- Offer Profile

-

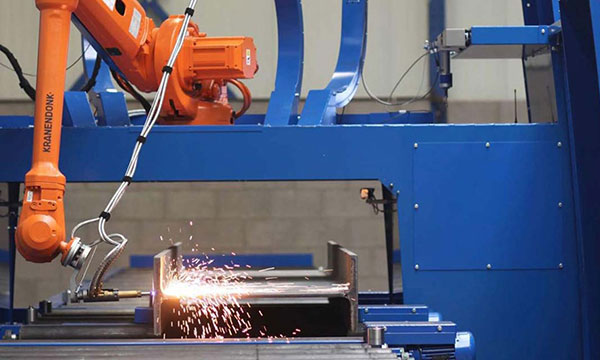

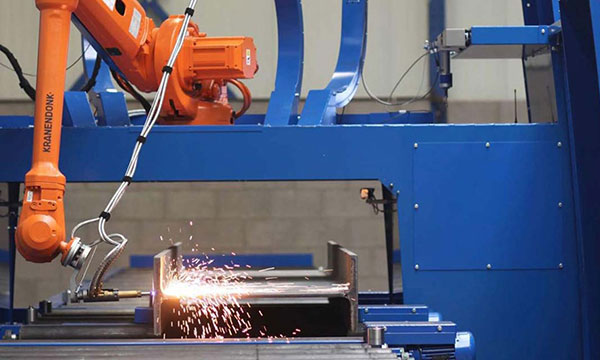

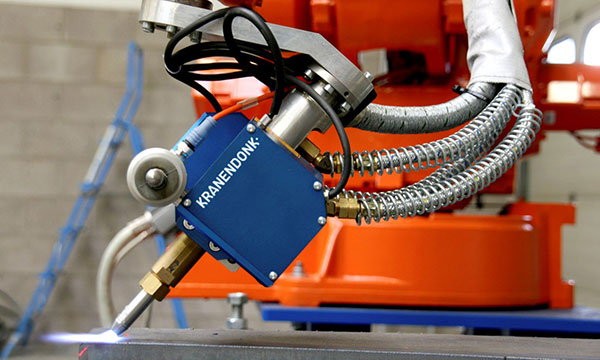

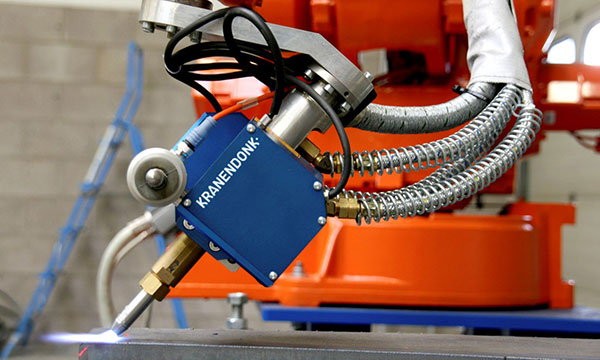

KRANENDONK is the robot technology centre for non-repetitive production. We take responsibility for engineering, commissioning and maintenance of high-end robot solutions. All our hardware and software is developed in-house, meaning our systems are seamlessly integrated into your production facility.

Traditionally, robots are used for repetitive tasks. At Kranendonk, we make the opposite possible. Our robot lines are designed for non-repetitive production, tailored to industries where products are never the same. This opens a world of automation opportunities for manufacturers.

SOLUTIONS

- Robots provide an incredible opportunity to accelerate your production. With tailored robot lines, we improve quality and productivity in steel processing industries. This enhances the entire work flow, making your production more efficient and safer and your company more competitive.

WELDING

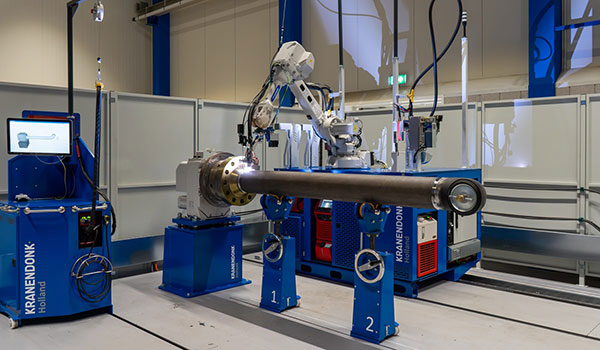

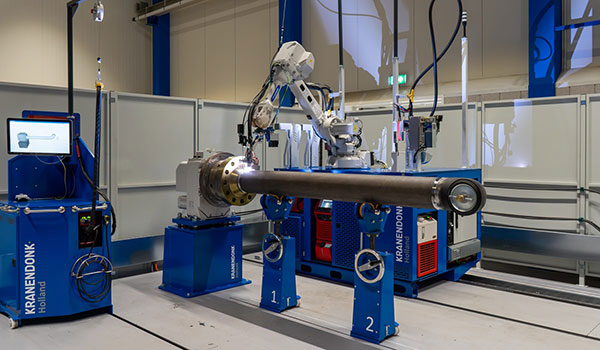

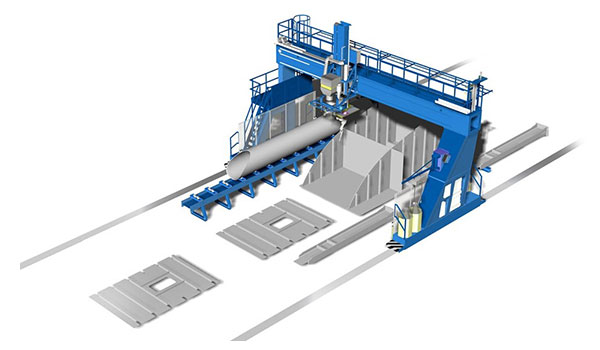

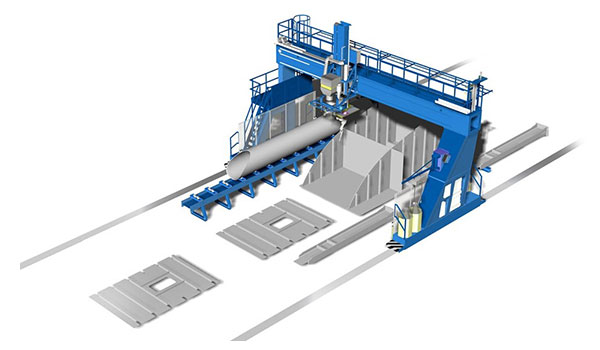

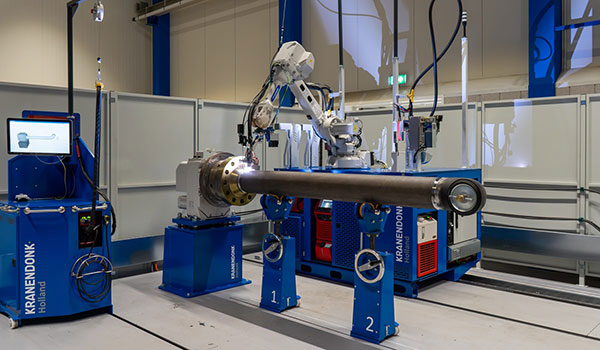

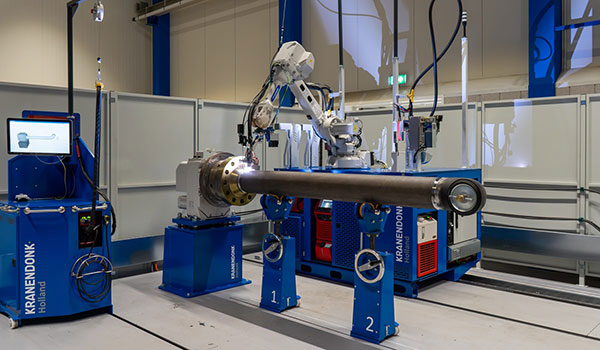

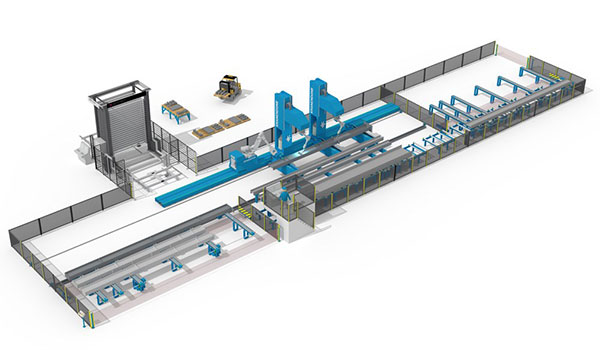

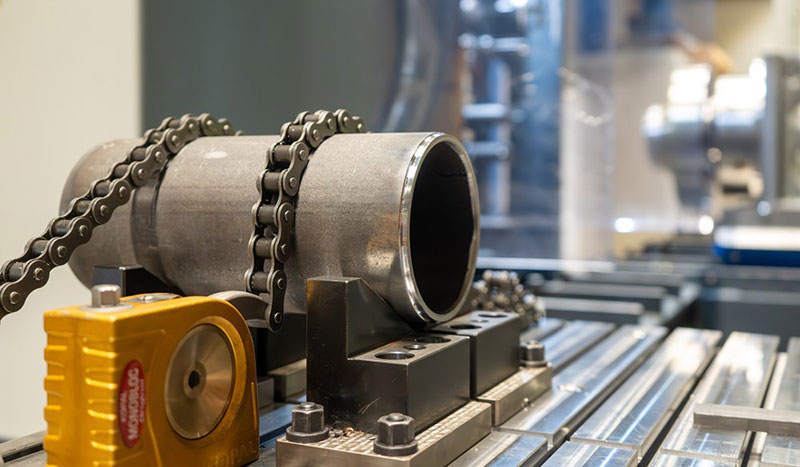

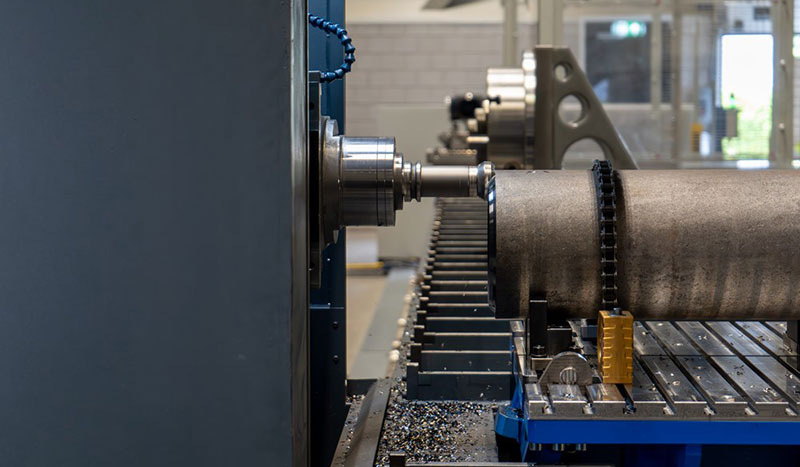

Robotic Pipe Shop

-

In today's fast-paced industrial landscape, speed and quality are paramount. Our new Robotic Pipe Shop is specifically designed to meet these demands head-on. From bevel creation for optimal fit-up to consistent, high-quality welds, this solution streamlines processes, reduces errors, and delivers exceptional results, ensuring you stay ahead.

