- Offer Profile

- An independant factory and

market leader in intra-logistic automation Technology

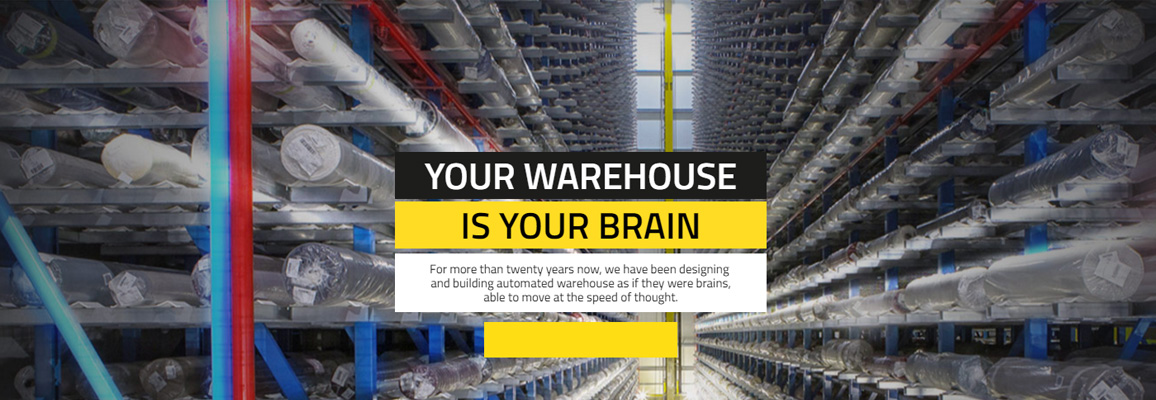

Today Automha is a leading technology company through its capacity to turn constraints into opportunities, designing each project based on our customers’ requirement – thanks to its team of designers and products, systems and solutions.

Automation is the result of ideas, inventions, implementations coming from our technical background and built up over the last 30 years out of new sciences such as electronics, information technology and mechatronics.

Solutions

For every industry

- SPECIFIC CONFIGURATION OF EACH SECTOR

Automha has the experience and the expertise to engineer specific solutions for each industry, optimizing the response to a number of variables in terms of product size, method performance and storage, and picking and operating conditions.

The products’ features and the configuration of Automha systems are designed to ensure higher performance standards that can be implemented in each industry.

With every technology

- FROM EQUIPMENT TO MECHATRONICS

Solutions based on various sciences and technologies in the most appropriate configurations and implementations:- mechanics: the basis of any technology, it is the science of the movement of bodies (dynamics) and their balance (statics) which becomes the technology used to design and manufacture equipment, machines, mechanisms and all their components.

- electrotechnics /electronics: the technique used to control electrical energy, electrical machines and circuits in which information is translated into electrical signals

- information technology: it is the science and technique for automatic processing of information via electronic processes

- mechatronics: it is the engineering of the interaction between mechanics, electronics and information technology

For every requirement

- TAILORED PROJECT IN EACH STAGE

Automation is the winning choice for efficiency in intra-logistics. Automha has developed a variety of methods and strategies depending on the customer’s requirements:- green field projects: new sites, new warehouses

- on site restructuring: a completely redesigned and rebuilt space, with customized procedures to avoid business disruption when work is in progress

- revamping: revision, general restructuring and technological modernization and structural changes

- retrofitting: implementing, adding a new technology and new functionalities

Systems

Miniload Booster

- AUTOMATIC SOLUTIONS: HEAVY MINILOAD

Heavy Miniload warehouses by Automha, are automatic storage systems for containers or trays used in all the requirements characterized by high flows of collection of heavy-weight goods.

The warehouse is formed by a central corridor where a stacker crane moves, with two shelves located on both sides for the arrangement of boxes and trays. To the side there are one or more automation areas where the stacker crane drops off the load extracted from the rack. Transporters approach the loading unit to the operator and, after the collection, return the loading unit to the stacker for its allocation in the rack. This happens with maximum speed and full computerized management.

The entire system is coordinated by the management software by Automha (AWM).

SRM Autostore

- AUTOMATIC SOLUTIONS: STORAGE

Autostore warehouses allow the automated storage of loading units of any size and weight. The machines are designed in different solutions for maximum utilization of the available volume. The Autostore storage can be installed in industrial buildings and in self-supporting, independent structures.

