igus

Videos

Loading the player ...

- Offer Profile

-

motion plastics: High-performance polymers for motion

igus is a manufacturer of high-performance polymers for motion, so-called motion plastics. We have been developing and producing innovative products made from lubrication-free plastics since 1964. These include energy chains, cables, plain bearings, thread technology, robots and intelligent sensor technology, which help our customers to improve their technology and reduce costs. igus is headquartered in Cologne (Germany), but is represented by 30 other locations and 50 dealers worldwide.

Product Portfolio

Mechanical components

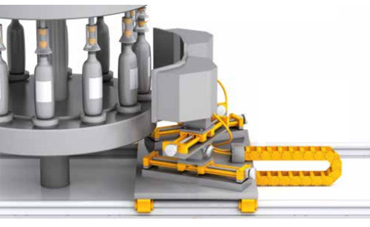

Energy chains

- Energy chains are the umbilical cord of modern machines. Customised directly from stock. With experts for quick design and calculation.

3D energy chains

- Energy supply systems for robots, also as a complete solution including excellent torsion-resistant cables. With quick configurator.

Plain bearings

- Increase service life, reduce costs and eliminate lubrication. 10,000 types from stock. With quick product finder and service life information.

Linear guides

- Rail, shaft and other linear guides from stock. Lubrication-free, quiet, lightweight and affordable. With quick product finder and service life information.

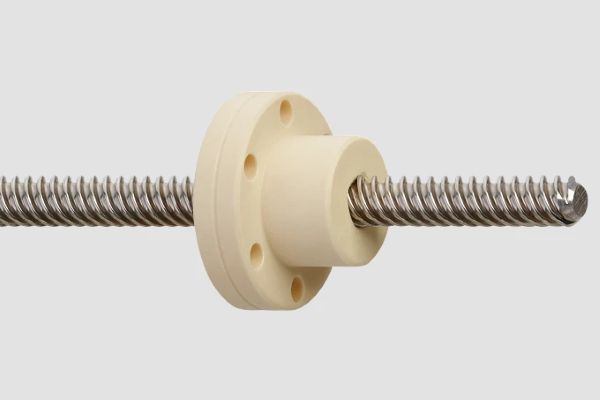

Lead screw technology

- High helix, trapezoidal and metric threads with dryspin technology. With quick product finder and service life information.

Spherical bearings

- Self-aligning, maintenance-free bearings made from sliding plastics. Almost 2,600 types from stock. With quick product finder and service life information.

Ball bearings

- For maintenance-free dry operation, lubrication-free, for temperatures up to 150°C. With quick product finder and service life information.

Guide rollers

- Guide rollers made of wear-resistant plastic, no minimum order quantity, without additional lubrication, with high load-bearing capacity and low maintenance.

Knife edge rollers

- Knife-edge rollers for particularly tight belt deflection. Maintenance and lubrication-free and suitable for direct contact with food.

Gears

- Wear-resistant plastic gears with no minimum order quantity up to high-volume production of several million. In different manufacturing processes.

Drive technology

- Lubrication-free linear modules with lead screw, toothed belt or gear rack and pinion drive. For every installation space, customised stroke lengths, with configurator.

Gearbox

- drygear Apiro gearboxes as worm, gear rack or bevel gears. Available in different versions.

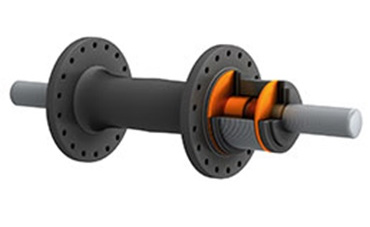

Slewing ring bearings

- With sliding elements made of absolutely maintenance-free and lubrication-free material. With quick product finder and service life information.

Guide rings

- Replace expensive stamped PTFE tapes with clip-on guide rings. Available in a choice of materials and with a quick product finder.

Conveyor rollers

- xiros conveyor roller made from different tube materials. With diameters of 20-100mm and lengths of up to 1,500mm.

Disc springs

- Our polysorb disc springs are lubrication- and maintenance-free and resistant to a wide range of chemicals and media.

Recycling of technical plastics

- With our Chainge product range, we enable our customers to return and recycle our products.

Bar stock & 3D printing & coating

Round bars

- Our round bars made of iglidur materials are suitable for low and high speeds, temperatures up to 250°C and other requirements.

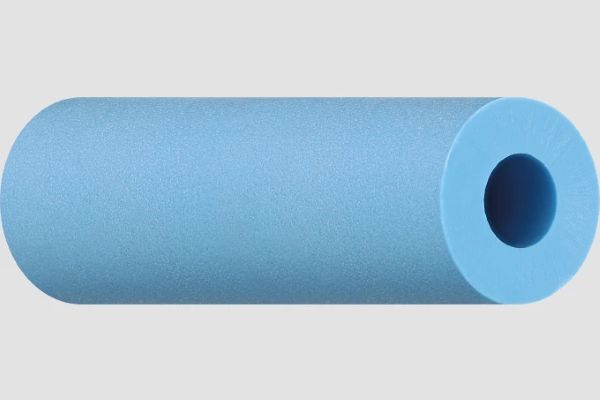

Hollow bars

- We offer iglidur hollow bars in individual lengths of 100-1,000mm and with an outer diameter of 110, 125 and 150mm.

