- Offer Profile

-

Weingärtner Maschinenbau GmbH is an international company specializing in the manufacture of special machine tools for the energy, plastics, aerospace, and heavy duty machining sectors.

Weingärtner has always been known as a competent and reliable partner for the manufacture and assembly of industrial systems.

As far as machine tools are concerned, Weingärtner's many years of experience have enabled it to bring whirling to series maturity as the most economical process for manufacturing even complicated extrusion and injection molding screws.

The success of the machines for the production of rotors for progressive cavity pumps and mud motors as well as the latest machine generation of the mpmc turning/milling center also confirms Weingärtner's leading position in the field of machine tools on the world market.

Machines

-

Weingärtner specializes in machine tool manufacturing. We offer a diverse range of modular machines designed for high-performance machining and finishing of complex shafts and helical parts. Our products are globally distributed and supported with exceptional technical assistance.

To complement our machine tools, we develop CAD/CAM software for precise control and provide advanced process and machining technologies.

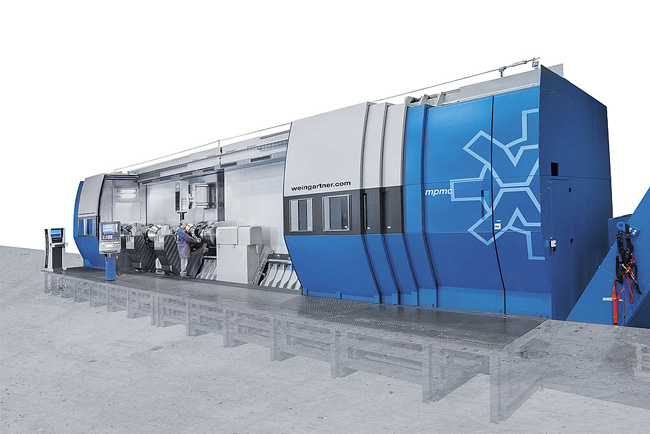

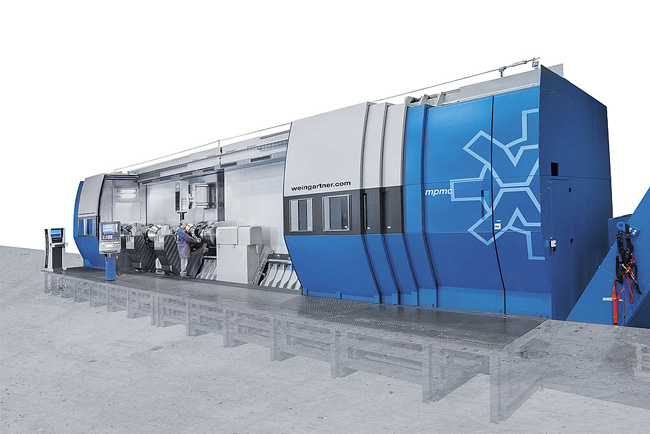

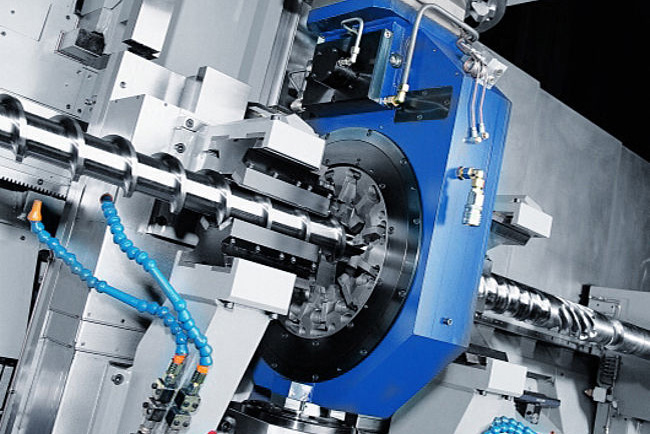

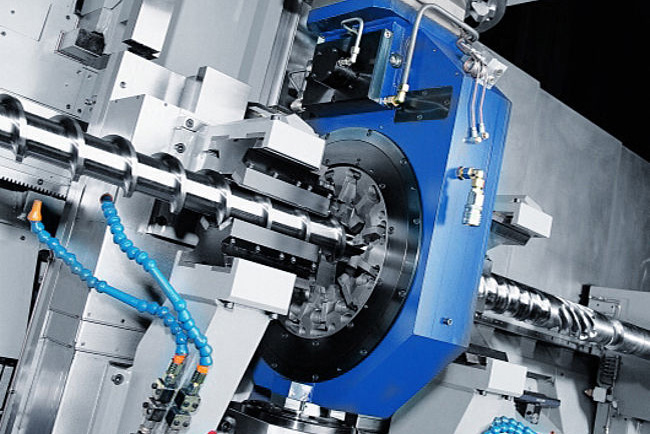

mpmc

- Multi-Product Machining Center

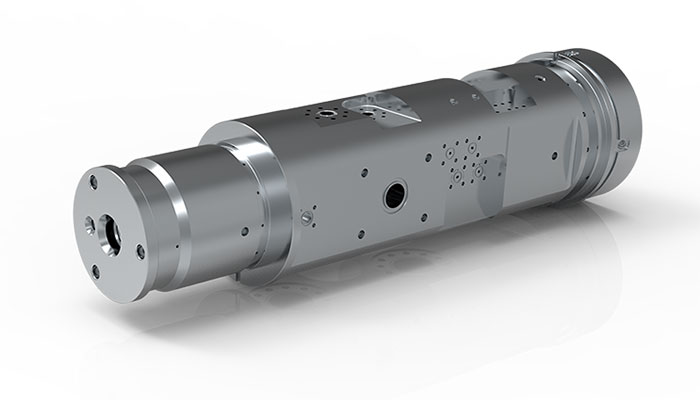

Weingärtner has long been the standard-bearer in complete horizontal machining with its flagship product, the mpmc (Multi-Product Machining Center). Our team of highly skilled engineers is dedicated to continual improvement and development, ensuring that the mpmc remains at the forefront of technology.

