Digmesa

Videos

Loading the player ...

- Offer Profile

- 35 Years Swiss & Original

Digmesa develops and manufactures Swiss quality precision flow sensors. We specialise in the field of small and micro flow rates and we offer a wide range of mechanical and non-contact flow sensors.

Digmesa is dedicated to the development of (individual) solutions that help sustain and grow our clients businesses. We are well known for our quality and service worldwide.

Product Portfolio

DIGMESA SWISS QUALITY PRECISION FLOW SENSORS

A PRODUCT SOLUTION FOR EVERY APPLICATION

- Digmesa flow sensors can be found around the world. Numerous renowned customers control and measure liquids in a number of segments: the food and beverage industry, the industrial-, chemical-, medical- and laboratory technology as well as the semiconductor industry and the high-tech sector. Any kind of medium in any kind of application – within the measuring range of small and micro quantities, Digmesa can offer and optimal solution.

FLOW SENSOR NANO

-

- compact

- cost effective

- freely selectable mounting position

Flow Range

NOZZLE SIZE: FLOW RATE

1.1 mm: 0.08 – 0.4 l/min

Materials- PP

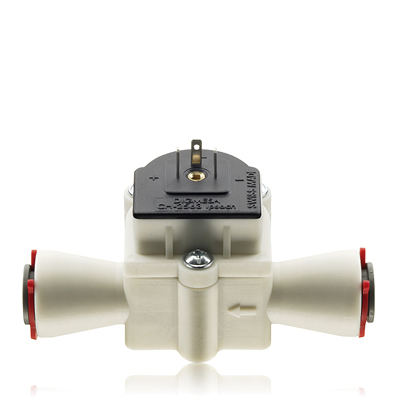

FLOW SENSOR FHKSC

-

- cost effective

- compact

- reliable

The FHKSC flow sensor is perfectly suited for applications requiring good quality at an attractive price, for instance in coffee machines for home use. It is installed on the pump’s suction side. Its light-weight design and flexible choice of connection position perfectly match manufacturers’ requirements. With millions of units shipped every year, this flow sensor is also extremely reliable: it has a return rate of practically zero.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: 0.05 – 0.40 l/min

1.2 mm: 0.08 – 0.57 l/min

1.8 mm: 0.09 – 0.90 l/min

2.0 mm: 0.14 – 0.91 l/min

2.7 mm: 0.33 – 3.13 l/min

FLOW SENSOR FHK

-

- modular

- flexible

- u-shaped flow path

The Classicline FHK and FHKU are also available with a display to enable simple, direct monitoring of the flowing medium. This display can be integrated into the upper part of the device, or it can be delivered separately and connected via a cable. This device is ideal for applications such as checking for compliance with maintenance cycles in water filters due to its many functions, such as count-down, count-up, display of instantaneous flow rate, timed control and data storage.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: 0.03 – 0.60 l/min

1.2 mm: 0.03 – 0.75 l/min

2.0 mm: 0.10 – 2.30 l/min

2.5 mm: 0.15 – 3.80 l/min

5.6 mm: 0.18 – 8.30 l/min

Materials- PPS

- PBT (Arnite)

- PVDF

FLOW SENSOR FHKU

-

- modular

- flexible

- straight flow path

The FHKU flowmeter is a versatile device that can be used in many applications. Thanks to its flexible and modular design, it is possible to offer a wide variety of configurations. This allows to tailor the product specifically to the customer’s needs. For continuos operation, for example to monitor cooling circuits, the optional ceramics bearing guarantees a long service life.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: 0.04 – 0.60 l/min

1.2 mm: 0.05 – 0.80 l/min

2.0 mm: 0.10 – 2.40 l/min

2.5 mm: 0.15 – 3.80 l/min

5.6 mm: 0.30 – 9.30 l/min

7.0 mm: 1.40 – 18.00 l/min

10.0 mm: 3.00 – 30.00 l/min

Material- PBT (Arnite)

- PPS

- PVDF

FLOW SENSOR FHK(U) LCD

-

- battery powered display

- integral or external LCD

- option for all FHK / FHK(U)

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: 0.04 – 00.60 l/min

1.2 mm: 0.05 – 0.80 l/min

2.0 mm: 0.10 – 2.40 l/min

2.5 mm: 0.15 – 3.80 l/min

5.6 mm: 0.30 – 9.30 l/min

7.0 mm: 1.40 – 18.00 l/min

10.0 mm: 3.00 – 30.00 l/min

Material- PBT (Arnite)

- PPS

- PVDF

FLOW SENSOR FF

-

- freely selectable mounting position

- can be opened and closed without tools

- optional foam detection available

The Digmesa Flow Sensor FF was developed with the requirements of German draft beer systems in mind. It can be opened without

any tools for easy cleaning. The version with a jewel bearing allows the mounting position to be chosen freely. Moreover, with the optional integrated foam probe, it measures only the actual amount of liquid that has been transferred. This prevents errors caused by carbonated gas when the line is empty.

Thanks to the low-friction ruby bearing it is also suitable for dairy products.