- 10x faster manufacturing efficiency

- Increase productivity with ease

- Achieving perfect fit-up conditions

- Simplifying work preparation

- Consistent, high-quality welds

- Commitment to excellence

Aurora Spool Welding Station

-

Experience the versatility of the Spool Welding Station, a cutting-edge solution designed to handle a wide range of pipe spool components. From elbows and tees to flanges and reducers, this advanced station empowers you to tackle diverse welding applications with ease.

- Consistent, high-quality welds

- Fitting made easy

- Streamlined production with PSWP

- Seamless ZEROGAP integration

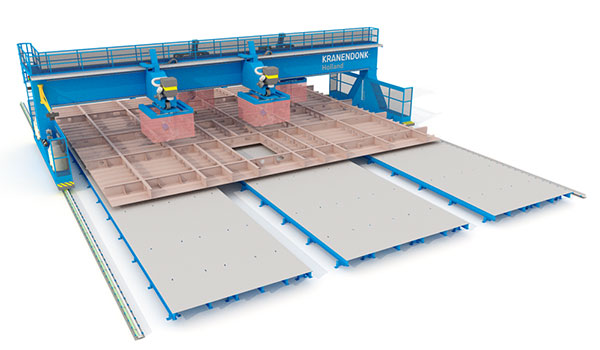

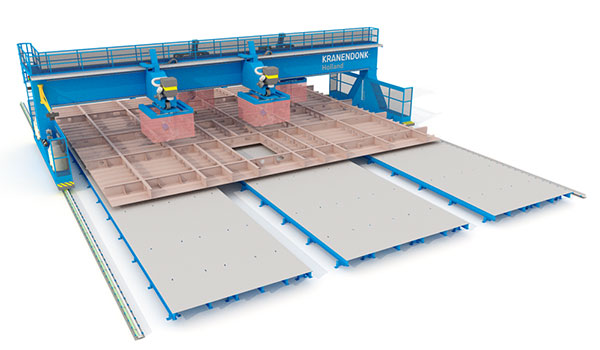

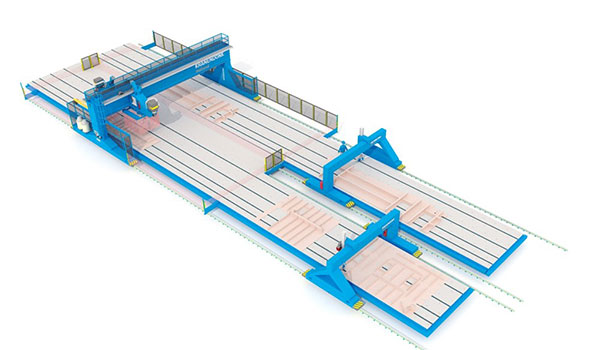

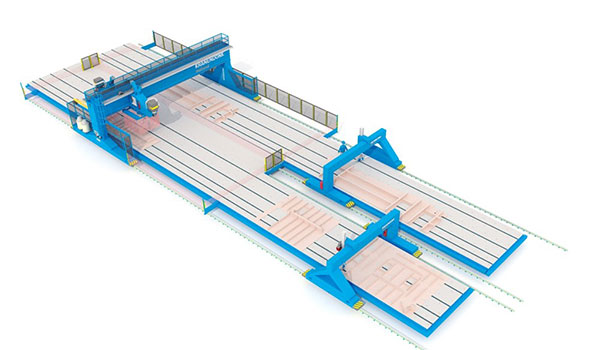

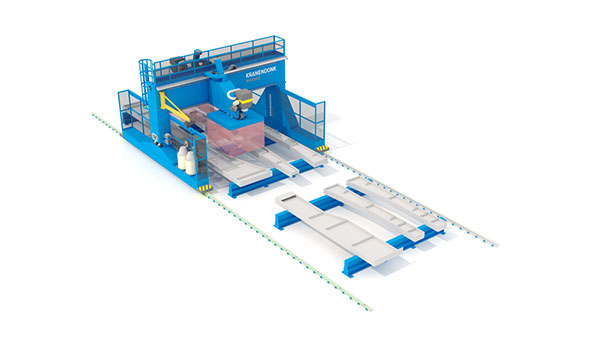

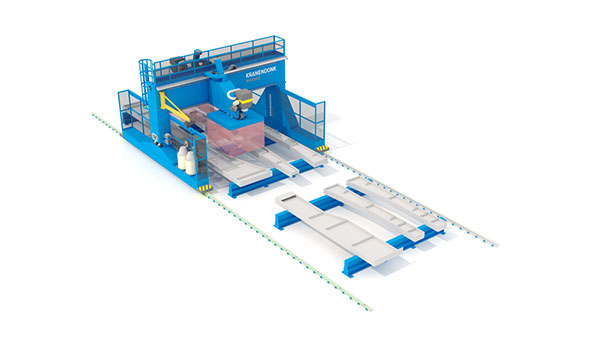

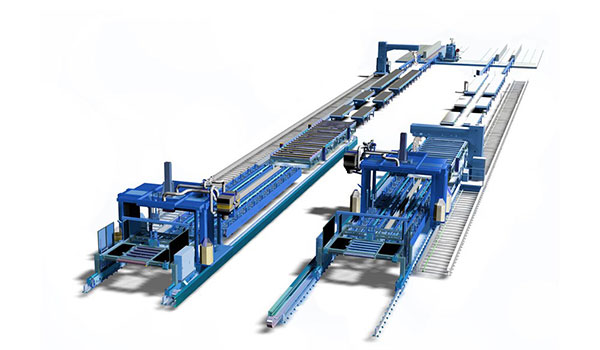

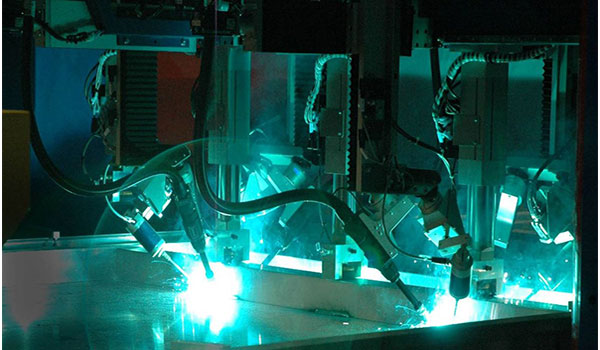

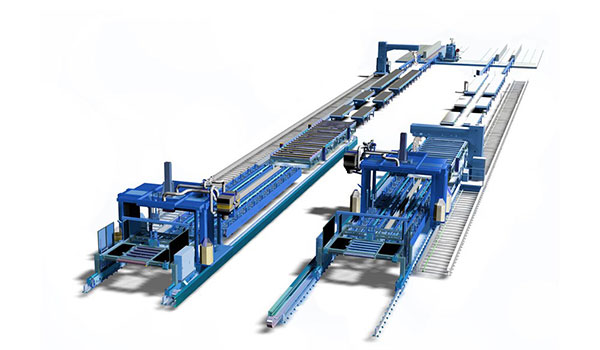

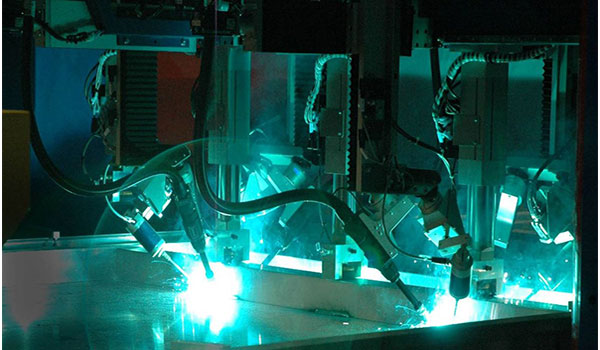

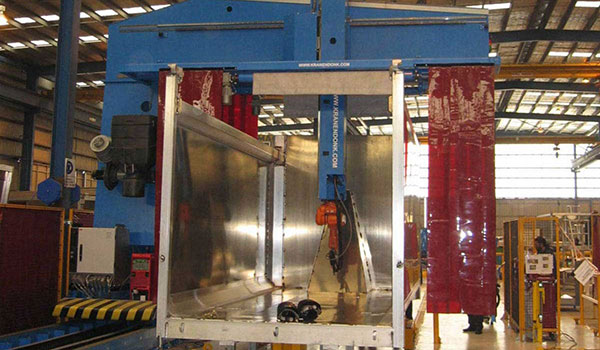

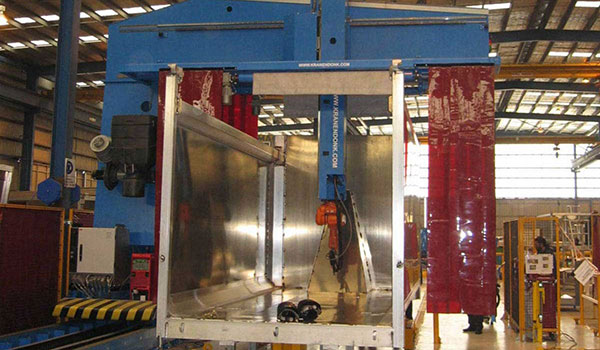

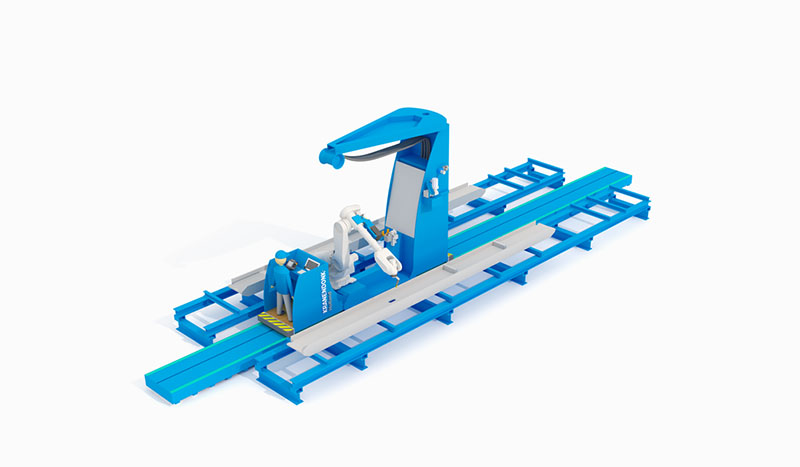

Panel Welding Line

-

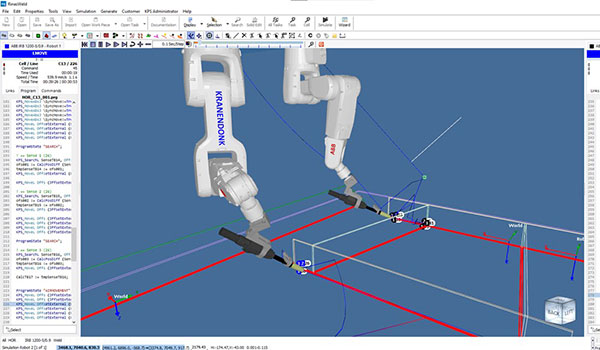

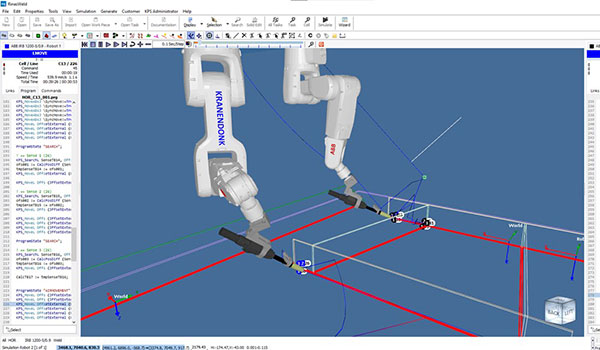

Robotic panel welding, the smart way. Our panel welding gantry operates on its own. No human setup, no human programming. Valuable production time is saved by automatically letting the robot find their paths, and distributes tasks between them. Fully automatic robot welding of complex one off designs is now available.