Equipped with a comprehensive and regularly updated software package, the mpmc offers extensive customization options to meet specific and individual requirements. Precision, efficiency, and versatility are just a few of the exceptional features that define this machine concept, enhancing the quality of workpieces while reducing production time.

Designed with ergonomics in mind, the mpmc guarantees comfortable and safe operation. Its wide base, excellent guide ratio, and carefully configured guideways ensure stability and minimize vibrations, even under extreme cutting conditions.

pickup 400

-

Introducing the pickup 400, the new generation machine from Weingärtner optimized for the economical complete machining of extrusion and injection molding screws. Building upon the success of the pickup machine series in the plastics industry, this consistent further development is a response to the strong demand from our customers who already utilize the weinCAD Screw-Designer software on Weingärtner machines.

The machine concept is ingeniously simple, combining the "old proven" workpiece clamping concept of the pickup machine series with prism jaw steady rests, a stable headstock, and tailstock, along with the powerful and flexible machining technology of the mpmc turn-mill centers. The result is a highly efficient machining center designed specifically for the complete machining of plastic screws.

The pickup 400 offers our customers significant added value through its integrated system, encompassing programming to the finished workpiece. Existing customers who utilize weinCAD for their screw production can seamlessly transition their program data to the new machine generation, saving valuable time in part programming.

