- Offer Profile

- STAMH LTD was established in

1998 with main services- design, supply, installation, service and overall

engineering of all types of storage systems. At present the company has

realized over 1800 projects of storage systems in the Balkans as well as in

Italy, Austria and Russia.

Some of our biggest clients are Coca Cola, Liebherr, Schenker, Nestle, Hemofarm, Miroglio,Actavis and many more.

5 years ago STAMH LTD. was the main contractor for one of the biggest automated projects for Bella Bulgaria for 15,000 pallets with 7 stacker cranes.

For years we have been delivering the most advanced storage solutions that are easy to use, make the most available space, and are cost effective.With our knowledge and expertise we develop innovative products.We are always alerted to new developments, which allow us to always offer an advanced and complete product range.

We believe that our products not only meet your needs, but also contribute to your business success.

STORAGE TECHNOLOGIES & MATERIAL HANDLING

SOLUTION FOR EVERY WAREHOUSE

STORAGE SYSTEMS

STORAGE SYSTEMS FOR PALLETS

- The storage systems for pallets are the best answer for warehouses in which you need to store palletised products

RACKS FOR PALLETS | CONVENTIONAL RACKING SYSTEM

-

To store parallelized products with a wide range of load types. The most universal system for pallets. Direct and easy access to each pallet in the warehouse.

PURPOSE OF THE CONVENTIONAL RACKS SYSTEM

Conventional Racks System is the best solution for warehouses, where it's necessary to store palletized products with a wide range of load types and weights. The pallets are accessible and easy to reach with the Material Handling Machines. Pallets and loads don't need to be shifted or moved, to access other pallets' positions.

The Conventional Pallets Racking Warehouse System is generally laid out with single entry wall racks on the perimeter sides and double-entry racks in the middle. The working aisle dimensions between each rack and the rack's height depending on the characteristics of the fork-lift trucks, lifting devices, or Material Handling Machines.

The engineering project STAMH will provide you, depending on the size of the pallet, the height of the construction of the warehouse, the weight of each pallet, and many other variables. Let our experienced engineering team advise you for further warehouse storage space optimization.

ADVANTAGES OF THIS RACKING SYSTEM:

- The most universal and used system for pallets racking with proven qualities;

- A very stable construction, allowing direct access to each pallet;

- Perfect stock control - each storage location is dedicated to a specific pallet or SKU;

- Significant improvement of all processes in the warehouse, after installation;

- Maximum adaptability to any load type, both in terms of weight and volume.

RACKS FOR PALLETS | DRIVE-IN RACKING SYSTEMS

-

Designed for the storage of homogeneous products. Better use of the available surface and warehouse height, than any other system.

MAIN ADVANTAGES AND PURPOSE OF THE DRIVE-IN RACKS SYSTEM

Drive-In Racks System is designed for the storage of homogenous products.

It's the best solution when you aim to store a large number of pallets for each SKU in the warehouse. Drive-In Racks System makes better use of the available surface and warehouse height, than any other Storage System for Pallets. The installation is made of a set of racking units and inner loading aisles, with supporting rails for the pallets.

Material Handling Machines enter the inner aisles with their load. The Material Handling Machines has to carry the load higher than the level at which it has to be unloaded. The Drive-in Racks System is made of extremely robust material, making it possible to store very heavy and fully-loaded pallets.

ADVANTAGES OF THE DRIVE-IN RACKS SYSTEM

- Drive-in Racks Systems are designed for the storage of homogenous products;

- Better use of the available surface and available warehouse height, than any other system;

- Storage by accumulation: the most suitable system for working with the LIFO principle;

- Drive-in Racks Systems allows pallets with the same SKU to be stored in one loading aisle.

RACKS FOR PALLETS | MOBILE RACKING SYSTEM

-

Increase the capacity of your warehouse with the Mobile Racking System from STAMH. The perfect solution for refrigerated warehouses and cold storage, where maintaining storage conditions is expensive.

DESIGN AND PROPOSE OF THE MOBILE RACKING SYSTEM

The Mobile Racking System is one of the best racking solutions to increase warehouse capacity, keeping direct access to each pallet. Pallet racks are installed on mobile bases. Racks slide smoothly on rails, fixed to the floor, opening an access aisle only where needed. The bases are equipped with motors, electronic control, and storage security systems, ensuring safe and efficient operations. Тhe rest of the mobile racks stand close to each other, ensuring maximum storage density.

MAIN ADVANTAGES OF THE MOBILE RACKING SYSTEM

The Mobile Racking Storage System opens an access corridor between the racks only when/where needed with a push of a button. It can be managed with remote control from the Material Handling Machine operator, for example. The rest of the racks remain compact and close to each other. This is how you save space and increase the storage capacity of the warehouse, within the same volume.

FREEDOM OF OPERATIONS OF THE MATERIAL HANDLING MACHINES

The rails for the mobile bases of the Mobile Racking Storage System are dug into the floor of the warehouse. This way, they don't interfere with the free maneuvers of the Trucks and Material Handling Machines used in the warehouse. The working corridor width can be tailored to your exact requirements.

MORE ADVANTAGES OF THE MOBILE RACKING SYSTEM:

- Design, engineering, installation, and service by one of the most experienced Mobile Racking Systems suppliers in EU - STAMH;

- Increase the warehouse capacity and profitability immediately after the installation;

- Innovative and modern software module to control the system, provided by STAMH Solutions;

- Direct increase of the storage space, without investing in new storage buildings and areas;

- Quick access to each pallet;

- Systems and machines working even in adverse storage conditions;

RACKS FOR PALLETS | RADIO SHUTTLE RACKING SYSTEM

-

The Radio Shuttle Storage System is a semi-automated pallet racking system. This storage system for pallets is the perfect solution for warehouses with high pallets capacity and intensive loading and unloading works. This system reduces the time for each operation using a remote-controlled platform, moving independently.

APPLICATIONS OF THE RADIO SHUTTLE PALLETS RACKING SYSTEM

Maximum efficiency and speed for pallets storage and retrieval of loads from 25 to 1,500 kg.

Radio Shuttle Pallets Racks are a semi-automated solution for the storage of high-volume palletized goods and mass storage products. They are often used in warehouses and distribution hubs for food, beverages, or warehouses with special storage conditions.

Radio Shuttle is especially effective for distribution or logistics centers, where you may need quick and efficient supply and distribution.

At the same time, this type of Pallets Storage and Retrieval System allows maximum optimization of storage capacity as it reduces the need for corridors between the racks. With this system, you store different amounts of pallets in-depth, according to specific needs or seasonal load. At the same time, each pallet is quickly accessible.

REMOTE-CONTROLLED RADIO SHUTTLE PLATFORM

Fast, accurate, and cost-effective storage and retrieval of pallets

The Radio Shuttle Racks System uses radio-controlled platforms, moving autonomously along the rack itself. The special design and engineering provided by STAMH allow the platform to move smoothly, whether it's storing or retrieving a pallet at this moment.

Material handling machines don't need to enter the aisles of the Radio Shuttle Storage System, to place or retrieve a pallet. This significantly reduces the distances they cover, the need for new lifting equipment, maintenance costs, and operators and drivers.

The steel structure of the racks in the warehouse suffers less damage because the lifting machine doesn't need to enter the racking system to place or remove a pallet.

Each Radio Shuttle shuttle platform counts on very durable lithium batteries with long autonomy, sufficient for over 16 hours of constant operations. At the same time, charging is extremely fast and can be done in less than 3 hours.

The forklift driver easily commands the automated shuttle platform for all storage and retrieval movements using a remote control. As there are no forklifts in the storage tunnels and thanks to the construction of the system, the risk of accidents is very reduced. At the same time, storage capacity is significantly increased.

RACKS FOR PALLETS | LIVE STORAGE RACKING SYSTEM

-

Perfect storage system to store perishable goods with high rotation, as well as high consumption goods with a continuous rotation.

PURPOSE OF THE LIVE STORAGE RACKS SYSTEM

The Live Storage Racks Systems for palletized loads are compact structures, with incorporated roller tracks sections. They are placed on a sloping lane to allow the pallets to slide. Pallets are placed at the highest part of the rolling section and move by the forces of gravity with a reduced speed towards the other side of the rack, where they remain until ready to be removed.

This minimizes the time needed for certain operations and saves working space. Live Storage Racks Systems enable perfect rotation of stored products, applying FIFO system. This makes it perfect for storing perishable and fast-moving goods.

ADVANTAGES OF THE LIVE STORAGE RACKS SYSTEM

- Optimal rotation of items and stored SKU's using the FIFO method;

- Maximization of the capacity of the available warehouse area;

- Perfect control of goods;

- Possible Pick to Light System integration;

- Minimum time for orders preparation;

- Wide variety of articles in front of the rack.

