- Offer Profile

-

Lifting and commercial vehicle systems from haacon

Products and solutions for integrated logistics, lifting and commercial vehicle systems. Discover our wide range of products for yourself. Our success is founded on the strength of our team and our conscious approach to quality.

Lifting and commercial vehicle systems from haacon

-

Lifting systems for logistical tasks in civil defence, disaster control and the armed forces

It’s when you move away from permanent infrastructures that haacon hebetechnik gmbh’s container and shelter lifting devices demonstrate what they are truly capable of – in civil defence, in disaster control, in transporting equipment for the army, air force and navy, in technical relief services, international crisis aid – in fact, anywhere heavy loads need to be moved by muscle power alone.

LIFTING SYSTEMS

-

Lifting systems for logistical tasks in civil defence, disaster control and the armed forces

It’s when you move away from permanent infrastructures that haacon hebetechnik gmbh’s container and shelter lifting devices demonstrate what they are truly capable of – in civil defence, in disaster control, in transporting equipment for the army, air force and navy, in technical relief services, international crisis aid – in fact, anywhere heavy loads need to be moved by muscle power alone.

CONTAINER ROLLS

-

Container Rollers - Moving Containers on Paved Ground

Container rollers are suitable for moving containers on paved ground. The rollers are mounted from below into the ISO corners, the side openings of the ISO corners remain free for other use.

LIFTING, ROLLING AND LOADING SYSTEMS

-

Lifting, rolling and loading systems for setting down and rolling containers

Lifting, rolling and loading systems type 1350 are suitable to set down and roll containers and shelters from vehicles without crane assistance.

LIFTING DEVICES

-

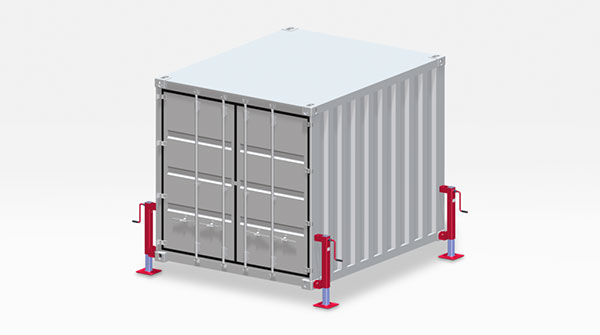

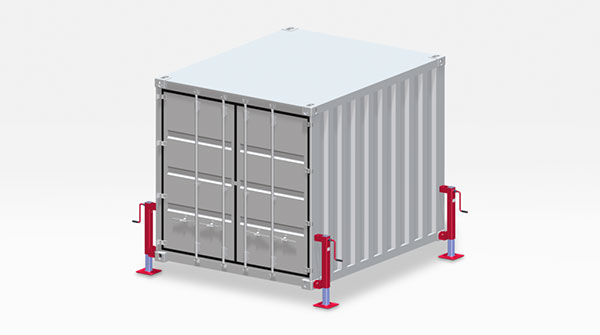

Lifting devices - helpers for transportation

Lifting devices are suitable for lifting containers from the truck and setting them down on the ground without the help of a crane. One lifting device consists of 4 lifting supports, where the load capacity of the single lifting support is half of the system load capacity.

LEVELING DEVICES

-

Leveling devices - When things get uneven

Leveling jigs for lifting heights up to 800 mm with system load capacities up to 25 t (dynamic) and 25 t (static). Leveling jacks are used on containers that need to be aligned in a defined way on the ground so that they can then be connected to form larger functional units (e.g. mobile hospital facilities, field storage).

Industrial lifting equipment

-

Industrial lifting equipment with custom solutions

Custom solutions are our strength. In many cases, we can already implement your lifting technology requirements by modifying standard components. Get in touch with us!