The cutting-edge technology and the efficiency of the Automha stacker cranes is guaranteed by the control systems of operational functions and by the lack of cable connections between machines in motion and concentrator on the ground. The running rails are installed, with an exclusive system, on anti-vibrating pads. The energy supply is provided via double brushes and busbar positioned on the ground.

Autosatmover

- AUTOMATIC MODULAR STORAGE SYSTEM FOR PALLETS

AutosatMover® is the next generation modular system, fully automatic for the automation of multi-depth storage of pallets. It is composed by:

- Mover, the mother shuttle, which moves on rails that are perpendicular to the storage channels, powered by busway at each loading system

- Supercap®, the satellite on board, commanded by the mother shuttle via wifi and allocated to the operations in different storage channels, for the automatic collection and storage of pallets.

The different system configurations are composed of elevators/descenders for Pallets. These are intended for the delivery of pallets to the different storage channel for its management by AutosatMover, and elevators/descenders for the Mover. This happens only in configurations where a single AutosatMover is working on different levels.

Even for AutosatMover®, the management of the entire system is provided by our WMS software.

Handling

- INTERNAL HANDLING SYSTEM, AGV, ROBOTICS

Automha designs, manufactures and installs automatic transport solutions – systems of pure internal transport, or serving automatic warehouses – able to increase productivity, reduce operating and manpower costs.

The modules that form the transport lines by Automha are determined by motorized conveyor belts, chains, belts and tapes, and can integrate orthogonal transfers, transhipment shuttles, elevators or other specially designed machines. Every section can be integrated with stations that identify, weigh, control and align the products.

Vertical lift module

- THE EXPANDABLE VERTICAL

WAREHOUSE

Masterlift is an automatic storage and refilling system, characterized by a simple construction.

Through the addition of vertical modules you can expand it, allowing a remarkable storage of the products in the drawers and a quick, computerized collection of items.- Flatpack system: it extracts and inserts the trays on the brackets supporting the involved levels, and serves the work bays. An automatic machine manages the translation and lifting movements.

- Handled load units: the drawers are made of metal sheet with slotted walls for the division into compartments and/or provided with plastic containers for small parts.

- Drawers compartment: it is guaranteed by a reading, in the loading bay, of the encumbrance in maximum height, which determines dynamically the storage location of the drawer.

- Integrated safety in the bay/operator: photocells system of intrinsically safe barrier.

- Modular total: it allows to realize the warehouse with the most consistent storage capacity, always having the maximum expandability.

Products

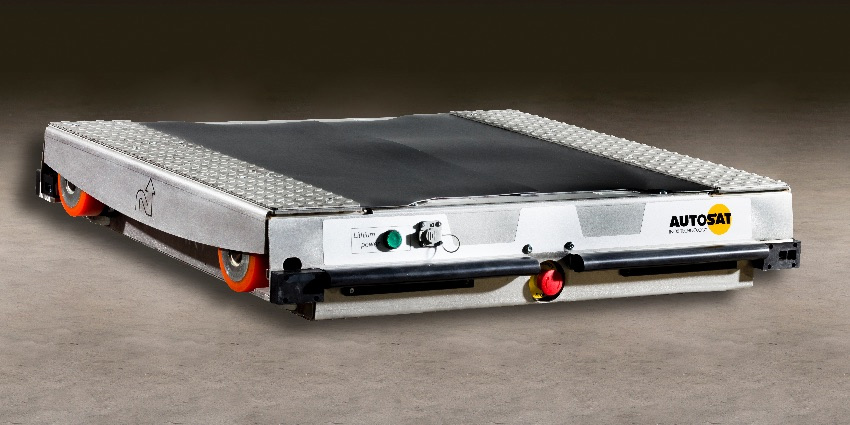

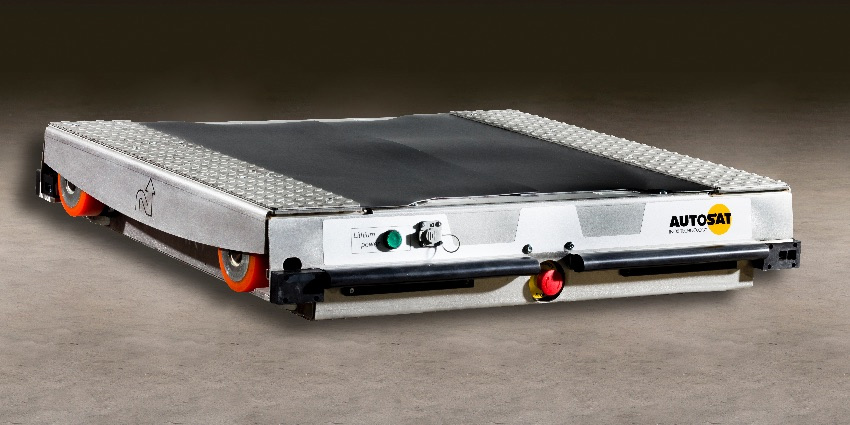

Autosat

- SEMI AUTOMATIC/BATTERY-POWERED MACHINE

Autosat® is a machine able to move independently and destined for the automatic storage of pallets, in a traditional drive-in shelf of the lane.

