- Offer Profile

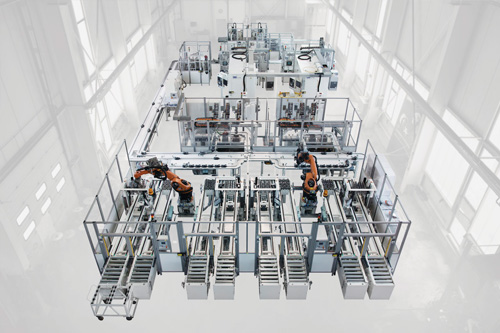

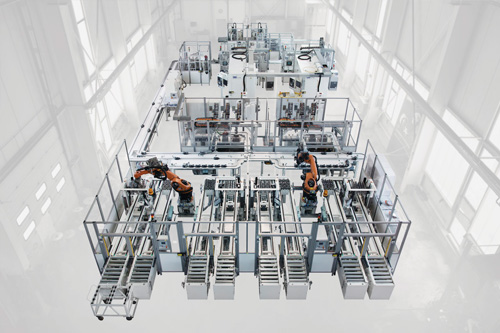

- The EMAG Group products cover the entire spectrum of machining processes in the metal working industry. Whether chucked, shaft-type or cubic components − the companies under the EMAG umbrella offer the best manufacturing solution for every customer. With its variety of technology centers EMAG has become an important partner in the realization of complete process streams for the manufacture of transmission, engine and chassis components.

TURNING MACHINES

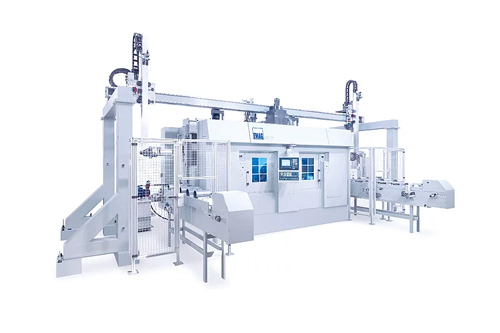

Modular VL - Integrated Precision

-

Vertical Modular Turning Machines - Low Unit Costs Guaranteed

A design that results in higher production performance: The lathes in the VL series are space-saving vertical turning machines with integrated automation.

VL 2

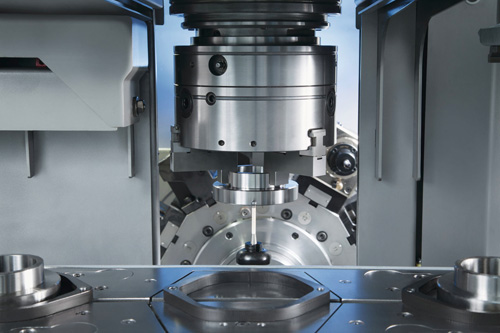

- VL 2 – Vertical Pick-Up Turning Machine for Chucked Components up to 100 mm in Diameter

VL 3 DUO

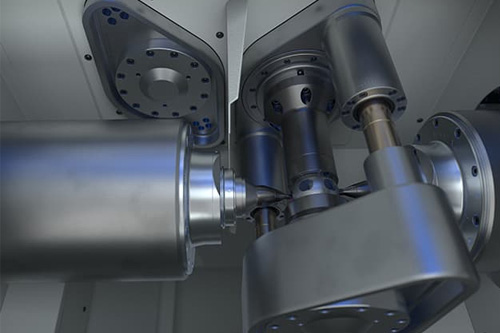

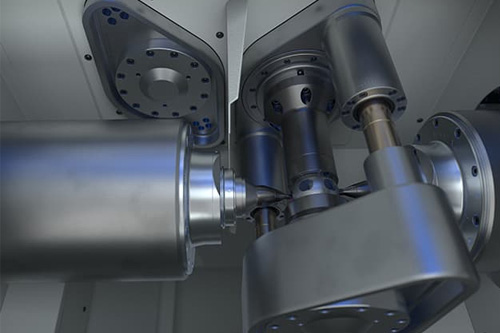

- VL 3 DUO – Multi-Spindle Machines for High-Productive Manufacturing of Chucked Parts

VL 4

- VL 4 - Vertical Turning Machines for Chucked Components up to 200 mm in Diameter

VL 6

- VL 6 – Vertical Lathe for the Machining of Heavy Workpieces up to 300 mm in Diameter

VL 8

- VL 8 - CNC Turning at the Highest Level for Chucked Parts up to 400 mm in Diameter

Modular VM

-

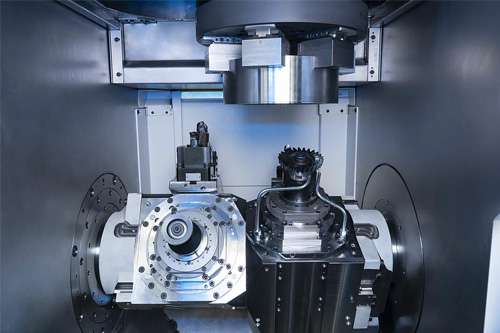

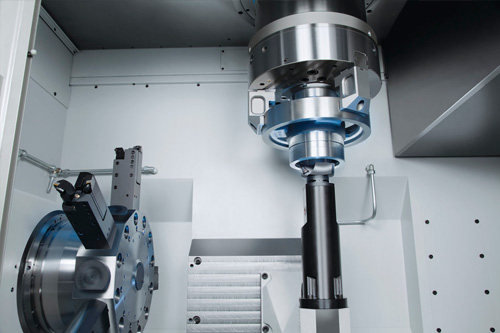

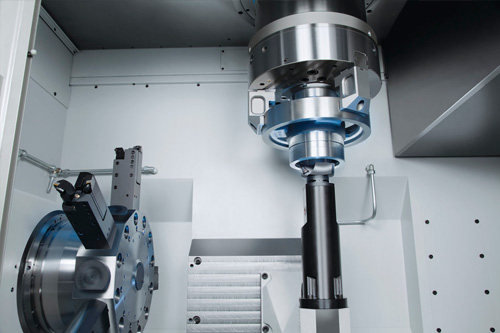

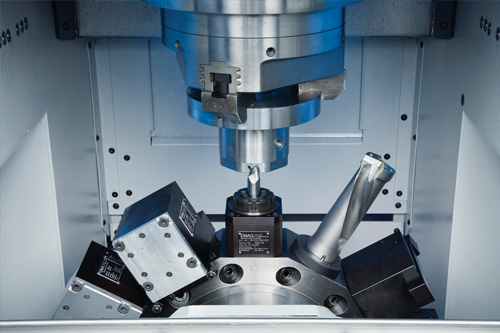

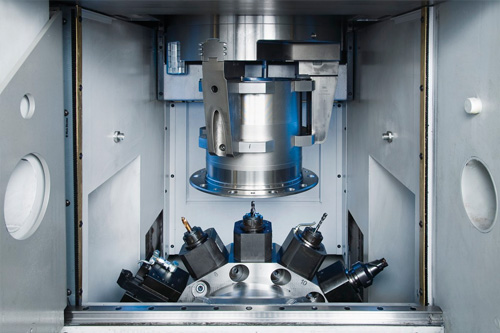

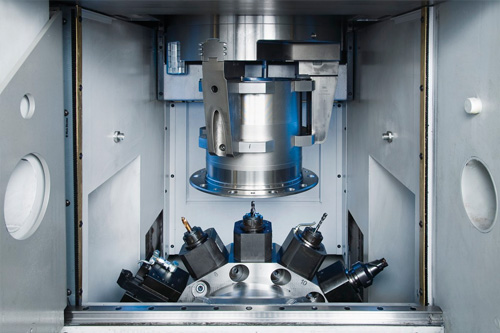

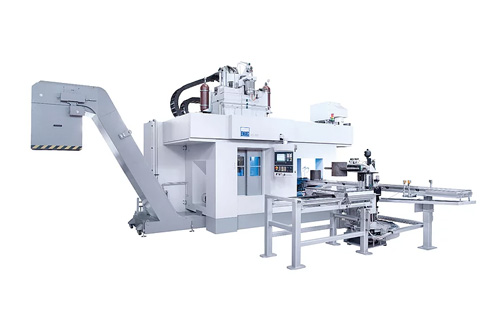

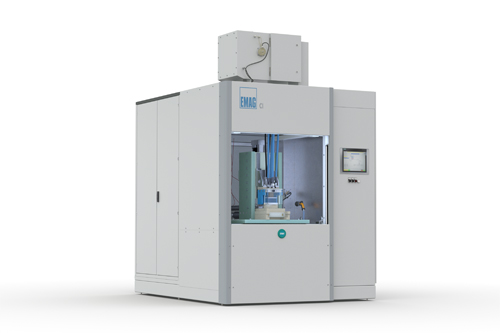

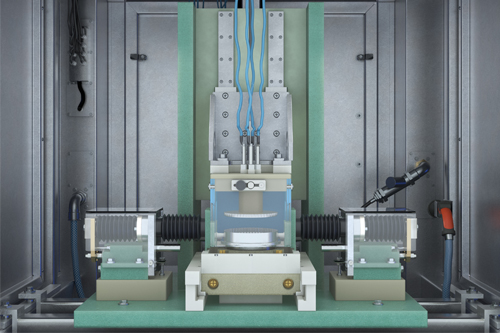

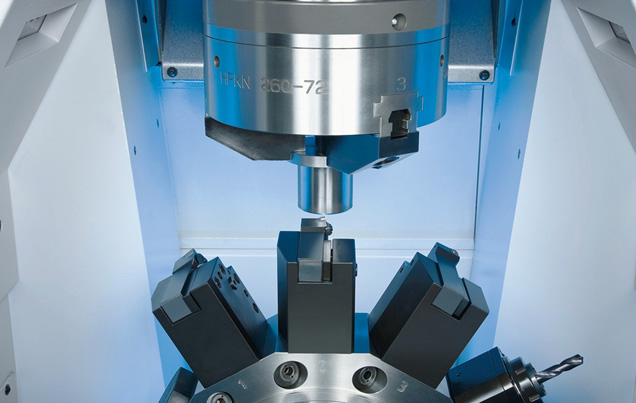

VM 9 Vertical Turning Center for the Manufacture of Large Components

With the new VM 9 vertical turning center, EMAG has introduced a platform that covers a broad spectrum of applications thanks to the combined turning, milling and drilling technologies and intelligent machine design. The highly accessible machining area and workpiece spindle fitted at the bottom ensure short tooling times and maximum flexibility in the production of large components.

VM 9

- The VM 9 Vertical Turning Center Machines Large Chucked Components up to 450 mm in Diameter

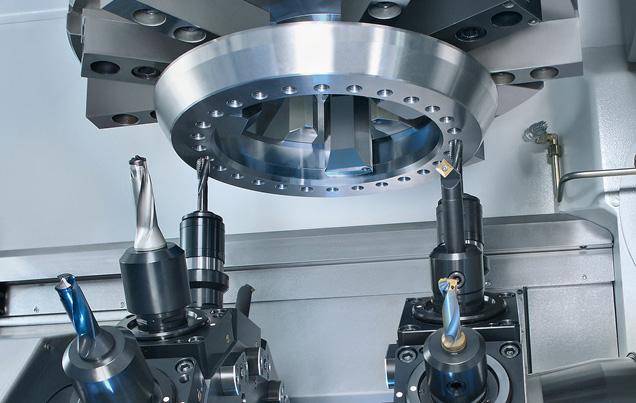

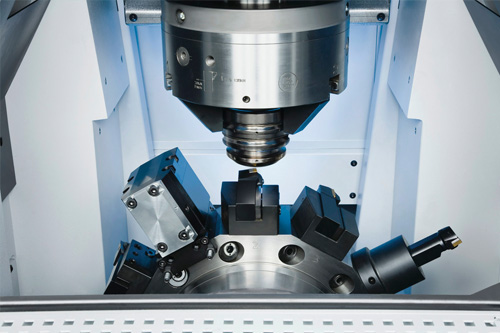

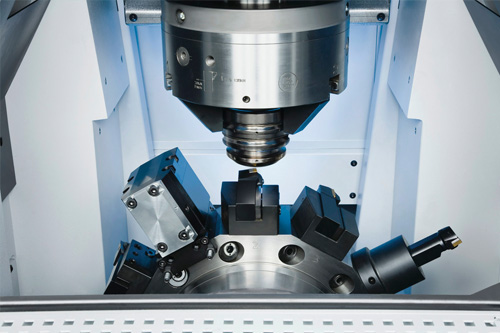

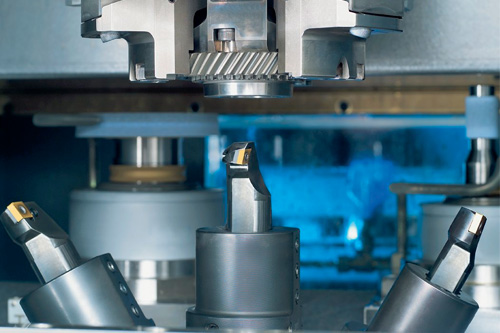

Customized VLC: Custom Solutions

- VLC Series Turning Machines – Universal Machining Thanks to Integrated Technology

As workpieces become more complex and precise, batch sizes are becoming smaller and throughput times shorter. EMAG’s answer to these demands is to use the high-performance, multifunctional machines of the VLC series to produce components in a single set-up through technology integration.