- Completely automated welding of complex panels

- Direct data entry at the shopfloor

- Automatic offline work preparation with RinasWeld

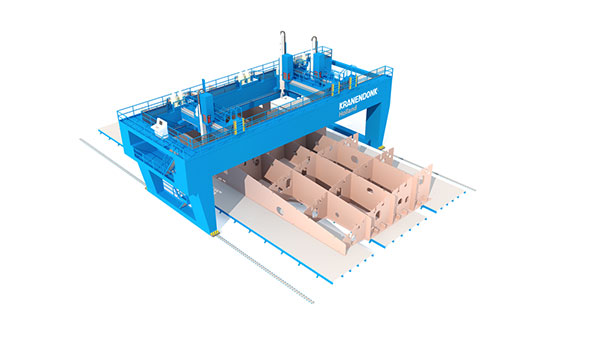

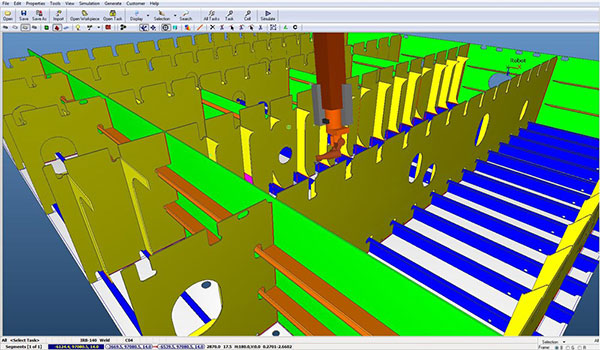

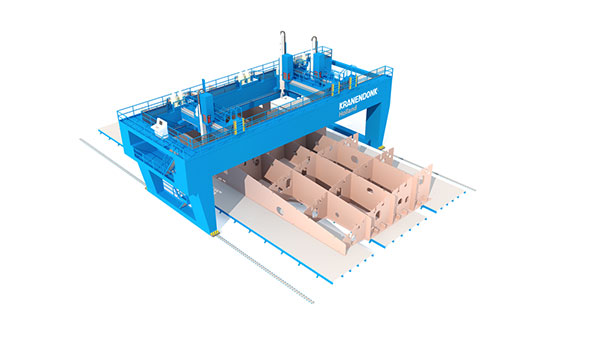

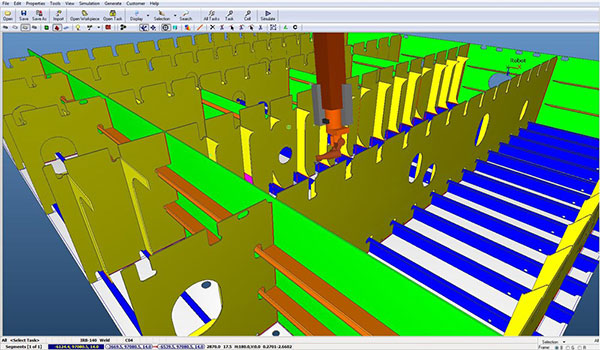

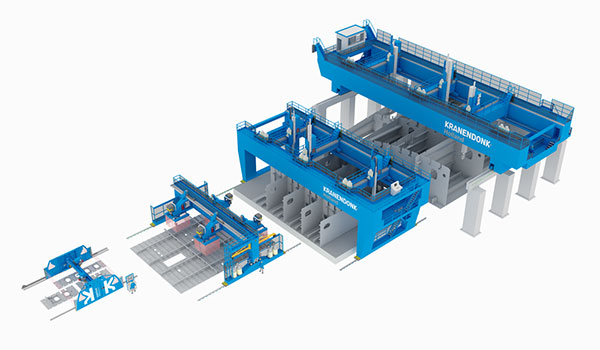

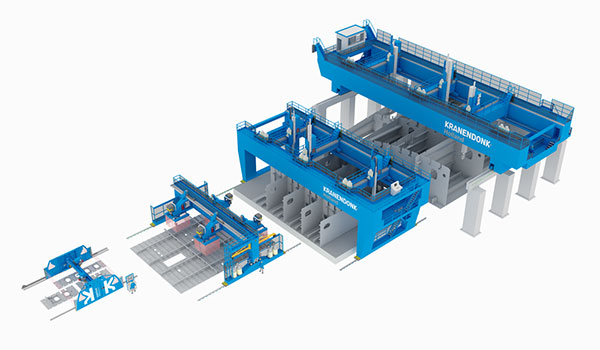

Goliath Block Welding Line

-

Fully automated welding of large hull sections of a ship. Double hull blocks are giant, one-of-a-kind work pieces, with hard to reach spaces. Suspended into this limited places, smart robots work together and weld without colliding.

- "Hands-off" robotic welding in hard to reach places

- High quality welds and easy operating

- Intelligent and powerful production software based on your 3D CAD models

- Powerful software

- Robot welding in small places

- Robot welding of large sections

Web and Micro Panel Welding

-

Making optimal use of the minimal available space in hard to reach spots. A flexible and intelligent solution for continuous robotic welding of complex designs of micro panels and webs in shipbuilding. Make optimal use of the space available in your yard.

- Here is the smartest robot welding line

- Automatic operation with RinasWeld

- Automated programming

- High quality and throughput

- Complex panels and shapes

Welding Gantry

-

Combining robot welding and cutting, for ultimate flexibility. Creating and easy to use and reliable operation. Making optimal use of your limited floorspace with this combined beam and tube cutting cell, saving you hours of valuable time.

- Combined beam and tube cutting cell

- Beam cutting functionality

- Robot carriers for reach extension

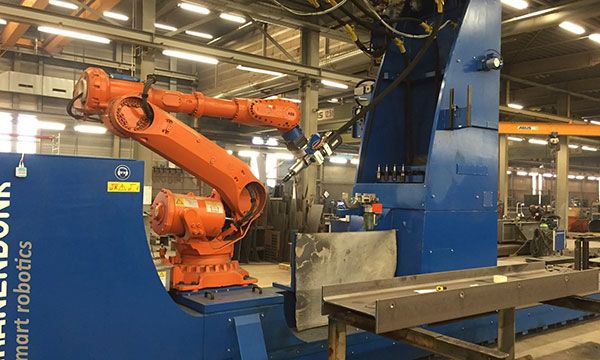

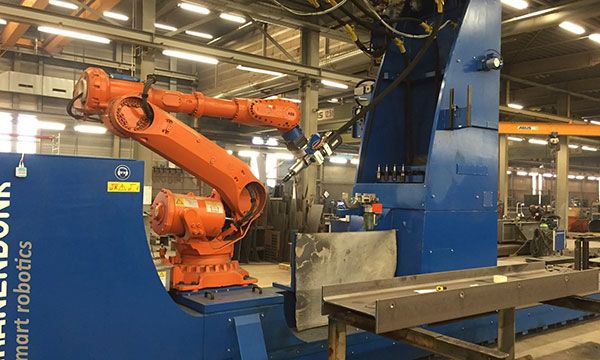

Beam Welding Gantry

-

The beam welding gantry provides flexible welding of stiffeners and end plates to large sized beams. A travelling portal suspends one or more robots. While the robot is welding on one part, operators can assemble and tack weld beams elsewhere.