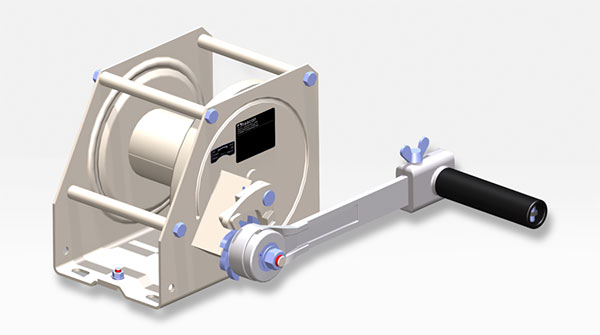

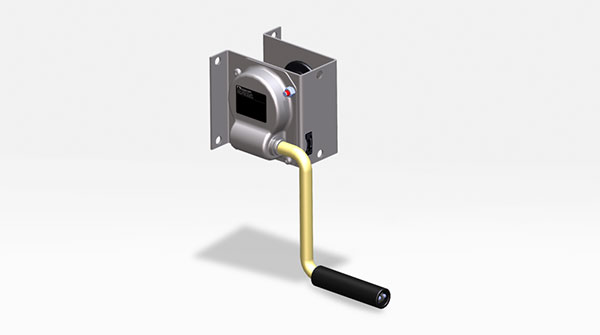

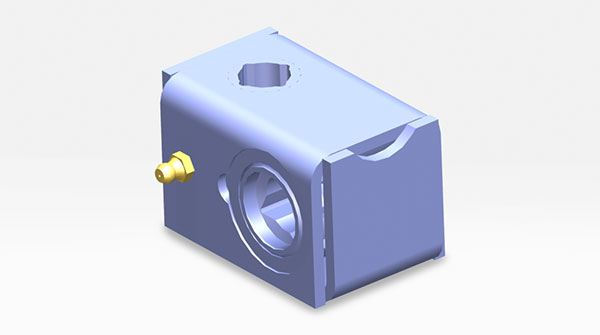

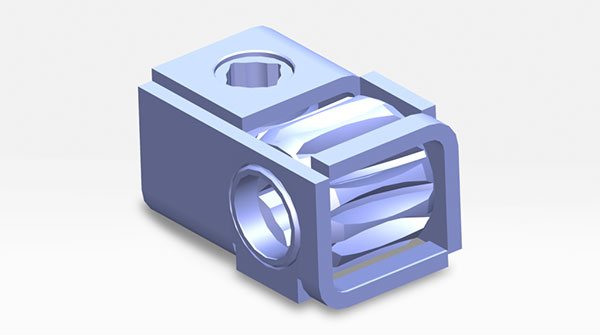

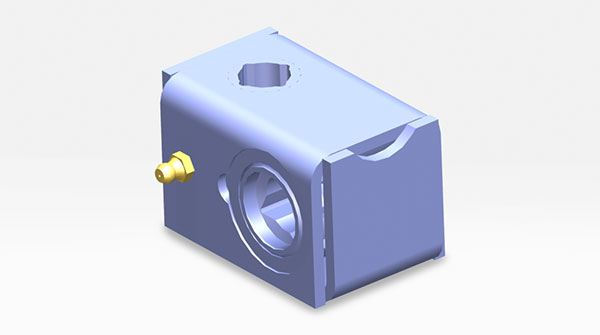

UNIVERSAL GEARBOX

-

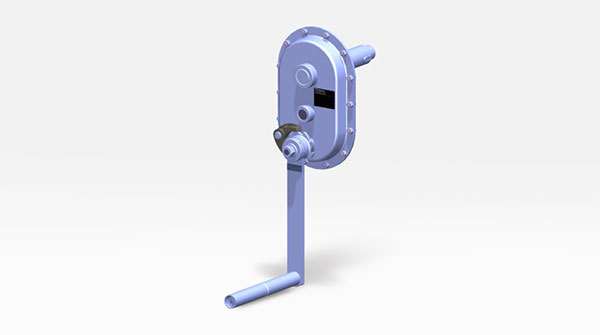

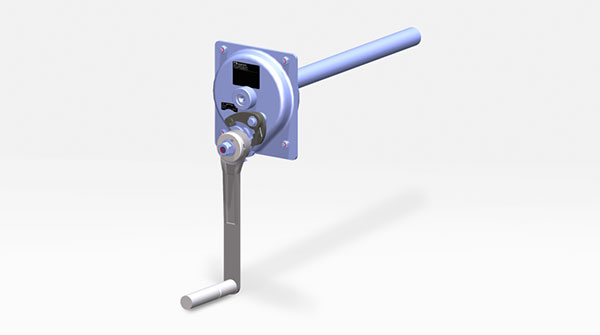

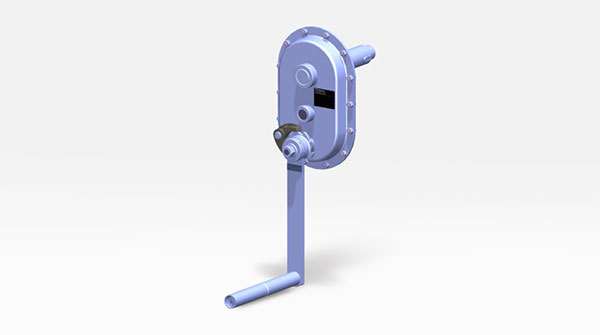

