- intermediate layer designs

Robot palletizer

Articulated arm robots: high-performance robot systems 4- or 6-axis jointed-arm robots operate flexibly: The high-performance systems palletize, sort, load, charge, and pick single pieces, rows, partial layers, or complete layers quickly and with high precision.

TRAPO’s High Speed Robot Systems (HRS series), articulated robots mounted on rails or automated guided vehicles, provide the decisive plus in flexibility. They move to different palletizing stations on demand and, depending on the application, can be MRC-capable.

Robotic palletizers provide support within the production line. Palletizing robots provide consistently high performance – and in the process make the first, important contribution to securing palletized loads so that goods survive intermodal transport undamaged. Articulated-arm robots offer probably the most economical way of safely palletizing goods – especially cartons. The basis is a standard industrial robot that is individually equipped with TRAPO gripper technology. In order to sustainably increase production, the robotic palletizer can be implemented in existing production architecture. It is adapted to the respective palletizing task, different payloads and containers.

Advantages

- Low space requirements

- For different applications

- Flexible use

- For different packages and load carriers

- Gentle product handling

- Freely-selectable layer patterns

- Placed on rails or agvs, the jointed-arm robot moves to different palletizing stations

- On request: suitable for clean rooms

Gripper technology

The perfect gripper for every product. The handling of objects is the central task of the robot systems. The robot grippers used are precisely adapted to the object’s properties – gripper technology is developed and tested in the TRAPO technical center. The use of the optimal gripper developed by TRAPO is crucial when it comes to sustainably increasing performance and quality.

Key to the robot’s success is individual gripper technology. TRAPO offers maximum flexibility when it intelligently automates intralogistics tasks – in the perfect interplay of conveyor systems, robots and customized gripper technology. Product-specific gripper technology perfects the application possibilities, function and performance of a robot system.

Feeding and layer formation

Precisely distribute products and form layers Precise layer formation is the basis for ensuring that loads are optimally secured on their journey to intermediate storage or in intermodal transport to their destination. A wide variety of products are moved and precisely positioned depending on their nature.

The automation of partial and complete systems requires adjustments in the effectiveness and performance of palletizing tasks. In the in-feed area, depending on the product and the task, the flexible, omnidirectional OMNI CON® table, the high-performance parallel kinematics of the HKS series with intermittent conveyor, or conventional methods form the layers as a preliminary stage to palletizing.

Once the layer pattern and product dimensions have been specified, the kinematics and OMNI CON® program themselves – thanks to TRAPO’s own software. With this considerable advantage, the HLP shows its unique selling point, absolute flexibility: Until now, a great deal of modification work was required to implement complex layer patterns. The basic modules of the HLP 6000 are the lifting column, the layer gripper and the in-feed section.

Equipment options for palletizers

Optimal securing of pallets through additional options. Whether it’s a short transport route or intermodal transport: We create the conditions so that your products are optimally packaged for their journey! Before transport by truck, rail or sea freight in a container, the goods stacked on pallets must be secured.

The basis for this is careful layer formation, followed by exact layer formation before the pallet load is secured against external influences by the wrapper. The layer pattern is based on the requirements of the product and the industry. Benefit from numerous equipment options and customer-specific additional modules for our palletizers. The range of load-securing equipment is supplemented by additional modules that enable the traceability of goods. TRAPO load-securing ensures optimal securing of the load through various transport securing systems – with minimal use of film. TRAPO convinces in pallet handling with worldwide expertise – choose between different, coordinated modules in the additional options!

Benefit from our numerous equipment options and customized add-on modules:

- Pallet handling

- Layer detection

- Bag racking

- Empty pallet magazine

- Layer pad applicator

- Gluing system

- Scales

- Metal detectors

- Labeling systems

Advantages

- Tailored to product and industry

- For all transport modes

- Traceability of the goods

- Various transport security

- Resource-saving

- Worldwide expertise

High-Speed Depalletizer

From manual operation to a fully automated depalletizing system. Until now, depalletizing has often been done manually – automating this activity enables stable, safe operations with consistently efficient production processes. A depalletizer as an integral part of an automated line works reliably in 24/7 three-shift operation. High-speed depalletizers complete automated production lines. This is because products are not only stacked on pallets, they also have to be unpacked and removed at a constant rate. This is a time-saving intralogistics challenge that is geared to the product and the subsequent task.