- Automatic beam stiffener welding solutions

- Easy operating and smart software

- Advanced safety features

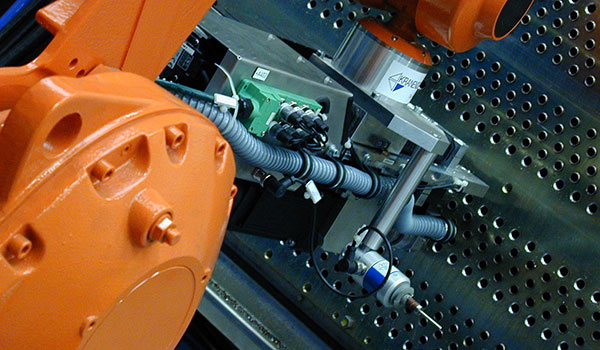

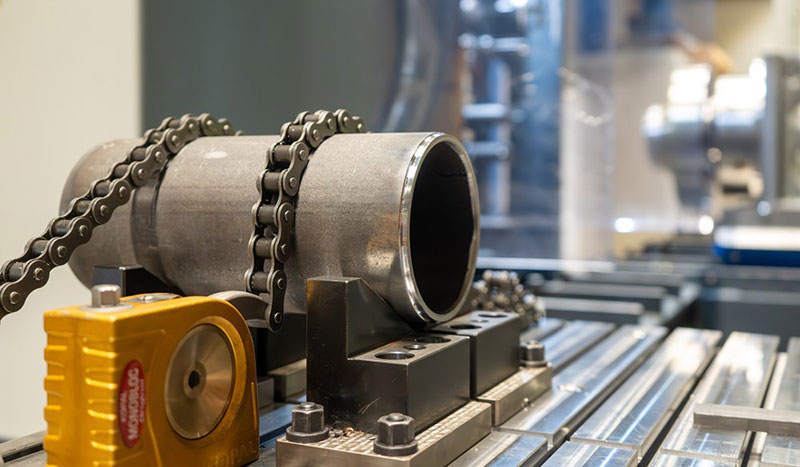

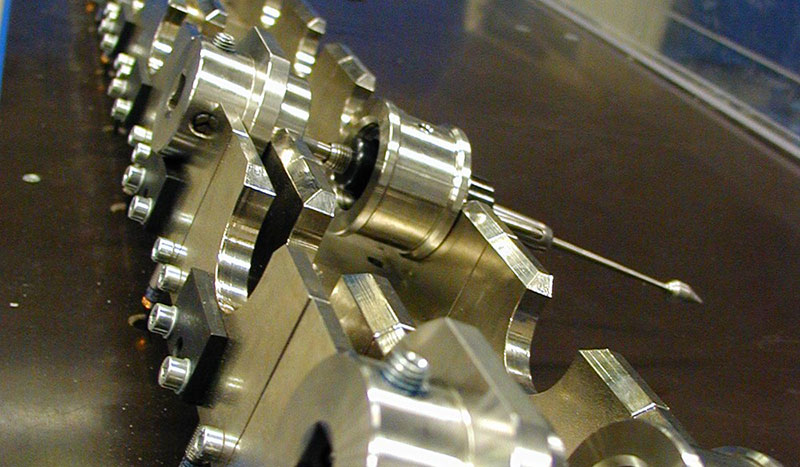

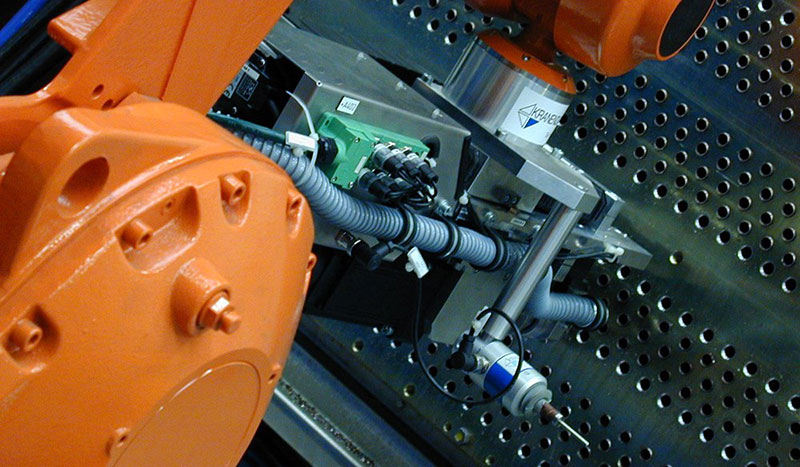

Tube to Sheet Processing Cell

-

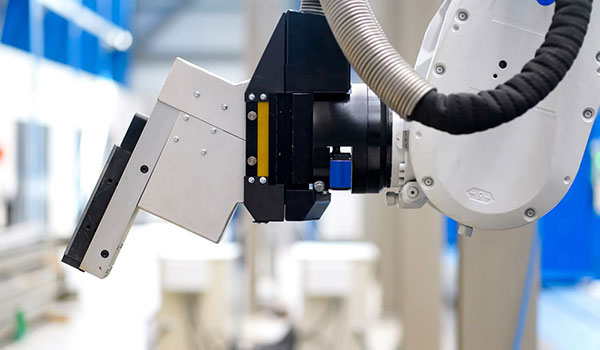

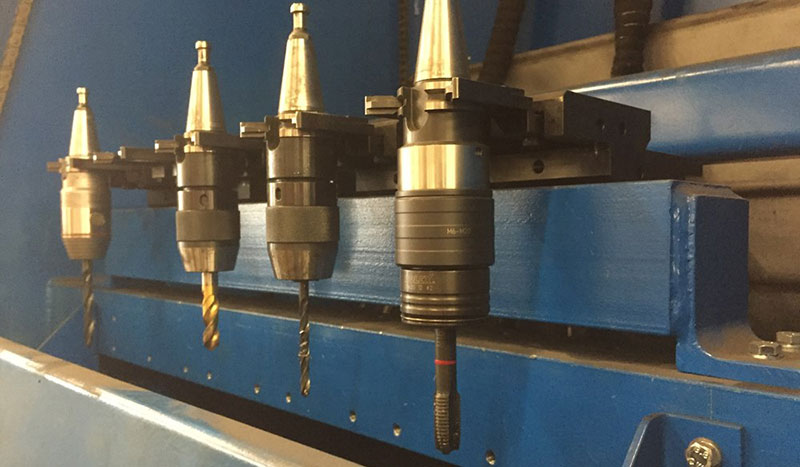

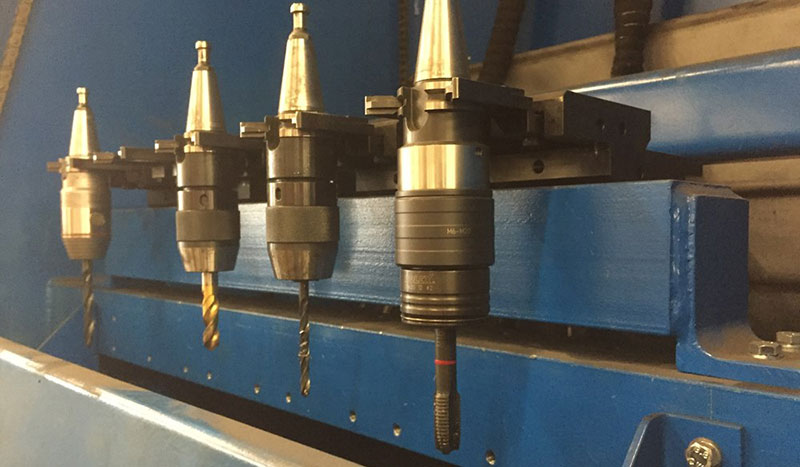

Besides the welding of tube to tubesheet connections, KRANENDONK also has supplied complete systems for tube expanding. Such a system is used for rolling of tube to tubesheet connections and the cleaning and end face milling of tubes.

- Flexible robot

- Tube-to-sheet welding

- Tube expanding and end face milling

- Automatic tool change

Beam Welding Cell

-

Beam welding cell features on or more robots travelling alongside structural steel beams or even larger structures. Beams can be randomly placed and will be automatically detected by the welding robot. This gives you amazing flexibility.

- Big welding robot, big steel products

- Robotic Submerged Arc Welding

- Boosting welding quality and productivity in beam fabrication

Trailer Production Lines

-

No truck and trailer shop is the same. Nor are the products being fabricated. We design and engineer custom production lines that handle your continuously changing products. That's efficient automation for trucks and trailers, with 90% reduction in man-hours.

- Automated trailer manufacturing

- High quality aluminum welding

- One piece production

- Low deformation

Chassis Welding Cell

-

The welding of chassis is a labour intensive job. Robotizing this process reduces production time, increase weld quality and creates a more work friendly environment.

Various robot systems for welding aluminum or steel chassis have been supplied by KRANENDONK. If needed, the option of multi layer welds is added. Since most chassis have to be welded on both sides a product manipulator is used. Due to our smart ARAC software, various product parameters can be imported, so single piece production can be performed.

Since sizes of products differ per customer different solutions for robot extension(tracks, columns and gantries) can be supplied. This means all axis of the robot carriers are controlled by the robot and therefore are able to work together as one coordinated system. An additional working station can be added for increased efficiency of logistics.

- Various systems

- Low heat deformation

Tipper Welding Cell

-

Modern trailers are often made out of aluminum tippers. The production of these structures is complicated due to the large products that have to be welded. We have developed a special robotic welding system for this task.

- Aluminum trailer welding

- Robot reach extension

- Compensation of tolerances

ASSEMBLY

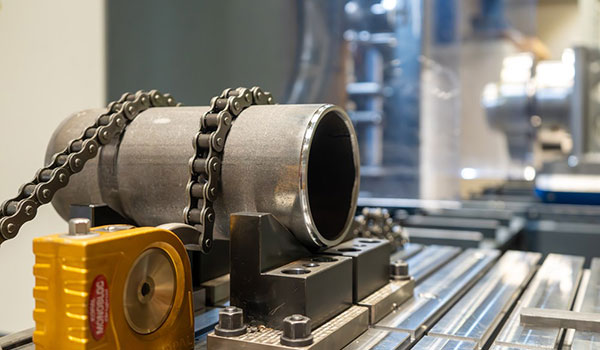

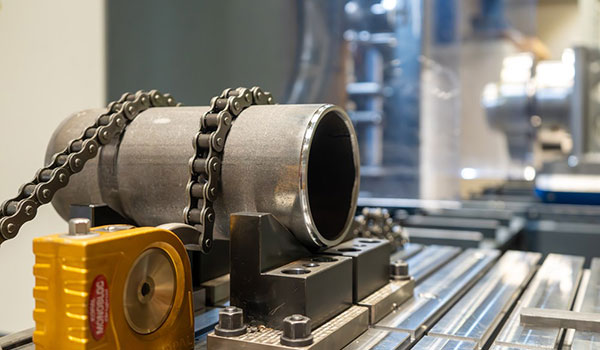

Robotic Pipe Shop

-

In today's fast-paced industrial landscape, speed and quality are paramount. Our new Robotic Pipe Shop is specifically designed to meet these demands head-on. From bevel creation for optimal fit-up to consistent, high-quality welds, this solution streamlines processes, reduces errors, and delivers exceptional results, ensuring you stay ahead.

- 10x faster manufacturing efficiency

- Increase productivity with ease

- Achieving perfect fit-up conditions

- Simplifying work preparation

- Consistent, high-quality welds

- Commitment to excellence

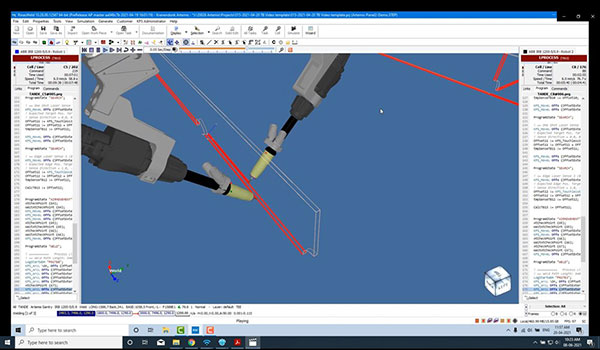

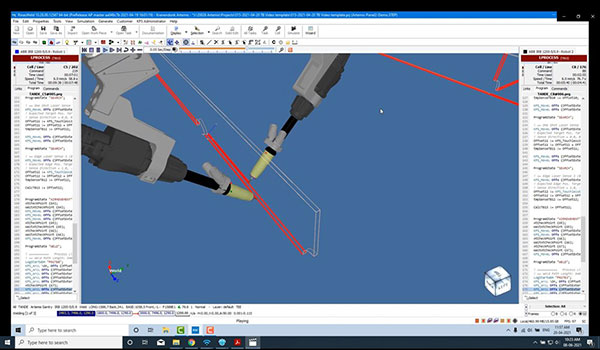

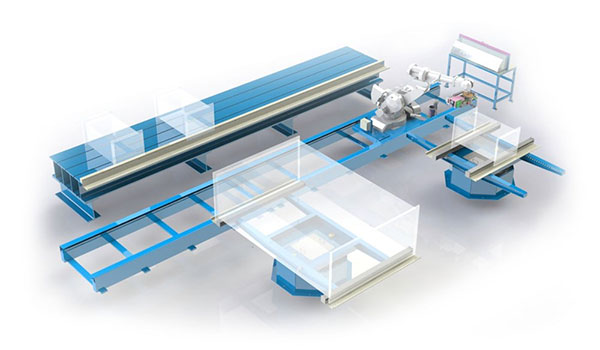

Artemis Micro Welding Gantry

-

KRANENDONK has been the market leader for customized welding automation solutions for decades. We are known worldwide for our range of robot welding columns, (micro) panel gantries and especially for our biggest block welding gantry, the GOLIATH. The ARTEMIS Micro Welding Gantry expands our product range with our smallest solution, perfect for small, medium and large enterprises!

