- Offer Profile

- Since 1953 CREFORM has

incorporated in its modular system all elements for an efficient material

flow. With the proven philosophy (KAIZEN) and the suitable CREFORM products

you will increase the efficiency of your products dramatically.

No matter whether you are active, for example, in the automobile industry, food industry or in aviation; whether you distribute medical devices or assemble electronic components, CREFORM helps your corporation with the introduction of lean manufacturing.

Through the use of CREFORM systems a well organized manufacturing process with very short response times and high flexibility develops. Optimal quality, cost reduction and time saving are only a few of the resulting competitive advantages.

Products

-

Stable, light, flexible: the CREFORM system adapts completely to your requirements. Increase the efficiency and quality in your production.

Pipes

-

CREFORM pipes are characterised by extreme lightness and high stability. Their sheathing made of robust ASA thermoplastic ensures high resistance to weathering and heat deformation.

Our wide range of different colours and diameters promises the ideal solution for every application.

CREFORM naturally also offers ESD-capable components with which you can also use your required structures in ESD protection zones.

Inform yourself in our catalogue about our large selection of different basic and combination elements.

In addition, CREFORM also offers many different types of pipe with which almost any application can be implemented.

Our product variety:

- Ã 28 mm for all kinds of applications

- Ã 42 mm for high loads

- Ã 32 mm for individual solutions

- Optional ESD conductivity

- Large choice of colours

- High flexibility through the ability to reuse

- Optional ESD conductivity

- Large choice of colours

- High flexibility through the ability to reuse

Joints

-

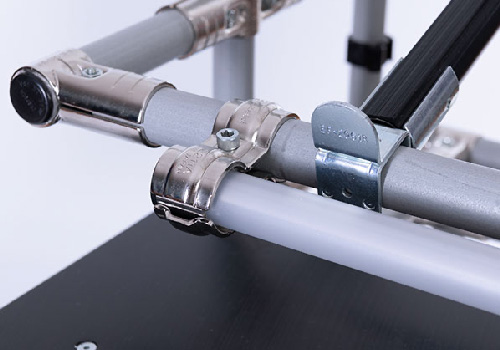

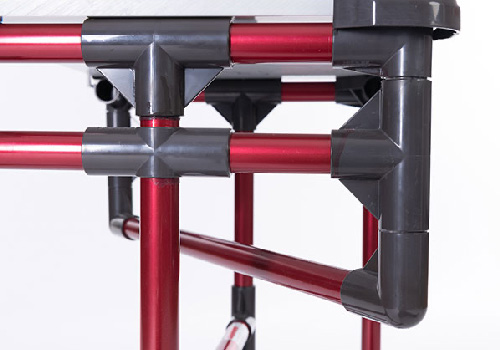

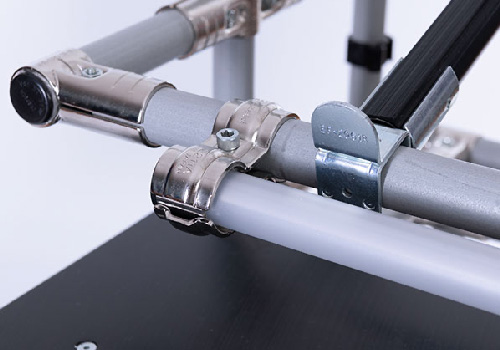

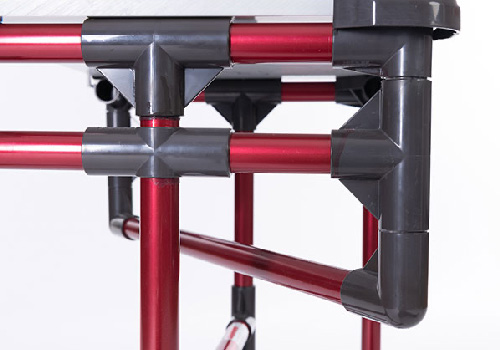

The CREFORM pipe elements only develop their full effect in combination with our CREFORM standard joints. They form the basic components of all CREFORM structures and are made of metal or plastic depending on the application.

Manufactured from cold rolled steel, CREFORM metal joints offer optimum protection against corrosion due to their surface treatment. They consist of two or more components, which are secured with special nuts and bolts. Thanks to deep-drawn claws, a non-positive and reliable connection is created between pipe and metal connector.

Consisting of high-quality thermoplastic ASA plastic, CREFORM plastic joints are ideally suited for permanent connections. A durable and stable connection is guaranteed by the bonding of pipe and plastic joint.