Autosat® guarantees an automatic high-density storage, allowing the maximum exploitation of the stock volume. It demonstrates its effectiveness in the event of repeated draining/filling of the same channel (eg. buffer zone management).

Depending on your needs, the machine is available in two versions:- Autosat®: controlled by a simple multi-function remote control with LED display

- Autosat® wifi: controlled via wifi with WMS communication (Warehouse Management Software) between PDAs and AGV laser-guided shuttles.

The semi-automatic vector is distribuited with Pallet-runner brand, in USA and Canada.

Supercap

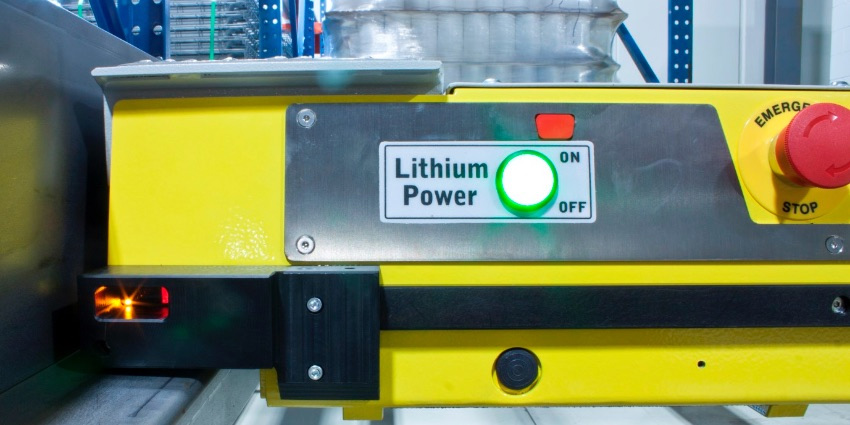

- FULLY AUTOMATED MACHINE/NO BATTERY/SUPERCAPACITOR

TECHNOLOGY

Supercap® is the satellite that carries a multi-depth storage into fully automated systems. With the introduction of the Supercapacitor technology, we were able to overcome the typical problems of battery-powered systems that claim long charging times (in the case of satellite with integrated batteries) or the presence of operators for the replacement of accumulators (in the case of machine with extractable energy source). In order to overcome the recharge problems, Supercap® ND (Never Die) is provided with a Supercapacitor and a further lithium battery.

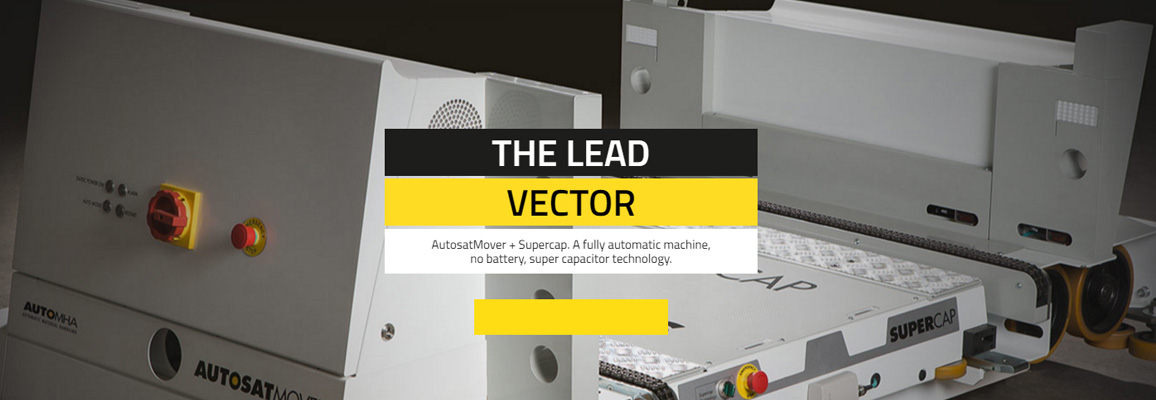

Autosatmover

- AUTOMATIC MODULAR STORAGE SYSTEM FOR PALLETS

AutosatMover® is the next generation modular system, fully automatic for the automation of multi-depth storage of pallets. It is composed by:- Mover, the mother shuttle, which moves on rails that are perpendicular to the storage channels, powered by busway at each loading system

- Supercap®, the satellite on board, commanded by the mother shuttle via wifi and allocated to the operations in different storage channels, for the automatic collection and storage of pallets.