- Small footprint, maximum productivity

- Easy to use

- Plug and play

- RinasWeld: No more programming on the shop floor

- Automatic robot welding including welding parameters (WPS)

- Get valuable feedback from the shopfloor

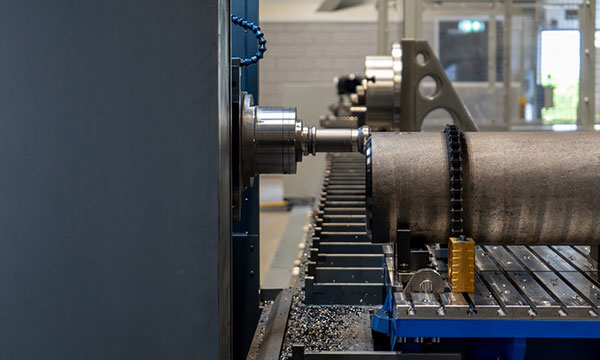

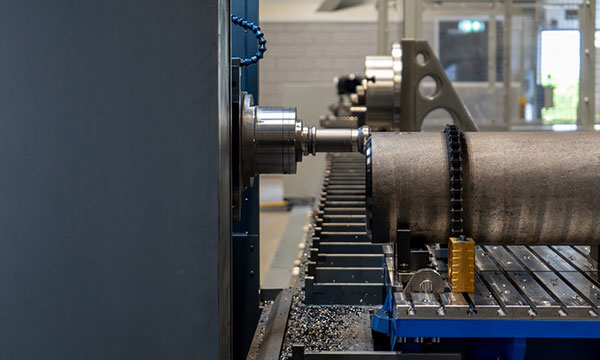

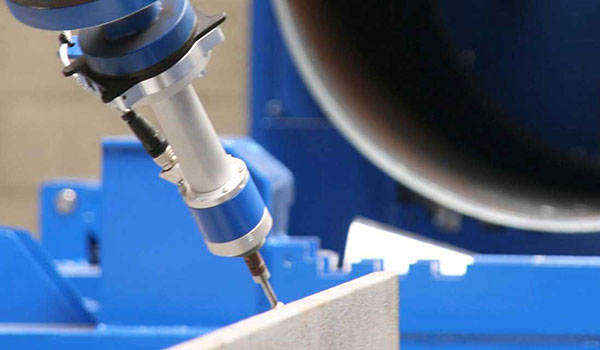

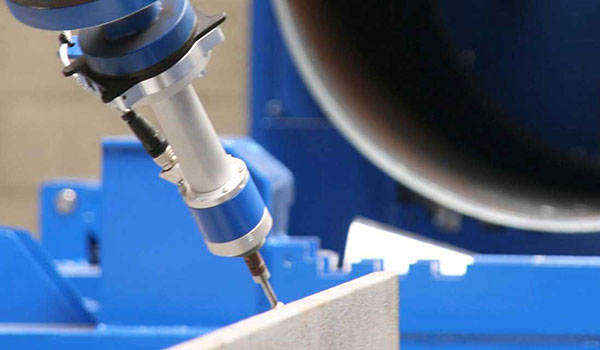

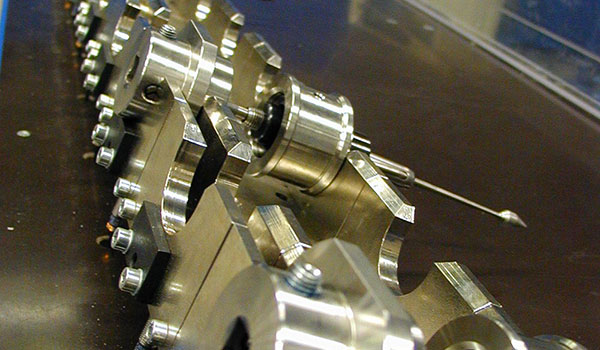

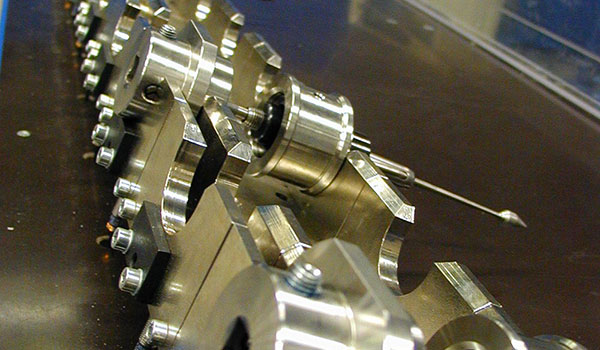

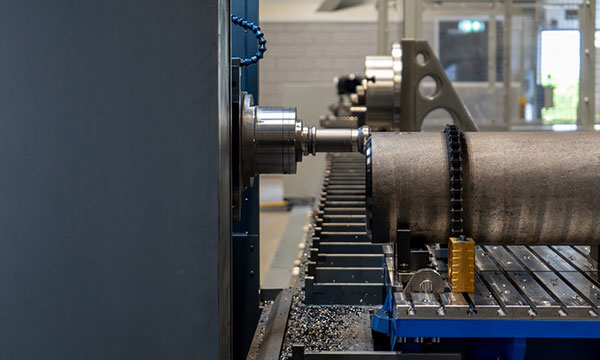

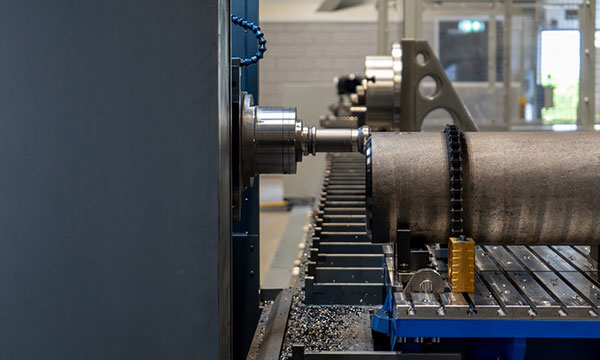

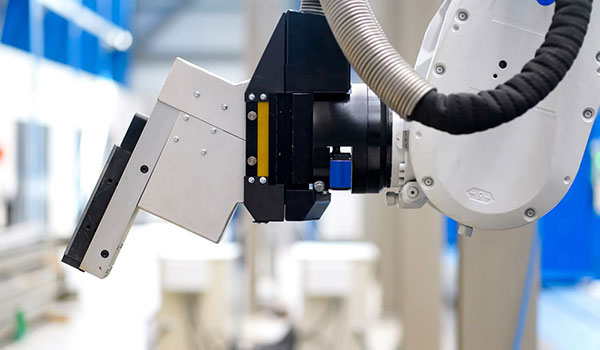

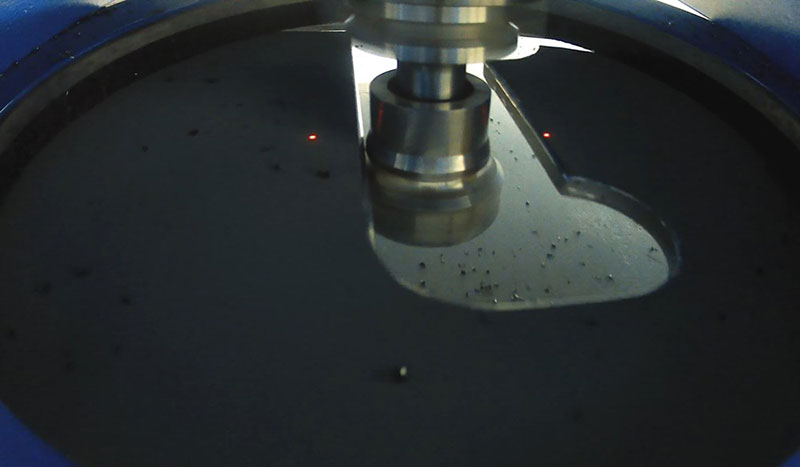

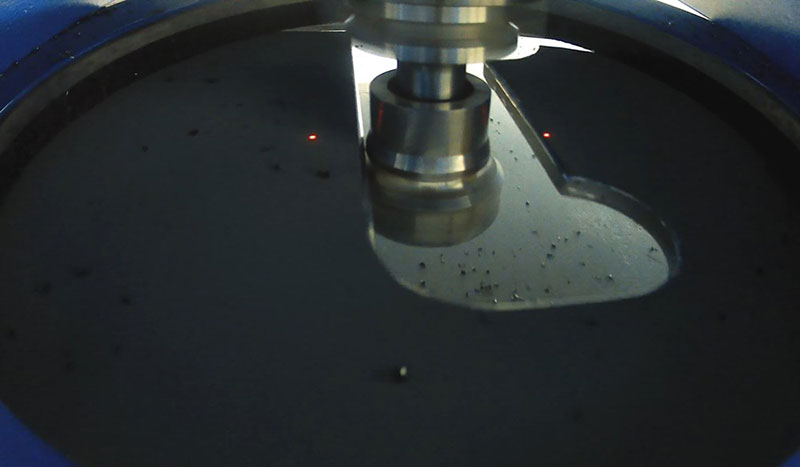

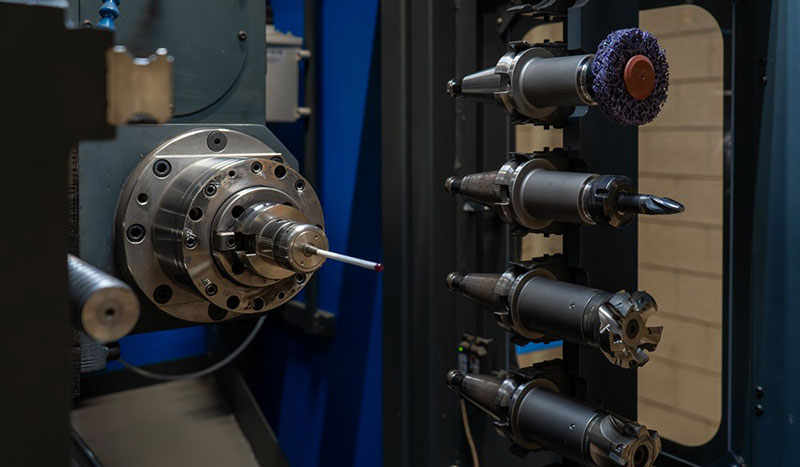

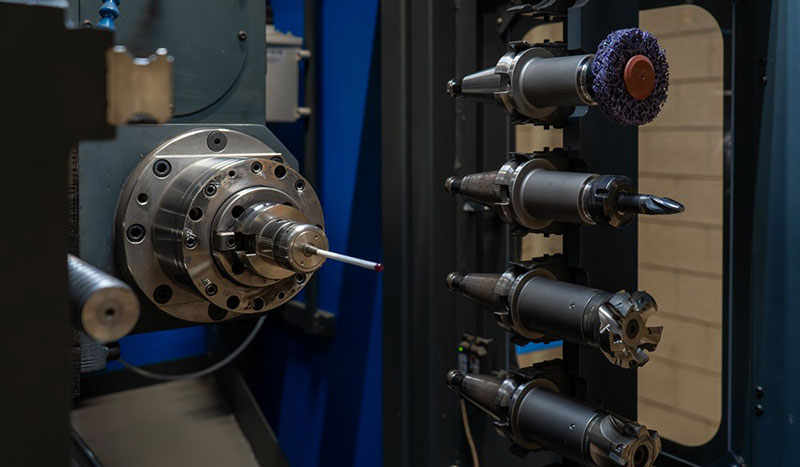

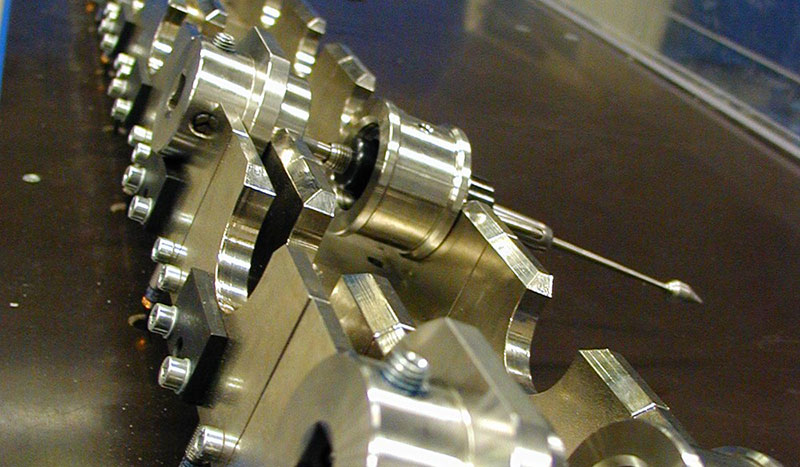

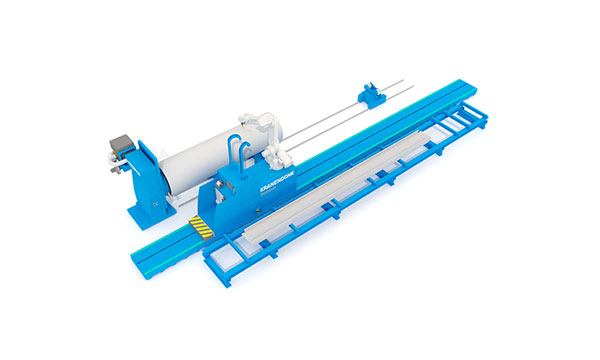

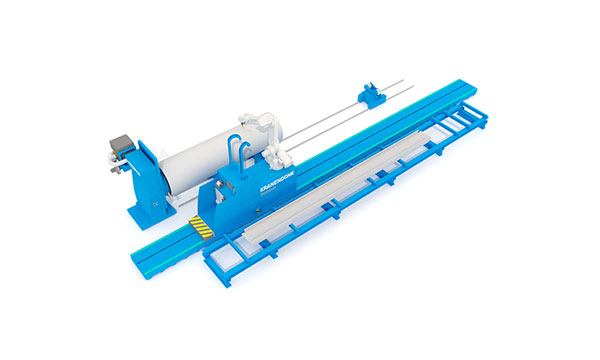

Apollo Spool Milling Station

-

Experience precision in pipe manufacturing with our advanced Spool Milling Station. Designed to automate bevel preparation for welding processes, this cutting-edge solution ensures flawless results every time.

- Accelerating manufacturing efficiency

- Achieving unmatched alignment

- Creating gap-free connections

- Embrace next-level spool production

- Flexible solution for manufacturing

Aurora Spool Welding Station

-