VLC 100

- The VLC 100 – Flexible CNC Turning Machine Available With a Range of Technologies

VLC 200

- The VLC 200 – Flexible CNC Turning Machine with the use of a Range of Technologies

VLC 200 GT

- The VLC 200 GT: hard machining of chucked components up to 200 mm (7.87 in.) diameter

VLC 300

- Pick-up turning center VLC 300 for advanced machining of chucked parts

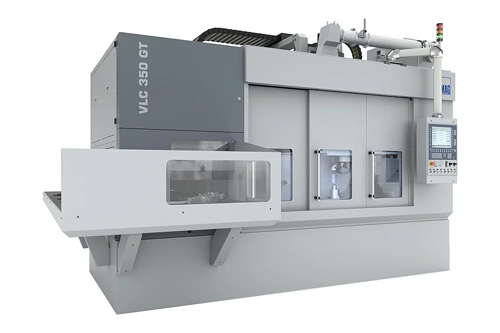

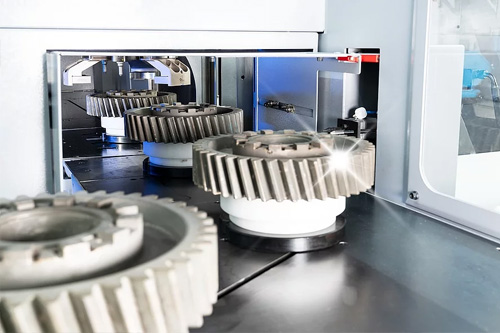

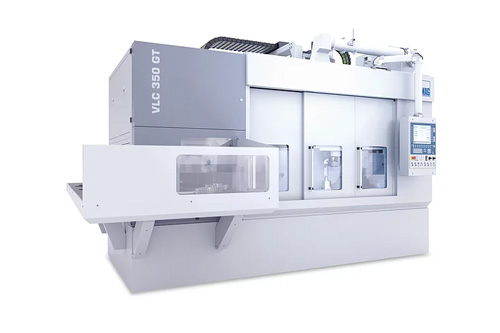

VLC 350 GT

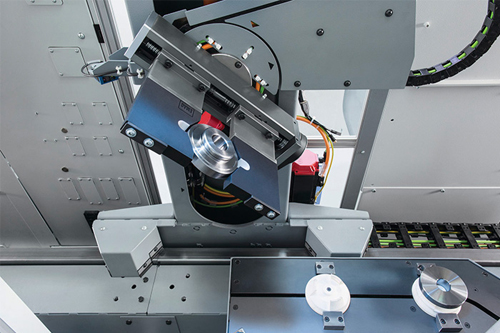

- The VLC 350 GT Turning/Grinding Machine

VLC 400

- VLC 400 Vertical Turning Machine for the Productive

Machining of Large Chucked Parts

VLC 500

- Combined turning and machining center: VLC production

machine

Production VSC

-

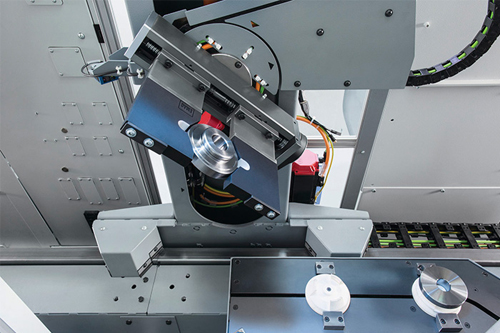

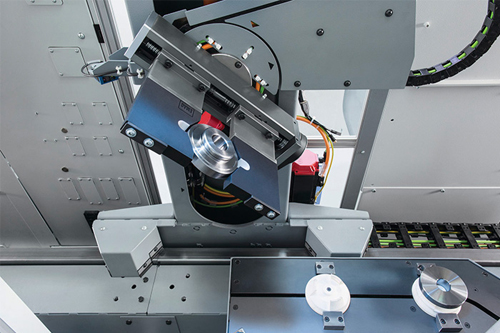

VSC – Multifunctional Production Centers

In 1992 EMAG was the first manufacturer to build a vertical turning machine with an inverted work spindle that traveled the main axes. EMAG continues to turn traditional manufacturing processes on their head! Every machine in the VSC series is a production cell where the pick-up spindle loads the machine itself.

VDZ 220 / VDZ 220 DS

- Single-spindle and double-spindle

VDZ 320 / VDZ 320 DS

- Single-spindle and double-spindle VDZ 320 and VDZ 320 DS CNC vertical lathes

VDZ 420 / VDZ 420 DS

- Single-spindle and double-spindle VDZ 420 and VDZ 420 DS CNC vertical lathes

VDZ 520 / VDZ 520 DS

- CNC lathe VSC 250: vertical turning + automation + measuring

VSC 250

- CNC lathe VSC 250: vertical turning + automation + measuring

VSC 400

- Machining + Automation + Measuring: The VSC 400 Vertical Pick-Up Lathe Equipped to Suit Production Requirements

VSC 500

- Automated heavy-duty machining of large workpieces on

the lathe VSC 500

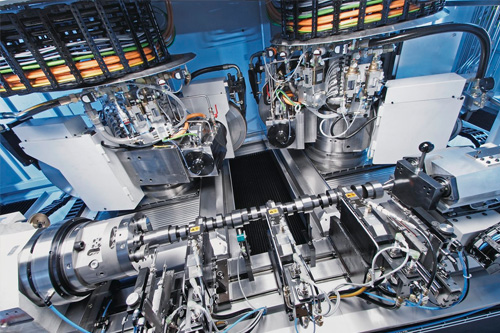

Multi-Spindle Automatics: High Output Production

-

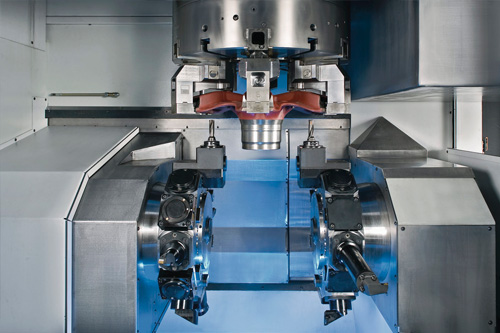

Vertical Multi-Spindle Machines: The Benchmark of Productivity

The powerful and compact multi-spindle vertical pick-up turning machines from EMAG are predominantly used in medium and large batch production of precise components and are known for their high output rates.