High-Speed Layer Depalletizer: six layers/minute The High-Speed Layer Depalletizer (HLDP series) combines several innovations at once: Its output of up to 90,000 empty cans per hour is impressive. Thanks to its modular design, the HLDP can also handle jars and bottles in the same way. This innovative solution is impressive thanks to the use of a lifting column in combination with a magnetic or vacuum gripper, thus enabling the efficient depalletizing of empty food cans (tinplate/aluminum) or empty jars – at a rate of up to six layers per minute. This corresponds to around 1,500 empty cans per minute. A safety innovation in this performance class: the depalletizer is operated completely at ground level – a second operating level by means of a platform is avoided.

Advantages

- Output: up to six 6 layers per minute

- For empty cans (tinplate, aluminum) and empty jars

- Modular system

- For empty glass: no broken glass in further production due to vacuum

- Level operation

- Pallet formats: all common formats (euro, industrial, chep etc.)

- TTS ready shuttle connection

- Sustainably increase depalletizing performance for empty cans and jars

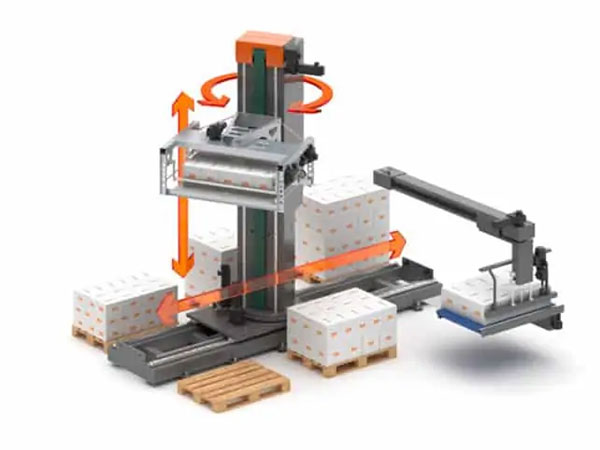

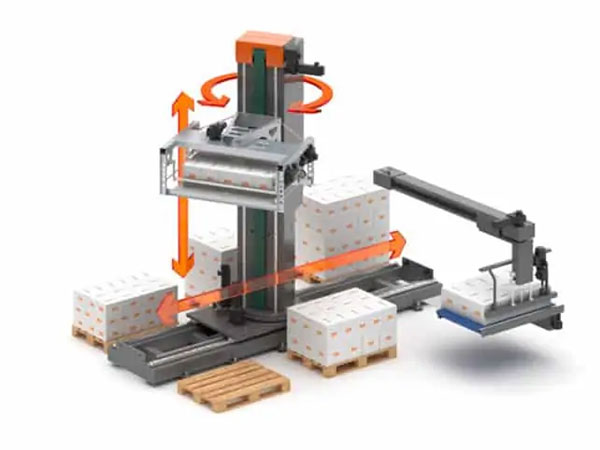

Load Securing

Strong hold – low film consumption: Wrapper for pallet load. The TRAPO Stretch Wrapper (TSW series) enables fully-automatic, sustainable securing of palletized cargo. While the pallet is stationary, the film is wrapped around the load at high speed.

After pallet-feeding, the wrapping cycle starts automatically. The machine is designed for continuous operation with very high wrapping capacity – for users with equally high levels of requirement. The Stretch Wrapper provides perfect fixation of goods stacked on the pallet – with minimum film consumption. It allows flexible applications with different palletized goods. Thus, adapted programs can run one after the other with fluent transition. On request, the machine can also be equipped with a holding mechanism for unstable goods.

Advantages

- High packaging capacity

- Increased packaging output due to the use of two pre-tensioning devices

- Low film consumption

- Strong hold

- Integration into conveyor lines

- Neither the pallet nor the goods are subjected to dynamic forces

Autonomous Systems

Safe, efficient intralogistics: driverless shuttle plus autonomous loading and unloading. The central benefit of modern intralogistics is optimized safety through efficient automated processes. TRAPO uses autonomous systems in combination for loading trucks or containers with pallets. Automated, driverless pallet transfer between production and loading ramp is handled by shuttle swarms.

