Navigation : EXPO21XX > MATERIAL HANDLING 21XX >

H35: Profiles and Structural Elements

> item Industrietechnik

item Industrietechnik

- Offer Profile

- We set extremly high

standards for the design of our products and the fusion of form and function

so that we can continuously develop innovative and original products that

satisfy the stringent requirements of our customers.

Exceptional functionality and ease-of-use

Consistently high product quality, high-grade materials, exeptional functionality,

ease-of-use and excellent value for money - these are the features common to all our products.

Product Portfolio

MB Building Kit for Mechanical Engineering

- The item MB Building Kit System is the solution for

all design and construction tasks involving factory equipment engineering.

It can be used to build everything from simple frames to fully automated

production lines.

For more than 25 years, engineers around the world have been relying on the MB Building Kit System because it presents solutions that simply work. The modular components can be combined in a virtually unlimited number of variations, helping you turn your ideas into reality. Reliability and extendibility ensure that systems and structures have an extremely long useful life.

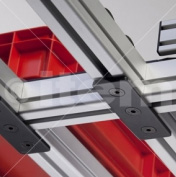

Profiles and accessories

- Using extremely strong aluminium profiles, any type of

structure can be assembled cleanly and rapidly without further surface

processing.

All profiles are anodized and are produced in modular dimensions compatible with specific Lines.

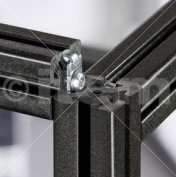

Fasteners

- The elements in the Fasteners product group provide power-locking profile connections of extreme rigidity.

T-Slot Nuts

- Different types of T-Slot Nuts with threads and groove profiles for customised processing generate a counter-bearing for the screw in the groove.

Screws and Universal Elements

- Various Screws and universal fixing elements to connect accessories to profile constructions.

Panel Fasteners

- The rigid connection is made using components which

differ depending on the requirement made on them in terms of strength,

installation and design.

Rigid panels can be formed using profiles or special clamping profiles.

Enclosure and guard system elements

- Special components for building secure guards and enclosures that are either connected directly to the machine base (machine-mounted) or are inherently stable and free standing (remote-mounted).

Hinges and Fittings

- Swing, sliding or lifting doors can be produced with the

aid of movable panel fasteners.

In this arrangement, the doors can be in the form of either inherently stable panels without frames or frame elements with integral panels.

Handle

- Swing, sliding and lifting doors are operated with

handles or grip systems.

The grips are either screwed directly into an inherently stable panel element or they are attached to the profile of the panel frame.

Locks and Catches

- As well as the latching function, locking systems also provide security against unauthorised entry via swing or sliding doors constructed from inherently stable panel elements.

Panel Elements

- This product group comprises panel elements of various

materials.

These panel elements are ideal for producing machine casings, guards, enclosures and housings as well as for constructing work benches.

Floor Elements

- The Floor Elements product group comprises:

- Adjustable Feet for jigs, machines and enclosures

- Castors for apparatus, containers and other mobile applications

- Special elements for securing constructions to the floor or wall

- Transport and base plates for connecting adjustable feet and castors to various applications

Conveyors

- Conveying operations can be incorporated into the profile structure with the aid of specialised accessories.

Machine accessories

- Accessories for machines – from operating machines and supplying information, power and data to preventing damage and protecting against vibration.

Installation Elements

- The Installation Elements product group consists of simple conduits, the highly variable modular conduit system, profiles with integrated conduits, Electronic Boxes and fasteners for cables and switches.

Linear Slides

- Linear Guides:

- Roller Guides on shafts secured to the profile groove

- C-Rail Guides in special profiles

- Ball Bearing Guide Bushes on free-standing guiding shafts

- Linear Guide Systems on guide rails on profiles 8

Mechanical Drive Elements

- The drive elements allow flexible design of any number of axes of movement when combined with item linear slides.

Components made of special materials

- For applications that place special requirements on the

materials in the structural elements of the building kit system.

The special item profiles made from either stainless steel or an innovative plastic composite.

