HWACHEON

Videos

Loading the player ...

- Offer Profile

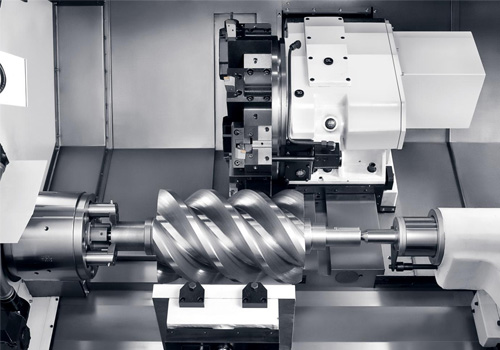

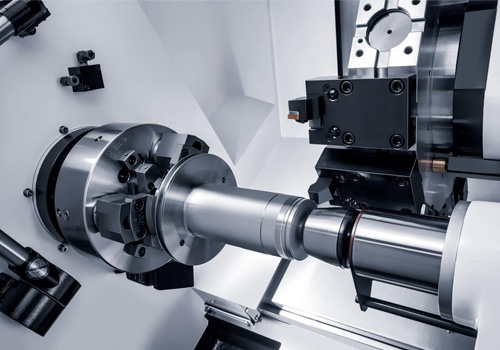

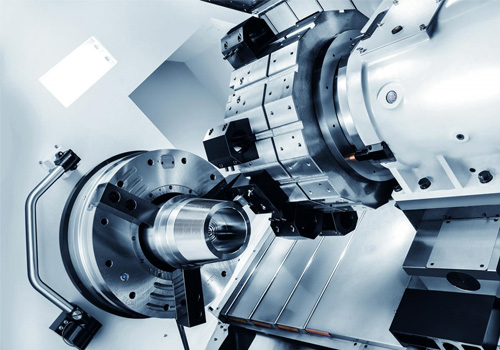

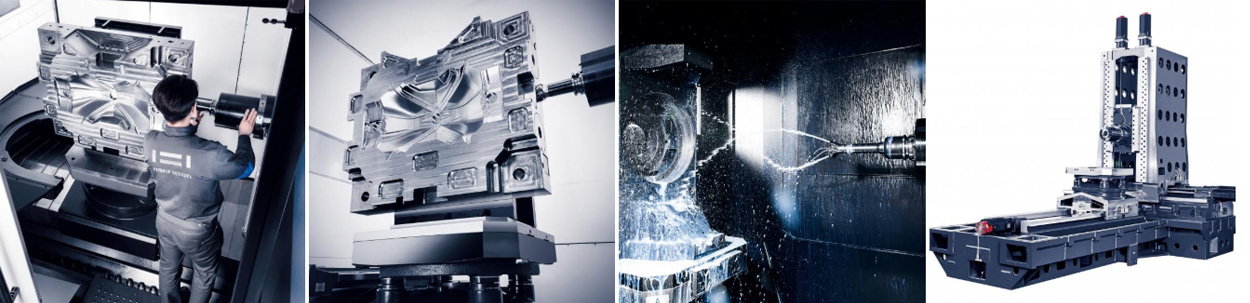

- Since more than 60 years Hwacheon is manufacturing machine tools at top-level standards. Furthermore Hwacheon produces and markets engine blocks, cylinder heads, crankshafts and other engineering essentials. These automotive parts are being manufactured with Hwacheon’s own machine tools at the highest level of precision and quality.

Product Portfolio

CNC MACHINE TOOLS

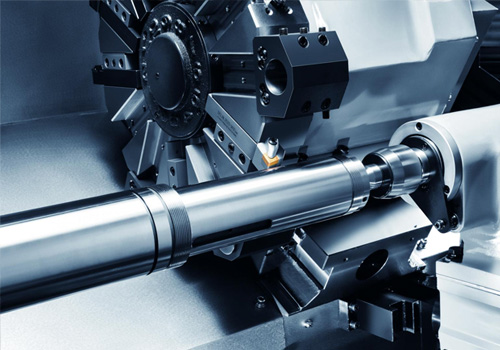

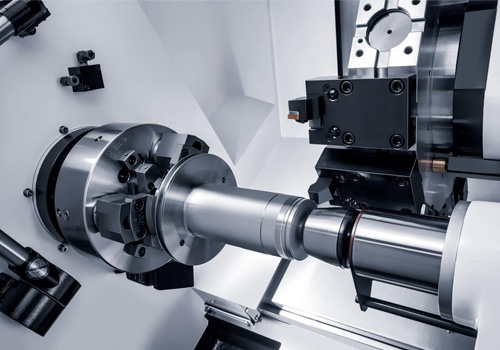

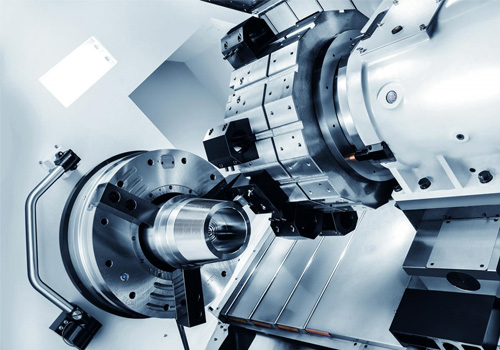

HORIZONTAL CNC LATHE

- Hwacheon's horizontal turning centers offer the best performance in the class, and are perfect solutions for a wide range of applications from small component machining to large-size processing.