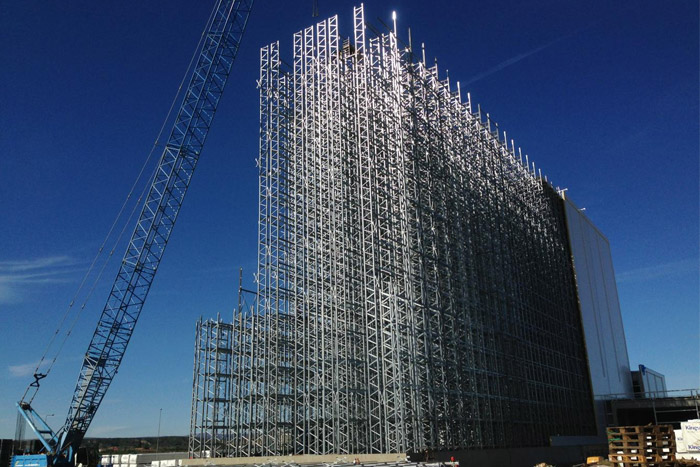

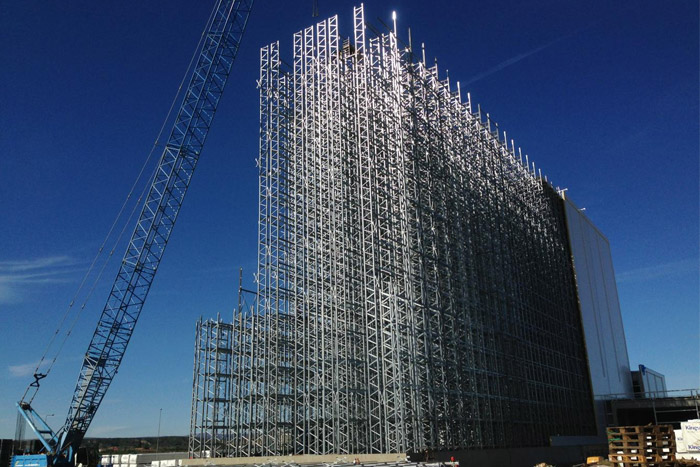

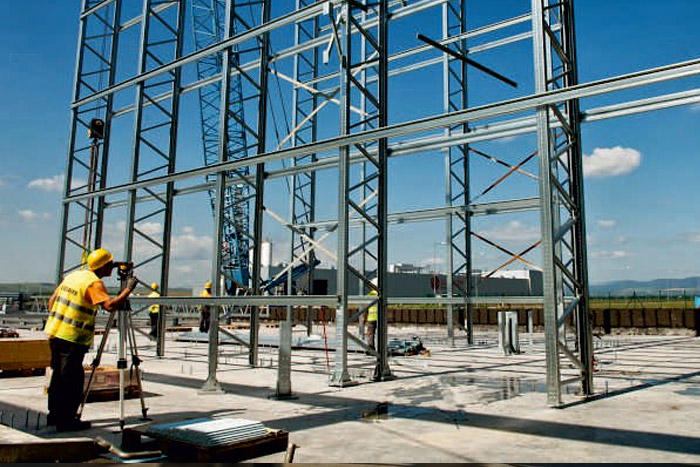

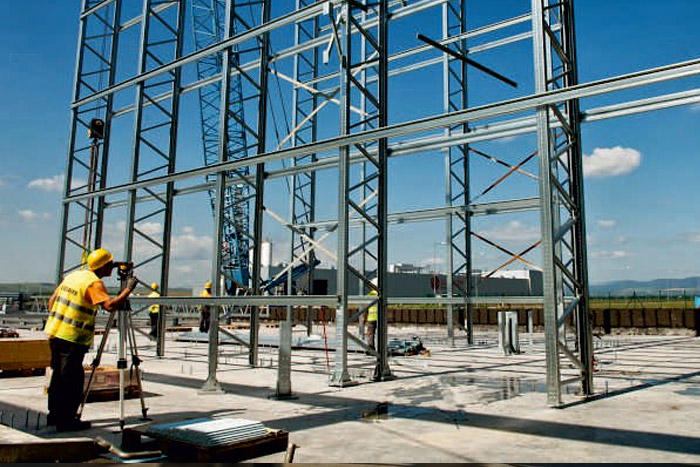

RACKS FOR PALLETS | SELF-SUPPORTING RACKING SYSTEM

-

The perfect solution for very high storage. The racks structure supports stored goods, different building elements, automated storage solutions, and also external elements: wind, snow, seismic movements, etc.

ESSENTIAL PURPOSE OF THE SELF-SUPPORTING RACKS SYSTEM

The Self-Supporting Racks System for warehouses is the perfect solution for very high storage. It is designed to ensure that the racking structure supports not only the actually stored goods and the different building elements, but also the load of the Material Handling Machines, Automated Storage Solutions, and also external elements: wind, snow, seismic movements, etc.

Furthermore, the only limitation of the height of these buildings is either governed by the local authority regulations or the handling devices to be used. These warehouses allow different levels of automation and optimal performance.

ADVANTAGES OF THE SELF-SUPPORTING RACKS SYSTEM

- Great engineering achievements make possible the Self-Supporting Racks Systems to form the structure of the building;

- This system enables maximum use of the available surface;

- A wide range of goods can be stored: pallets, containers, bulky packages, and very heavy loads.

STORAGE SYSTEMS FOR BOXES

- The storage systems for boxes are designed to achieve a high level of productivity and manage loads with boxes or treys.

RACKS | MОVIBLOCK STORAGE SYSTEM

-

Compact warehousing archive system, designed to achieve the best distribution and perfect order.

PURPOSE OF THE MOVIBLOCK RACKS SYSTEM

Moviblock is a compact archive storage system made of shelving or lockers, mounted on mobile bases, sliding on rails. It is designed to take maximum advantage of the storage space, meaning all but one of the aisles between the storage units are eliminated. Storing modules move laterally to access the required aisle. Eliminating aisles, the system increases the capacity of your storage area.

The Moviblock Storage System makes sure that archived materials are stored in order, clean and safe. Mobile lockers adapt completely to the available space and to the characteristics of the product, you need to store. Moviblock is perfect to store all kinds of books and documents, making it the most suitable storage system for offices, libraries, publishing houses, technical archives, etc. It can also be used to store other types of small articles, such as pharmaceutical products or spare parts.

ADVANTAGES OF THE MOVIBLOCK RACKS SYSTEM

- It is a compact storage system, so it makes the best use of your warehouse;

- It's a modular system and can be adapted to any available space;

- Total security of stored materials thanks to the limited access to the modules;

- Perfect for the storage of all types of books and documents;

- Aesthetically designed with light tones of finishing, the system fits well in any environment.

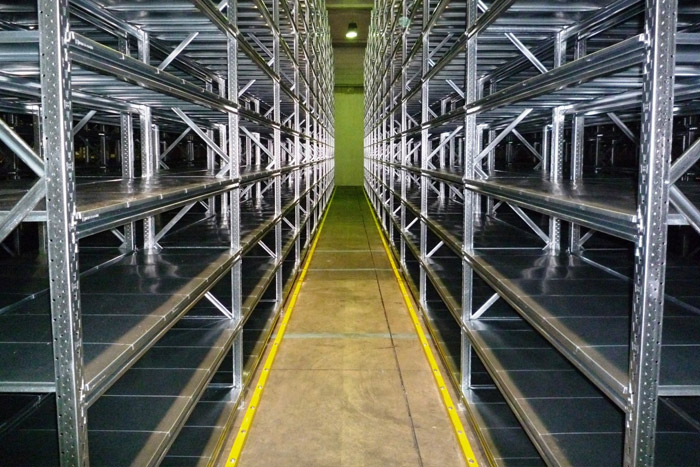

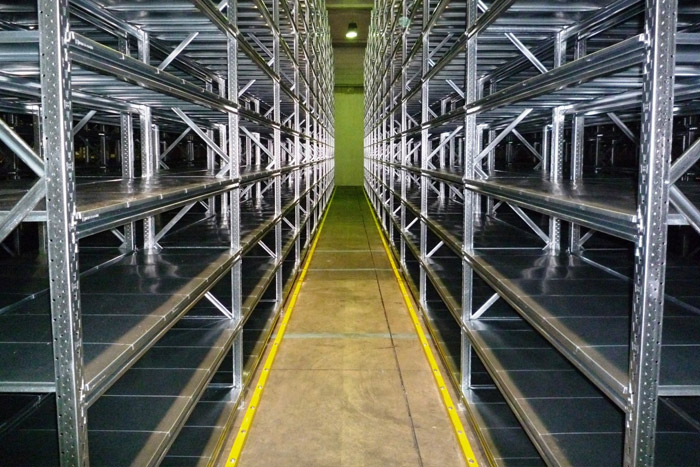

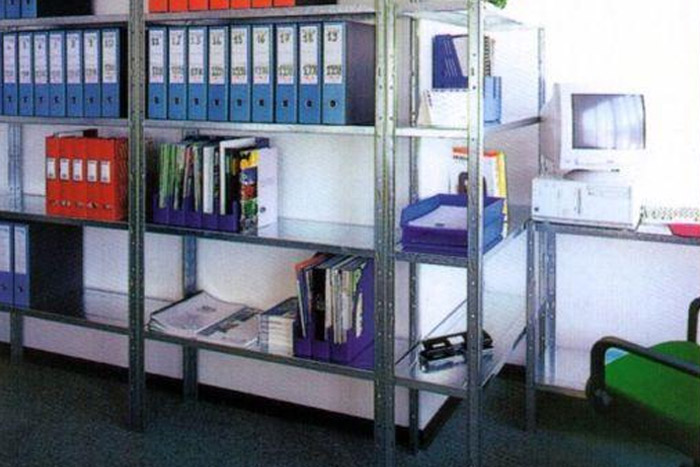

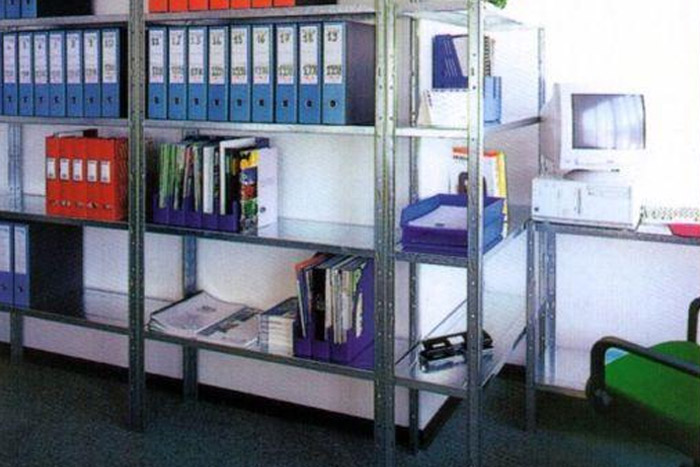

RACKS | LIGHT BI BLOCK STORAGE SYSTEM

-

Medium-load capacity racks system for containers or goods in bulks.