Jigs and Tools

- Special jigs and tools for processing elements of the MB Building Kit System.

Work Bench System

- Your own customised work bench configured from our

broad, standardised portfolio – fast, flexible, economical and ergonomic.

Whether integrated into production lines, as a module for production islands

or as a standalone work bench, our new item work bench range will always

have the right solution for all your needs! All work benches are height

adjustable, with electrical systems available on request.

The basic configuration (table design and table top) alone offers a range of 80 work bench variants. What’s more, these variants can be combined with Uprights, Overhangs and a whole range of innovative accessories.

Work Bench

- Your own customised work bench configured from our broad,

standardised portfolio – fast, flexible, economical and ergonomic. Whether

integrated into production lines, as a module for production islands or as a

standalone work bench, our new item work bench range will always have the

right solution for all your needs! All work benches are height adjustable,

with electrical systems available on request.

The basic configuration (table design and table top) alone offers a range of 80 work bench variants. What’s more, these variants can be combined with Uprights, Overhangs and a whole range of innovative accessories.

Work Bench Equipment

- The range of accessories available from item enables users to customise their work benches. Drawer Units and Shelves create storage space for documents, tools and personal items. When everything is in easy reach, work can be completed much faster.

Chairs

- Added comfort and reduced strain – the keys to boosting

employee performance at the work bench. The ergonomically designed Chair

from item provides noticeable relief from the stresses and strains

associated with processes in production operations, workshops and

laboratories.

Back pain, particularly in the case of seated activities, is among the most common complaints and causes of illness-related downtime. Unsuitable seating exacerbates the consequences of poor work bench design caused by the inefficient provision and positioning of tools and workpieces.

Power and Data Supply

- For us, ergonomics and health and safety start right from

the power supply.

Virtually every work bench needs energy in one form or another. That’s why integrating a power supply is a key aspect of work bench planning.

Whether electricity, compressed air or data – you can stay flexible by integrating Distribution Strips, Multi-Socket Power Strips and compressed air supplies into your working environment. Depending on requirements, the power supply can be fed in above or below working level. Making subsequent changes to the work bench design is also extremely straightforward.

Lighting

- Casting the right light on any work bench – from the LED Illuminated Magnifier to the large Light Fitting 55W, item has the ideal solution for every need. Whether you need the pin-point lighting of a Lamp 35W at your work bench, or want to light up the working area safely with the compact LED Machine Light Fitting, we have the perfect lighting solution for you!

Information provision

- Practical solutions for holding your information – with innovative work bench accessories from item. Work benches are nodal points in a networked production system. They need to be able to send and receive information as integral components in a production control and material flow system. Our comprehensive range keeps your information flowing!

ESD Equipment

- The safe dissipation of electrostatic discharges (ESD) is a basic requirement for modern work benches. Static charges can affect or even destroy measuring devices, factory equipment and of course electronic circuits in a workpiece. A work bench concept must take into account all the components involved in a process and incorporate the people who will be carrying out the work. That is why item offers a wide selection of ESD-safe components including table tops and frames.

Tool handling

- New, innovative accessories for the work bench – the item range of holders. Whether hooks, holders, tool holders or magnetic holders – we have thought of everything! Choose the right solution for your work bench from a wide range of mounting accessories. The universal fastening system is suitable for all Line 8 profiles.

Material Supply

- Maximise your flexibility by keeping everything you need close to hand. Pivot Arms are an ergonomic means of keeping small parts, holders and tools within easy reach at all times. item offers you three different variants as accessories for your work bench.

Work bench interlinking

- Flexible structures of group work benches and production islands support integrated checking procedures, independent process control and high-productivity manufacturing. The modular design of the item work benches provides the ideal basis for delivering cutting-edge workplace organisation. Adjusting and controlling material flows couldn’t be easier when also using the variable interlinking elements supplied by item.

SystemMobile L

- SystemMobiles L are the ideal addition to standalone work stations. They bring working materials closer to personnel and support rapid and ergonomic handling. Rear-facing material provisioning makes short work of reconfiguring work benches for new products.