Autonomous Systems: Protect and relieve personnel in the transport sector The innovative TRAPO Loading System (TLS 3600) is a high-tech vehicle with laser scanners for detecting the truck’s contour, which thanks to rear-wheel steering is able to automatically compensate for slight tilting of the truck. In combination with automated guided vehicles (AGVs), it replaces forklift transports between production, warehouse and loading zone. This automation relieves personnel in the transport sector, increases safety and requires little space. This is because the TLS – optionally placed on rails or moved by the TRAPO Moving System (TMS series) – can serve several hubs.

Autonomous truck loading and unloading

TRAPO closes safety gap between warehouse and loading bay. Autonomous truck loading and unloading: By dispensing with forklifts in the warehouse and loading area, TRAPO GmbH defuses this danger zone and realizes the handling of goods with the TRAPO Loading System (TLS 3600) in terms of effective overall logistics safely and with short distances.

The compact, autonomous TRAPO loading system is unique in terms of function and design. The TLS 3600 gets its name from a special feature: It loads three pallets of 1,200 kg each, i.e. 3,600 kg, in parallel in a single operation. Autonomous loading takes place in three central steps. First, up to three pallets are placed next to each other in a row on conveying technology (step 1) and aligned. This is followed by picking up (step 2) and loading of the row (step 3). During the loading process, another row of pallets is formed and provided on the stationary part. A continuous process that saves time and distance and avoids waiting times during pallet loading. Unloading takes place in reverse order.

Advantages

- Safety at the loading bay – no need for forklift trucks

- Fully automated for truck loading and unloading / for any industry

- Autonomous regulation of the position before and during truck entry

- Reduction of loading time up to 30 minutes (depending on the load/14-meter trailer with 33 pallets pick-up)

- Closes safety gap between warehouse and loading bay

Automated guided vehicles

Automated guided vehicles with customized structure. The use of automated guided vehicles such as the TRAPO Transport Shuttle (TTS series) makes it possible to move pallets flexibly from production or the warehouse to the loading bays. At the same time, the entire area remains free of rigid conveyor technology, enabling flexible use of the space.

The TRAPO Transport Shuttle (TTS), for example, transports loads weighing up to 2000 kg and can be equipped with customer-specific attachments such as an additional conveyor or integrated lifting function, depending on the company’s needs. The Transport Shuttle offers a choice of inductive, autonomous or optical navigation – and thus the widest possible range of applications.

Shuttle plus HRI competence. The combination of an automated guided vehicle and a cobot promises maximum flexibility. Two requirements of the packaging industry are combined in one system: Equipped with an MRK robot, the TRAPO Transport Shuttle (TTS series) is spatially absolutely flexible when the robot is used as an additional hand of the human colleague. It conveys, (de)palletizes, forms exact layers and packs.

Advantages

- Replaces and complements rigid conveyor systems – more space and flexibility

- Various designs, loads and speeds

- Modular system

- Control and traffic light function via tim, the trapo intelligent managementsystem

- Capacity increase via additional TTS, warehouse shuttle and lift

- Special design hygienic design

- Single application and as a swarm or fleet

- Mechanically one structure, control-technically one system

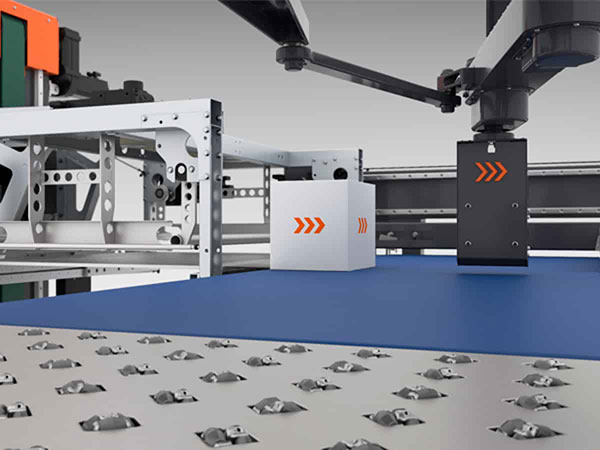

Sorting and distribution technology

High-performance sorter: direct routes between warehouse and loading. Modern sortation and distribution systems act at the heart of distribution. With the TRAPO Omni Sorter (TOS Series) and the TRAPO Sphere Sorter (TSS Series), TRAPO offers two highly-flexible solutions that help maintain supply chains without disruptions even in challenging times.