PURPOSE OF THE LIGHT BI BLOCK RACKS SYSTEM

Medium-load capacity system for containers or goods in bulks (up to 6.5 tons each upright frame and 800 kg each shelf), when the load is distributed uniformly. The system is made of galvanized steel elements: frames, beams, shelves.

It is used for manual picking of medium-weight products. It can be completed with catwalks to obtain multi-functional installations for intensive utilization, also in combination with automated systems.

ADVANTAGES OF THE LIGHT BI BLOCK RACKS SYSTEM

- With Light Bi Block Racking System, you have the possibility to store medium to heavy loads;

- Frames have loading capacity up to 6.5 tons when the load is distributed uniformly;

- This racks system saves space for storing non-standard items;

- Adaptable to the specific needs of the client;

- Quick and easy to assemble;

- Excellent mobility.

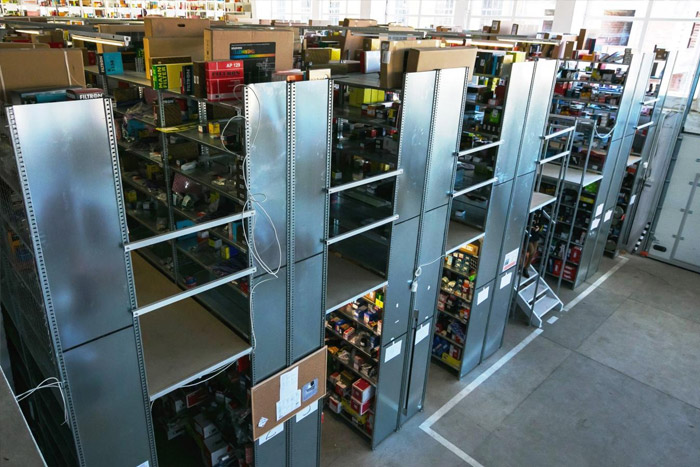

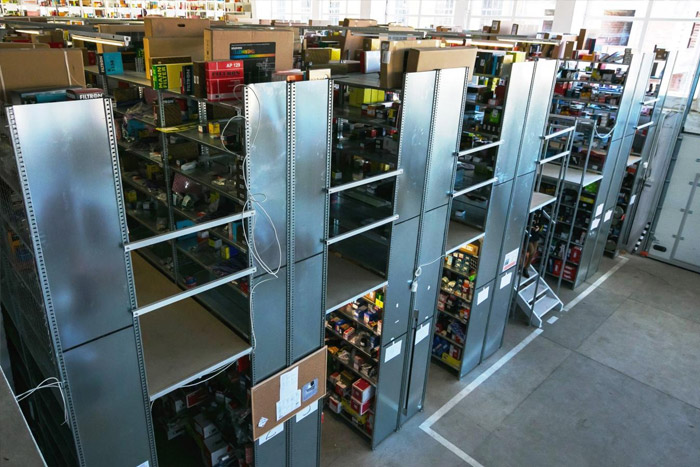

RACKS | MITO RACKS SYSTEM

-

Easy to assemble, boltless system for manual picking.

PURPOSE OF THE MITO RACKS SYSTEM

Perfect for manual picking, constructed with galvanized elements. Mito Storage System is perfect for storage and warehouses areas. This shelving system can be easily and rapidly assembled and dismantled. This beltless construction consists of: shelves, shelves support, uprights

This eliminates issues, often experienced with bolts systems. Gangway Racks Systems and Mito Racks Systems may share some constructive and engineering elements.

ADVANTAGES OF THE MITO RACKS SYSTEM

- The optimal solution for manual storage;

- Reaching different references and SKU's simultaneously;

- Perfect for storing small or voluminous items;

- Adjustable loading levels, making it possible to store a large range of products;

RACKS | IDEA 5 STORAGE SYSTEM

-

A cost-effective way to provide hard-wearing solutions to any storage problem.

PURPOSE OF THE IDEA 5 RACKS SYSTEM

This bolt-free steel shelving system offers a cost-effective way to provide hard-wearing storage solutions to any warehouse storage problem. The hard-wearing pre-galvanized steel enables the Storage System to be used in demanding environments. This material gives the IDEA 5 racks system a modern and bright look and feel. With only two components – upright and shelves - the IDEA 5 design has eliminated the need for nuts, bolts, or clips meaning that shelves can be erected quickly and without fuss.

ADVANTAGES OF THE IDEA 5 RACKS SYSTEM

- No clips or bracing;

- Unique interlocking uprights;

- Assembling in minutes;

- Wide range of sizes to meet your storage needs;

RACKS | CARTON FLOW RACKS SYSTEM

-

Possibility to fit a pick-to-light system - a screen that provides order details to the operators and reduces the items searching times.

PURPOSE OF THE CARTON FLOW RACKS SYSTEM

With Carton Flow Racks Systems goods slide on roller platforms. This guarantees perfect product rotation, preventing interferences during the replenishment phase and collection of materials. This system increases the speed in order preparation.

The system is designed for areas in the warehouse with a large volume of picking activity, as it increases the number of lines of preparation and reduces waste of time for the unnecessary moving of staff during these operations.

Carton Flow Systems is a perfect solution for unit loads with flat and rigid bottoms. With the universal connector, the Carton Flow platforms can be installed on most of the racking systems, regardless of the brand.

With different variants of unloading methods—regular, 5°, 10°, and 15°— the Carton Flow Racks System is the best way to increase your picking rate up to 150 picks per hour in a safe way. The rate can be increased up to 800 picks per hour when the Carton Flow Racks System flow is combined with the pick-to-light system.

ADVANTAGES OF THE CARTON FLOW RACKS SYSTEM

- Perfect products rotation in the warehouse or the distribution center;

- Greater number of references at the front of the rack;

- Increased storage capacity;

RACKS | GANGWAY STORAGE SYSTEM

-

Gangway systems are the best solution, making it possible to double storage area, with a minimal footprint.

PURPOSE OF THE GANGWAY RACKS SYSTEM

The importance to take advantage of the space in the warehouse requires smart solutions. Gangway Racks Systems makes it possible to access higher levels. Gangway system consists of installing high-bay racks with one or more levels of gangways, supported by the racking system itself. You can access different levels of the gangway system, using stairways located in suitable places. They are placed in the function of accessibility and safety.

In addition, stairways freight lifts, or elevators can also be installed.

ADVANTAGES OF THE GANGWAY RACKS SYSTEM

- Optimization of space;

- Full exploitation of the height of the warehouse;

- Double the storing area;

- Possible combination with other racking systems.

SPECIAL STORAGE SYSTEMS

- Specially designed racking storage systems for nonspecific articles- tires, reels, long materials, archives, and more.

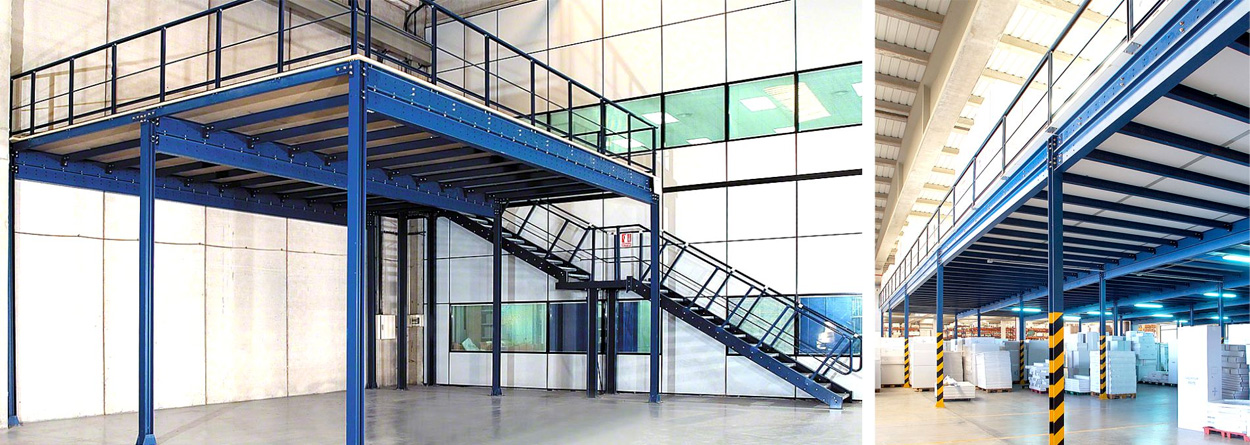

RACKS | MEZZANINE RACKING SYSTEM

-

Systems that double (with one story) or triple (on two stories) the surface of warehouses and premises.