SystemMobile U

- SystemMobiles T have central struts that allow easy access to shelves and storage boxes from both sides. As a result, tools and materials can be placed between two work stations. Parallel removal and filling also supports group work with a flexible material flow.

SystemMobile T

- SystemMobiles U transport heavy loads with maximum safety. Four stable struts located directly over the transport castors ensure the trolley is exceptionally stable and provide secure support for Shelves. Consequently, even complete mobile work stations and other special solutions can be moved around with ease.

SystemMobile S

- SystemMobiles S are exceptionally compact. These manoeuvrable picking and provisioning trolleys get tools and small quantities of materials to where they are needed – fast. The single central column is also available in a height-adjustable version. The all-round edging on the tray makes sure everything stays put so that both standard storage boxes and individual items can be moved around as necessary.

Accessories for SystemMobiles

- Individual right down to the smallest detail

Work materials have to adapt to the work at hand – not the other way round. That is why SystemMobiles can be configured to suit the specific features of the production system where they are being used – no matter how often that production system changes.

Line D30

- Simple handling is the key feature of Line D30 and

delivers maximum cost efficiency through continuous improvements in

manufacturing processes. It is made possible by non-machined connections,

simple joining and a forgiving design principle. The freedom and flexibility

of a tubing system coupled with the item Building Kit System result in a

diverse range of possible combinations. Giving you the ultimate flexibility

for turning your ideas into reality.

The components deliver exceptional performance – significantly lighter than steel designs but still stable, thanks to the benefits of profiled tubes. Fastenings can be implemented anywhere – in the perfect position and at any angle. Furthermore, support of the item Profile 6 groove enables users to take advantage of the wide range of accessories in the MB Building Kit System.

Profiles and accessories

- A fully rounded solution

The Tubes and Profiles in Line D30 have one thing in common – their basic diameter of 30 mm makes solutions incredibly rigid. It also corresponds to the modular dimension of item Profile 6, producing a whole range of opportunities for combination.

Fasteners

- Ingenious fasteners

The unique concept of Fasteners D30 allows unrifled Tubes, Profile Tubes and Profiles with standard grooves to be connected together using the same fastening elements.

High clamping forces ensure the construction is stable and the item clamping technology prevents twisting in contact with unrifled Tubes.

item provides additional bracing struts as an optional extra to counteract high moment loads.

Fastening Elements

- Endless possibilities

Structural components are enhanced by fastening elements for panelling and working surfaces and for making sure information and container mountings are close to hand. This opens up new opportunities for integration into existing production facilities or adding functional elements with ease. Elements from third-party suppliers can also be added.

Material Flow

- When movement matters

Goods, finished parts and consumables – in a modern production system everything has to keep flowing. Achieving that requires cost-effective conveyor systems.

Sliding items over abrasion-resistant strips ensures that they reach the work bench safely.

Various types of roller conveyor help keep the supplies coming in from Kanban shelves. The material flow components in Line D30 are incredibly easy to build and install – ensuring that everything flows smoothly.

Applications

Mechanical and factory equipment

- Thanks to more than 150 profile variants and specialised fasteners to suit every need, the MB Building Kit System offers unlimited combination options.

Enclosure and guard systems

- The system with safety built in. item provides all the components required to build enclosure and guard systems of the highest technical standard. The results are safety solutions.

Work Bench Systems

- Whether ergonomic standalone work benches, interlinked assembly lines or partially automated production lines – item supplies the components required to create efficient and fatigue-free working practices.

Lean Production

- Solutions from item deliver the freedom and flexibility that cost-effective manual assembly systems require. Easy to assemble, easy to convert – self-explanatory functional elements can be configured and reconfigured rapidly.

Dynamic Elements

- The efficient linear systems from item enable users to develop automatic solutions of the highest standards. The highly accurate linear slides can be used to connect numerous axes into complete handling and positioning systems.

Industry Solutions

- Pre-configured industry solutions from item help you find the ideal solution for typical tasks in next to no time. All the components are from the MB Building Kit System and can be combined with customised designs.