Sorter systems control complex flows of goods In a globalized world where producers and end consumers are often separated by continents and time zones, logistics plays a crucial role. Only with well-functioning distribution is it possible for complex transport chains with various (intermediate) stations to interlock seamlessly. The use of sorters is always advantageous when product units originating from one or more sources have to be distributed to one or even more destinations. In distribution centers, sorters point goods in the right direction, ensure an uninterrupted flow of materials and perform connecting functions in the logistics process chain. With their help, goods can be separated according to orders, sorted, brought together and finally assigned to the right destination.

Application range of flexible sorter systems Direct routes between warehouse and loading: Thanks to their modular design, TRAPO GmbH sorter systems can be optimally adapted to given on-site conditions. They offer flexible and multiple configuration possibilities within the production areas. The result is an optimal use of space and a smooth onward transport of the goods. Areas of application include goods-receiving, for example, when unloading trucks or containers for onward transport of products to the warehouse, the order picking area for batch picking, and the goods issue area for tour compilation and truck loading.

TRAPO Omni Sorter

TRAPO Omni Sorter as a connecting element between conveyors. The TRAPO Omni Sorter (TOS series) is a convincing sorter system that combines different components: The TOS plus upstream and downstream conveying systems, for example curves or 45⁰-winding.

Its name is derived from the high throughput of up to 5000 packages per hour. As a connecting element between conveyor sections, the TRAPO Omni Sorter can discharge products on both sides. Goods that pass through the TOS are either transported onward by its rollers or discharged by swiveling the rollers to the left or right at an angle of 45⁰ or 30⁰. Depending on the application and product, the modular design allows multiple configuration options within given production areas. Depending on product dimensions, the pitch and overall dimensions can be adapted to customer requirements.

Advantages

- Easy replacement of modules for maintenance

- High-precision discharge of conveyed products

- High-flexibility conveyors with little space requirement

- Table size is adapted to the customer’s needs

- Modular system

- Package capacity of up to 5.000 packages/hr.

- Moves, positions, orients and rotates products simultaneously and independently in any direction

TRAPO Sphere Sorter

Precise forwarding with one meter of travel per second. With the TRAPO Sphere Sorter (TSS series), TRAPO offers a precise sorter for forwarding, turning, distributing and ejecting packages. The basis is a conveyor belt in which spheres are incorporated.

When the ball chain runs from left to right during operation, the balls run with it. This movement results in doubling the speed at which the material is transported on the belt. The TRAPO Sphere Sorter ensures precise forwarding, rotation, distribution and ejection of packages of various sizes, such as boxes and parcels. It can flexibly rotate and distribute the transported goods to multiple outlets at a speed of up to one meter per second. The sorter can be implemented in any width and length and requires a comparatively small area, as it combines several functions.

Advantages

- One meter of travel per second

- Distributes and discharges products from multiple in-feed and out-feed lines

- Any widths and line lengths

- Small space requirement: different functions on one area

- Modular system

- Small pitch of the balls (25.4mm): conveys even very small products from 75 x 75mm

- No limit to the number of articles that can be moved side by side

- Moves, positions, orients and rotates products simultaneously and independently in any direction

Robotics

Use Smart robotics or industrial robots. Smart robot applications and systems from TRAPO GmbH optimize production and intralogistics – also through the use of cobots. Depending on the product, industry and task, differentiated pick and place systems, jointed-arm robots or gantries are used. The key to the success of robotics is the combination with multifunctional robot grippers.

Cobots

A strong team together: humans and robots. Instead of replacing employees, the declared goal of TRAPO is to use cobots as an additional hand to the human colleague and to sustainably relieve employees, especially in monotonous or dangerous tasks.

Our vision is to improve the living and working conditions of the future with modern automation solutions. In doing so, human–robot interaction revolutionize cooperation within production process by isolating sources of error. When humans and robots perform assembly work together, this optimizes working conditions within production process – and subsequently increases efficiency, flexibility and safety.