PURPOSE OF THE MEZZANINE RACKS SYSTEM

Mezzanines are steel structures made out of main beams, secondary beams, and columns. They create new elevated surfaces on the warehouse or premises floors, enabling more vertical space for storage, working areas, offices, etc. >> in a very quick and inexpensive way.

Considering that land is an increasingly rare and expensive commodity, especially in urban areas, mezzanines racks offer a cost-effective and highly versatile solution for companies that need to increase their storage surface, without expanding the warehouse building. It's possible when you install a mezzanine double or triple storage surface area. It is the best way to solve space problems at a minimal cost.

Mezzanine floors are totally dismountable. That means that all elements are recoverable and their structure, dimensions, and location can be easily modified.

ADVANTAGES OF THE MEZZANINE RACKS SYSTEM

- Mezzanine racks multiply surface space in industrial areas;

- These racks are adaptable to any specific need, thanks to the great variety of sizes available, floor types, construction systems, etc;

- Quick and easy to assemble by our specialized team;

- They can be combined with any racking or shelving system.

RACKS | CONSOLE SYSTEM FOR LONG LOADS

-

Perfect for storing long materials of different weights. Easy to configure and adapt to different heights and types of goods.

PURPOSE OF THE CONSOLE SYSTEMS FOR LONG LOADS

This system is specifically designed to store long loads such as beams, pipes, and timber. These racks enable loads to be handled by using lifting systems such as lift trucks and material handling machines with special attachments.

The system consists of columns with a vertical beam and one or two horizontal beams at the base to provide stability. A series of arms are attached and the load is placed on them. These columns are made of hot-rolled metal beams at variable heights enabling them to be fitted. Moreover, its design allows the loads to be fitted on one side of the structure only, or on both sides.

ADVANATAGES OF THE CONSOLE RACKIGN SYSTEM

- Easy-to-assemble;

- Structure of great simplicity and strength;

- All the elements involved fit together easily and allow excellent mobility;

RACKS | FAMI RACKING SYSTEMS

-

Industrial metal shelving systems for the most effective organization of the working area and space.

PURPOSE OF THE FAMI STORAGE SYSTEM

Fami Storage Systems industrial racking systems are the most effective and user-friendly way of organizing goods and products, by rationally making the most of the available space and by easily adapting to any use or setting: they can even be simply placed against a wall. Fami Storage Systems offers a complete range of shelving systems for warehouses, divided by type and size.

ADVANTAGES OF THE FAMI STORAGE SYSTEM

- Configuration Freedom

- Modular Structure For Containers And Boxes

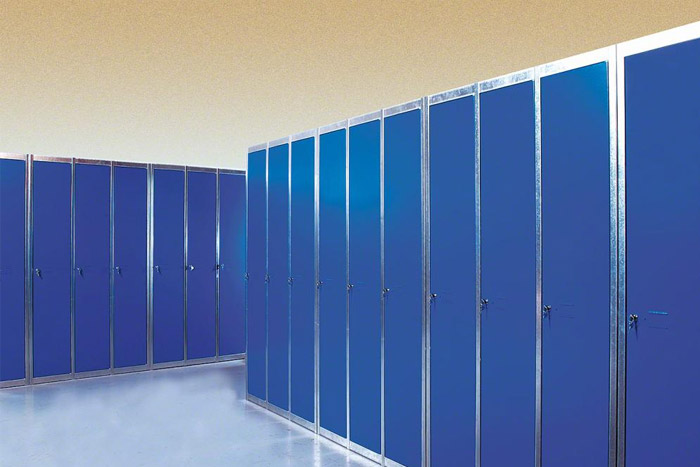

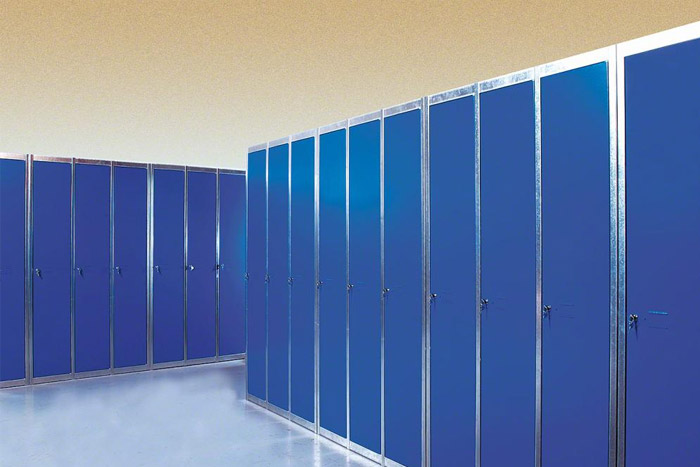

RACKS | INDUSTRIAL LOCKERS

-

Aesthetic design, comfort, security and more organization. Perfect for all type of industries, productions plants, warehouses or dressing rooms in offices, schools, swimming pools etc.

PURPOSE OF THE INDUSTRIAL LOCKERS

These lockers embrace a new concept in compact, aesthetic design that can suit any type of environment: dressing rooms, offices, schools, etc.

Frames integrated into the side panels, exclusive connection systems, two options (with or without feet)... each of these elements has been carefully designed to provide high rigidity, moreover, the lockers are built using high-quality cold-rolled steel, specially treated to ensure durability and resistance.

MAIN INDSUSTRIAL LOCKERS ADVANATAGES

- New compact and attractive design

- Extremely easy to assemble - no need for nuts and bolts

- A modular system that allows for multiple combinations

AUTOMATION AND CONVEYING

- Automated Storage Systems and Conveyor (Transport) Systems, tailored for the specific needs of each stored goods. Maximum automation in warehouses.

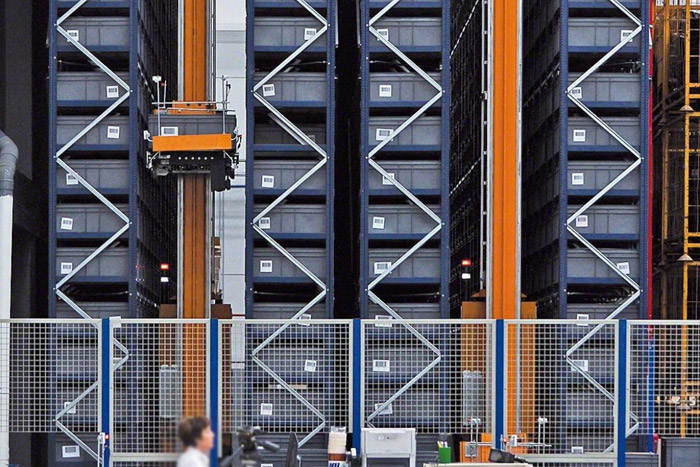

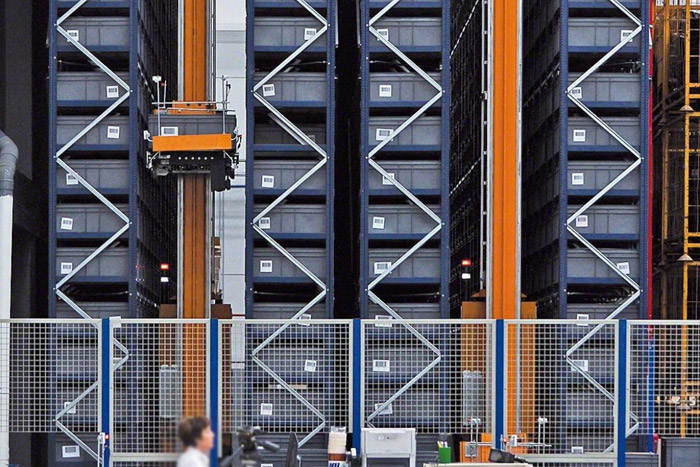

AUTOMATED STORAGE SYSTEM FOR PALLETS

-

Increase the productivity and profitability of your warehouse with optimal space usage. High bay automated warehouses guarantee faster access to each stored pallet.

WITH STAMH YOU WILL RECEIVE ALL COMPONENTS OF THE SYSTEM FROM A SINGLE SUPPLIER

Customized solutions, fitting perfectly in the available warehouse or distribution center space, starting from the static configuration and elements to all mechanized and automated components of the Automated Storage System for Pallets – racks and racking systems, stacker cranes, transport and conveyor systems, and all necessary automation software and hardware solutions.

RACKS AND RACKING SYSTEMS

The racking system of the Automated Storage System for Pallets has a particular and unique steel structure, corresponding to the specific goods or items, that your facility will be storing or processing.

The structure itself can be internal or made as a self-supporting unit (where the racks and the racking system also support the structure of the warehouse). Self-supporting Racking Structures maintain the weight of the goods and the weight of all external elements like snow, wind, or even earthquakes.

MECHANIZED AND AUTOMATED EQUIPMENT (SRM)

Pick-up equipment or pallet transfer shuttles ensure automatic pallet handling and maximum efficiency. The automated technical equipment efficiently stores, retrieve and transport palletized loads through the exceptionally robust high-bay racking system. The equipment moves in three directions along the length, height, and depth of the warehouse. Its handling units (telescopic forks or the onboard shuttle platforms) store and retrieve pallets automatically.