The different system configurations are composed of elevators/descenders for Pallets. These are intended for the delivery of pallets to the different storage channel for its management by AutosatMover, and elevators/descenders for the Mover. This happens only in configurations where a single AutosatMover is working on different levels.

Even for AutosatMover®, the management of the entire system is provided by our WMS software.

Pallet Runner

- PALLET RUNNER – THE ORIGINAL

PALLET RUNNER® is a semi-automated deep lane storage system. Especially suited to applications with high volume SKU’s, PALLET RUNNER® has proven to be an ideal choice for companies worldwide for over 10 years.

Pallets are loaded into the system by lift truck and transported into deep lanes by the PALLET RUNNER® cart. Once the load is positioned the cart returns to the front of the system to receive the next pallet. With the cart doing the deep lane transport the lift truck operator travels only between load source and lane entry, maximizing productivity and minimizing travel distance.

The process of unloading realizes the same efficiencies. The PALLET RUNNER® cart carries loads out of the system while an operator moves between the lane and the shipping dock or other destinations.

Extremely robust, PALLET RUNNER® carts are available in different sizes to suit a widevariety of pallet designs. PALLET RUNNER® can be set up for FIFO or LIFO applications in both ambient and freezer environments.Value added options let us tailor PALLET RUNNER® to suit your specific needs.

PALLET RUNNER® is a proven platform brought to you by AUTOMHA, the world leader in cart based automation. If you want to maximize storage and occupancy in your facility while simultaneously reducing your overhead, PALLET RUNNER® may be the perfect choice.