Advantages

- Assistance robots recognize humans and grip “hand in hand” – without presenting a risk of injury

- Robots act on mobile tool trolleys of the TTS series

- Docking to manual workplaces

- Humans and robots work at a strong team together

Conveying systems

Conveyor technology for every task. As diverse as the workpieces, products and production lines, is our cross-divisional portfolio in the field of Conveying systems, with which we efficiently and flawlessly answer every task for every industry.

TRAPO grew up with expertise in materials handling technology to this day, we supply customized elements of materials handling technology for every task in order to sustainably optimize the flow of materials in production and intralogistics. The solutions are based on the tasks of the industry-with special expertise for conveying in clean-room environments. Get to know and appreciate the latest generation of conveyor technology: Modular belt conveyors, transfer conveyors, all-side roller conveyors, discharge and distribution stations, rotary and collecting tables, belt conveyors, chain and belt conveyors, slat-band conveyors, roller and vertical conveyors, and empty and full pallet conveyors.

Advantages

- Conventional, autonomous or combination

- Customized elements

- Individual, cross-product and cross-sector solutions

- Special designs in hygienic design

Warehousing

Optimized warehousing through flexible transport systems. With the increase in the degree of automation, the importance of flexible load carriers is growing. Logistics companies and warehousing operators are using autonomously functioning, in-plant transport systems that independently organize their route and fill shelf spaces.

The TRAPO Transport Shuttle (TTS), the TRAPO Warehouse Lift (TWL) and the TRAPO Warehouse Shuttle (TWS) act together as a trio and can be used in combination. As a flexible transfer unit, the TTS takes over internal goods transports – and transfers to the TWL and the TWS in the area of the high-bay warehouse. With this portfolio, TRAPO answers any requirements with flexible, economical systems. Via TIM, the TRAPO Intelligent Managementsystem, the vehicles can coordinate who takes which job and which is the shortest route for loading.

Temperature-controlled warehouses for food and pharmaceutical industries. Warehouse and material flow planning for companies in the food industry or pharmaceutical industry requires compliance with additional requirements and legal regulations. In their planning, TRAPO’s expert teams take into account requirements of the products to be stored in terms of darkness, temperature and storage conditions. In order to find sustainable solutions, mobile shuttles are also used there, which make optimum use of the available space, avoid multiple trips and make optimum use of storage space.

Advantages

- Use of the shuttles in combination

- Automation of internal goods transports

- Modular system

- Multiple feeders

- Different designs, payloads and speeds

- Everything from a single source: no interfaces, one mechanical structure, one control system

- Modular design

- Control via TIM

- Optimized warehousing

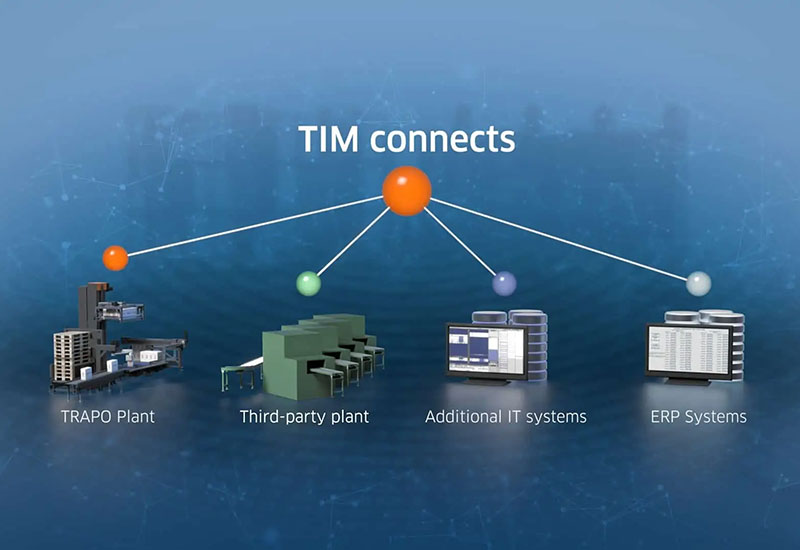

TRAPO Intelligent Management system

TIM: Controlling, optimization and monitoring of your plants! As a web-based system, TIM, the TRAPO Intelligent Management System, was already introduced in 2018 in the TRAPO technical center for the needs of plant engineering and mechanics as a ME (Manufacturing Execution System). TIM is industry-independent, customer-configurable, connects production plants and also includes third-party plants. TIM monitors production and intralogistics processes based on predefined OEE performance. With TIM, customers have a real-time overview of key business data. TIM can be integrated with customers’ ERP systems.