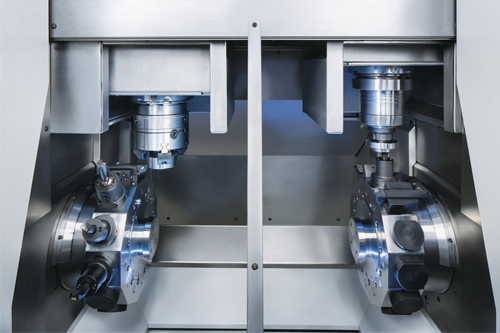

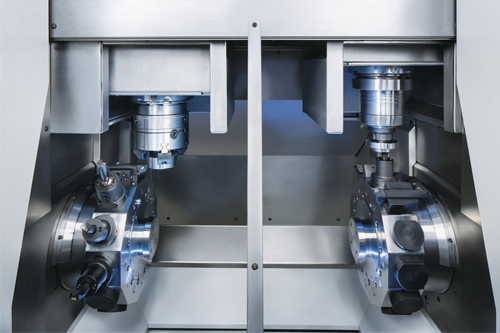

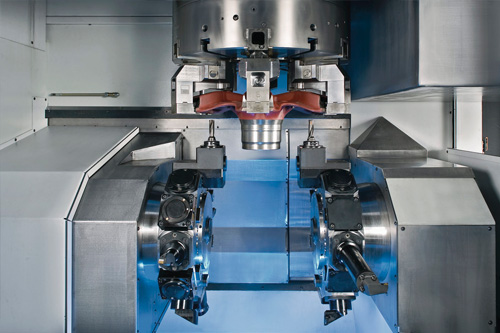

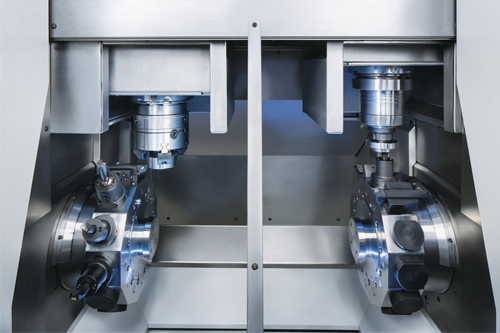

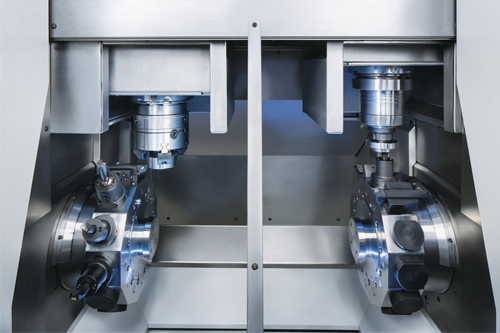

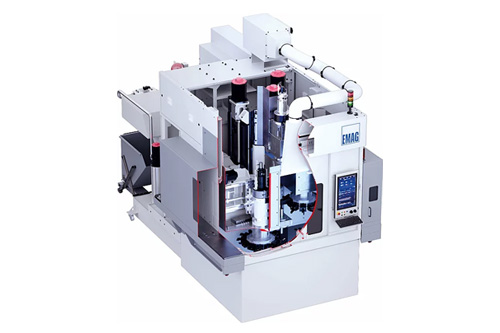

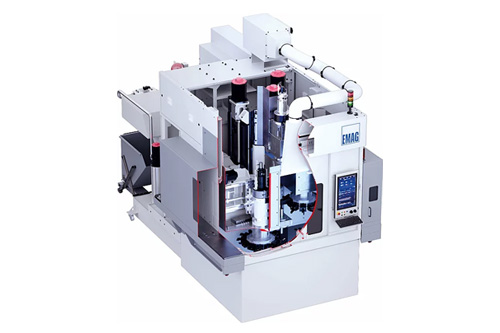

VL 3 DUO

- Modular Multi-Spindle Machine with Two Work Areas for Vertical CNC Turning

VSC DUO

- VSC DUO multi-spindle machines for medium and large batch production

VDZ 220 / VDZ 220 DS

- Single-spindle and double-spindle VDZ 220 and VDZ 220 DS CNC vertical lathes

VDZ 320 / VDZ 320 DS

- Single-spindle and double-spindle VDZ 320 and VDZ 320 DS CNC vertical lathes

VDZ 420 / VDZ 420 DS

- Single-spindle and double-spindle VDZ 420 and VDZ 420 DS CNC vertical lathes

VDZ 520 / VDZ 520 DS

- Single-spindle and double-spindle VDZ 520 and VDZ 520 DS CNC vertical lathes

VSC 160 TWIN

- Multi-Spindle Machines – VSC 160 TWIN

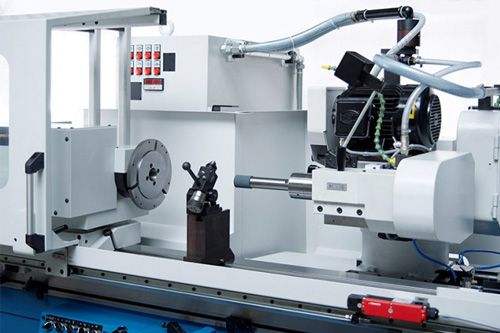

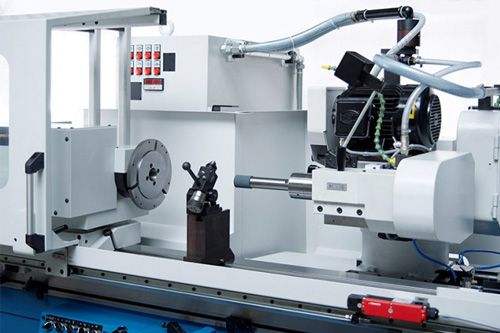

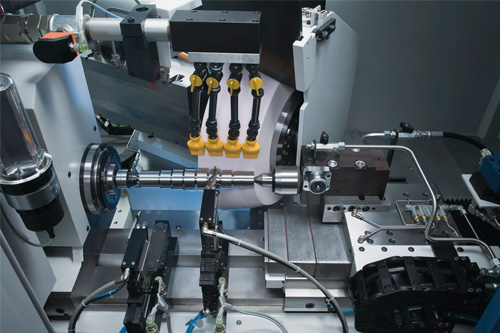

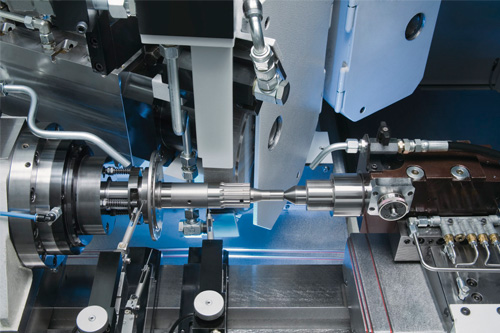

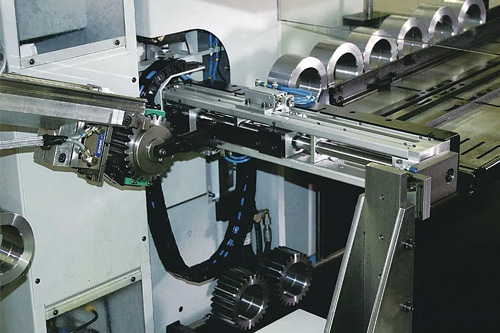

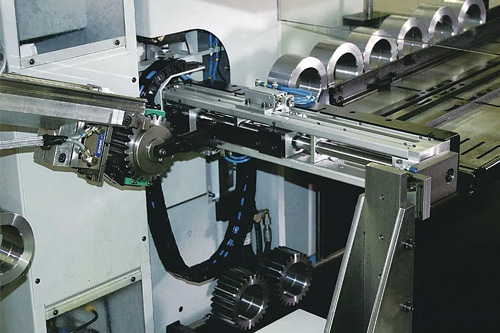

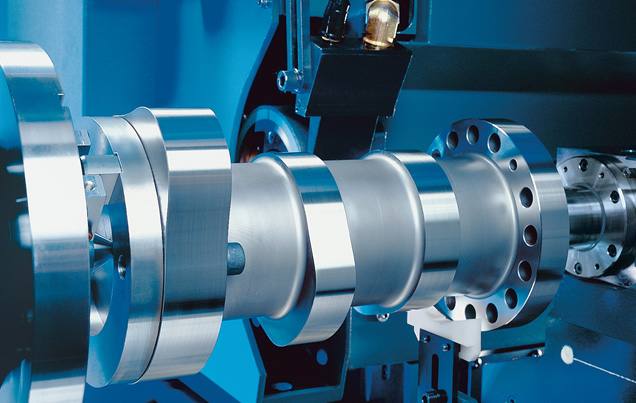

Shaft Machining Modular VT

-

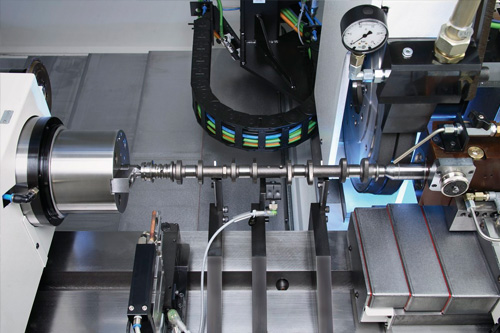

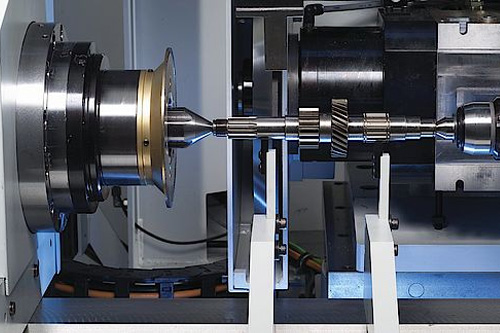

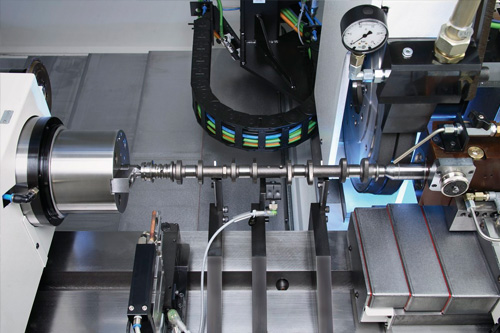

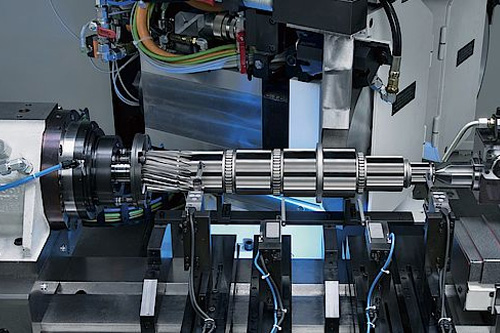

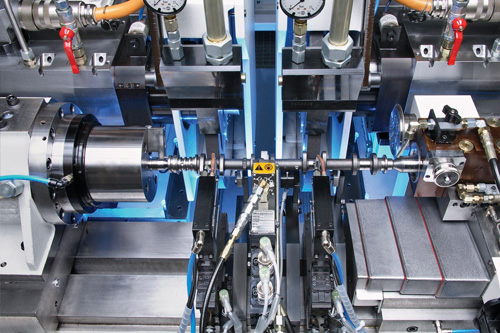

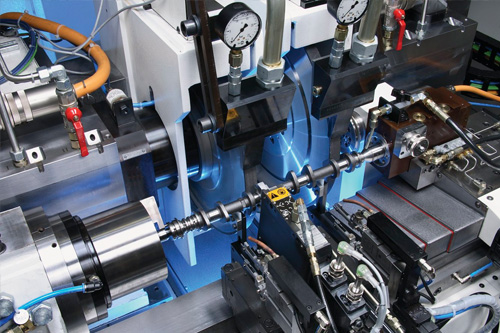

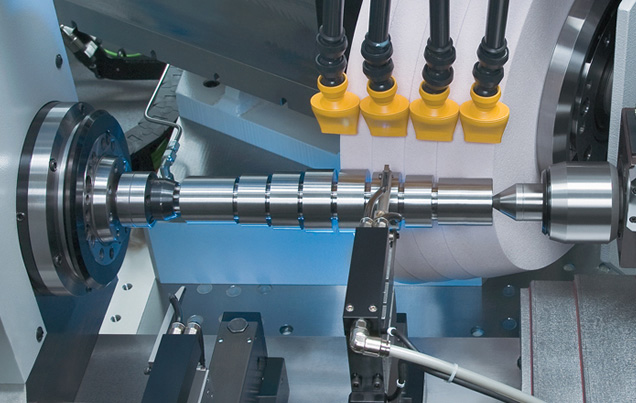

VT Series: Maximum Performance for Shaft Production

Fast processes are required for machining large quantities of shafts. Both the machining process and the loading and unloading processes must be completed extremely quickly. The VT 2-4 and VT 4-4 machines guarantee the maximum performance you require.

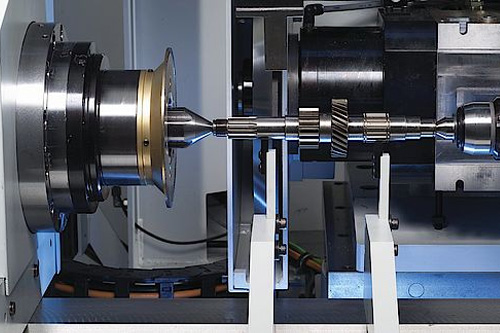

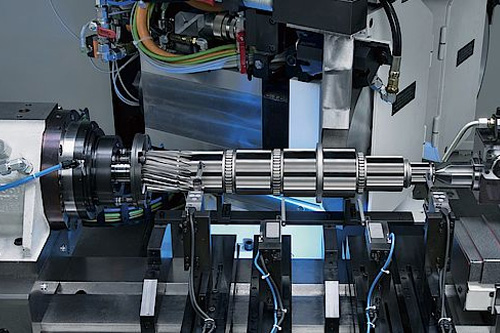

Maximum Efficiency in Shaft Production – VT 2 Lathes

- Modular Lathe for Vertical 4-Axis Shaft Machining

Maximum Efficiency in Shaft Production – VT 4 Lathes

- Vertical Lathe for Demanding Shaft Production

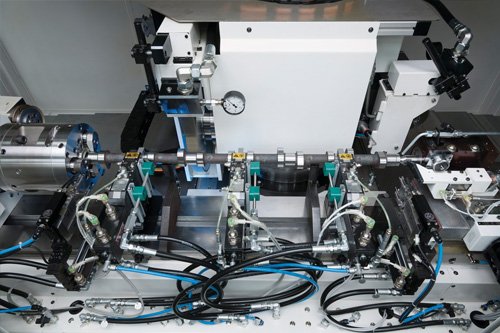

Customized Shaft Machining VTC

-

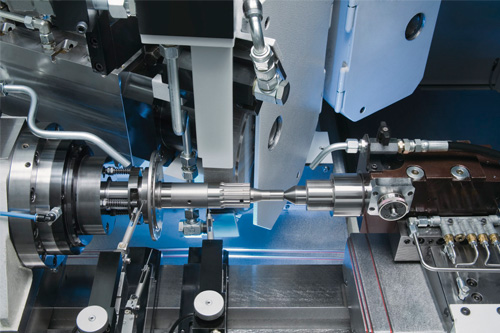

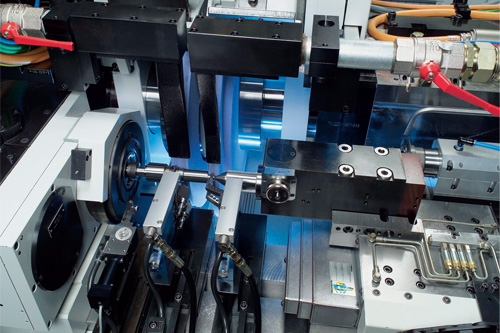

Shaft Production on Turning Machines from the VTC Series

Shaft machining in mid-sized to large-scale production creates special challenges for the machine

design. Short idle times, flexible automation systems for workpiece families and implementing the

ideal manufacturing technology are the main criteria for ensuring efficient production processes.

With the VTC series, EMAG supplies machines specifically designed to meet these requirements.

VTC 100

- 4-Axis Vertical Turning Machine

VTC 250 / 250 DUO

- VTC Customized Vertical Shaft Machining

VTC 200

- VTC 200 Turning Center for Flexible and Productive Shaft Manufacturing

VTC 100 GT

- All-round solutions for shafts

VTC 315 DS

- The production tool for the machining of challenging shaft-type components, the VTC 315 DS turns and grinds vertically.