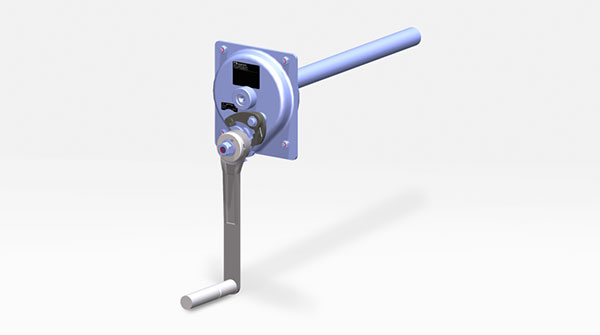

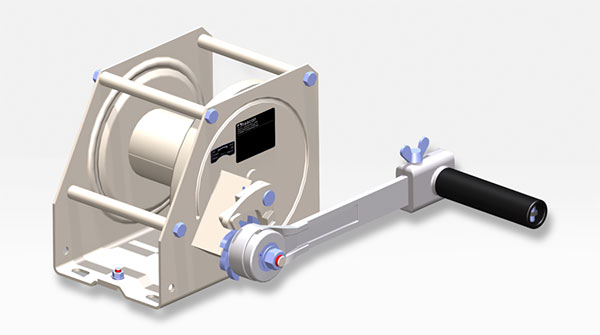

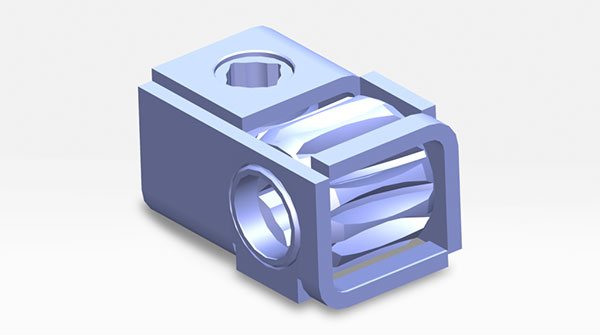

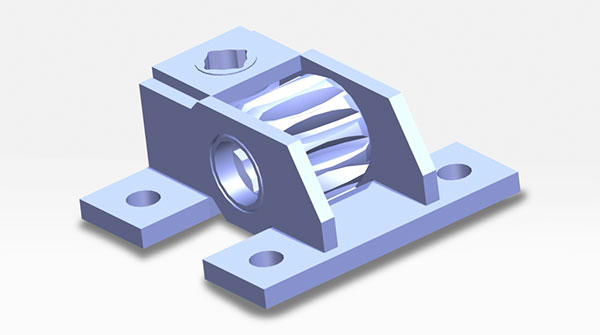

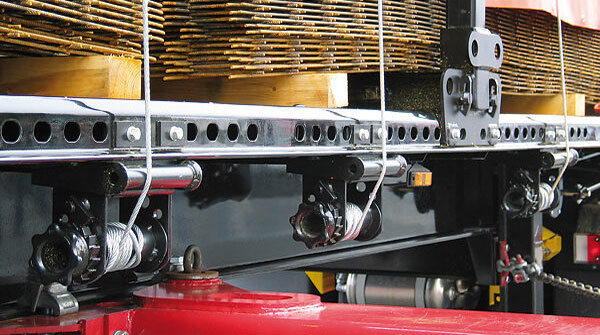

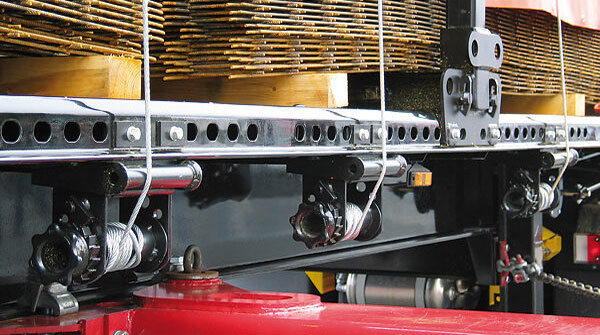

All-purpose universal gearbox

Universal gearbox with safety crank and folding handle. Motorized drive possible at input speed up to 100/min. in short time operation.

- Universal gearboxes for manual drive

- Motorized drive possible at an input speed of up to 100 rpm in short-time operation

- Robust and reliable

- Maintenance-free

- Safety crank with load-dependent backstop

- Alternatively without backstop, when used for shifting loads

- Can be equipped with:

- One or more rope drums

- Sprockets for roller chains

- Chain sprockets for link chains

- Outer frame operation

- Crankshaft extension

OUTLET TORQUE 200 Nm to 1800 Nm

ELECTRIC WINCHES

-

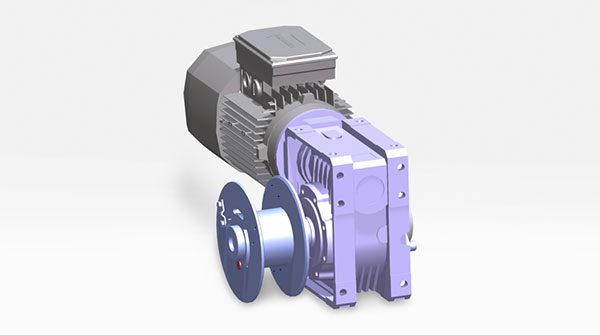

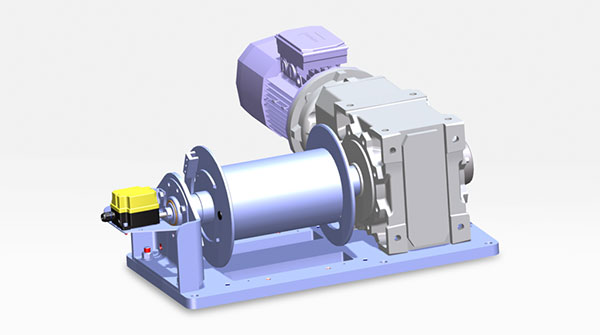

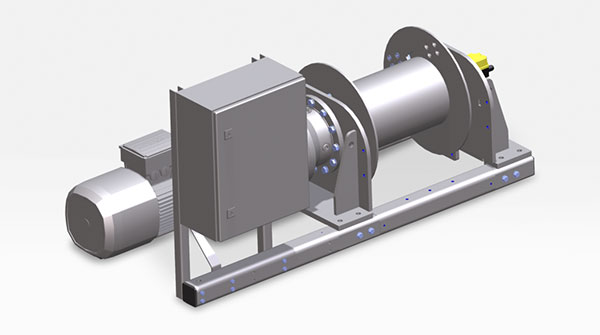

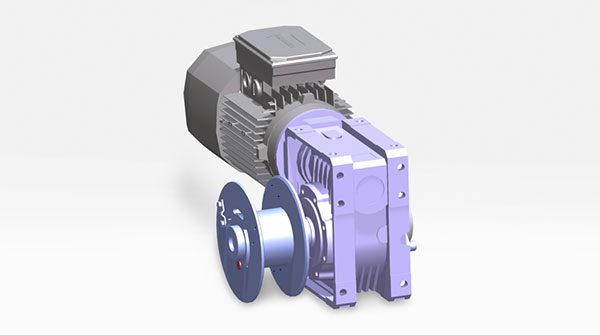

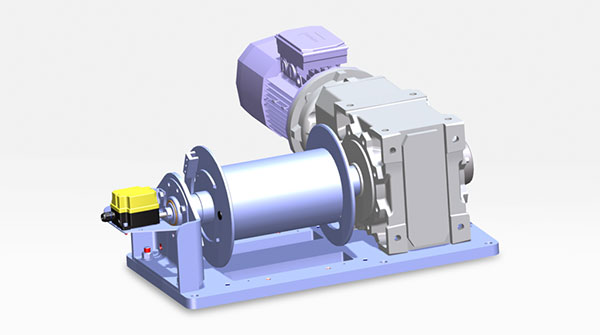

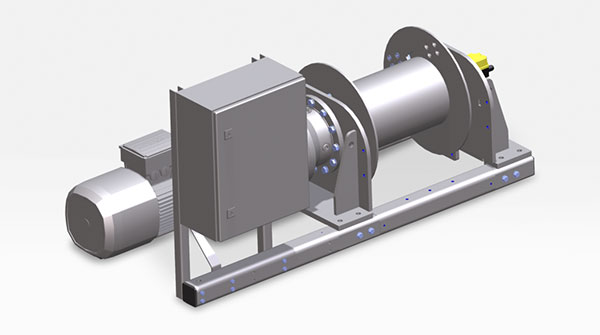

Electric winches for industrial use - also in special design

Electric rope winches and driven rope winches, series program and special designs

different versions:

- Electric wire rope winch ESF

- Electric wire rope winch ESG

- Electric wire rope winch ESP

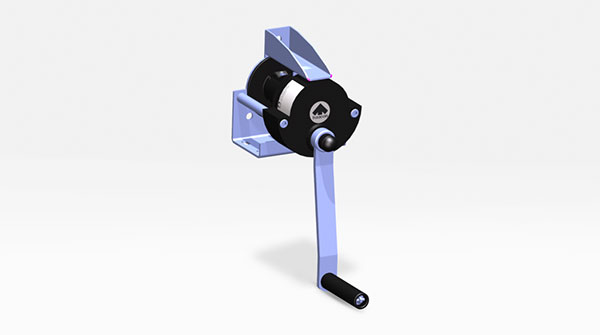

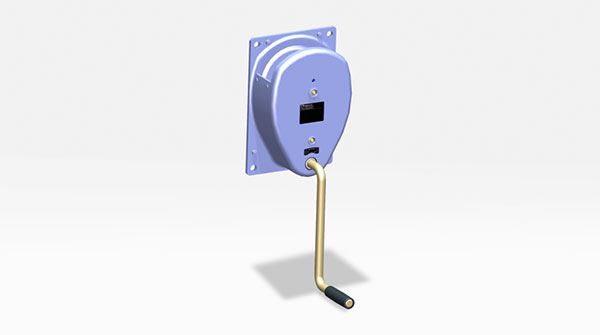

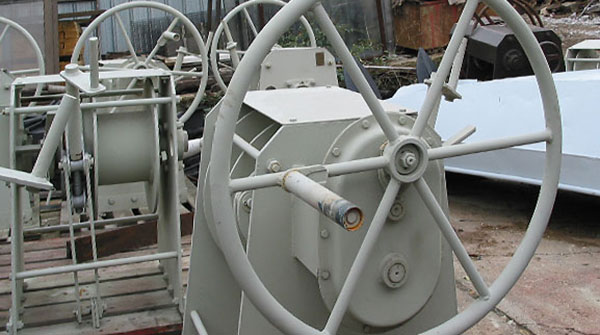

HAND ROPE WINCHES

-

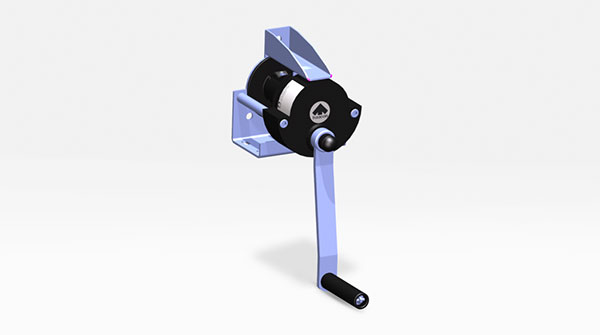

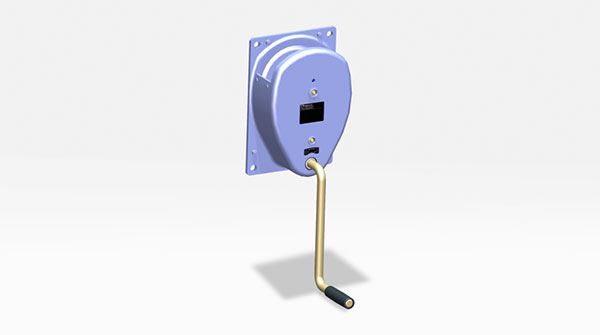

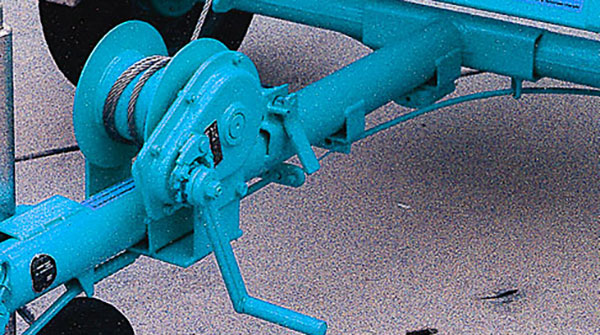

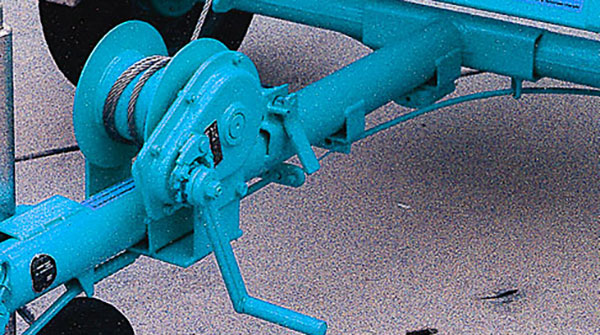

Compact manual winches for lifting and moving.

Manual winches for wall and console mounting. Made of steel, galvanized or powder coated, aluminum or stainless steel, from 50 kg to 3000 kg.