Whether made of metal or plastic - both product variants are equally convincing with their high stability:

CREFORM metal joint:

- Ã 28mm

- Ã 32mm

- Ã 42mm

- Suitable for (almost) any application

- High flexibility through the ability to reuse

- Optional ESD conductivity

- Huge selection

- High strength, durable steel

- Corrosion-protected sheathing

CREFORM plastic joint:

- Ã 28mm

- Large selection (over 90 joints)

- Low weight

- Easy to bond

- Permanent stability

- Wide range of colours

- UV and moisture resistance

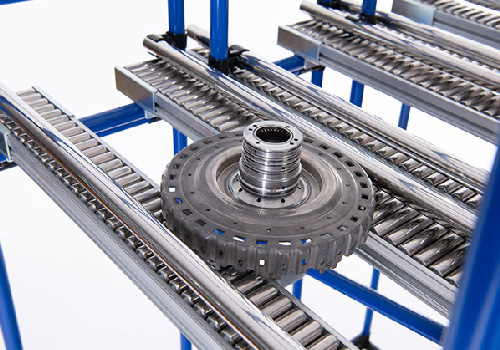

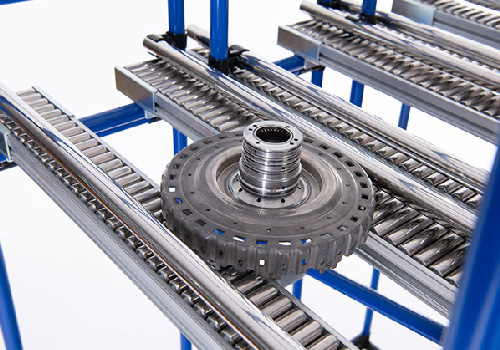

Conveyors

-

Process-reliable material feed for all requirements - thatÂs what CREFORM roller track can do. Flexible in use, a wide variety of containers and goods can be transported gently on many material levels in parallel at an incline of just two percent.

Our CREFORM conveyors are available in the standard version with stable aluminium frame and individually removable rollers for easy maintenance and reconfiguration.

Alternatively, you can opt for the wide conveyors of our PW series, which can also be used for easy corner transition of containers and individual parts.

All CREFORM conveyors can be combined with ALU profile systems.

Our product variety:

- 2500 mm length

- 3000 mm length

- 4000 mm length

- Optional side guide

- Cylindrical rollers

- Conical rollers

- Transport of individual workpieces with structured or uneven surfaces

- Corner transition

- Transport of workpieces with susceptible surfaces

Accessories

-

CREFORM accessories consist of a wide range of castors, rollers and floor elements. These intelligently round off your personal CREFORM structure.

The different diameters, running surfaces and mounting options can be selected according to your production requirements and modified at any time.

- Rolls and castors

- Monitor holders

- Monitor holders

- Tool holders

Tools

-

The right tool is essential for working with your individual CREFORM solution. CREFORM offers you here corresponding standard equipment for all hand tools which are necessary for the handling of our pipe system.

For work with more advanced power tools such as band saws, we will be happy to provide you with a recommendation if required.

Automated Guided Vehicles

-

Automated Guided Vehicles (AGV) from CREFORM bring movement into your production process. Material transport is optimised more efficiently, more flexibly and particularly cost-effectively.

CREFORM Automated Guided Vehicles not only perform conveying tasks, such as the linking of production and assembly facilities, but also tasks in warehouse provision and order picking. Materials of all shapes and weights - from 250 kg to 1800 kg - can be transported reliably and safely using our various vehicle types VM1, VM2 and VM3.

In order to be able to move as dynamically and efficiently as possible, CREFORM Automated Guided vehicles (AGV) are navigated freely along natural features in the surroundings that serve as their orientation. The track guidance can be adjusted quickly and in just a few steps on the PC in case of new or changed surroundings. Alternatively there is the possibility of track-bound line navigation.

Based on a specially designed modular principle, we are able to design, construct and manufacture individual Automated Guided Vehicles (AGVs) and systems (AGSs) exactly to your personal requirements - all Made in Germany.

Our product variety:

- Magnetic track or freely navigating

- Lead gel or li-ion battery technology

- Siemens components & Sick sensor technology

- Solid metal frame in individual colour

- TÃV Saar approval / CE declaration

Individual solutions

-

The solutions we develop for you are as individual as your requirements. That is why we want to ac-company you on your way to "Lean Manufacturing" right from the start. Our CREFORM system not only offers exactly the right product for this purpose, but also enables the consistent implementation of the KAIZEN philosophy. Our goal is to accompany and support you from the first draft to the plan-ning and installation of your personal CREFORM system.

Our services at a glance

- Consultancy & planning

- Technical support (structure design, CAD draft)

- Picking and packing (cutting, bending, rack kits)

- Assembly on-site

- Training, KAIZEN workshops

Workshops and starter kits

The CREFORM starter kit is the ideal way for new users to familiarise themselves with the world of KAIZEN and for employees to overcome their reservations. With the help of the standard equipment of components and tools you learn the skills to build basic elements such as trolleys, shelves, conveyors or desks independently.

If required, the starter kit can be adapted to your special needs and individual requirements. In a one- or two-day workshop, we train your employees in the use of the CREFORM system and develop initial applications together. According to the philosophy of Gemba-Kaizen (Gemba= the actual place) our workshops always take place directly on-site in your production facility. In this way we can respond to your personal improvement potential individually and develop suitable optimisation approaches to-gether.

For experienced users, we also offer Karakuri workshops at regular intervals. Learn more about the traditional, Japanese design principle Karakuri and gain your first practical experience together with our experts.

Supply methods

CREFORM delivers your goods fast, uncomplicated and tailored to your needs. By stocking our stand-ard components, we guarantee short delivery times.

For complete CREFORM solutions, we will develop a design drawing based on your own ideas and vi-sions, which can serve as a construction manual for assembling your structures. All required materials are then delivered to you compiled as a kit.

Of course, we are also happy to support you with on-site assembly or supply you with completely as-sembled structures on request.