VTC 200 CD

- Center-drive machine for high-productivity four-axis end machining of shafts

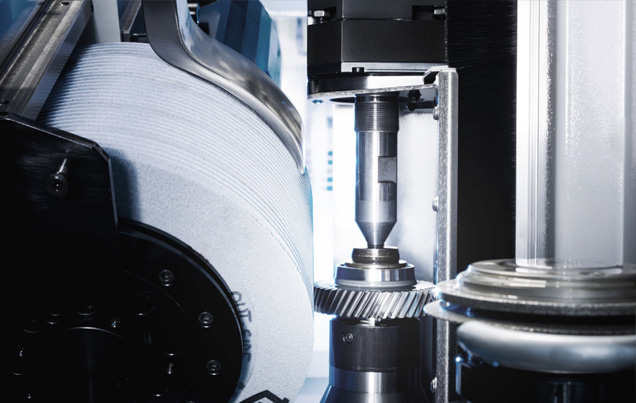

GRINDING MACHINES

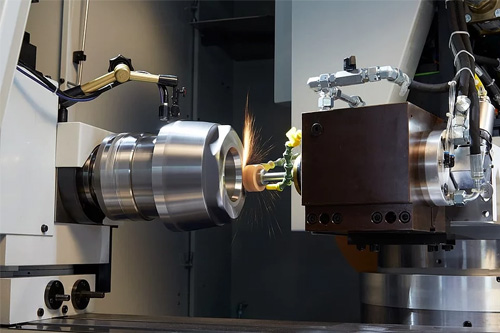

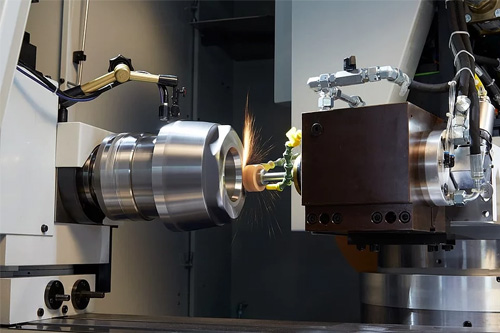

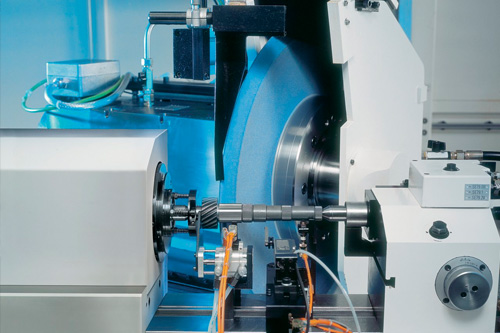

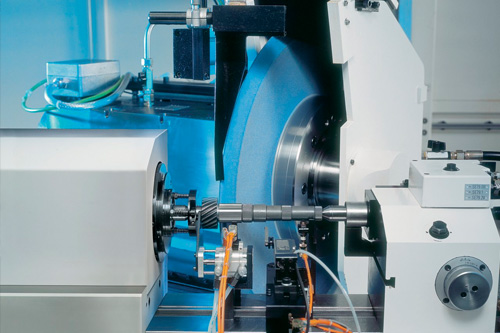

Vertical Turning and Grinding Centers

-

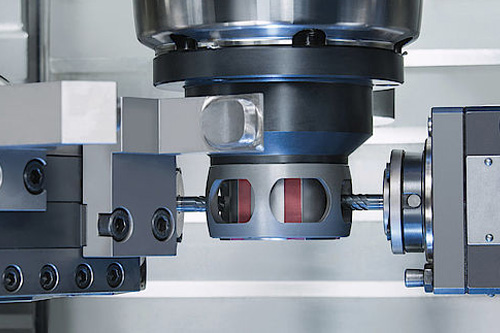

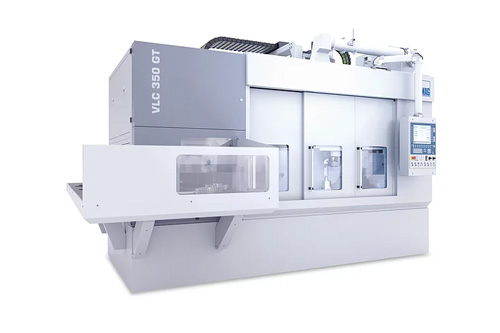

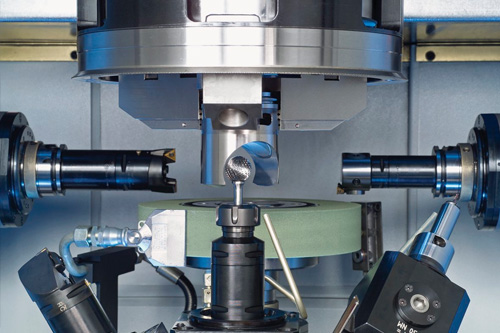

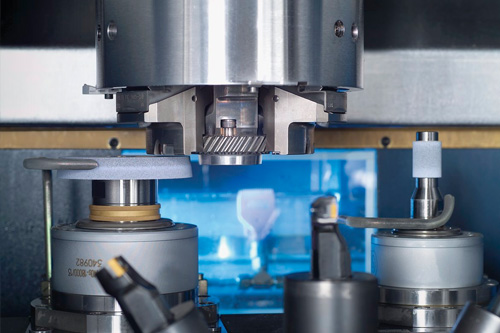

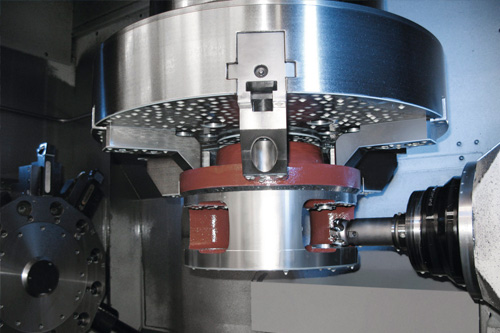

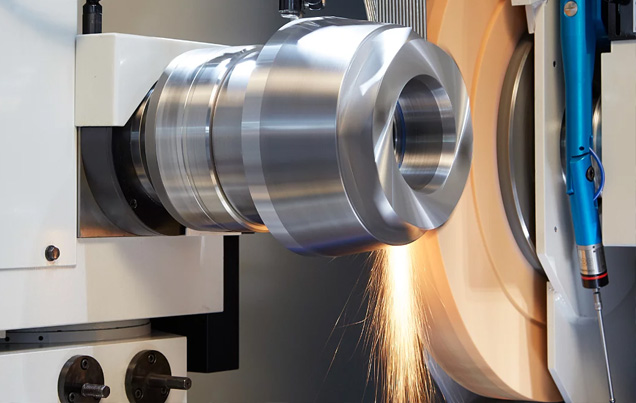

Vertical Turning and Grinding Centers for Chucked Components

Vertical turning and grinding centers combine the advantages of hard turning with those of grinding on a single machine, in a single set-up.

VLC 350 GT

- Vertical Turning and Grinding Centers, Chucked Componentsa

VSC DS / DDS

- Complete production processes with the turning and grinding center VSC DS

VLC 200 GT

- The VLC 200 GT: hard machining of chucked components up to 200 mm (7.87 in.) diameter

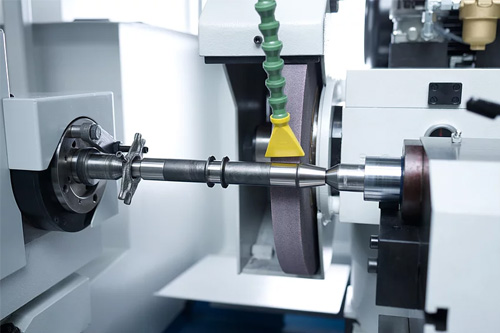

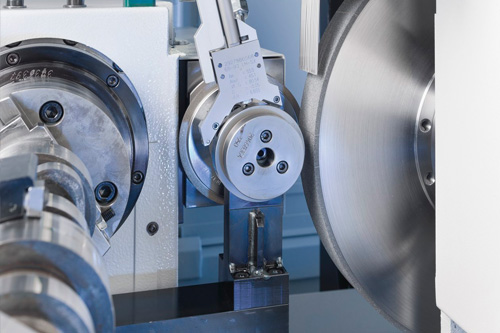

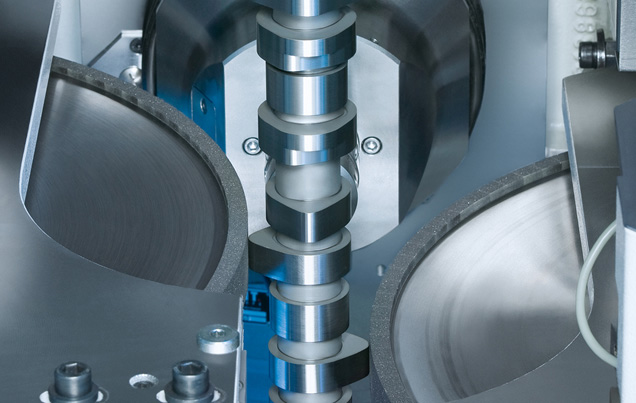

Vertical Turning and Grinding Machines, Shafts

-

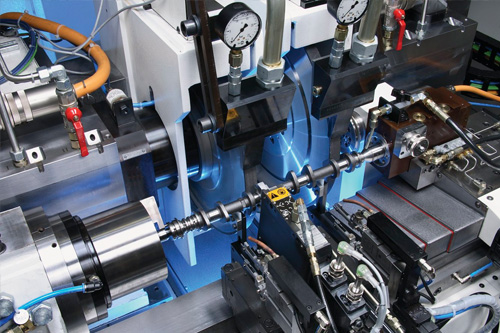

Vertical Turning and Grinding Machines for Shaft Production

All-around solution for shafts: The VTC 100 GT turning and grinding machine ensures fast combined hard turning and grinding processes. All turning operations are performed with the tool turret, and grinding follows at the second station. The VTC 315 DS is the model for machining demanding shaft-type workpieces.

VTC 100 GT

- All-round solutions for shafts

VTC 315 DS

- The production tool for the machining of challenging shaft-type components, the VTC 315 DS turns and grinds vertically.