SMALL CRANES

-

Small cranes for sewage treatment plants and biogas plants

Slewing cranes, corrosion-resistant, main application area sewage treatment plants

CONTACTOR HOISTS

-

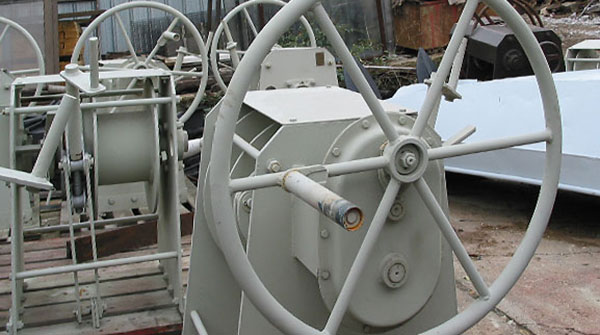

Contactor hoists with manual or automatic drive

Contactor hoists for opening and closing sluices, ditch and pond barriers. haacon manufactures simple contactor hoists for manual drive up to contactor hoists with automatic variable speed drive and high travel speeds. Each model can be individually adapted to the local conditions in a modular system. We also supply ready-to-use control systems.

Double and single contactor hoists for opening and closing sluices, ditch and pond barriers

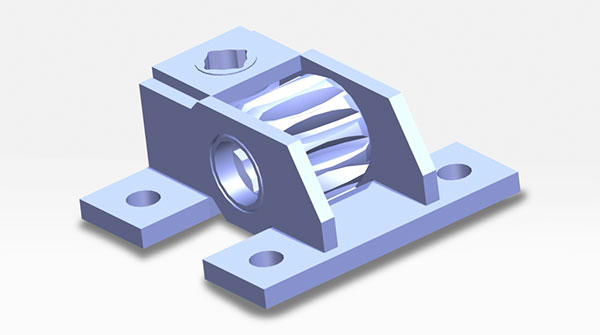

GEARS

-

Low-cost, hand-operated clamping and worm gear units.

Worm gear units, self-locking for manual operation.

SPINDEL WINCHES

-

Spindle winches - Lifting, supporting, leveling or shifting loads without great effort.

Spindle winches self-locking, manually operated for ergonomic adjustment and support, for leveling and shifting, etc., optionally with removable crank and paired operation, load 0.5 to 3 t

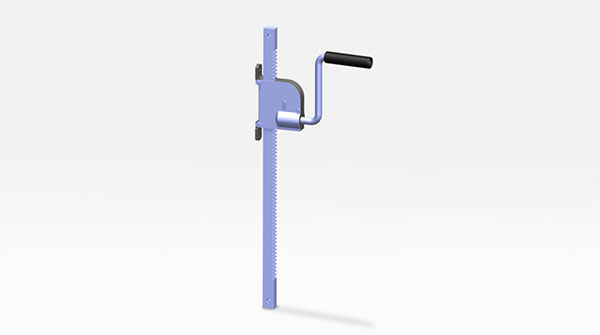

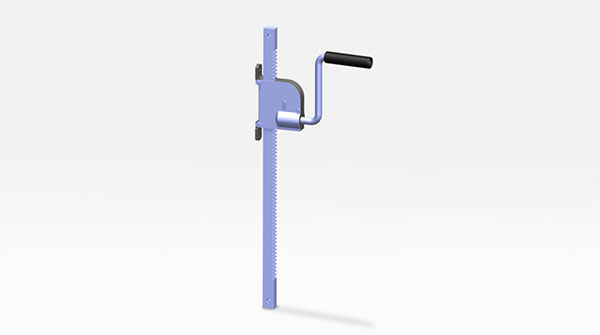

RACK AND PINION WINCHES

-

Lifting, lowering, adjusting and fixing of components by means of rack and pinion winches

Rack and pinion winches for lifting, lowering, adjusting and fixing components, devices, machines, etc., load 0.5 t -10 t

Commercial vehicle equipment

-

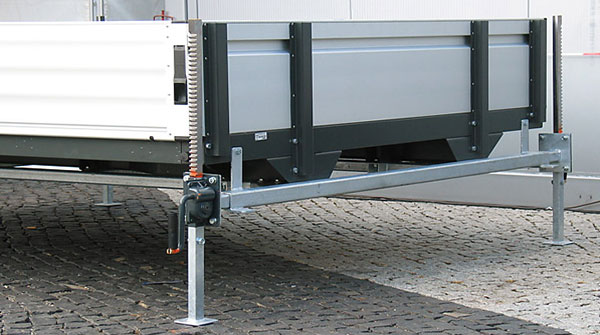

Supporting, offsetting and lashing with haacon commercial vehicle equipment

Trailer landing gears, standard landing gears, spare wheel carriers and all sorts of other equipment for trailers. The commercial vehicle equipment business division focuses on supporting, offsetting and lashing.