Experience the versatility of the Spool Welding Station, a cutting-edge solution designed to handle a wide range of pipe spool components. From elbows and tees to flanges and reducers, this advanced station empowers you to tackle diverse welding applications with ease.

- Consistent, high-quality welds

- Fitting made easy

- Streamlined production with PSWP

- Seamless ZEROGAP integration

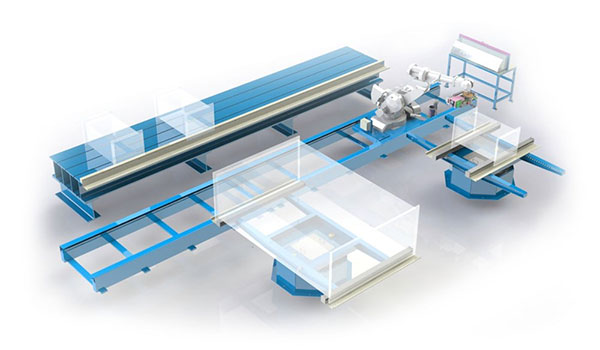

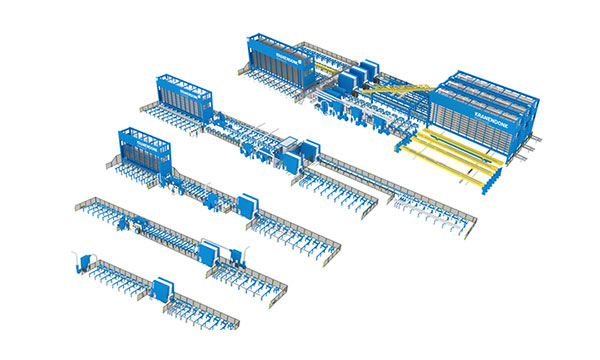

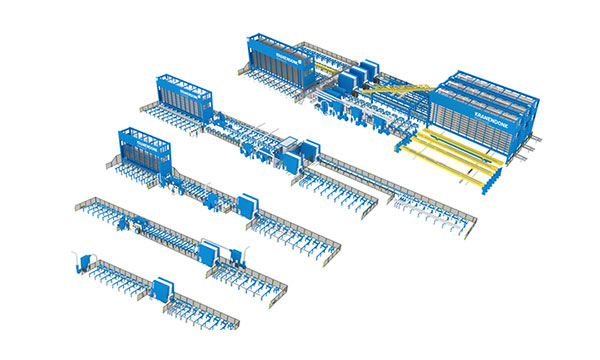

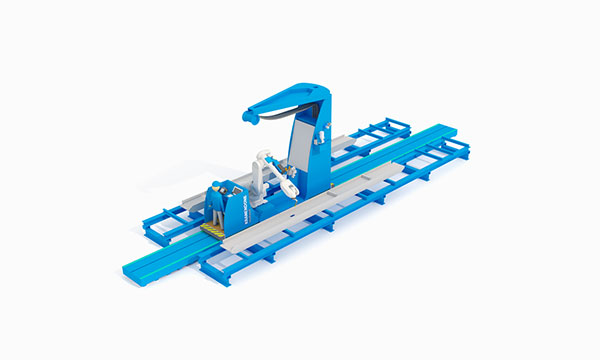

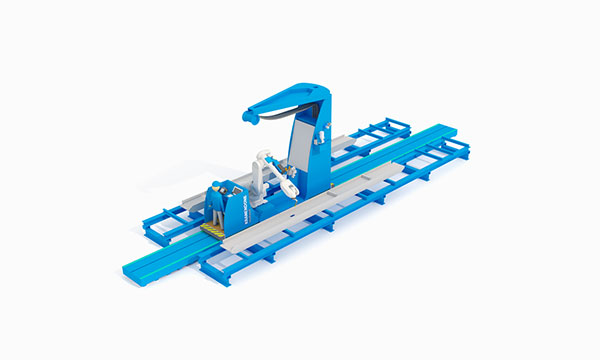

Robotic Beam Constructor

-

Robotic Beam Constructor automates assembling and welding of structural steel beams. Save hours on manual preparation and welding, and greatly enhance your production flow. Are you ready to bring your structural steel fabrication to the next level?

- Here's the proven steel beam assembler

- Streamline production with the high rise storage

- Automatic assembly with scanning technology

- Easy to operate and highly efficient

- Simplifying operations with smart software

Stiffener Mounting Gantry

-

This solution drastically reduces the time necessary to properly fit and tack-weld stiffeners onto steel plates. The vertical pressure that the cylinders provide on the stiffeners make sure that there are no gaps between the stiffener and the plate blanket when tack welding. Specifically engineered for a large variety of heavy profiles, including built-up profiles with height differences. The design and specifications can be customized to the requirements of the end-user.