Plates

- Plastic plates in five materials from the iglidur product range. With high wear resistance, suitable for various applications.

3D printing filaments

- Our 3D printing filaments for maximum service life. With low coefficients of friction and good wear properties.

SLS materials

- Wear-resistant plastics for selective laser sintering. Our iglidur i3 powder is at least 3 times more abrasion-resistant than conventional materials.

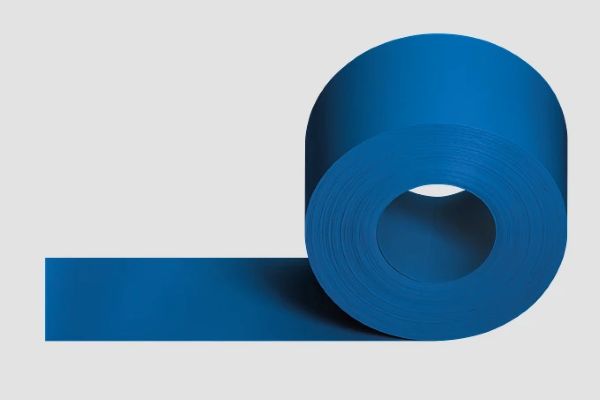

Liners

- Tribo-tape liner for lining tribologically stressed surfaces and moulds. Easy-to-install protection for all surfaces.

3D printing resin

- Resin for DLP 3D printing of wear-resistant parts with the finest details. At least 30 to 60 times longer service life than conventional resins.

Coating

- iglidur coating for the polymer coating of electrically conductive components with outstanding friction and wear values.

Electrical components

Cables sold by the metre

- Cables for moving applications with up to 4 years guarantee. Over 1,354 types from stock, with no minimum order value and no cutting costs.

Ready-to-connect cables

- For use in energy chains. Various cable types with different approvals and conformities. With quick product finder.

Electric motors

- Discover our extensive product range of stepper motors, DC motors and EC/BLDC motors. Many motors available from stock.

Motor control systems

- The right controller or output stage for every motor. From simple automation to complex control tasks.

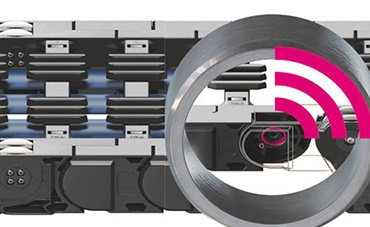

Predictive maintenance

- Defects are recognised before they occur. Downtimes or failures are avoided and maintenance costs are reduced.

Ready-to-connect guide systems

- Ready-to-install e-chain systems and harnessed cables. With no minimum order quantity, delivered in 1 to 10 days. With fast configurator.

Drive technology

- Lubrication-free linear axes with trapezoidal thread, high helix thread or toothed belt. With quick drive technology configurator.

Gearbox

- Ready-to-install rotary axes with drygear gearbox: Lubrication-free, lightweight and shock-resistant. Modular and can be extended as required.

plug-in connectors

- Connectors and more than 3,500 connector components – all from a single source. Various connector types available from stock.

Module Connect

- Our modular plug-in connector is ideal when several cables need to be connected in the tightest of spaces.

Engineering & installation service

- Whether converting or installing a new energy chain, we develop customised solutions together with our customers. Everything from a single source.

Low Cost Automation

Cobot

- ReBeL cobots in various designs made of high-performance plastic. With accessories such as 7th axis, strain wave gear and various grippers.

Linear robots

- drylin linear robots consisting of various linear actuators for xyz movements. Sliding instead of rolling, for quiet and smooth operation.

Delta robot

- Delta robot with 2 or 3 axes for fast pick & place tasks. Pick rate of 100/60 picks/min. Further accessories available.

SCARA robot

- SCARA robots with 3 or 4 axes for reliable work in the laboratory. Available in different sizes and with reach ranges from 400-600mm.

Articulated arm robot

- Automate processes cost-effectively and easily with articulated arm robots. Customise the configuration of robot arms and combine them with grippers.

Robot modular system

- Construction kit with fast, simple and cost-effective robotic components for Low Cost Automation.

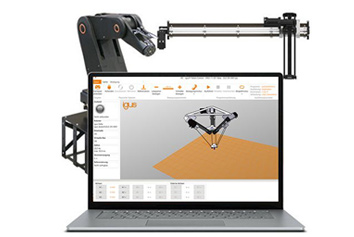

Control systems

- Robot control and programming with the igus Robot Control. Simple and intuitive, for an easy introduction to automation.

RBTX

- Our platform for automation and low-cost robotics. We bring users and component suppliers together quickly and easily.