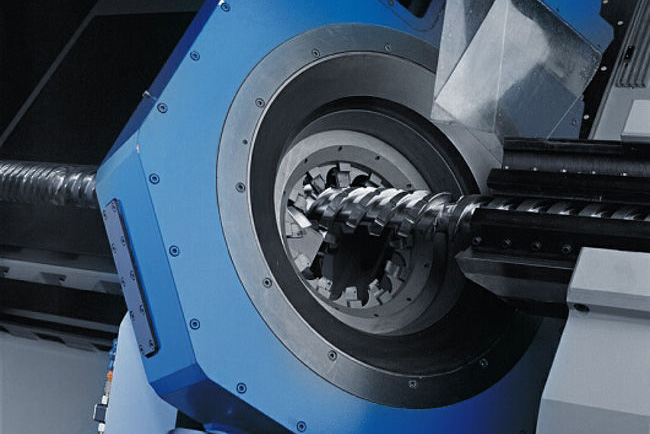

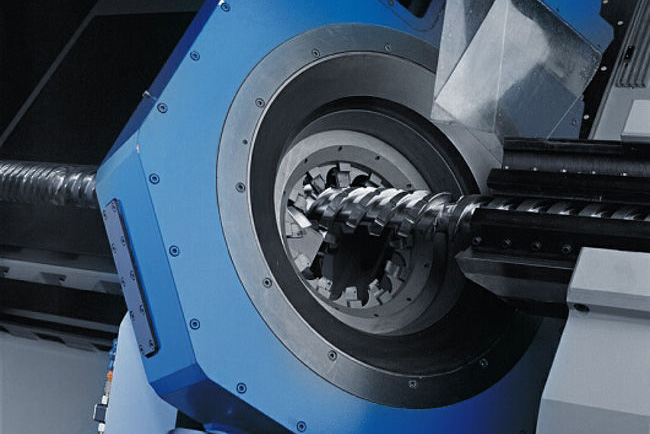

vario+

-

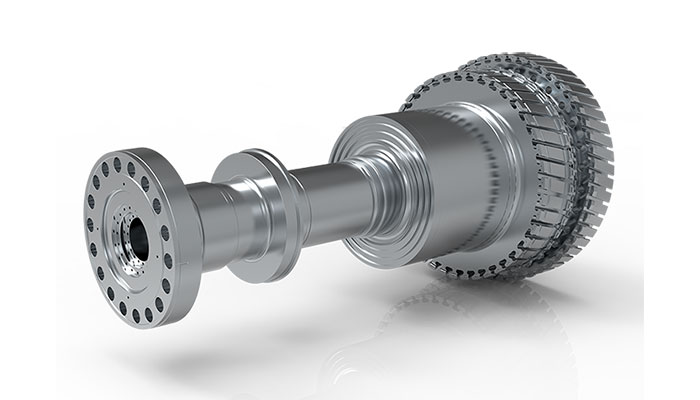

The vario+ is an advanced machining center designed for high-performance applications such as power section rotors, PC-pump rotors, and ball screw spindles. Its compact design ensures maximum space efficiency without sacrificing precision, making it a versatile solution for diverse machining needs.

Key Features:

- Enhanced Versatility: Accommodates various workpiece dimensions with multiple machining unit sizes.

- Exceptional Capabilities: Advanced milling, peeling, and whirling technologies deliver superior accuracy and surface finishes.

- Pull-Through Process: Handle extended workpieces beyond the machine bed length, enabling the manufacturing of longer, more complex components.

- Integrated Measuring: Automatic measuring capabilities enhance productivity and ensure precise quality control.

- User-Friendly Operation: Intuitive programming and intelligent software simplify even the most complex machining tasks, optimizing production processes.

- Safety & Comfort: Comprehensive safety features and ergonomic design ensure a secure and comfortable working environment.