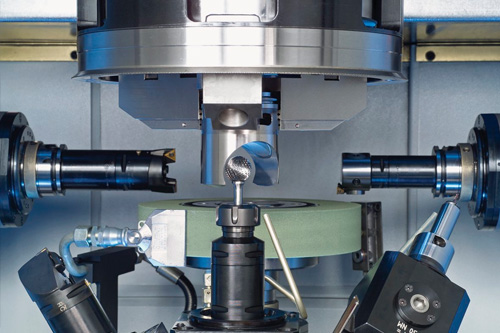

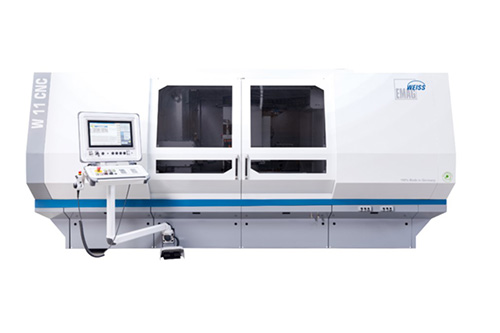

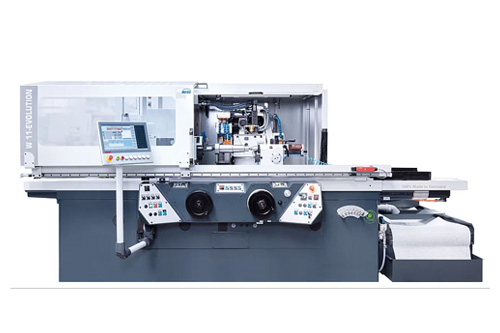

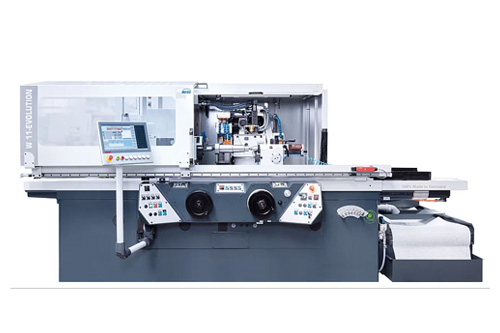

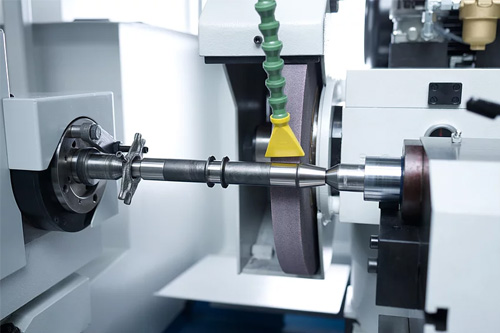

Universal Circular Grinding Machines

-

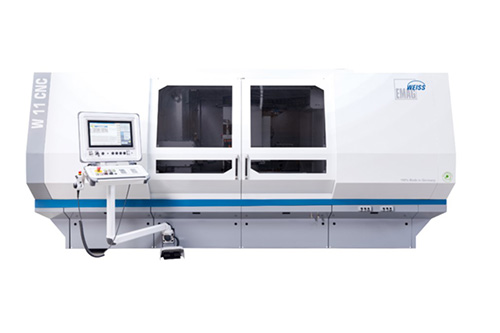

Universal Circular Grinding Machines

Universal Cylindrical Grinding with EMAG Weiss Grinders

W 11 CNC

- Universal Circular Grinding Machines

WUG 21

- Universal Circular Grinding Machines

WPG 7

- Universal Circular Grinding Machines

W 27, W 37, W 50

- Universal Circular Grinding Machines

W 11

- Universal Circular Grinding Machines

ECO 200 / GCU 350 / GCH 440

- Universal Circular Grinding Machines

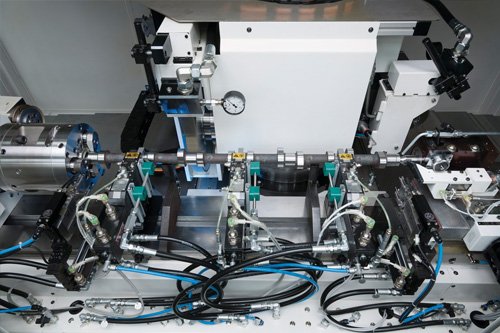

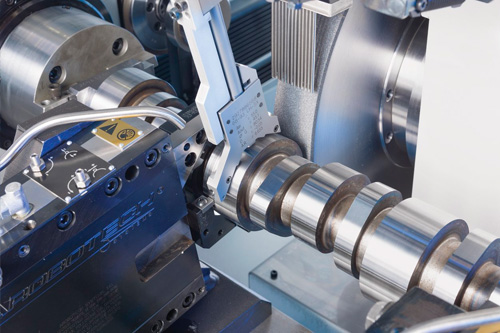

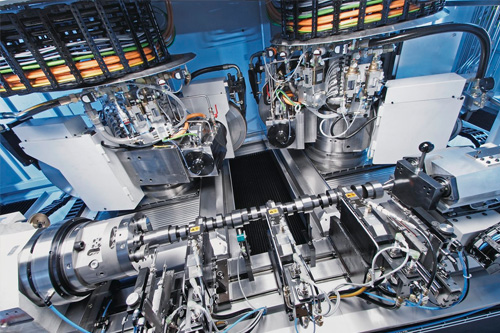

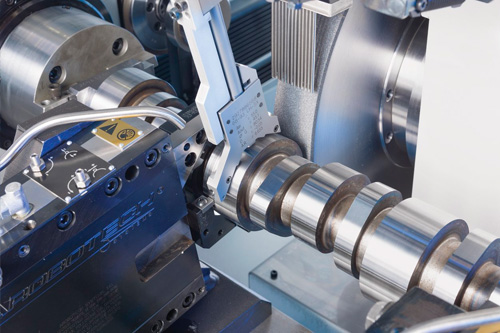

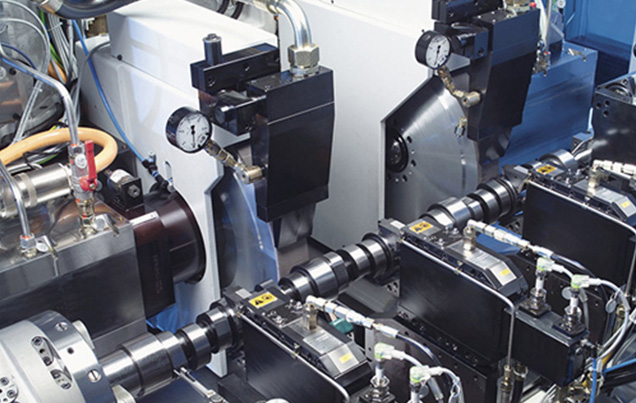

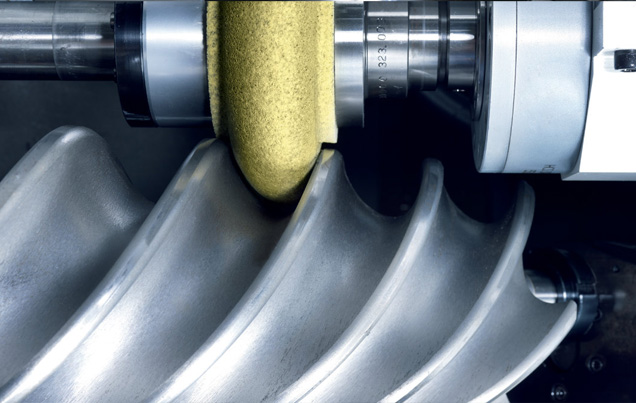

Camshaft grinding machines

-

Cam and Camshaft Grinders

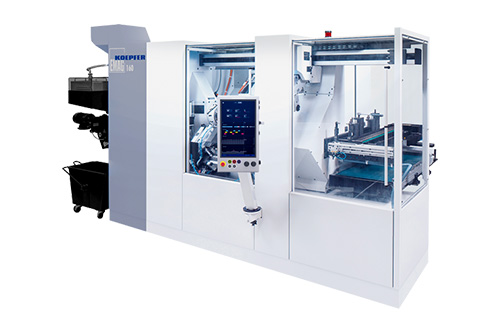

Kopp of the EMAG Group offers machines tailored to the grinding of cams and camshafts. Multiple operations, including internal and external machining as well as grinding for single-part and batch production.

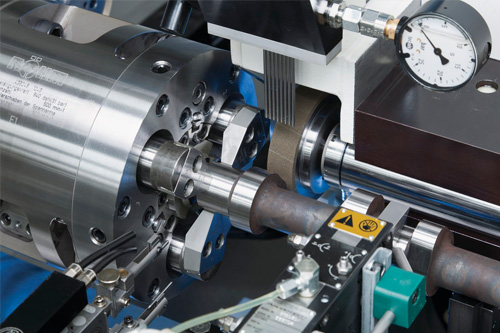

SN 204 / SN 208

- EMAG Camshaft Grinder SN 204 / SN 208

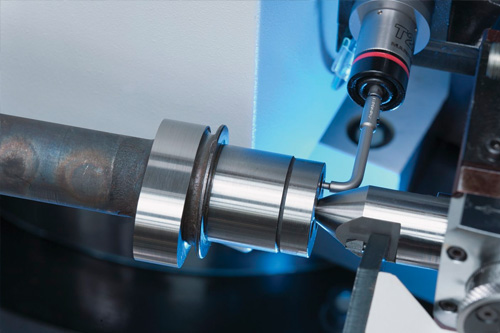

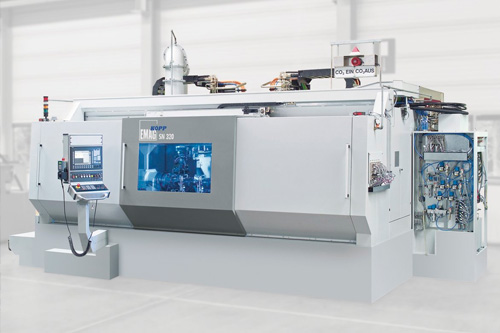

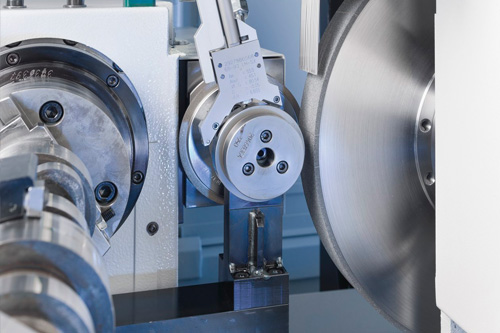

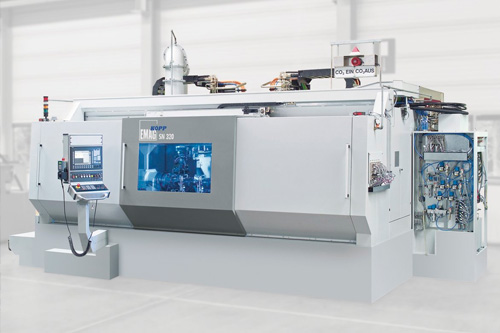

SN 310 / SN 320

- EMAG SN 310 / SN 320 for one-offs and volume production of camshafts

Internal and Face Grinder

-

Internal and Face Grinding Machines for Small Chucked Components

The production of small chucked components often involves very large quantities. In particular, gearbox wheels, planetary gears, sprocket wheels and flange parts are required in millions of units for passenger cars. EMAG vertical grinders have been specially developed for the productive and high precision manufacturing of these components.

VG 110

- Face grinding and internal grinding or combination of turning and grinding in a single machine

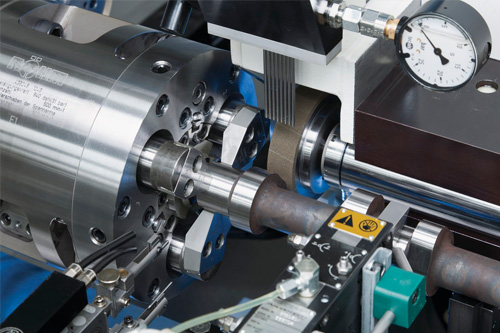

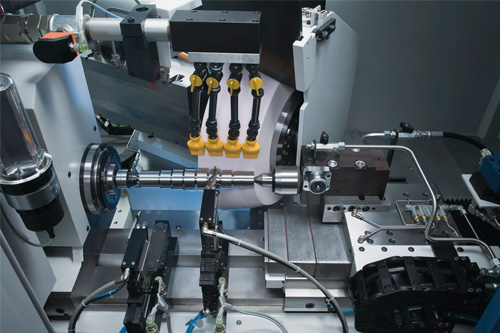

External Cylindrical Grinding

-

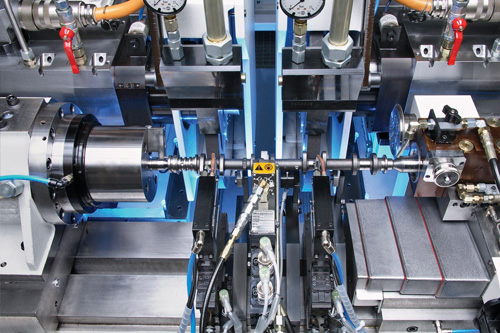

External Cylindrical Grinding for Shafts

The HG series is a machine platform for the external cylindrical grinding of precision shaft components.

The VTC DS series handles challenging machining of shaft components.