Flow Range

NOZZLE SIZE: FLOW RATE

4.0 mm: 0.22 – 07.75 l/min

5.0 mm: 0.35 – 11.50 l/min

6.0 mm: 0.35 – 16.20 l/min

Material- PBT (Arnite)

- PVDF

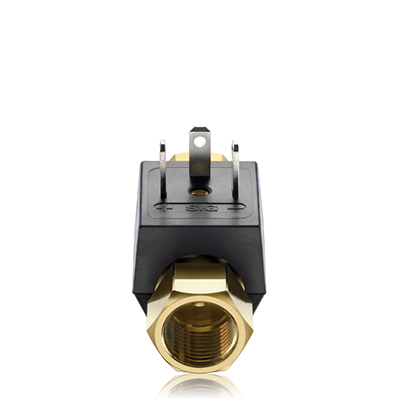

FLOW SENSOR FH

-

- lead free brass housing

- high pressure resistance

- robust design

Coffee brewing is a fine art, especially when a consistent quality level is to be attained. Accordingly, it is critical to ensure that only high-quality materials are used in professional coffee machines. The FH flowmeter meets even the most exacting standards. This proven flow sensor made of solid, lead-free brass provides dependable service for many years, even under the extreme conditions encountered in professional machines.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm 0.04 – 0.60 l/min

1.2 mm 0.05 – 0.80 l/min

2.0 mm 0.10 – 2.30 l/min

2.5 mm 0.15 – 3.80 l/min

6.0 mm 0.20 – 7.80 l/min

Material- lower part: lead free brass (food grade, uncoated)

- upper part: PA / lead free brass

FLOW SENSOR EPI

-

- positive displacement meter

- for viscous liquids

- acurate and cost effective

This volumetric measuring device is suitable for measuring the flow rate in media with high viscosity, such as syrup, soap, lye, oil, ketchup and honey. The EPI is also available in PEEK, which features high chemical resistance; possible uses include sterilisation of surgical instruments in hospitals.

Flow Range

7.0 mm: 0.06 – 6.00 l/min

Material- PBT (Arnite)

- PEEK

FLOW SENSOR FM

-

- large dynamic range

- high durability

- high flow rates

The FM flow sensor is ideal for measuring flow rates during continuous operation, such as in bottling plants, welding robots and laser cooling systems. The central loading of the turbine blades combines with the robust design to give this extremely durable flow sensor (also available with ceramic bearing) an exceptionally long lifespan. Other properties include high precision obtained by using the multijet measurement technique, large measurement range and low pressure loss.

Flow Range

NOZZLE SIZE: FLOW RATE

8.0 mm: 0.25 – 17.00 l/min

15.0 mm: 2.83 – 25.30 l/min

Material- PBT (Arnite)

- PA

FLOW SENSOR NANO BRASS

-

- lead free brass housing

- compact and robust design

- cost effective

NANO BRASS is a very cost-effective sensor device perfectly tailored to fulfill the highest demands of the professional coffee machine manufacturers.

With its solid and yet very compact lead-free brass housing and sealed electronics, this device is designed to be the successor of the well-proven FH.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: 0.035 – 0.4 l/min

1.2 mm: 0.05 – 0.50 l/min

1.4 mm: 0.06 – 0.70 l/min

Material- Brass (lead free brass, uncoated) (CW510L)

FLOW SENSOR NANO INOX

-

- stainless steel housing

- compact and robust design

NANO INOX is an innovative sensor device perfectly tailored to fulfill the highest demands of the professional coffee machine manufacturers.

With its solid and yet very compact stainless steel housing and sealed electronics, this device is designed to be the successor of the well-proven FH.

Flow Range

NOZZLE SIZE: FLOW RATE

1.0 mm: ~0.035 – 0.40 l/min

1.2 mm: ~0.05 – 0.50 l/min

1.4 mm: ~0.06 – 0.70 l/min

Material- Inox (stainless steel) 1.4401/AISI 316

FLOW SENSOR SONIC

-

- contactless measurement

- fast response time

- straight-through, unobstructed flow path

Today’s technical standards for flow sensors require measurements to be fast, accurate, and economical, while simultaneously not contributing contaminants to the fluid and providing long sensor life. Digmesa investigated the issue and concluded that the ultrasonic flow sensor

could be reinvented. The result is a new ultrasonic flow sensor that interprets the well-established ultrasonic time of flight technology. Due to the diagonal measurement, this configuration provides highly accurate and repeatable results and a very fast response time. Additionally, mechanical improvements are integrated into the design by the use of one seamless inline injection moulded piece, eliminating dead ends or dead-legs.

Applications range from handling high-purity liquids and slurries in the semiconductor or chemical industries, to the pharmaceutical and biotechnology industries, to the food and beverage market. Today’s technical standards for these industries all require the highest precision and a careful choice of materials.

Flow Range

MATERIAL: FLOW RATE

PA66: 0.10 – 12.00 l/min

PEEK: 0.10 – 20.00 l/min

PFA: 0.10 – 20.00 l/min

Material- Outputs Pulse / Analog / 2 programmable outputs

- Inputs 2 programmable inputs

DISPLAY UNIT FC PRO

-

- backlit LCD

- compatible with all Digmesa flow sensors

- customizable on request

The FC PRO can be used with any Digmesa Flowmeter. It shows values such as total flow, current flow rate, and date alarm. It can be adapted with customer specific features on request.

Features- Display 8 character, 16 segment display.

- background light (requires external power source)

- Processor 16-Bit microcontroller

- Temeprature Range – 10°C to + 60°C

- power supply 5-28VDC external power source

- Additional features such as battery power, relais contacts, inputs and outpts can be added as customer specific development projects