finish

- Advanced Grinding, Polishing, and Measurement Machine

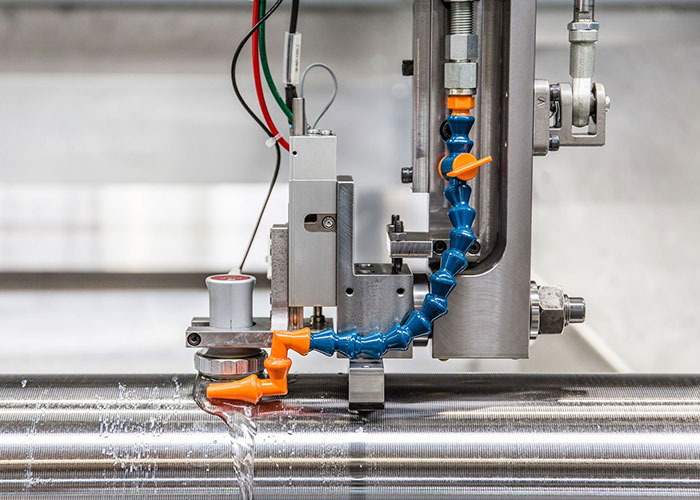

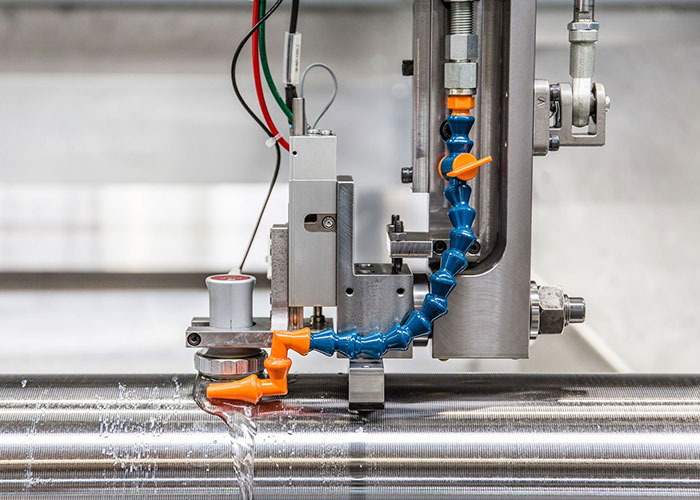

The finish machine tool from Weingärtner offers a comprehensive solution for the controlled grinding, polishing, and measurement processes required to achieve the perfect finish on parts machined with Weingärtner machines. With its advanced features, this machine covers the entire spectrum of finishing operations, including polishing, grinding, and precise measurement.

The machine is available in a single or double slide design, featuring a multifunctional unit for polishing with various options such as belts, contact wheels, or flap wheels. Additionally, optional units for grinding and measurement, as well as a profiling unit for the efficient production of single and multi-start rotors and stator cores for eccentric screw pumps/motors (Moineau) and plasticizing screws, are available.

Key Features of the Basic Machine Configuration:

- Welded base design with four hardened linear guides, support blocks, splash guard, and guideway covers.

- Headstock with a hollow spindle and adjustable passage (C axis).

- 3-jaw chuck for secure workpiece gripping.

- Longitudinal slide with rack and pinion drive system for precise movement along the Z axis.

- Face slide with a precision ball screw and weight compensation for smooth and accurate movement along the X axis.

- Tailstock (W axis) with pneumatically operated quill, offering flexibility according to technical requirements.

- Fully enclosed machine with automatic safety doors and protective glazing (B3/C3 - DIN EN 12415) for operator safety.

- Integrated flushing system for maintaining a clean working area.

- Pneumatic system with filtration and automatic water separation for efficient operation.

- Optional hydraulic equipment, including a power unit with a cooler, valves, and piping, can be added as needed.

- Electrical equipment includes a control system with digital drives (AC servo/main drive) for precise control and operation.

- Movable operating panel that is rotatable and height adjustable for convenient access and control.

- Documentation provided to ensure proper setup, operation, and maintenance.

Applications / Industries

Aviation/Aerospace Industry

-

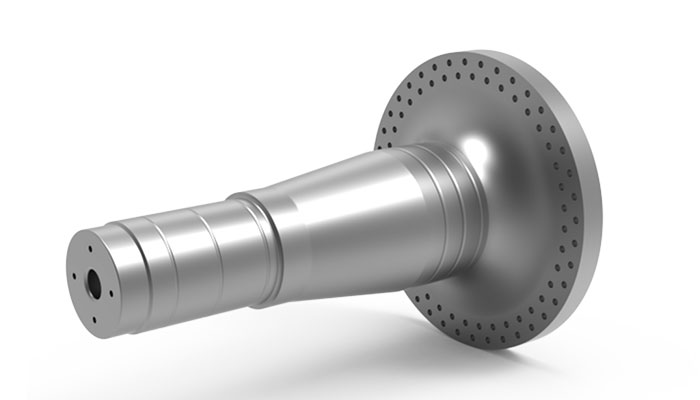

In the demanding realm of aviation and aerospace, precision and reliability are paramount. Weingärtner's mpmc machines are engineered to meet these exacting standards, making them the ideal choice for producing critical components such as landing gears, turbine shafts, engine casings, compressor discs, blades and vanes for turbines, and other complex workpieces integral to aircraft performance and safety.

Our state-of-the-art mpmc machines offer unparalleled precision, ensuring each part meets the stringent tolerances required in aerospace applications. Furthermore, our advanced technology enhances production efficiency and reduces lead times, enabling you to maintain a competitive edge in the industry.

Choose Weingärtner for your aerospace manufacturing needs and benefit from our commitment to quality, innovation, and excellence in every workpiece we help you create.

Oil & Gas Industry

-

In the critical oil and gas industry, where durability and precision are essential, Weingärtner's range of machines—including the mpmc, vario+, and finish—are expertly designed to meet these high standards. The oil and gas sector, responsible for over half of the world's energy supply, demands the utmost reliability from its components. Our machines are ideal for producing vital parts such as rotor pump shafts (single-, double-, and multi-lobe shafts), gas turbines, valve blocks, stabilizers, power section rotors, drill bits, wellhead components, pump and compressor parts, downhole tools, and manifold blocks.