HG 2

- HG 2 – the efficient solution for the cylindrical grinding of shafts

HG 204

- The cylindrical grinder HG 204 – a grinding system

that meets high-quality requirements

HG 208

- The cylindrical grinder HG 208 – perfectly ground – perfectly round

HG 208 CD

- The EMAG Grinder HG 208 CD – External and internal machining in a single set-up

HG 208 DW

- Grinders for Simultaneous machining: EMAG HG 208 DW

VTC 315 DS

- VTC 315 DS – Equipped with Various Technologies for Shaft Production

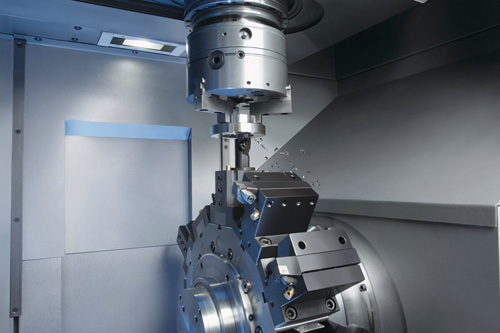

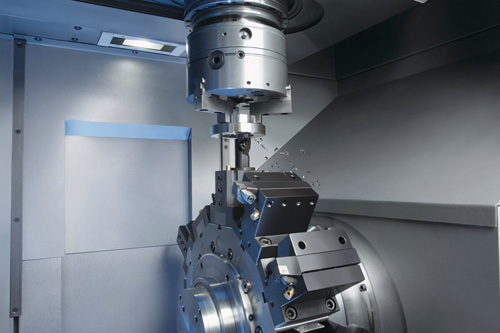

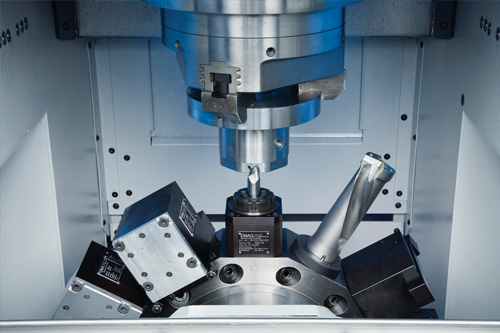

MACHINING CENTERS

VLC 500 MT

- The Machining Centers VLC 500 MT: multi-functional, flexible, sturdy

HCM 110

-

Machining Centers & Milling Machines HCM 110

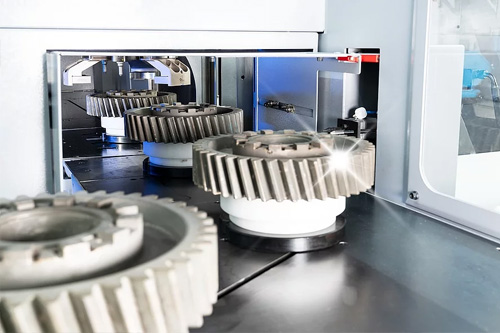

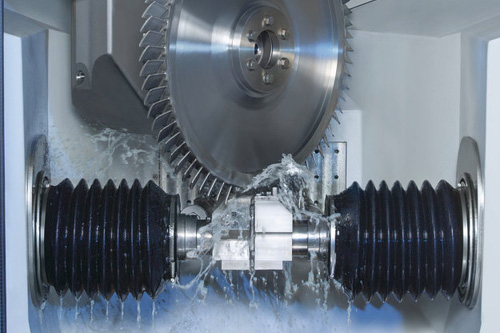

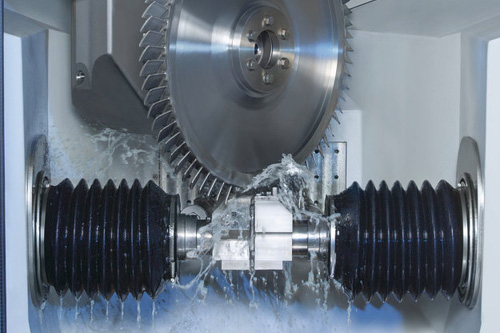

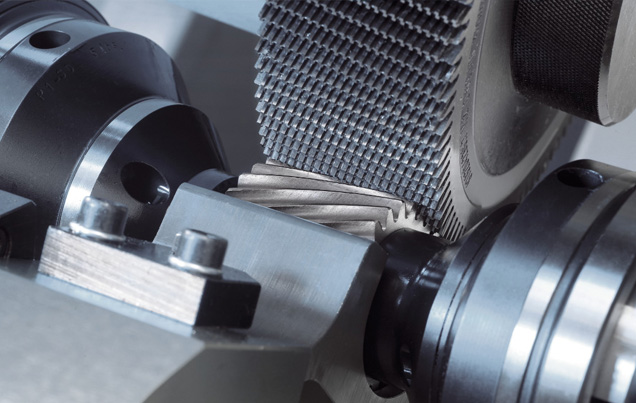

GEAR HOBBING MACHINES

Gear Hobbing Machines Vertical + Horizontal

-

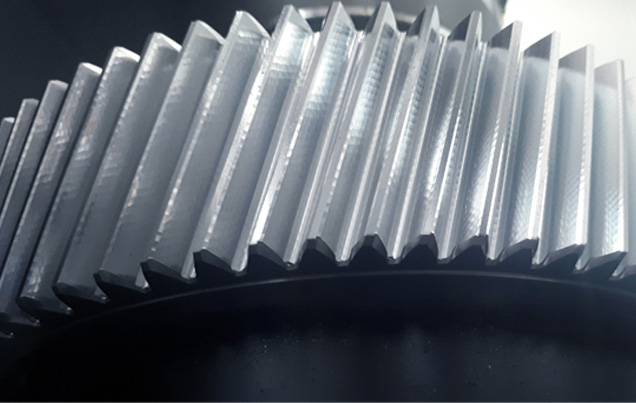

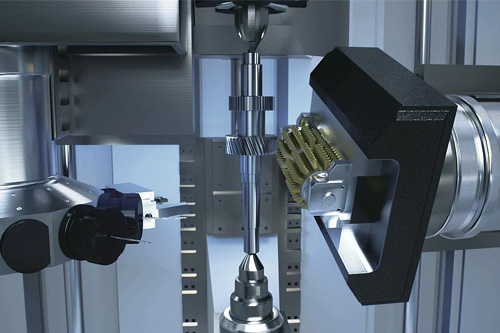

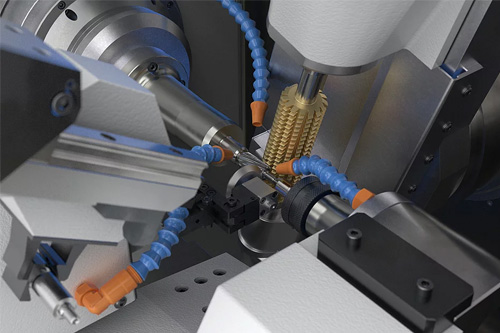

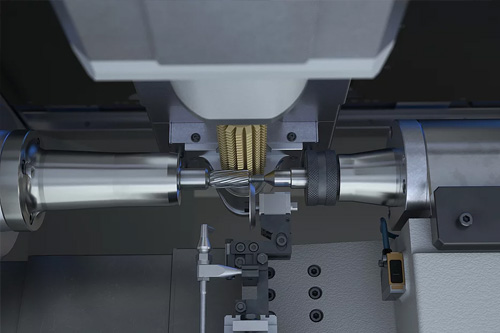

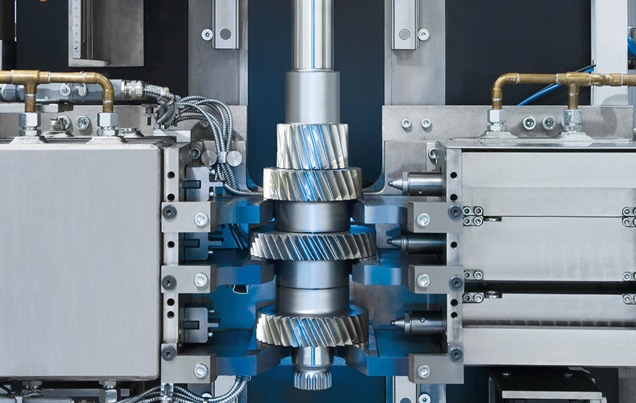

Gear Production with Hobbing Machines From EMAG

EMAG is known as a supplier of top-quality gear hobbing technology for high-efficiency gear production. EMAG has the right solutions for gear production: cutting-edge gear hobbing technology and the complimentary machines for chamfering and deburring.