BENEFITS OF THE AUTOMATED STORAGE SYSTEMS FOR PALLETS

- Solutions, designed especially for the specific requirements, but using the modularity of its components;

- Different storage options, depending on the size and height of the system and the products;

- Working perfectly in very demanding conditions, such as refrigerated warehouses or special storage conditions;

- The systems can be extended and modified in the future if your business needs change;

- Complete range of accessories and additional elements;

- The perfect combination of flexibility and strength;

- Optimal storage density within the same area;

- Quick access to each stored pallet;

- Easy to maintain due to high-quality parts;

- Fast supply, installation, inspection, and services;

- Connection to the ERP system or integration of solutions through MFS and WMS software;

- Complete solutions from a single supplier, saving you time and money;

- Reliable planning and cost management;

- Professional project management and installation, supervised by experienced project managers in STAMH;

- After-sales service from STAMH (repairs, checks on shelving systems, spare parts, or modifications).

AUTOMATED STORAGE SYSTEM FOR BOXES

-

Miniload Automated Storage System gives you the opportunity to store, pick and transport containers, boxes, cartons, and trays, saving space and mainly >> a lot of time.

This Automated Storage System for boxes and trays is part of a fully automated warehouse, suitable for faster storing and retrieving different kinds of small handling units as totes, cartons, boxes, etc. An additional value of this Automated Storage System is that you can execute fast picking directly from it, using cranes as supporting hands, and delivering the items in front of the person.

The Automated Storage System for Boxes follows the "goods to person" principle with an impressive speed of about 120 double cycles per hour. This system converts the picking process into a play using the modular console.

The Automated Storage System for boxes and trays consists of Racks, Cranes, Conveying System and Management Software

- Racks are elevated in the warehouse. Cranes are moving in very narrow aisles, leaving enough space for other activities and storage;

- The Miniload Crane (smaller unit of the Storage Retrieval Machine or SRM) is the perfect solution for a fully Automated Miniload Intralogistics. This system enables the storage and picking of containers, cartons, and trays.

Benefits at a glance:

- Solutions, designed individually for your needs, but using the modularity of the components;

- Diverse storage options and the possibility to store different items and shapes of the SKU;

- Adaptability - different system sizes and heights;

- Resilient to extremely demanding conditions such as deep-freeze temperatures;

- Systems can be expanded and modified, even after many years;

- A comprehensive range of accessories;

- Flexibility and sustainability;

- Optimum storage density;

- Rapid access to each stored pallet;

- Maintenance-friendly machine elements, due to the proven high-quality of all components;

- Problem-free transport and short installation times resulting from modular design;

- Connection to higher-level ERP systems or integration of the solutions via MFS and WMS software;

- Complete solutions from a single partner;

- Reliable planning and costs management;

- Professional project management and installation, supervised by experienced project managers, engineering crew, and installation professionals;

- After-sales service from STAMH (installation, inspection, and services, rack inspections, spare parts, or modifications)

- STAMH provides all needed software and hardware solutions to ensure the functioning of the entire system;

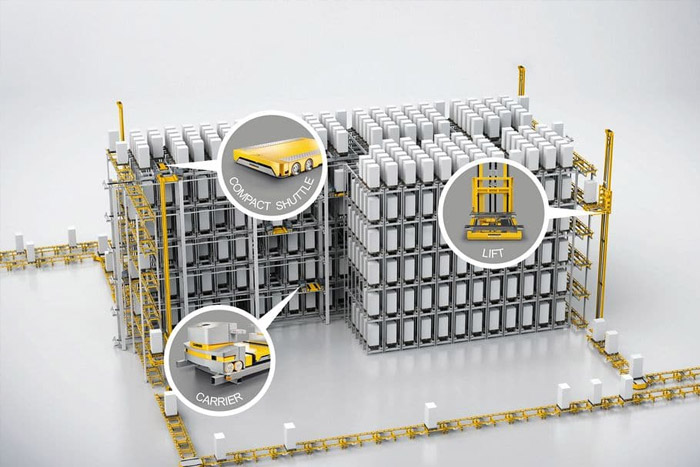

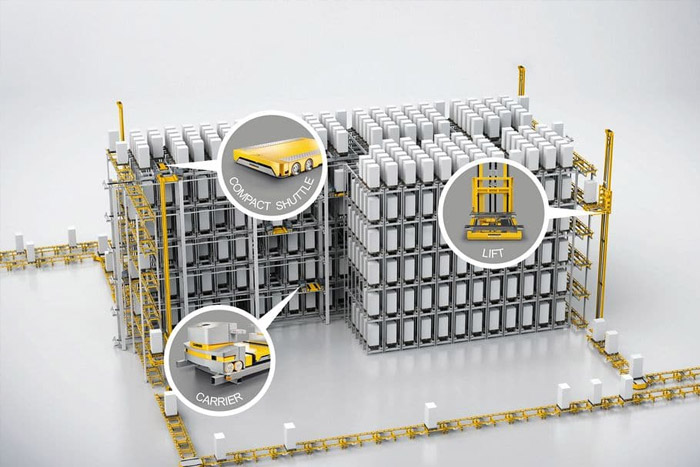

MULTISHUTTLE STORAGE SYSTEM

-

Automated Pallet Shuttle System. High storage and retrieval velocity, and maximum storage density.

Multilevel Shuttle Storage System sets new standards for throughput, flexibility, and efficiency. It consists of three modules, coordinated by a software module:

- Shuttle car;

- High-performance vertical lifts;

- Special carrier, transporting the shuttle car to the exact location on a certain level.

Similar to the Small Parts Shuttle Technology, the Multilevel Shuttle System enables multi-level deep storage and highly dynamic commissioning of various types of pallets. All this, combined with high storage density.

With its modular structure, the Multilevel Shuttle System is totally adaptable to different customer needs. The fields of application for this Pallets Shuttle System are suitable for:

- cold storage;

- buffer storage;

- dispatching warehouses;

- sequence storage, commissioning warehouses or supply, and distribution centers;

Benefits at a glance:

- Scalable, for further increases in performance and speed;

- Optimum use of space with any building layout;

- Suitable for different types of loads and items;

- Low energy consumption;

- High throughput rates up to 250 pallets per hour;

- High availability;

- Multishuttle Storage System can be retrofitted in existing warehouses;

- Compact design for high storage density;

- Less installation work;

- Quickly executing and installing of the systems if needed;

- Cold store compatibility - down to -30 °C

- Rated load: up to 1.500 kg.

- Speed: up to 300 m/min.

- Acceleration: up to 1.2 m./s2

- Power supply: inductive/conductor rail

- Integral control

- Repositioned by vertical conveyor

АUTOMATED STORAGE AND RETRIEVAL SYSTEMS

-

Automated Vertical Lift Machines and Horizontal Carousels to increase the picking and orders preparation efficiency and accuracy with a very high loading capacity

Up to 90 % space optimization, faster picking, and security for all stored items are just some of the advantages of the Automated Vertical Lift Machines and Modular Horizontal Carousels.

Discover more advantages of this systems here

Automated Vertical Lift MachinesThe Automated Vertical Lift Machine is specially designed for storing, commissioning, and faster picking in different areas, such as production, distribution, retail, and warehouse logistics.

Compact Automated Vertical Lift MachinesThe Automated Compact Vertical Lift Machine or VLM means maximum use of the vertical space in a minimum footprint.

Automated Horizontal CarouselsThe Automated Modular Horizontal Carousel consists of a set of containers, taking the selected items directly to the picking zone.

CONVEYORS AND CONVEYOR SYSTEMS

-

Automated Conveyor Systems to significantly increase productivity and accelerate all operations in the warehouse, production bases, or distribution centers.

Systems with Dynamic Multifunctional Conveyors from STAMH can increase the efficiency and productivity of the warehouses, production facilities, or logistics, distribution, and sorting centers.

The main purpose of the Conveyor Systems is to reduce the times for transportation of goods between the receiving area and the storage or picking areas.

There are systems implemented with belt, chain, or roller conveyor modules. They are powered by electric motors.

Conveyors are suitable, not only for large automated warehouses but also for smaller spaces. They provide the connection between the receiving areas, the material handling areas, the shipping and expedition areas, the lifting equipment and cranes, or the storage and racking systems.

With a well-designed Automated Conveyors System for Boxes and the Automated Conveyor System for Pallets, it is possible to achieve constant goods flow - something practically impossible with a manual system. The conveyor system can provide a well-functioning connection between the cranes and the different processes of storing, retrieving, picking, and processing different units.

Distances in the warehouse or the distribution center can be covered using different transport devices and conveyor modules, depending on the SKUs. Systems are usually engineered following demanding requirements in terms of functionality, speed, and configuration of the system.

Learn more about and request an offer for

Conveyors and conveyor systems for palletsConveyors reduce transportation times in the warehouses and optimize all processes. The conveyor system for pallets is engineered with roller or chain conveyors, transfer modules, lifting tables, and turning tables.

Conveyors and conveyor systems for boxesFlexible and modular conveyor platform for boxes. Standardized conveyor modules keep the investment cost very low.

Conveyor systems for distribution or sorting centersTo provide high-speed intralogistics. To service an increasing number of orders - fast and reliable. In today's situation, a well-working sorting center is a must for good customer service and fast distribution.