Our versatile mpmc and vario+ machines provide a variety of machining methods, including milling, turning, drilling and peeling, ensuring flexibility and precision for your diverse manufacturing needs. Additionally, our finish machines deliver exceptional surface smoothing, meeting the stringent surface quality requirements critical in oil and gas applications.

Plastics Industry

- In the dynamic plastics industry, precision and efficiency are key to producing high-quality components that meet stringent standards. The global plastics market is vast, with applications ranging from everyday consumer products to critical components in automotive, medical, and packaging industries. Weingärtner's advanced range of machines—including the mpmc, vario+, pickup, and finish—are perfectly suited for this diverse and demanding sector. Our machines excel in producing essential parts such as injection molding screws, extruder screws (single and twin screws), tie rods, cylinders (single and twin cylinders), housings, and other complex workpieces.

Energy Industry

-

In the rapidly evolving energy sector, where precision and reliability are crucial, Weingärtner's advanced mpmc machine is designed to meet these high standards. The energy industry encompasses a wide range of applications, from traditional power generation to renewable energy solutions, making the demand for high-quality components ever-present. Our machines excel in producing critical parts such as turbine shafts, generator rotors, heat exchanger components, pump impellers, valve bodies, gearbox components, stator and rotor assemblies, and pressure vessel parts.

Our versatile mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision required for diverse energy applications and meeting the stringent quality standards necessary for optimal performance and durability.

Railway Industry

-

In the railway industry, where safety, durability, and precision are paramount, Weingärtner's advanced range of mpmc machines are expertly engineered to meet these high standards. The railway sector demands high-quality components to ensure the safety, reliability and efficiency of train operations. Our machines excel in producing critical parts such as wheelset axles, brake discs, suspension components, gearbox housings, coupler parts, drive shafts, bogie frames, and railcar body components.

Our versatile mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision needed for diverse railway manufacturing processes, and meeting the stringent quality standards required for optimal performance and safety.

Pump Industry

-

In the pump industry, where precision and reliability are critical, Weingärtner's advanced range of machines—including the mpmc, vario+, and finish—are designed to meet these exacting standards. Pumps play a crucial role in a wide range of applications, from industrial processes to water treatment and oil extraction, necessitating high-quality components for optimal performance. Our machines excel in producing essential parts such as rotor shafts, pump casings, impellers, volutes and sealing components.

Our versatile mpmc and vario+ machines support a variety of machining methods, including turning, milling, peeling and whirling, ensuring the flexibility and precision required for diverse pump manufacturing processes. Additionally, our finish machines deliver exceptional surface smoothing, ensuring that each component meets the stringent quality standards necessary for efficiency and durability

Renewable Energy Sector

-

In the rapidly growing renewable energy sector, precision and reliability are key to advancing sustainable solutions. Weingärtner's mpmc machines are specifically designed to meet the high standards required for this innovative industry. Renewable energy applications demand high-quality components to ensure the efficiency and durability of equipment used in wind, solar, hydro, and other renewable energy systems. Our mpmc machines excel in producing critical parts such as wind turbine shafts, generator rotors, wind propeller shafts, hydro turbine components, gearbox housings, and structural supports.

Our state-of-the-art mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the flexibility and precision needed for diverse renewable energy manufacturing processes. These machines deliver exceptional performance and surface smoothing, meeting the stringent quality standards necessary for the renewable energy sector.

General Machining Industry

-

The general machining industry encompasses a wide range of manufacturing applications, requiring versatile and precise machinery to produce high-quality components. Weingärtner's mpmc machines are perfectly suited for this sector, offering exceptional performance and flexibility for various machining tasks. A key specialty within this industry is the production of large crankshafts, critical components used in engines for ships, locomotives, and large industrial machinery.

Our state-of-the-art mpmc machines support a variety of machining methods, including turning, milling, and drilling, ensuring the capability to handle diverse machining needs. These machines are specifically designed to manage the complexity and precision required for producing large crankshafts, delivering exceptional accuracy and surface quality.

Software

-

Software solutions by Weingärtner

Experience the power of Weingärtner software solutions, designed to optimize your machining processes and drive efficiency. Our comprehensive suite of software offerings is tailored to meet your specific needs, providing intelligent tools and capabilities that enhance productivity and accuracy.

weinCAD®

- Our sophisticated programming and production software, weinCAD®, is user-friendly and offers intuitive navigation within the mpmc (multi product machining center) functionality. With regular updates available online, you can stay up-to-date with the latest advancements in software technology.