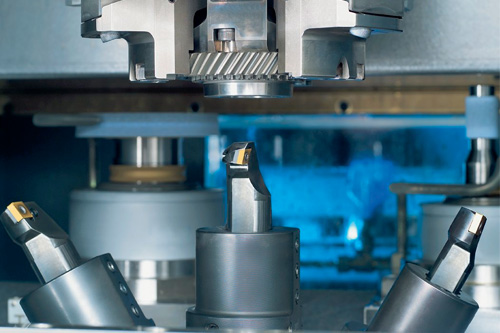

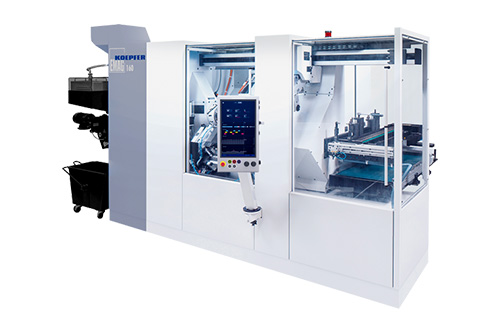

K 160

- Horizontal Gear Hobbing Machines

K 300

- Horizontal Gear Hobbing Machines K 300

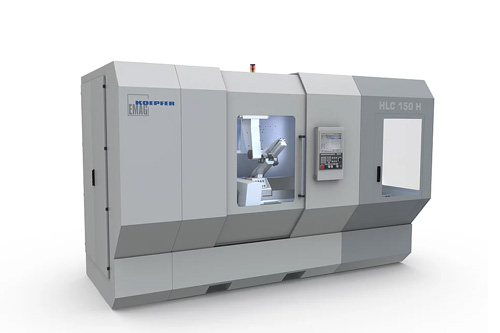

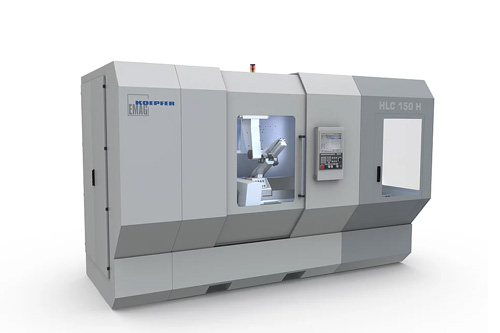

HLC 150 H

-

Horizontal Gear Hobbing Machines HLC 150 H

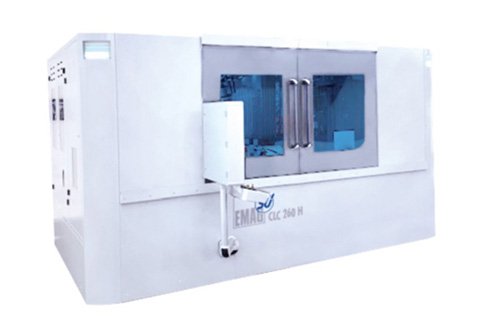

CLC 260 H / CLC 500 H

-

Horizontal Gear Hobbing Machines CLC 260 H / CLC 500 H

CLC Series

-

Vertical Gear Hobbing Machines CLC Series

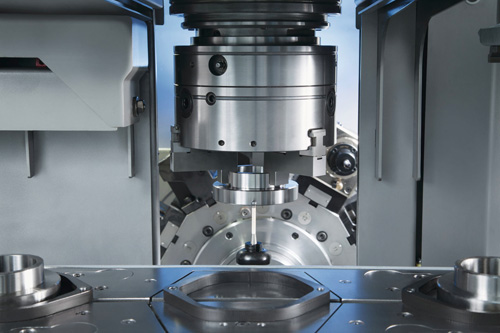

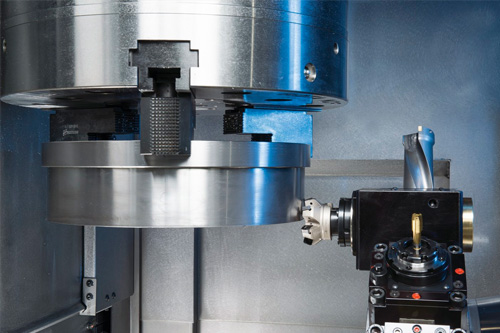

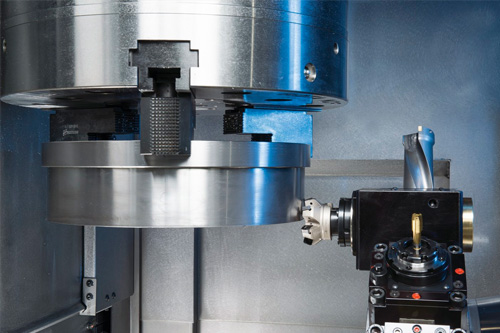

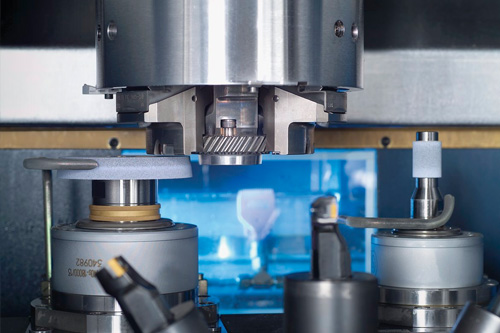

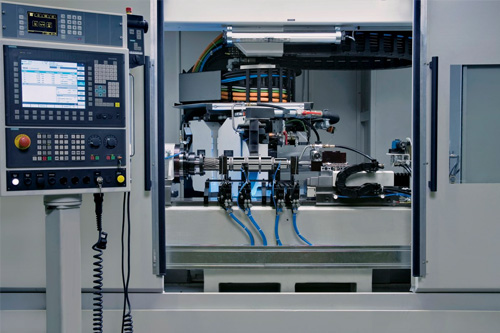

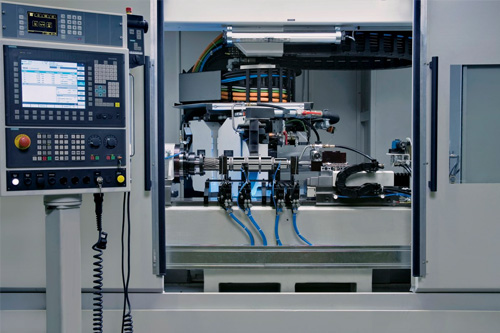

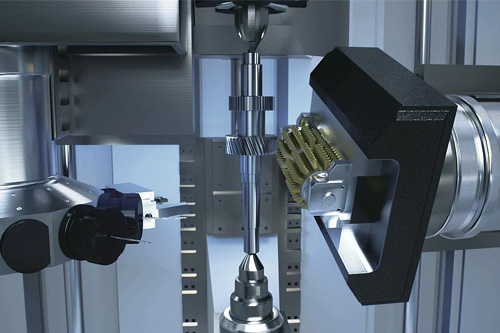

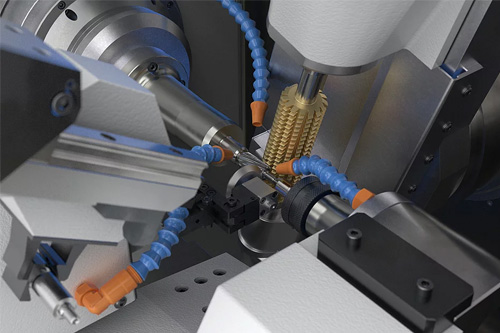

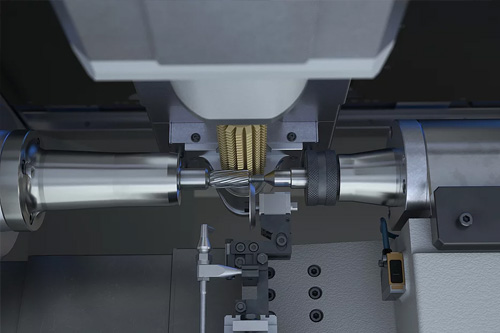

Skiving Machines

-

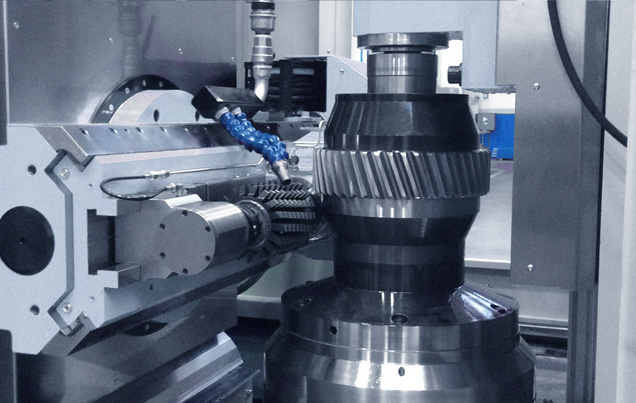

EMAG Skiving Machines

Faster than shaping, more flexible than hobbing and broaching - against this background, power skiving is developing into a highly effective alternative for gear production. With skiving technology, both internal and external gears can be produced. Here, power skiving is about 50 percent faster than shaping and also more flexible than gear hobbing. In addition, hobbing requires a relatively long runout on the component, which can be significantly shorter with power skiving. In any case, the end result is high gear quality. VSC 400 PS

-

Skiving Machines VSC 400 PS

EMAG SU Gear Shaping Machines

-

EMAG SU Gear Shaping Machines

Thanks to an innovative modular system, this series is extremely flexible and can be easily configured for any machining task involving gear wheels and shafts. It includes a number of different options such as an electronic inclined guideway for shaping gears with an angle of inclination, shuttle shaping, shaping of keyways and the introduction of crowning/tapering via the CNC controller. CLC SZ Series

-

Gear Shaping Machines CLC SZ Series

Gear Shaving Machines

-

Perfect Shaving of Gears with Shaving Machines from EMAG SU

Gear manufactures know well that in gear shaving the whole process need to be carefully controlled: machines, Cycles, tools, fixtures, automation, etc. With our shaving machine, developed by the experts of EMAG SU, we can significantly improve the performance and quality of your shaving process.

GS 400

-

Grinding machines for gear cutting tools GS 400

RASO 200

-

Gear Shaving Machines RASO 200

RASO 400

-

Gear Shaving Machines RASO 400

Gear Generating Grinding Machines

-

Gear Generating Grinding Machines from EMAG SU

EMAG SU offers a range of gear grinding machines for the machining of gears and shafts for small series to large series production. The focus is on customer-oriented solutions for every application.

G 375 H

-

Gear Profile Grinding Machines G 375 H

G 500 H

-

Gear Profile Grinding Machines G 500 H

GP 500 H

-

Gear Profile Grinding Machines GP 500 H

GR 250

-

Gear Profile Grinding Machines GR 250

GR 500 H

-

Gear Profile Grinding Machines GR 500 H

GRX 500 H

-

Gear Profile Grinding Machines GRX 500 H

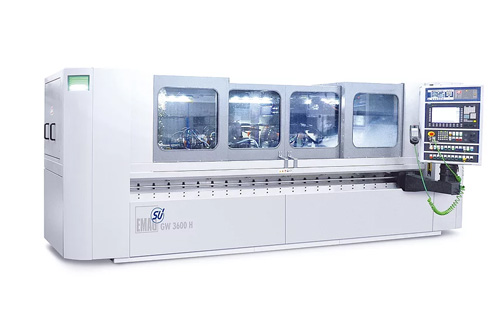

GW 3600 H

-

Gear Profile Grinding Machines GW 3600 H

Grinding machines for gear cutting tools

-

Grinding machines for gear cutting tools

GS 400

-

Grinding machines for gear cutting tools GS 400

HRG 350

-

Grinding machines for gear cutting tools HRG 350

Chamfering and Deburring Machines

-

Chamfering and Daburing Machines

In addition to high-quality gear-cutting technology, EMAG also produces matching chamfering and deburring machines. SCT 3

-

Chamfering and Deburring Machines SCT 3

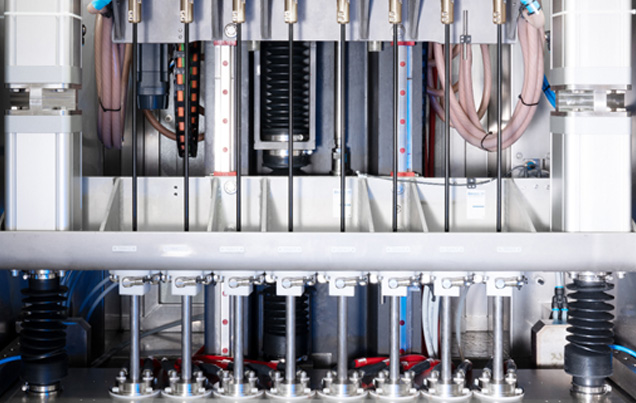

TUBE AND COUPLINGS MACHINING CENTERS

USC 21

-

Tube sleeve machining centers USC 21

USC 27

-

Coupling sleeve machining centers USC 27

VLC 800 CM

-

Coupling sleeve machining centers VLC 800 CM

VSC 400 CM / VSC 400 DUO CM

-

Coupling sleeve machining centers VSC 400 CM / VSC 400 DUO CM

VSC 500 CM

-

Coupling sleeve machining centers VSC 500 CM

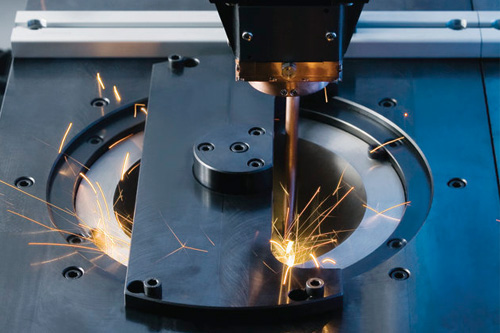

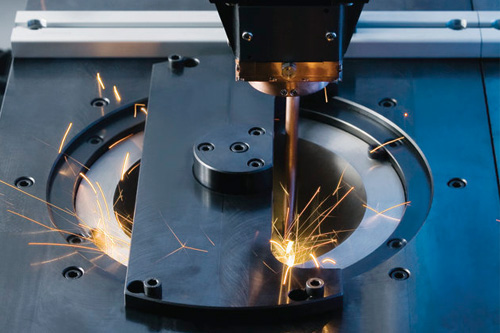

LASER-WELDING MACHINES

ELC 160

- Laser welding machine for high-productivity manufacturing

ELC 160 HP

- ELC 160 HP: Increased flexibility in joining and laser welding of the control gear and clutch

ELC 250 DUO

- The ELC 250 DUO is a compact laser welding system for

use on gear components. The ELC laser welding system is designed as a DUO

alternative with twin spindles. Its two-station operation makes it possible

to load and unload the spindles synchronously with the cycle time.