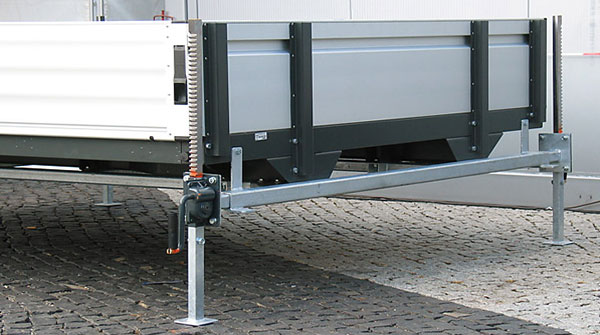

TRAILER LANDING GEAR

-

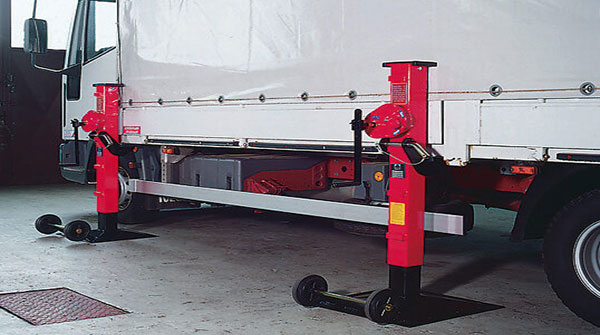

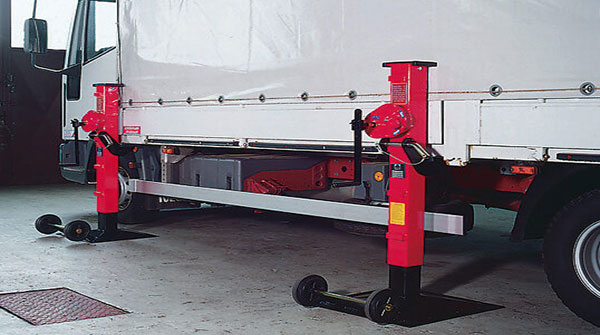

Load lifting heel supports for mounting on all vehicles

haacon heel supports for trailers are characterized by the continuous back plate, high rigidity and low weight.

ALL-PURPOSE UNIVERSAL GEARBOX

-

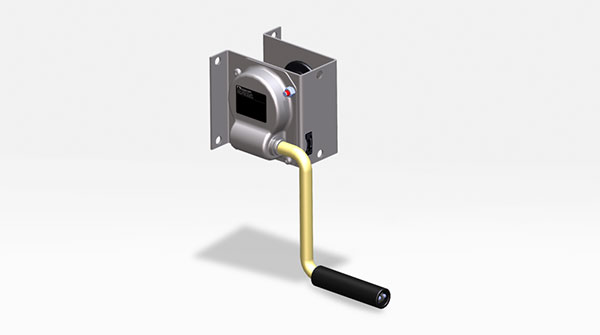

All-purpose universal gearbox

Universal gearbox with safety crank and folding handle. Motor drive possible at input speed up to 100/min. in short time operation.

SPARE WHEEL SYSTEMS

-

Spare wheel systems can be used on vehicles or in workshops

Spare wheel systems usable on vehicles or in workshops

SELF-LOCKING CLAMPING

-

Self-locking clamping gear for manual operation

Worm gear, self-locking, for manual operation

WORKSHOP EQUIPMENT

-

Workshop equipment - Fast use, fast lifting.

Load and high-speed gear for fast lifting with self-locking spindle, large stable foot plate for safe standing and rubber-tired chassis for fast use.