EspritEdge

- EspritEdge: Redefine manufacturing excellence with state-of-the-art digital twin technology, advanced artificial intelligence, next-generation automation tools, and robust CAM programming. Experience seamless, safe, and efficient CNC operations tailored to your needs.

CHECKitB4

- CHECKitB4: Leverage the power of CHECKitB4 and your machine tool's digital twin to verify and optimize NC programs using a virtual NC control—directly from your CAM workstation.

More Software Solutions and Partners of Weingärtner

Service

-

Service Department: Ensuring Machine Excellence

At Weingärtner, we understand the critical importance of keeping your machines in optimal condition to maximize productivity and maintain competitive advantage. Our dedicated Service Department is committed to providing comprehensive support, ensuring that your Weingärtner machines installed in the field are running smoothly and up to date.

Our highly skilled and experienced team of service professionals is equipped with the knowledge and expertise to handle a wide range of maintenance, repair, and upgrade tasks. We prioritize proactive maintenance strategies to prevent potential issues and minimize downtime, allowing your operations to run seamlessly.

Remote Monitoring and Assistance

- Through advanced remote monitoring capabilities, we can remotely diagnose and troubleshoot issues, saving valuable time and resources. Our service team can provide real-time guidance and support to your operators, ensuring efficient problem resolution and minimizing the need for on-site visits.

On-site Repairs

- In the event of unexpected breakdowns or malfunctions, our service team is available to provide prompt on-site repairs. Equipped with specialized tools and genuine Weingärtner parts, we swiftly diagnose and resolve issues to minimize downtime and get your operations back on track.

Training and Knowledge Transfer

- We provide comprehensive training programs to empower your team with the necessary skills and knowledge to operate and maintain Weingärtner machines effectively. Our training sessions cover machine operation, maintenance best practices, and safety protocols, enabling your workforce to optimize machine performance and ensure operator safety.

Maintenance

- We offer regular maintenance programs tailored to your specific machine requirements. Our technicians perform thorough inspections, lubrication, calibration, and other essential tasks to keep your machines operating at their best. By detecting and addressing potential issues before they escalate, we ensure uninterrupted production and extend the lifespan of your equipment.

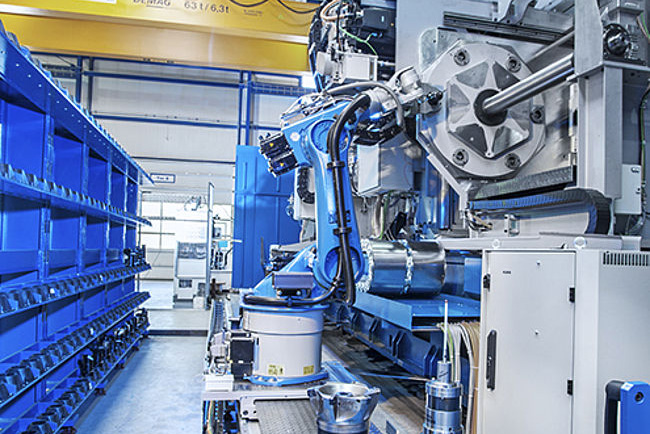

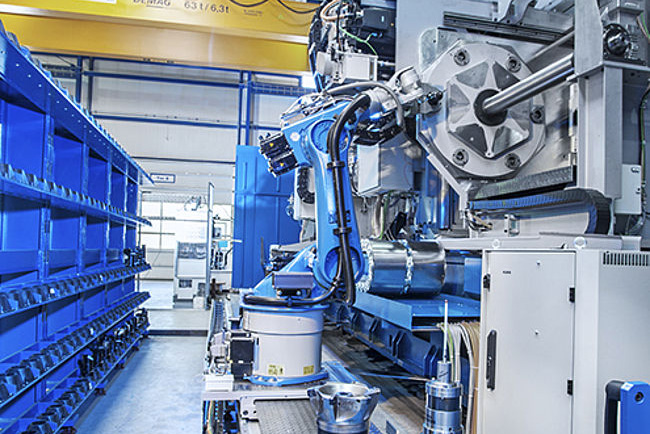

Retrofits

- As technology advances, we offer retrofit solutions to enhance the capabilities of your existing Weingärtner machines. Whether it's implementing new software features, integrating automation systems, or optimizing performance, our service experts can tailor solutions to meet your evolving needs and industry standards.