- Heavy duty lifting

- Easy to operate - primary mounting beam

- Optimal user friendliness - secondary mounting beam

- Battery back-up system

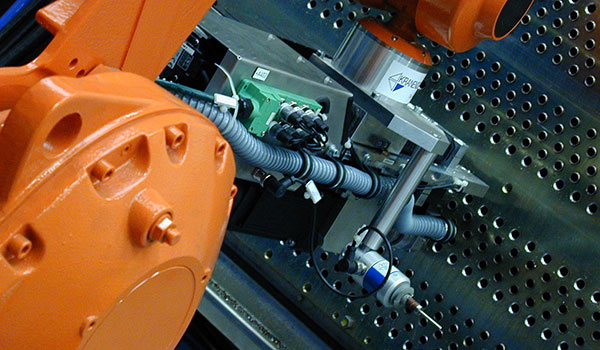

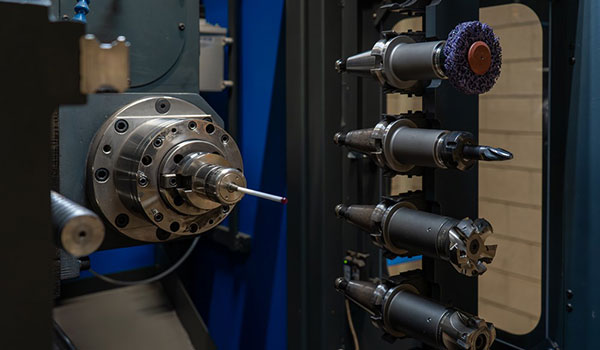

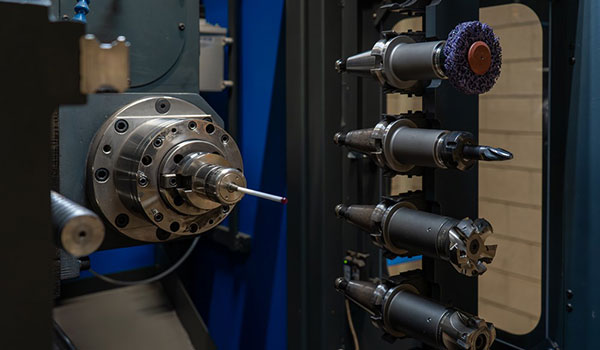

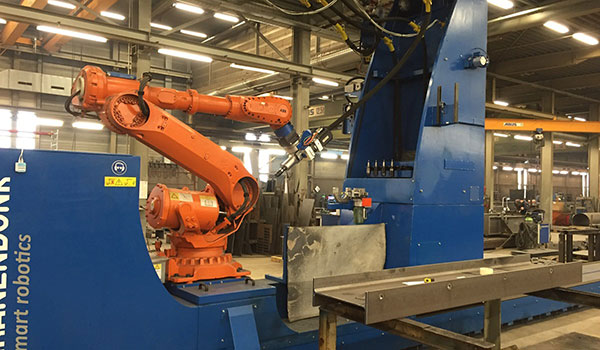

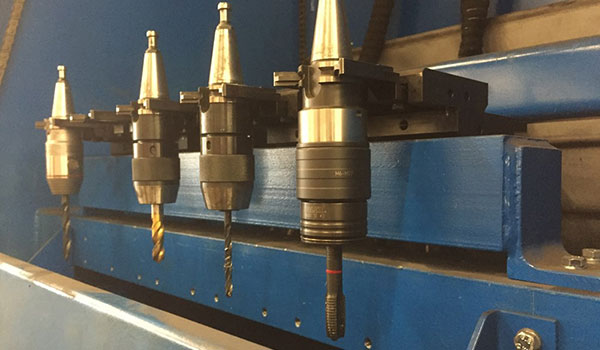

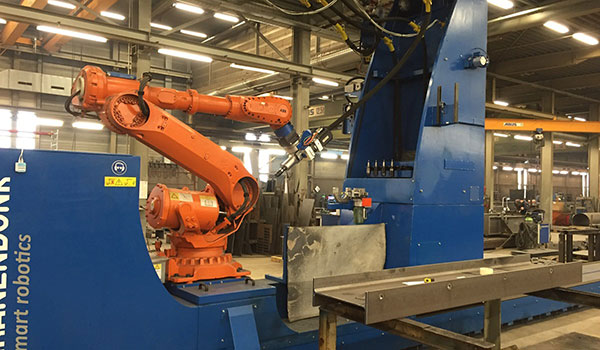

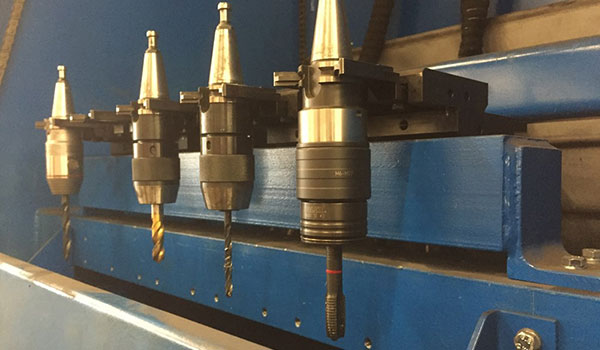

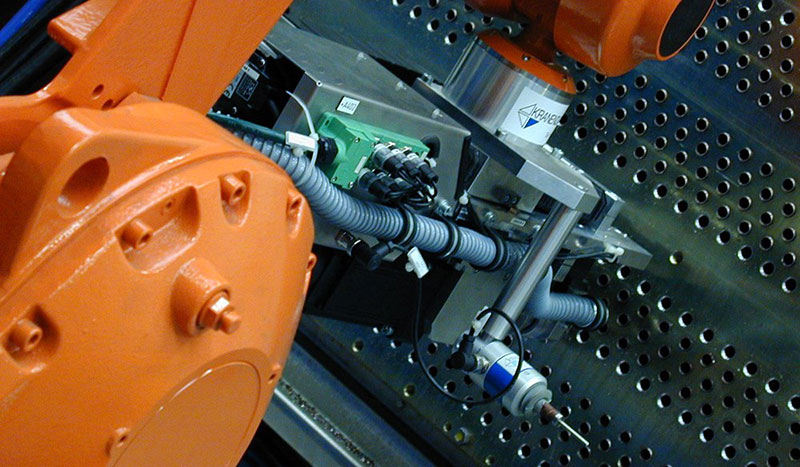

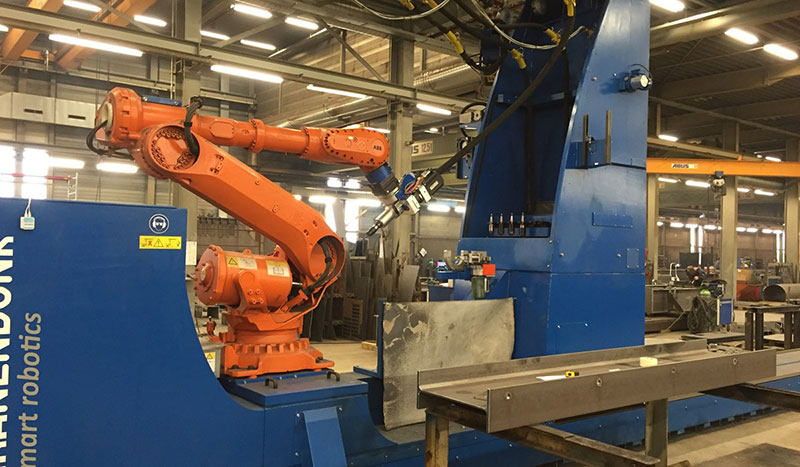

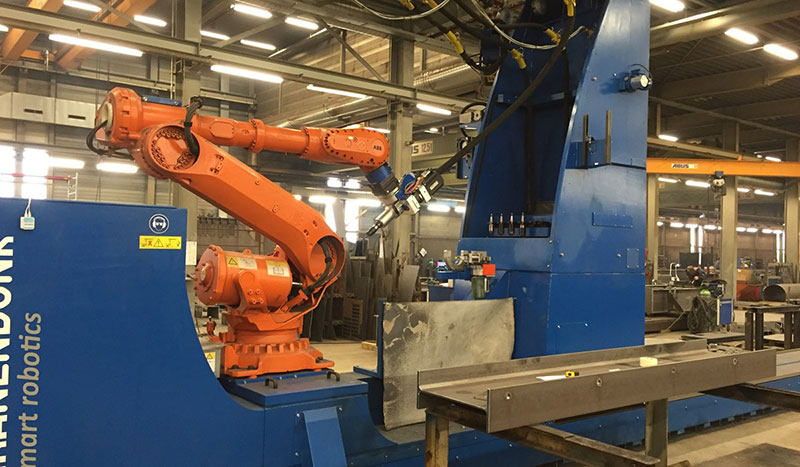

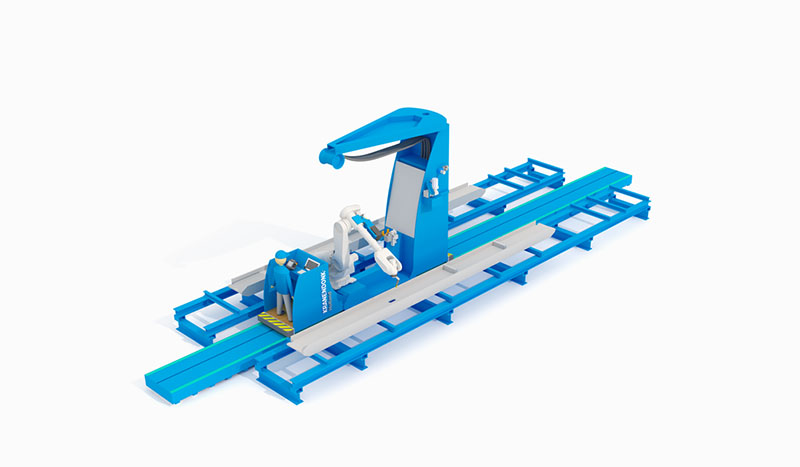

Multi-process Robot on Track

-

The Multi-Process Robot on Track offers unmatched flexibility for the processing of steel parts. The robot uses up to 5 different tools to drill, tap, cut, weld and mark on any steel part. The track is a fully coordinated robot axis, giving the system a large working area.

- Steel processing flexibility

- Drilling with robotic precision

- Unmatched accurate cutting

- Highly consistent welding

- Maximum flexibility in heavy steel processing

- Easy operation in a safe environment

Milling

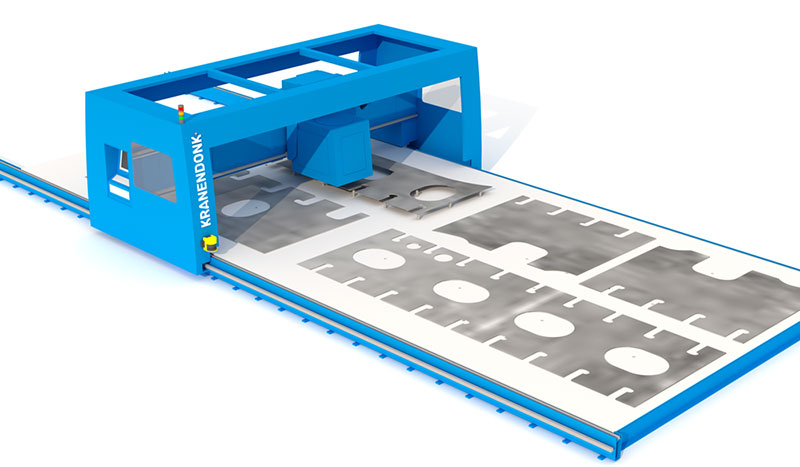

Edge Preparation System

-

No more rework! Due to the adaptive milling technology, the Edge Preparation System can achieve a perfect radius by adjusting to plate tolerances. This way you no longer have to worry about bottlenecks in production because of time-consuming rework activities. It contributes to the quality of your product with good coating lifetime.

- IMO PSPC compliant rounding of plate edges

- Adaptive milling technology

Apollo Spool Milling Station

-

Experience precision in pipe manufacturing with our advanced Spool Milling Station. Designed to automate bevel preparation for welding processes, this cutting-edge solution ensures flawless results every time.

- Accelerating manufacturing efficiency

- Achieving unmatched alignment

- Creating gap-free connections

- Embrace next-level spool production

- Flexible solution for manufacturing

Tube to Sheet Processing Cell

-

Besides the welding of tube to tubesheet connections, KRANENDONK also has supplied complete systems for tube expanding. Such a system is used for rolling of tube to tubesheet connections and the cleaning and end face milling of tubes.

- Flexible robot

- Tube-to-sheet welding

- Tube expanding and end face milling

- Automatic tool change

Multi-process Robot on Track

-

The Multi-Process Robot on Track offers unmatched flexibility for the processing of steel parts. The robot uses up to 5 different tools to drill, tap, cut, weld and mark on any steel part. The track is a fully coordinated robot axis, giving the system a large working area.