Plant monitoring via TIM: record, store, visualize TIM offers a web-based, user-friendly HMI (Human Machine Interface) interface as a human-machine interface. Continuous monitoring and the data collected from it enable targeted optimization of the monitored equipment. In addition, TIM specifies the optimal time for predictive maintenance – and simplifies ordering processes by providing a digital shopping cart. The actual data analysis forms the basis for restricted user authorization of different user levels. TIM enables insights into the control and management of orders, reads out capacities of actors and provides an overview of the productivity of plants on a daily basis. Central comparative data is available at the push of a button, which is relevant for auditing in the context of certifications, for example. TIM’s data analysis can be used uniformly – with restricted authorizations for the respective user level.

In plant monitoring, the following functions are visually prepared and displayed:

- Controlling, processing and providing data

- Data acquisition – storage – visualization

- Data query and analysis

- Automatic error reporting

- Resource management

- Evaluation for quality targets

Plant optimization and predictive maintenance. Whether preventive maintenance or the performance of routine maintenance: From now on, maintenance and personnel deployment can be planned. TIM keeps an eye on the maintenance cycles of the players and ensures the functionality of plants, reduces the probability of breakdowns and optimizes operating processes. Spare parts service is also taken to the next level thanks to a digital shopping cart and automatic shopping cart replenishment. TIM takes care of plant optimization on an as-needed basis with three central tools:

- Digital shopping cart

- Predictive maintenance

- Technical documentation

Plant control: HMI and route management for shuttle. In the context of plant control, TIM offers two application options at once.

- As HMI software, TIM handles the communication between people and systems. The HMI portfolio ranges from visualization to SCADA systems that control and monitor technical processes.

- In the context of plant control, TIM as a data highway takes over the fully automatic route calculation and control of a shuttle fleet of the TTS series. The vehicles move freely on traffic routes, whereby changes of the driving course can be realized with little effort.

TIM connects: Integration in customer systems As a superordinate system, TIM ensures transparency and maximum efficiency for plants and processes. In addition to company-specific queries, TIM also allows flexible customization. Of course: the definition of interfaces including import and export functionalities to third-party ERP systems. As a connecting tool, TIM functions in this context as a:

- Data hub for plants and systems

- Interface to ME and ERP systems

- Connection to in-house software systems

Industry

We are at home in these industries. As a partner for industrial automation, TRAPO offers automation concepts for all industries. Cover your total needs in production and intralogistics via one central partner. The compact applications developed in the TRAPO technical center and installed worldwide are unique – based on a modular system. Compact systems with autonomously acting components TRAPO places a special focus on strengthening supply-securing industries – with pick and place, high-performance (de)palletizers and conveyor technology. At the center autonomous systems such as automated guided vehicles and autonomous truck loading and unloading.

Food and beverage industry

Automation solutions for the food and beverage industry. Temperature, hygiene and documentation in view: TRAPO automation expertise offers the food industry optimum safety. We support production and intralogistics in the food and beverage industry with the highest possible, reproducible quality and highly efficient performance.

Pharmaceutical industry and medicine technology

TRAPO has been developing hygienic design for high care areas. We know the high demands on components and lines for the highly sensitive production area of the pharmaceutical industry and medicine technology. Thanks to many years of experience and developing, we offer customized solutions: with special cleanroom expertise and solutions for cleanroom classes ISO 1 to ISO 4.

Logistics

Ready for digitalization in intralogistics with TRAPO solutions. As TRAPO GmbH, we support our customers in projects for digital transformation in intralogistics. Choose partial and complete solutions. We support in-house transport, distribution, warehousing and ensure safety at the loading dock. Get to know our conventional and future-oriented autonomous systems – so that you are ready for digitization.