INSTALLATION, INSPECTION, SERVICES

- Complete construction of all types of storage systems. Repairs to existing warehouse systems. Suitability certification.

ASSEMBLY, DISASSEMBLY, RELOCATION

-

Assembly of all types of storage system; relocation - moving warehouses from one country to another.

Pallet racks installation requires an experienced crew with the proper tools and equipment. The installation needs to adhere to the design, which was created by skilled engineers took into account load levels, environmental considerations, building codes and other important factors when designing the system.

We know you're busy running your business. We understand that you may not know how or have the time to install or teardown your pallet racks and other warehouse equipment. At STAMH Service, our crews are specialists in installation and removal of material handling equipment. At STAMH Service, we have the resources at our disposal to help you with any project - large or small.

Our installation teams have over 10 years experience installing, moving and disassembling racks, conveyors, mezzanines or any other types of storage systems. STAMH Service's crews travel nationwide and arrive when & where our clients need us.

INSPECTION, SERVICE

-

Inspection of all types of racking systems

The annual inspection requires professionally trained rack inspectors to inspect your racking that complies with the latest Euro Norm.

The inspection is done systematically according to a detailed inspection protocol and is afterwards documented through a detailed report. STAMH Service has huge experience working in this area and has consulted extensively regarding the position of the DIN EN 15635 “Steel static storage, systems- Applications and maintenance of storage equipment”

Inspections are performed by a trained and accredited inspector, and undertaken at least once every twelve months. Following this inspection, a professional report is presented containing the description of the general condition of the installation (floor, usage, lifting device, load), and an overview of the measures to be taken, classified into risk categories depending on the severity of the damage and the urgency of the repair.

The inspector will be able to classify and evaluate certain forms of damage and deformation (protection systems, anchoring system, safety pins, yokes and beams).

REPARATION

-

Reparation isntead of replacement- the quickiest and cheapiest way to modify the damaged part of racking system.

Pallet racking repairs can be costly, but are a pivotal aspect of any racking maintenance program. Racking systems are constantly under attack by Fork Lift Trucks and inevitably damage occurs. However 90% of the time damage only occurs in the first 600mm of the upright. It seems a waste to replace the whole upright when only a small percentage of the upright is damaged. Our Stamh-service team enable repairs to be carried out with minimal fuss and disruption to the warehouse.

Benefits:

- No need to replace the whole upright

- No materials need to be offloaded

- No need to wait for replacement uprights and materials

Ease of repair encourages operators to deal with damage as and when it happens, creating a safer working environment.

PROTECTOR, BARRIERS

-

Different types of protectors and barriers made of steel or plastic.

Forklift trucks and other warehouse traffic can cause damage to unprotected equipment and structures.

Use protectors or barriers to protect your vulnerable pallet racking frame ends, machine guards, partitioning systems, mezzanine support columns and more.

We are offering different types of protectors and barriers made of steel or plastic.

GEODETIC SERVICES

-

Different types of geodetic services in construction.

Complex surveying work-related with prospecting, design, construction (installation) and operation of sites is defined as a specific portion of geodesy in the construction.

Geodetic photograph (shooting)

Surveying photograph (shooting) from earth observation image specify the location of specific points, which are subsequently applied to a plan, model number or card.

The determination of the position of points is done by means of geodetic work base, a network of permanently stabilized on the surface markers with precisely determined coordinates in a horizontal position and height.

Tracing

Under tracing is meant to mark the site of various points, made planes or surfaces, coordinate data, which are previously known.

In laying out the mutual position of points is determined on the basis of a drawing plan or a digital model to be implemented on site.

ROBOTICS

INDUSTRIAL ROBOTICS

-

Robots have changed manufacturing technology. Powerful automation begins with ready-to-use robots.

PalletizersIndustrial robots and automated robotic palletizing systems with impressive performance. Robust, compact, precise, and fast palletizers for more efficiency and productivity

Packaging robotsFast, accurate, and efficient industrial robots for packaging, opening, filling, sealing, labeling, and other packaging operations.

Sorting robotsAccuracy and speed for all your sorting operations, according to preset parameters. Find out more about the wide range of capabilities and loading capacities of sorting robots

Assembly and mounting robotsRobots and industrial robotic and automated systems for assembly, tools handling, buffering between different stages of assembly works, and much more

Welding, grinding and cutting robotsIndustrial robots and robotic systems for laser, plasma, or water cutting or arc welding. Precision and safety in the workplace and more cycles per hour

Painting robotsRobots and industrial robotic systems for applying all types of coatings - paints, varnishes, sprays, adhesives or primers.

Our portfolio offers perfectly matched automation solutions for more efficient manufacturing processes – from just a single robot to specialized cells and complete system concepts. Here you will find an overview of all industries that can benefit from a comprehensive product range.

IMPORTANT ADDITIONAL ELEMENTS OF ALL ROBOTIC SOLUTIONS

The robot periphery is a factor that must not be underestimated when considering the efficiency of your production processes. With end effectors, energy supply systems, linear units, and positioners, you can considerably expand the functionality of the robots. STAMH offers additional modules for all payload categories, for full automation and human-robot collaboration. We will happily advise you on the selection of the right additional module for your robot.

Industrial robots have been solving the problems of end customers, and ensuring their success, with efficient, state-of-the-art automation solutions.

SORTING AND PICKING ROBOTIC SYSTEMS

-

Multilevel robotic system for boxes, automated horizontal carousels, and area or linear robots

Area and Linear RobotsRobots-Optimum use of space / maximum working areas. Future-oriented and innovative.

Automated Horizontal CarouselsDynamic order picking processes with a very high performance of up to 1 000 picks per hour and 50% higher storage density.

Cuby - Multilevel robotic system for boxesFlexible Single Level Shuttle for Bins and Cartons. Maximum possible storage density.

TRANSPORT ROBOTICS - AGV SYSTEMS

-

Automated Guide Vehicles: smart and flexible. Higher efficiency and greater flexibility with AGV.

Automated Guided Vehicles (AGV) systems automate workflows by managing and executing transport tasks based on optimized and flexible strategies. The systems are very flexible. Do you need more throughput? Then add more AGVs. Compared to conveyors, AGVs can be moved to another facility very easily. One AGV can replace the other during maintenance, providing maximum availability in your daily operations.

Ideal for most types of material handling, AGVs safely and reliably fulfill their duties. With modern navigation options and customized load handling, these AGVs are efficient in highly complex logistics systems and simple A-B scenarios. AGVs can operate as a stand-alone system or, if connected to an ERP, as a fully integrated subsystem of a complete plant.

Logistics is the lifeblood of the fourth industrial revolution and is making a key contribution to the Industry 4.0 concept. The intelligent, auto-guided transport systems provide a ground-breaking response to current challenges in intralogistics.

Auto-guided transport systems are an integral part of the solutions portfolio for fully-automated intralogistics systems. The AGV fleet serves a diverse range of solutions for large and small load carriers that are capable of creating a logistics network, which encompasses various warehouses and working areas. The solution can be configured and also flexibly expanded to meet customer-specific requirements. Using a solution like this you will benefit from a significant reduction in operating costs and increased storage logistics efficiency.

BENEFITS AT A GLANCE

- Flexible and scalable automation of intra-company material flows

- Sustainable reduction of cycle times

- Low investment and operating costs. Minimal infrastructure construction required

- Reduction of subsequent costs (by minimizing transport damage and incorrect deliveries)

- Optimum adaptation to dynamic logistics market requirements

- The unique configuration of the individual AGV fleet

- Maximum flexibility for warehouse picking

- Gentle and safe transport of diverse goods and load carriers

- Easy integration and low requirements for the (IT) infrastructure

- Improved ergonomics and optimum material flows

- Increased operating safety and improved working conditions

- Suitability for use in demanding environments (deep-freeze environments or hazardous areas)

- Innovative energy concept (automatic and rapid charging)