- Steel processing flexibility

- Drilling with robotic precision

- Unmatched accurate cutting

- Highly consistent welding

- Maximum flexibility in heavy steel processing

Cutting

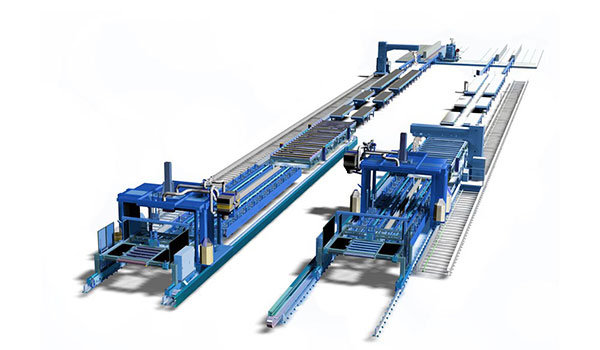

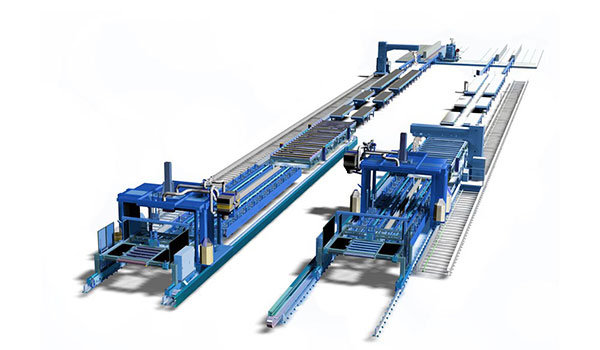

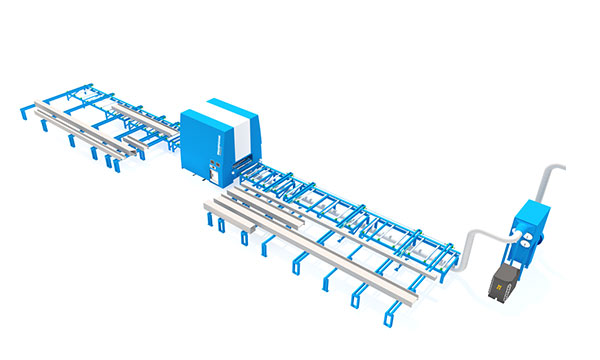

Profile Cutting Line

-

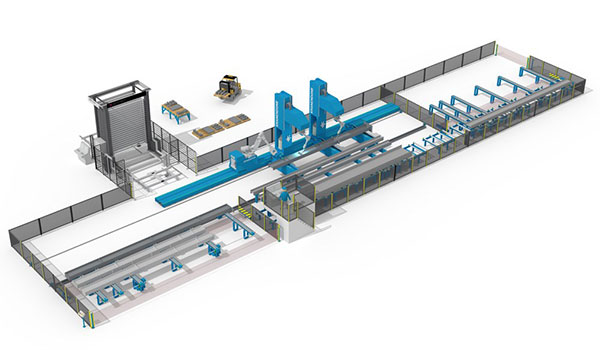

You can reach maximum productivity in the profile cutting shop, by connecting all processes. We supply tailored profile production lines with smart software that can run day and night.

- Integrated profile processing with plasma cutting

- The smart cutting line for shipbuilders

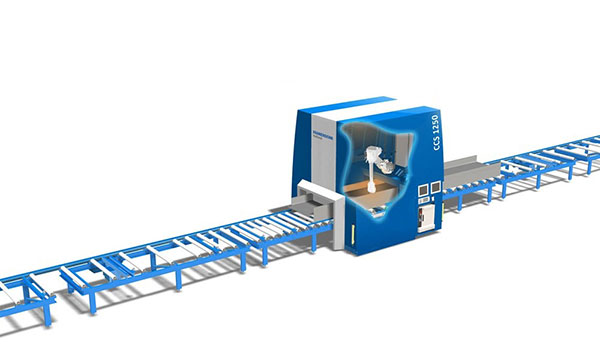

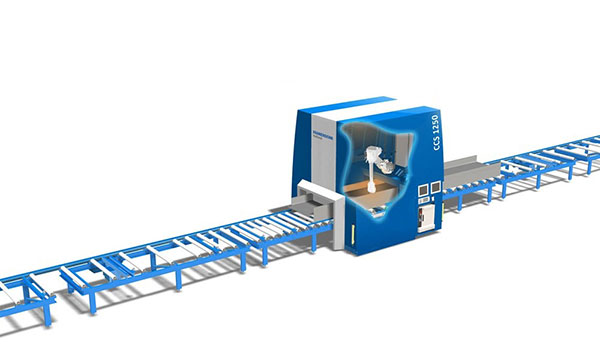

Beam Cutting Cell

-

A reliable solution for your beam production. Accurate cutting for all typical offshore shapes, using a large robot. A durable system, producing razor sharp results in harsh conditions. 30 years of steel cutting experience in one solution.

- Accurate robotic oxy-fuel or plasma beam cutting

- Reliable CCS steel cutting concept

- Reliable production with an all-in-one design

- Delivering a 3rd generation cutting line

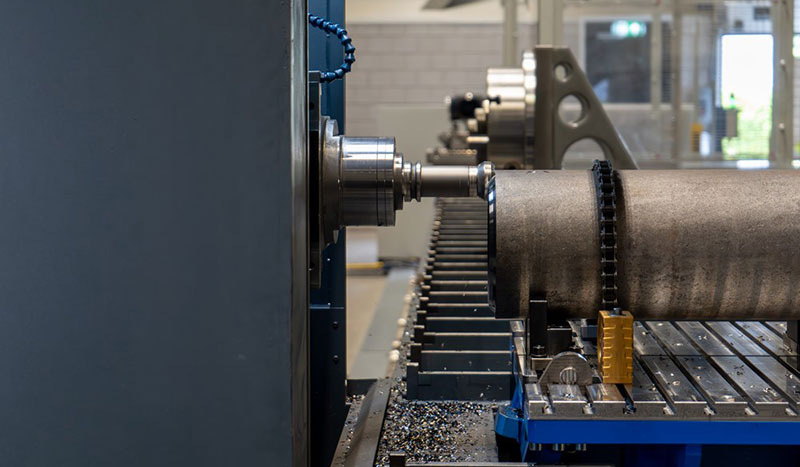

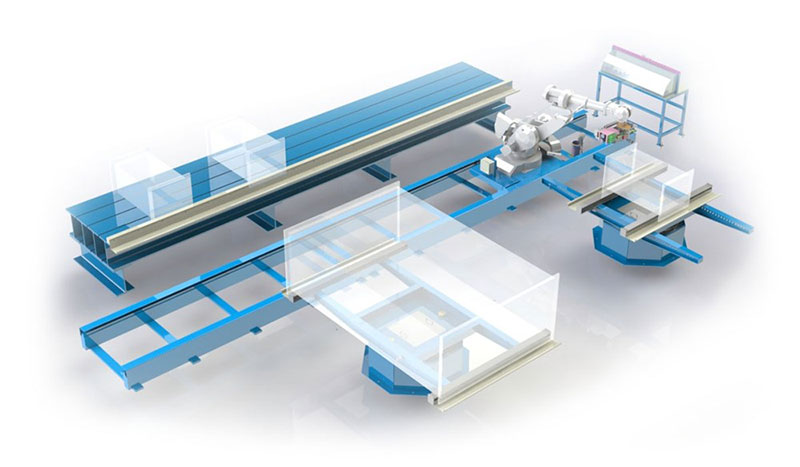

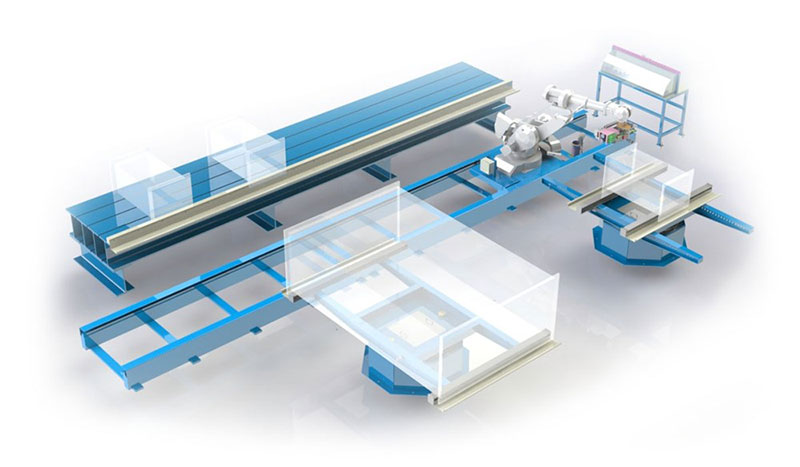

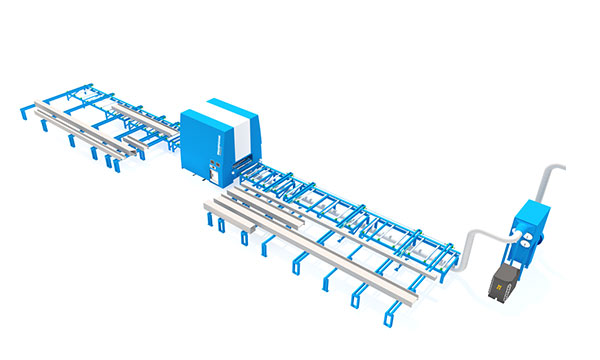

Tube and Beam Cutting Line

-

The combined tube and beam cutting cell is the ultimate solution for flexible offshore construction. A continuous flow of production is achieved as the system is able to proceed cutting while loading or unloading takes place at the other side.

- Flexible tube and beam cutting

- Ease of operation

- One machine: tubes and beams

- Highest safety standards

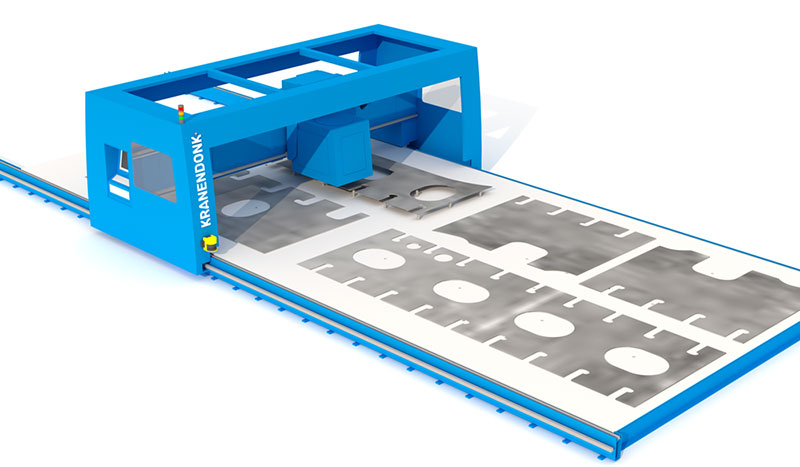

Plate Beveling Cell

-

Heat deformation problems when beveling? Not with our plate beveling robot. To cope with heat deformation, we have made an adaptive cutting torch. The KRANENDONK laser DLHC-sensor adapts to the material in real-time. Razor sharp bevels are the result.

- Accurate weld preparations

- Robot carriers for reach extension

- Adaptive oxy-fuel cutting

- Easy operating and programming

All-in-one Beam Processing Cell

-

Many steel construction companies are confronted with tighter budgets, putting pressure on the production process. Robotic beam processing offers a solution to produce leaner, by replacing multiple traditional machines. The all-in one solution will improve your efficiency and flexibility.

- One machine for cutting, drilling, marking, coping and grinding

- Ready for beams, hollow sections and angle bars

- From the world's most experienced robotic cutting supplier

Multi-process Robot on Track

-

The Multi-Process Robot on Track offers unmatched flexibility for the processing of steel parts. The robot uses up to 5 different tools to drill, tap, cut, weld and mark on any steel part. The track is a fully coordinated robot axis, giving the system a large working area.

- Steel processing flexibility

- Drilling with robotic precision

- Unmatched accurate cutting