ELC 1200 V

-

Laser-Welding Machines ELC 1200 V

ELC 6

-

Laser-Welding Machines ELC 6

ELC 600

-

Laser-Welding Machines ELC 600

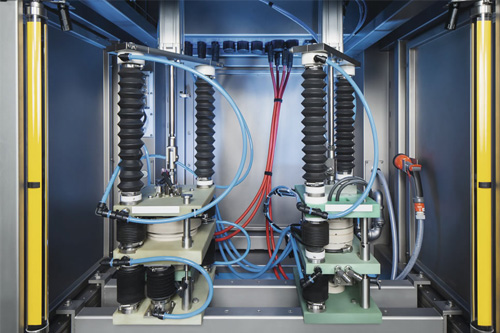

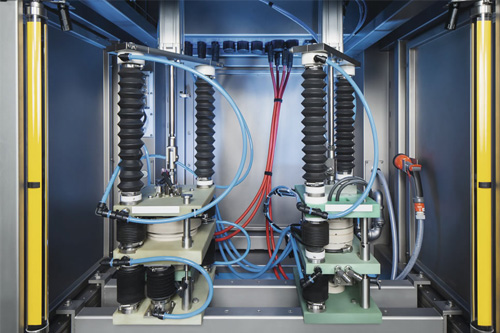

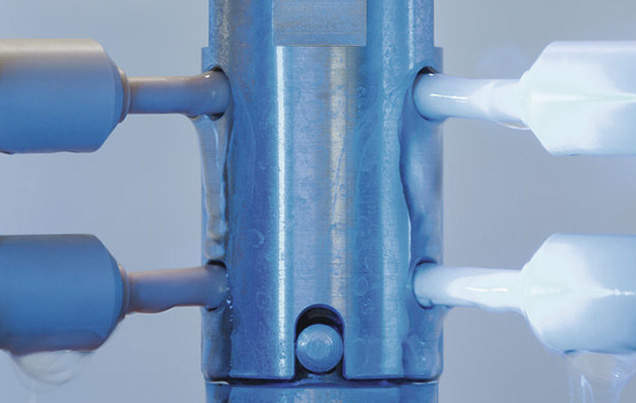

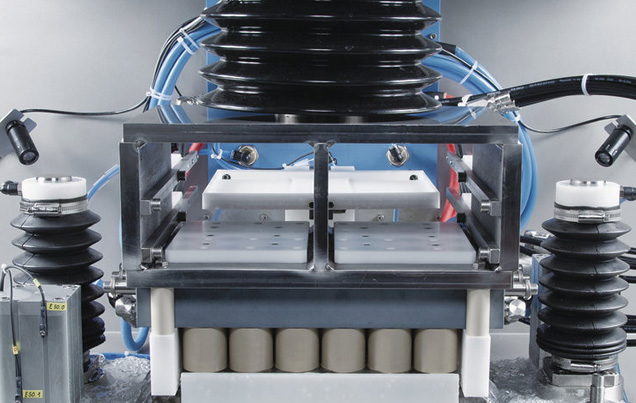

ECM / PECM MACHINES

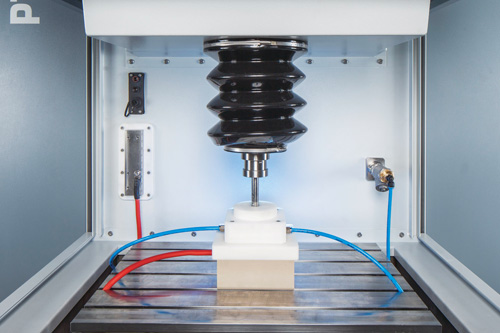

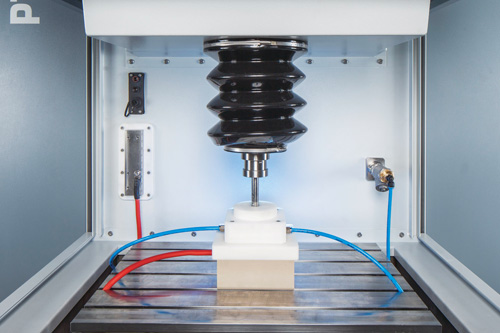

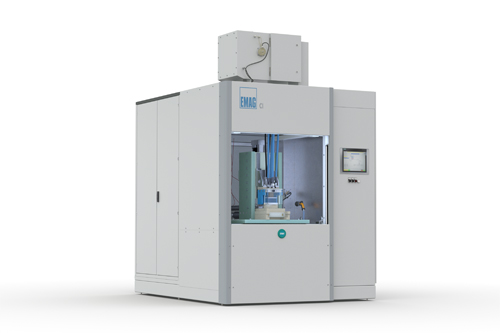

CS

- On the ECM Standard Machining System “BI smart” the operator loads and removes the workpieces from the ECM unit by hand. A two-handed control button activates the ECM (electro-chemical machining) process that carries out the deburring operation.

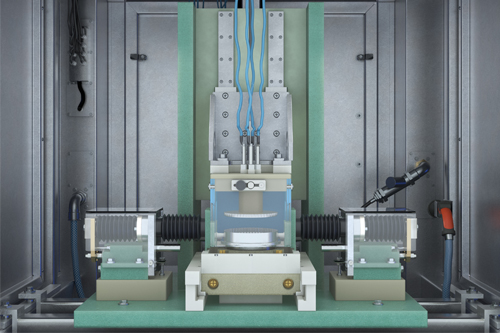

PO 100 SF

- The Comfort Standard / Comfort Integrated is the best introduction to the automation of ECM (electro-chemical machining) processes.

PO 900 BF

- PECM system with modularly upgradeable tool concept for sophisticated 2D and 3D structures.

PI 800

-

ECM / PECM Machines PI 800

PTS 2500

- The PECM PTS 2500 helps complete difficult machining tasks by reducing process streams. The high reproducibility of this premium series of PECM machines is achieved thanks to an intelligent machine concept and our patented PECM technology.

CI 400

- The EMAG CI 400 machining unit is an attractive solution for the electro-chemical machining of rotor carriers

PS - Premium Standard

-

ECM / PECM Machines PS - Premium Standard

JOINING MACHINES

SFC 600

- The thermal joining processes of EMAG are used to produce extremely precise components for powertrains. The process is also ideal for workpieces that will be subjected to high torques and dynamic loads. Custom solutions are always our focus when developing joining machines. Thermal joining technologies enable significant reductions in component weight and a very high functional density.

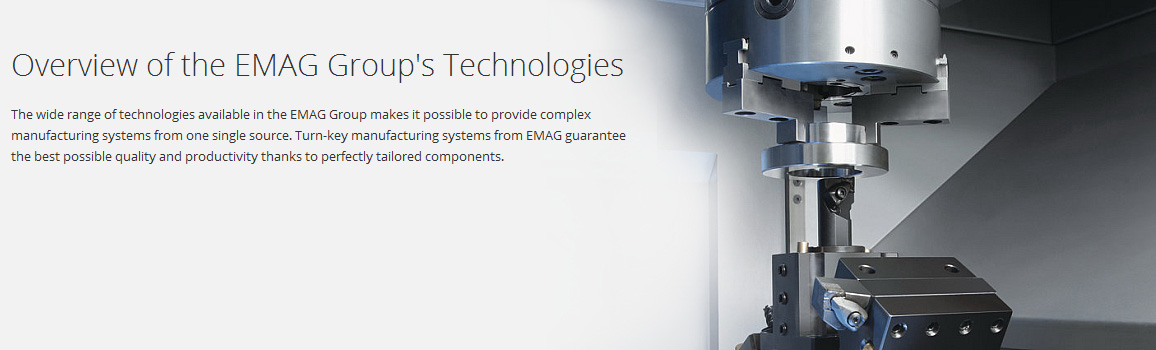

TECHNOLOGIES

- The technologies applied and refined in the EMAG Group include all chip-removal processes, such as drilling, milling, turning and grinding, as well as some particularly important special technologies of the Group's subsidiary companies.

Cylindrical grinding

- Cylindrical grinding for perfect roundness.

ECM

- ECM - Electro-Chemical Machining

ECM - Deburring

- Deburring and electro-chemical Deburring

ECM - Drilling

- ECM - Drilling: Tooling Costs Reduced

ECM - Inner forming

- ECM Inner Forming: Highly Precise and Reproducible

ECM Rifling

- ECM Rifling Ensures Perfect Internal Geometries on rifled barrels

Gear Shaping

- Gear Shaping: Perfect External and Internal Gearing at One Second Intervals

Gear Shaving

- Gear Shaving – The Perfect Gear Surface

Generating Grinding

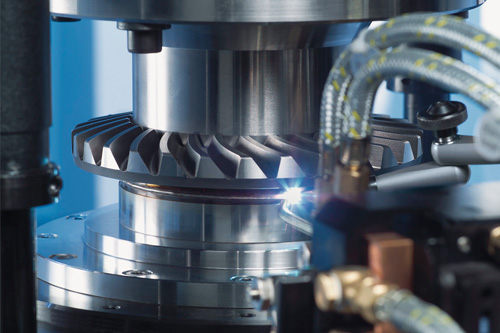

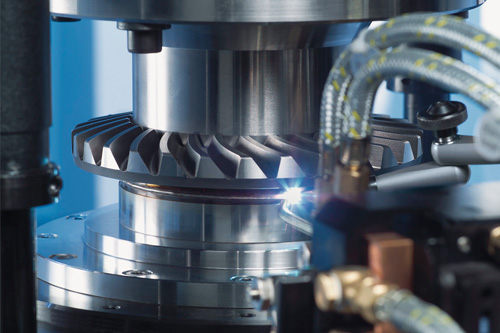

- Generating Grinding: Precise Geometries and High-Precision Surfaces for Gearing

Grinding

- Grinding - An Important Process

Hard turning

- Hard turning and grinding: improved quality and greater flexibility

Heat Shrink Assembly

- The thermal joining process from EMAG has its main application in the manufacture of high-precision powertrain components. It is also suitable for workpieces that are subject to high torque rates and great dynamic loads.

Hobbing

- Hobbing: Highly Productive Manufacturing of Gears, Gear Shafts, Worms and Rotors

Laser Cleaning

- Laser Cleaning: Energy-Efficient, Reliable and Cost-Effective

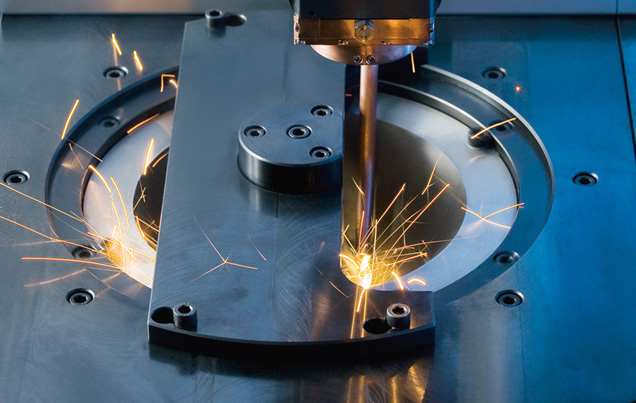

Laser welding

- Laser welding is a precondition for compact, weight-optimised components and thus for energy- efficient vehicles.

Out-of-round grinding

- Out-of-round grinding of cams, camshafts, cam elements and pump rings using CBN grinding wheels

PECM

- Precision Electro-Chemical Machining

Power Skiving

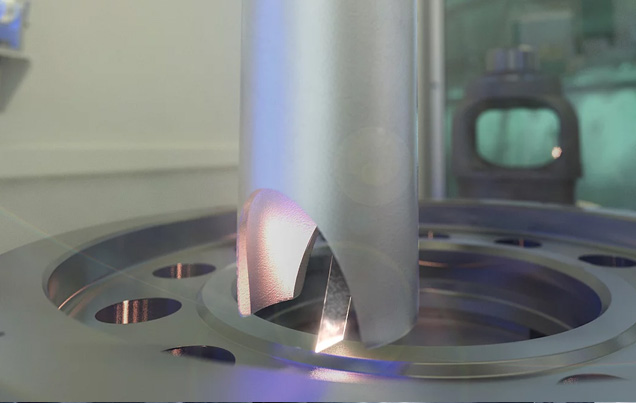

- Power Skiving of internal teeth hobbing – the alternative to broaching and gear shaping

Profile Grinding

- Highly Flexible Profile Grinding: Frequently the Best Choice, Even for Workpieces with Interfering Contours

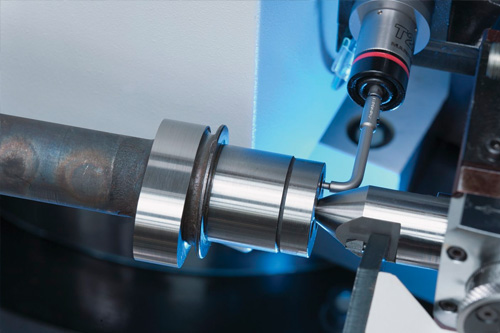

Scroll-free Turning

- Scroll-free Turning process is a very fast one

Synchronous Support Grinding

- The synchronous support grinding process on the VTC 315 DS uses two CBN grinding wheels to simultaneously grind – from opposite sides – vertically clamped shaft-type components supported by a trailing steady.

Universal Cylindrical Grinding

- Universal Cylindrical Grinding—External and Internal Cylindrical Grindinga

The Vertical Turning Technology

- Vertical turning is a highly productive process for the machining of round workpieces