- The greatest flexibility in terms of system adaptations and expansions

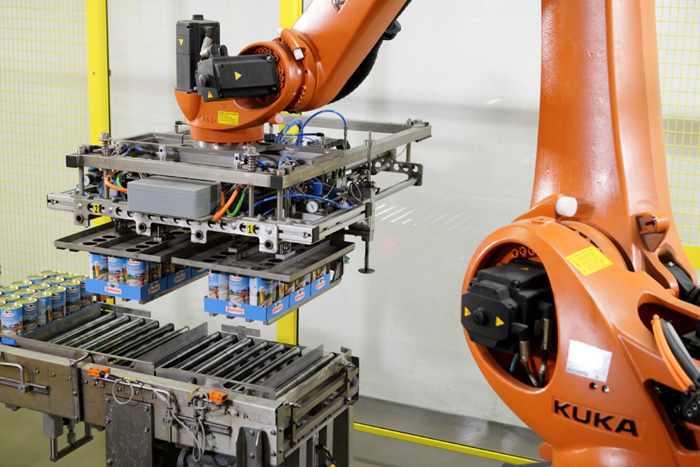

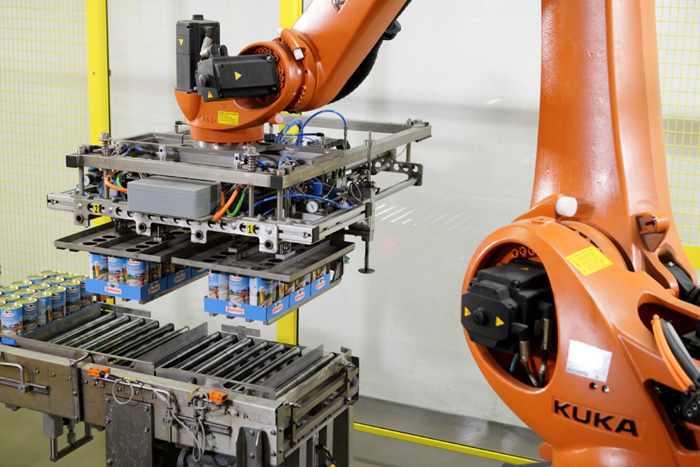

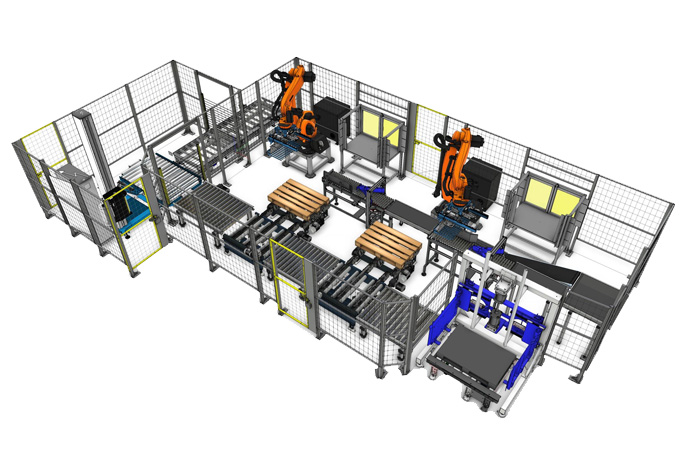

ROBOTIC SYSTEMS FOR BOXES OR STACKS PALLETIZING

-

Discover different elements of a robotic cell for high-speed palletizing of boxes or stacks.

Robotic palletizing systems and cells are designed to improve, optimize and speed up the processing of cartons or stacks, avoiding hard manual work. They are created to increase drastically your productivity!

The pallets processing

A pallet dispenser feeds empty pallets to the system, and roller conveyors and special transfer modules for pallets deliver it to the palletizing area - within the range of the industrial palletizer. These robots are created to cover a payload capacity range from 40 to 1300 kg. per cycle, during very long periods of time with 100% workload. When the pallet is ready, it is transported to a fully automatic wrapping machine. Once foiled, the pallet is ready for transportation or storage and the next palletizing cycle has already begun.

The products processing (boxes or stacks)

Stacks of boxes enter the robotic cell, through a conveyor system for boxes. They are automatically transported to the palletizing area. When a certain number of boxes or stacks (4,6,8 etc. - depending on their dimensions) is accumulated, the industrial palletizing robot picks them up, using a special gripper, and arranges them on the pallet, in a predetermined order.

WAREHOUSE AND PACKING EQUIPMENT

PACKAGING SOLUTIONS

-

Wide range of semi-automatic and fully automatic stretch wrapping and strapping machines, case erectors and sealers and consumables for packaging

Semi-automatic wrapping machinesMobile, turntable, and rotating arm semi-automatic stretch wrapping machines PKG Group (Italy). Perfect for fast wrapping of pallets, boxes, and long materials

Automatic wrapping machinesFully automatic stretch wrapping machines for conveyor lines suitable for pallets, boxes, and long materials

Semi-automatic strapping machinesSemi-automatic machines for strapping pallets, boxes and other material with PP or PET strap.

Automatic strapping machinesFully automatic vertical and horizontal pallet strapping machines

Shrink wrapping machinesSemi-automatic and automatic shrink wrapping machines for packaging

Case erectors and sealersAutomatic case erectors (box forming) and case sealers (box taping) machines

Stretch film & consumablesAll kinds of consumables for the packaging - stretch film, PP and PET strap, tape, etc.

WORKSTATIONS AND BOXES

-

Cabinets

Wide range of work cabinets and wardrobes for offices, workshops, warehouses, and any premises you want to equip.

WorkbenchesWorkbenches for industrial factories, workshops, and hardware stores.

WorkstationsHeight adjustable shelf reduced distances larger field of view

ТrolleysA wide range of indestructible industrial trolleys for your warehouse or workshop.

CNC Tool StorageRacking systems, tool trolleys and tool cabinets with bush holder frames.

ContainersMetal and plastic containers and boxes for all sectors.

LOGISTIC SOFTWARE AND AUTOMATED SOLUTIONS

- STAMH SOLUTIONS offers comprehensive software technology and logistics equipment that covers even the most sophisticated requirements of the warehouse logistics.

WMS - WAREHOUSE MANAGEMENT SOFTWARE

-

What is WMS? It stands for Warehouse Management System. It concerns all warehouse logistics. In other words, this is the software who knows WHAT EXACTLY happens in the warehouse and HOW to manage processes, people and machines. They have to work the best way altogether. Neither the accounting software, nor even the ERP do so. The WMS - Warehouse Management Software does it.

WHAT WMS BASICALLY DOES?

- Warehouse Management Software /WMS/ tracks and manages resources: raw materials, consumables, components and semi-finished goods, products, goods, packings, wrappings, etc.

- WMS keeps records of all parameters like quantitie, location, lot number, production, expiry date, hierarchy of packing, metrics, co-relations of metrics, etc.

- Warehouse Management Software manages all logistics processes: the inbound, the internal and the outbound logistics;

- It manages the personnel: tasking, time and priority management and KPI tracking;

WHERE TO USE WMS?

It is suitable in all fields of business related to logistics somehow. It manages warehouses in manufacturing companies (for raw materials, semi-finished and finished goods), distribution centers, fulfillment companies (for stock keeping, value added services and sophisticated billing), retail, transportation and forwarding business (for temporary warehousing, reorganization and grouping of freight), courier business (parcels and pallet management) etc.

HARDWARE AND LOGISTIC EQUIPMENT

-

There are many software systems managing the logistics processes. Obtain their full advantages using highly specialized equipment, enhancing the features of WMS, EMS, TMS, etc.

HARDWARE AND LOGISTIC EQUIPMENT

There are two sides of the “coin”: generating/emitting information and receiving/collecting it. It is a must to have a surrounding media (environment) to transfer real-time information.

Data collection - 1D and RFID scanners, 2D imagersOne of the key tasks in logistics is the fast, correct and precise collection of information. This information has to bring maximum data about the product and its attributes. Information is reused within the same system. Information has to be shareable with many other systems and data has to be coded and kept in digital formats. Apart from identification, data marking and data collection could be used to track movements and directions.

Label Printers and ConsumablesAll methods of collecting digital information depend on the proper coding of data and representing it on physical media. Attaching data to material media is done by printing (in case of graphic codes) or by inducing it (in case of radio frequency coding).

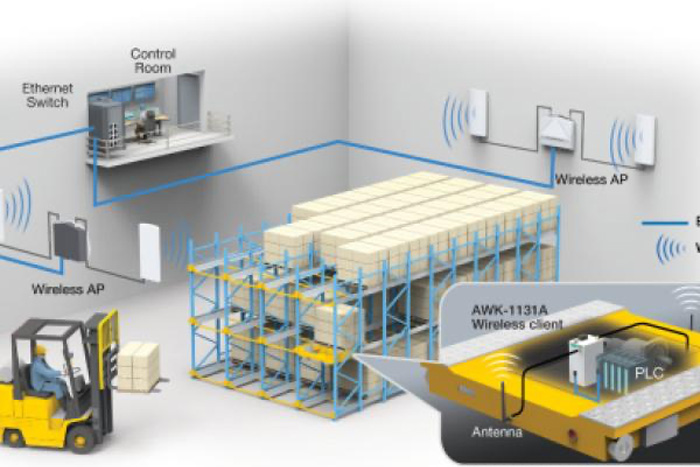

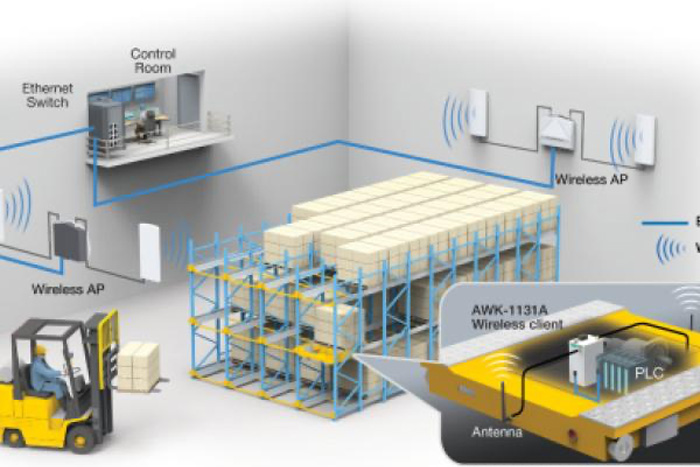

NetworksModern logistics needs mobility. The mobility needs agile devices and mobile networks to serve them. The backbones of the mobile networks are fixed networks with active radio-devices and communication points. STAMH SOLUTIONS designs and develops networks.