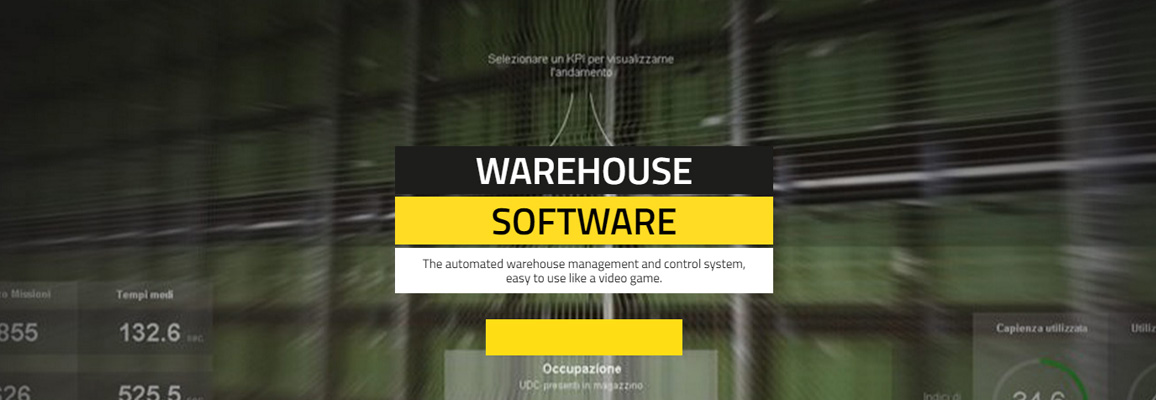

Sofware

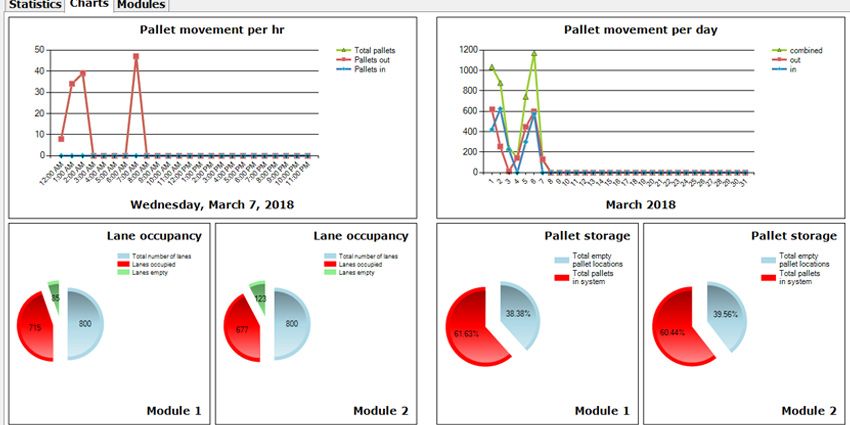

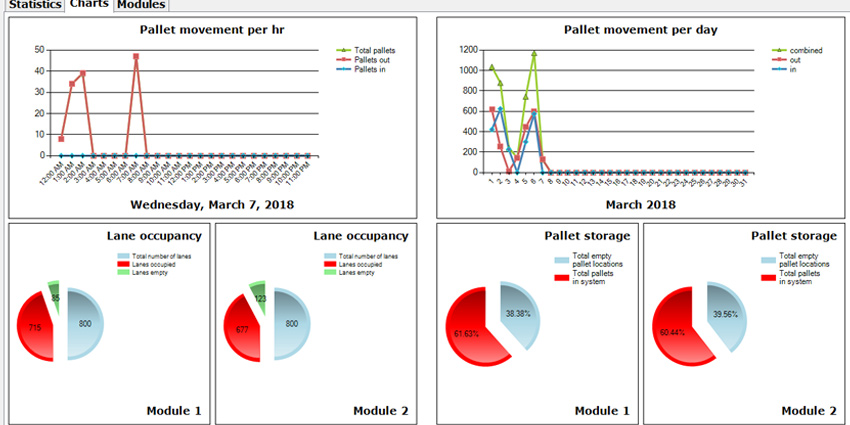

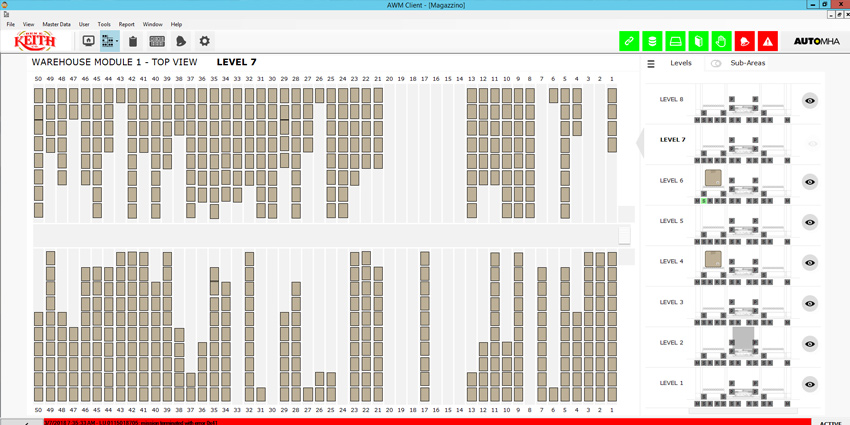

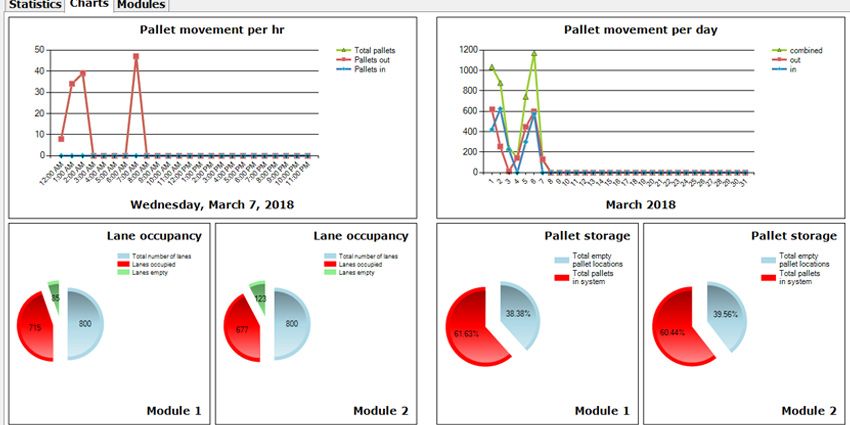

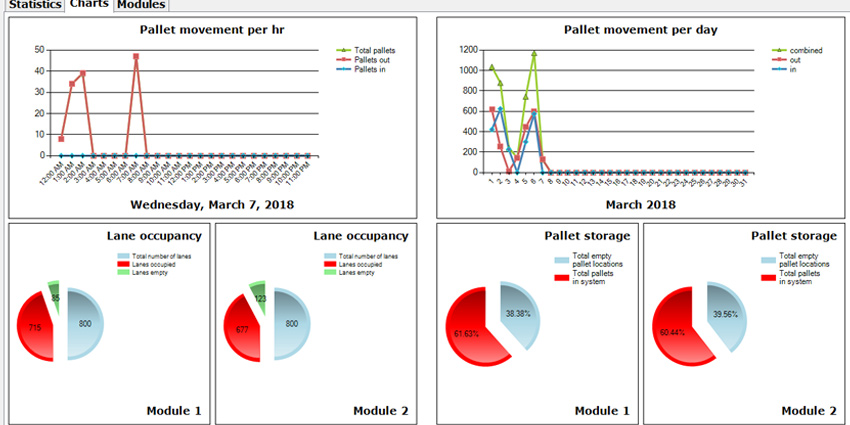

AWM

- WAREHOUSE MANAGEMENT SOFTWARE

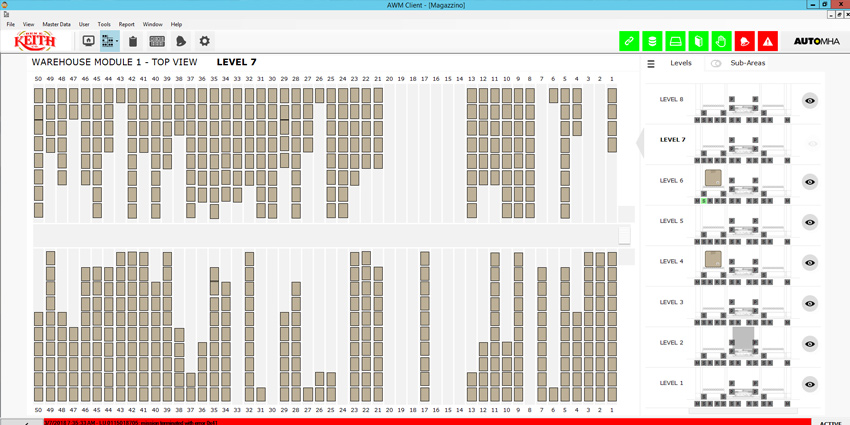

The AWM software is based on 4 softwares, each specific to every automation sector:- AWM: automatic warehouse manager, web interface for warehouse management

- PCM: PLC communication manager, communication software with PLC

- SQUL procedures: Microsoft Sql Software procedures for the management of warehouse logics

- HMI Siemens: operator panels on switchboard

AWM is the tool through which the operators interface with the system, through a series of masks, to manage and perform the insertion, loading, refilling and picking typical of automated warehouses. AWM allows the control and monitoring of the plant status.

LOG

-

AUTOSAT SEMI-AUTOMATIC WAREHOUSE MANAGEMENT SOFTWARE

LOG as logging, the recording software that makes the warehouse with AUTOSAT technology traceable and autonomous as a fully automatic system.

LOG, thanks to a simple and engaging interface, is a powerful and complete tool for processing data regarding the input and output handling of the Loading Units in the warehouse, whether manual or semi-automatic.

LOG processes all the information related to the stored goods and stores their characteristics and movements during the various management phases:

- RECEIVING: it acquires data of existence of the UDC and data of planning of the warehouse movements by the company ERP, processes them and sends them back to the ERP once the operations have been completed.

- STORAGE: regulates the management and assignment of UDC locations according to the company strategy (by product, customer, production batch, etc.).

- COLLECTION: regulates the handling of movements that make up shipping or picking orders according to the company strategy. This allows to keep mapped all the goods circulating in the warehouse, to know their characteristics, the movements and the location.

ADVANTAGES

- Mapping: allows to have constant and immediate awareness of the goods present in the warehouse, of the movements made, of the available positions and of the cycles sustained.

- Reorganization: the warehouse and the warehouse areas can be reorganized and compacted according to the company logic at any time.

- Pre-preparation: the LOG gives the possibility to suggest the preparation of the Load Lists, programmable in available warehouse areas.

- Traceability: the operator can immediately track the goods stored in the warehouse lanes.

- Reporting: LOG extrapolates punctual reports on the situation of the warehouse, on the cycles sustained or on the activities carried out by personnel, forklifts or customers.

- License free: LOG does not provide for the purchase of annual or subsequent licenses.

- Sizing: LOG allows the customer to size his logical or physical warehouse at any time through a two-dimensional array, personalizing the images, levels, channels and their properties.