Chemical Industry

Automation in the chemical and petrochemical industry. Safety is paramount in automation in the chemical and petrochemical industry. We know the requirements for production, handling and transport of bulk materials. TRAPO solutions offer – even in corrosive atmospheres – maximum process safety, reliability, transparency and plant availability.

Pet Food

We optimize the gentle production of food-grade pet food. For pet owners, dogs, cats etc., are real family members. They are optimally and variedly supplied with food-quality pet food. In the case of canned food, we provide support with a high-performance layer depalletizer operating at ground level, which makes up to 90,000 cans available for filling every hour. Because not only the feed, but also the production should be of the highest quality.

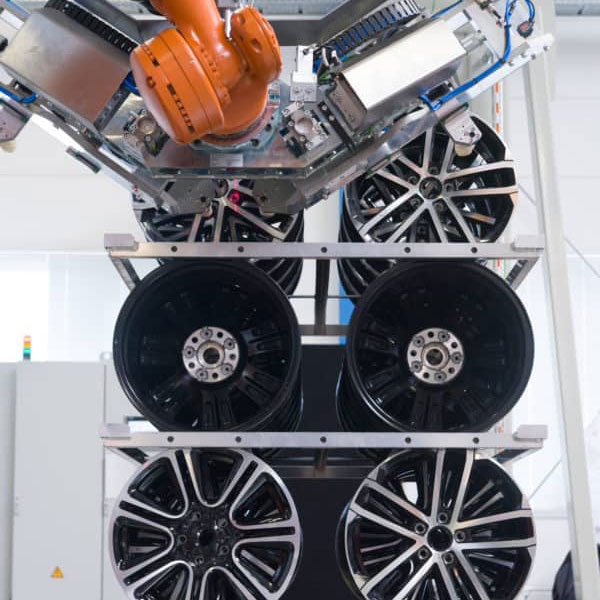

Automotive and Wheel industry

TRAPO innovations are the engine of the automotive industry. As TRAPO GmbH, we counter the shortage of skilled workers and the highly competitive situation in the automotive and wheel industry with individual automation solutions. We relieve employees and provide them with cobots. Our team is quick on the draw, reacts to changes – and optimizes production lines. TRAPO expertise from 20 years of industry experience speaks for itself.

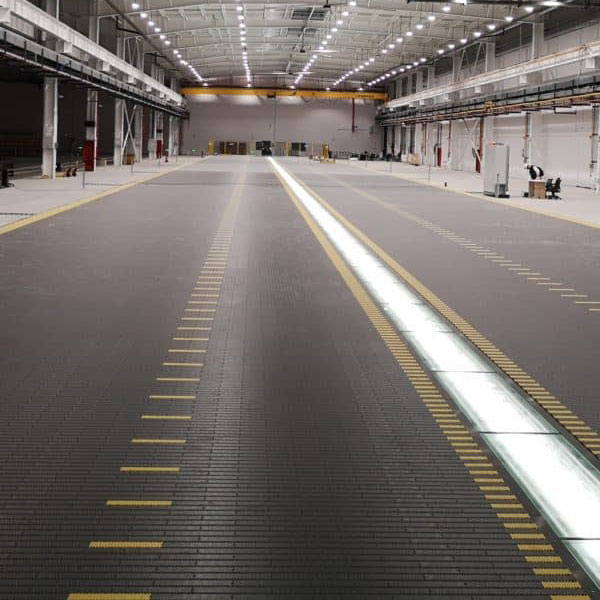

Shipyards

XXL conveyor lines produce cabins for cruise ships. Production space on ships is limited: Our XXL conveyor lines relieve the daily routine in shipyards, for example in cabin construction. For example, cabins are pre-assembled externally as finished modules and only finally installed on board by the shipyard. A time- and cost-efficient solution that is used by renowned German shipyards as well as industrial parks worldwide.

Other industries

Partner in automation in all industries. Packaging, building materials, furniture industry: Wherever special solutions are required in plant engineering, TRAPO is your partner for planning, development and implementation. With complete line competence for hardware and software, we find solutions. We focus on safety for man and machine: through automated, reproducible processes.