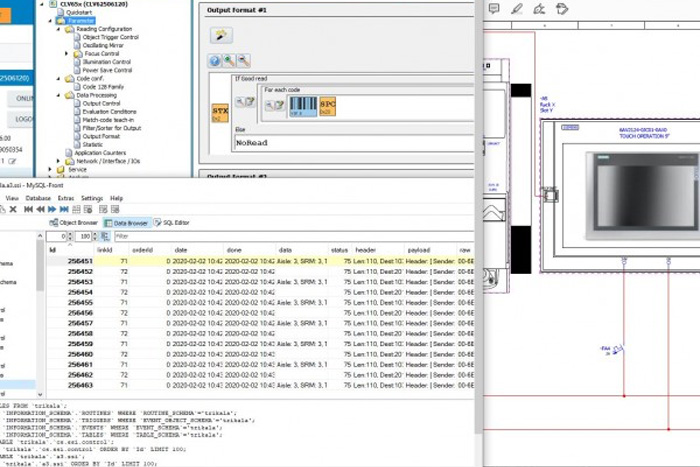

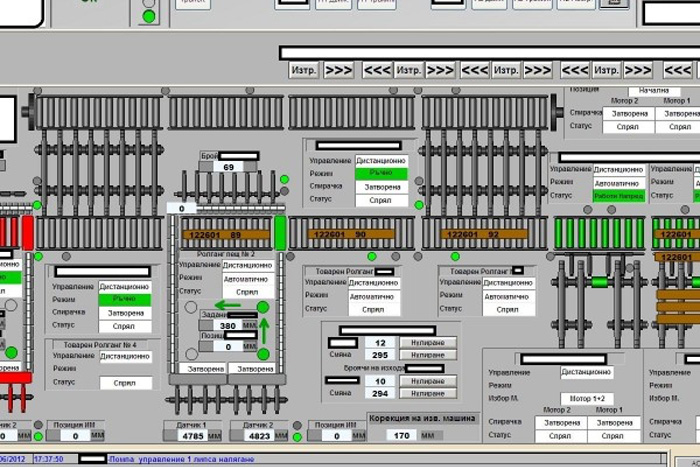

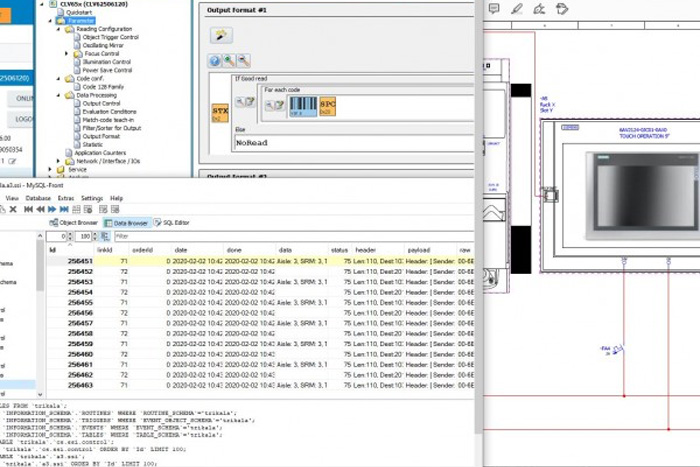

INDUSTRIAL AUTOMATION AND ROBOTIC SOLUTIONS

-

SOFTWARE AND HARDWARE SOLUTIONS FOR AUTOMATED STORAGE SYSTEMS

The management and control of the processes in the automated and conveyor systems is organized on several levels. This ensures the implementation of optimal intralogistic strategies for storage, transport and retrieval of palletized goods, boxes, cartons, trays, etc.

Proper programming and implementation of software and hardware for automation of modern and high-tech warehouse systems from STAMH Solutions allows:

- Intelligent warehouse process management;

- Much better operational efficiency;

- Optimization and acceleration of storage and retrieval of goods;

- Faster and more accurate execution of the orders;

- Significant reduction of errors caused by the human factor;

- Its’s helps the operators and the management of the company to make informed decisions based on real data, thus optimizing the processes.

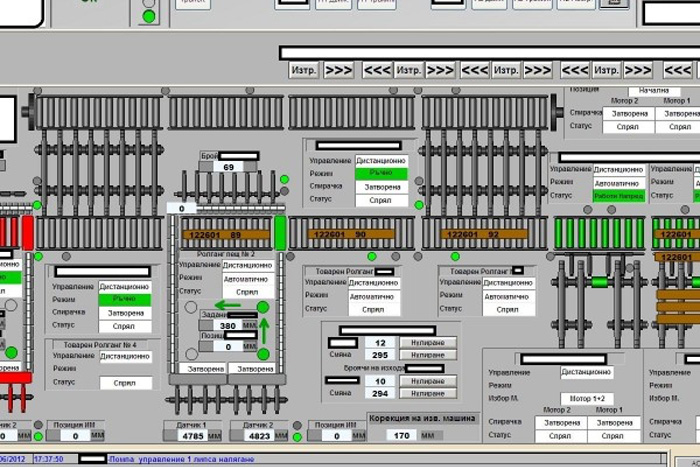

SCADA Software solutions to control and optimize the intralogsitics processes in the warehouse, the production base or the sorting center. One of the most important solutions in automation.

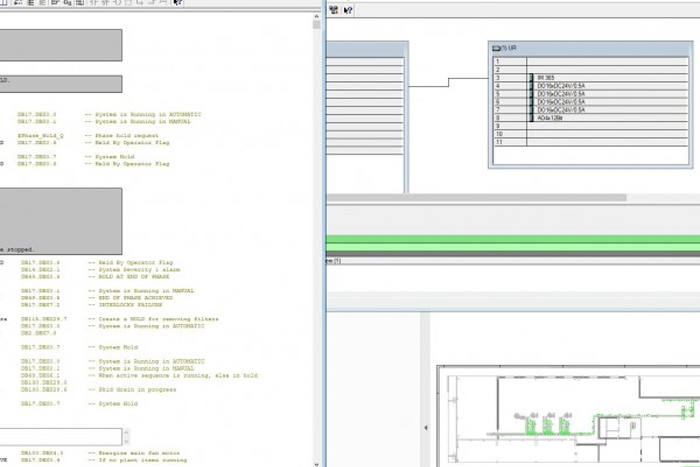

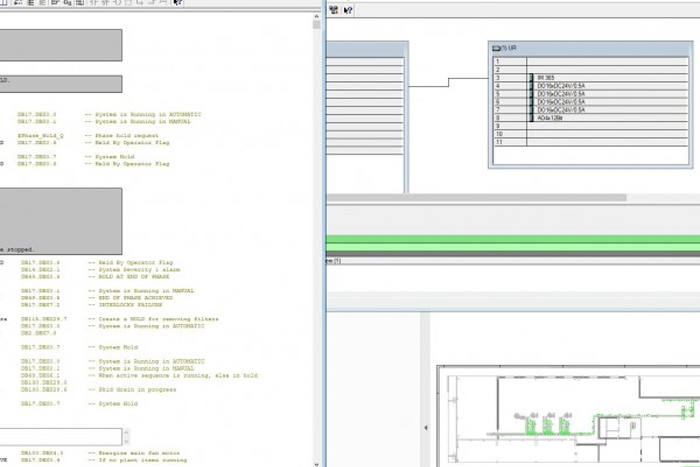

PLC programmingProgrammable Logistics Controllers or PLCs manage different devices in the Automated Storage Systems, Conveyors and Conveyor Systems. They are used to control and manage sensors, sensor stations, conveyors, lifting devices and cranes, rotary tables etc.

Hardware for automated storage systemsThe core hardware devises for the management of the Automated Storage Systems from STAMH Solutions are sensors, drive mechanisms and many more.

Custom automation software developmentWhether you are building new process/machinery/facility or you are in a process of revamping an existing one we could consult you, and develop a solution, fulfilling your needs.

PROFESSIONAL CLEANING MACHINES

- Full range of professional, industrial and municipal cleaning machines and equipment for any warehouse, factory or city

UPRIGHT SCRUBBER-DRYER TSM WILLMOP 50 UV-C

-

The lightest and the most maneuverable upright scrubber-dryer with Li-Ion battery. This cleaning machine is extremely suitable for cleaning of floors in hospitals, operating rooms and elderly centers.

SCRUBBER-DRYERS EUREKA

-

Full range or battery and cable powered scrubber-dryers for wet cleaning of hard floors in warehouses, factories, trade centers, hotels, schools and all other areas

INDUSTRIAL SWEEPERS EUREKA

-

Full range of industrial sweeping machines for dry cleaning of outdoor and indoor areas

Autonomous cleaning machines

-

Fully autonomous cleaning robot – designed to serve

STAMH Tech is official dealer of Adlatus Robotics (Germany), a company specialized in development and production of autonomous machines, and cleaning machines are main focus. Adlatus CR700 is the best and fully functional machines on the market today!

OUTDOOR UTILITY MACHINES

-

Wide range of electric, diesel and CNG cleaning machines for municipal areas - roads and streets, squares, pedestrian zones, parks, green areas, parking lots, etc. STAMH Tech is official dealer of european leaders Dulevo (Italy), TSM (Italy) and Max Holder (Germany).

INDUSTRIAL VACUUM CLEANERS

-

Full range of of industrial vacuum cleaners, centralized vacuum systems (CVS) and pneumatic conveyors

SINGLE DISC VACUUM CLEANERS

-

Wide range of professional single disk machines for floor maintenance, wet and dry vacuum cleaners, extractors for carpet washing and sanitizing machines for restrooms

RENT AND SERVICES

- Wide range of tecnical and finance services