CUTEX-160

-

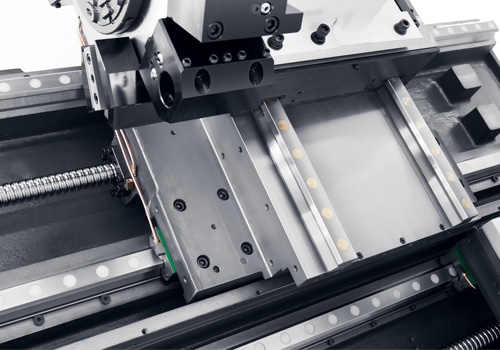

Horizontal lathe with linear guideways for Ø150 - 200 mm (6 - 8 inch) chucks

Thanks to the turret’s short indexing time of just 0.15 seconds and the high rapid traverse speed of 36 m/min, non-productive time is significantly reduced. The power chuck guarantees excellent performance in precision turning and high productivity for large batch sizes.

Standard equipment

Due to the high technological standard of Hwacheon’s CUTEX-160, the machine quickly became the industry standard for small turning centres following its arrival on the market. Thanks to its compact and solid construction and its large range of options, the CUTEX-160 is the ideal solution for many fields of application. With the L-HTLD software (Hwacheon Lathe Tool Load Detection System), which monitors power consumption and immediately prevents overload, you will be able to effectively protect your machines and tools from being damaged.

CUTEX-180

-

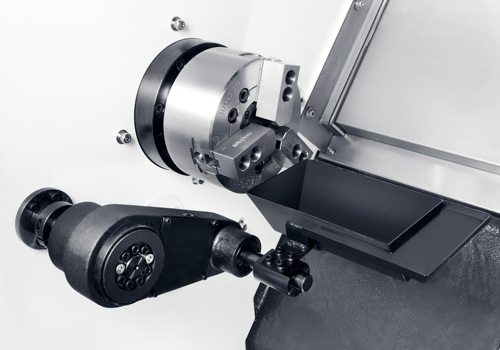

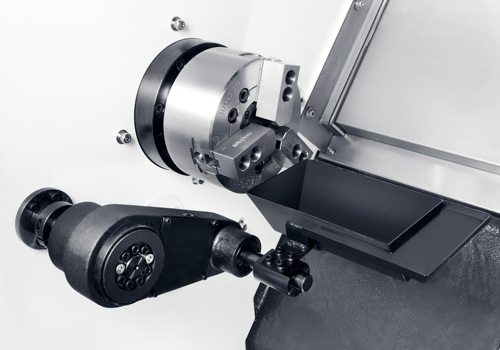

Universal Lathe with linear guide ways for chuck Ø150 - 200 mm (6 - 8 inch),

Y axis, sub spindle

Optimised productivity characterises the new CUTEX-180 compact lathe. the programmable tail stock reduces the cutting time of the workpiece by more than 70 percent. Optionally, the machine can be fitted with a sub spindle which makes it possible to machine the front and the back of the workpiece.

- High rigidity linear guideways on all axes

- Main drive with 15 kW drive power

- Driven tools of 5.5 kW

- Large spindle bore diameter

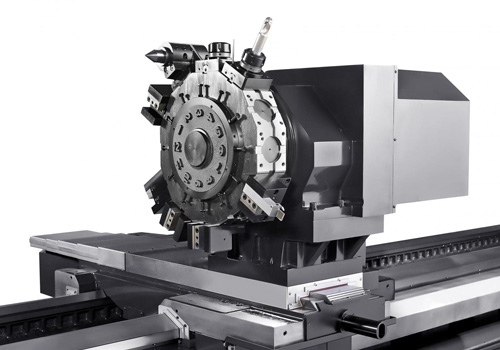

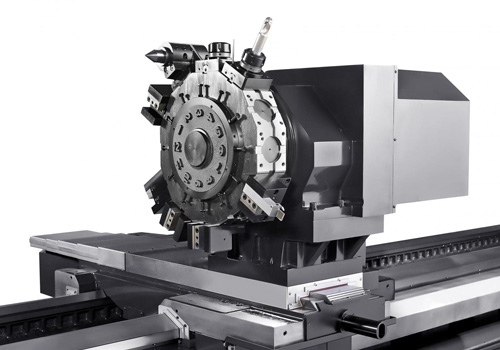

- Turret with 24 stations (double tool holder)

CUTEX-240

-

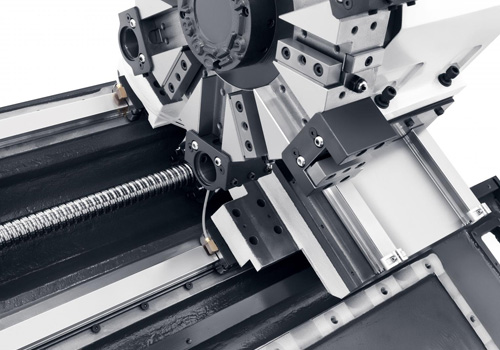

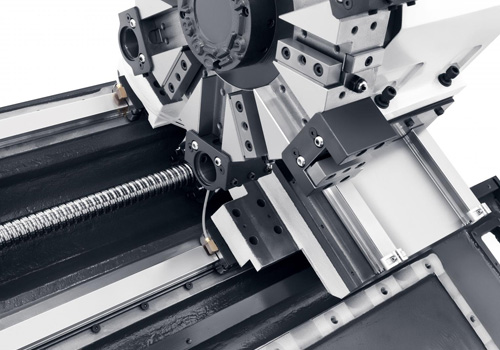

Universal lathes with linear guideways for Ø200 - 250 mm (8 - 10 inch) chucks

and sub spindle

Maximum productivity and reliability - the compact lathes of the CUTEX series

Thanks to the turret’s short indexing time of just 0.15 seconds and the high rapid traverse speed of 36 m/min, non-productive time is significantly reduced.

High rigidity linear guideways

The CUTEX-240 is equipped with high rigidity linear guideways on all axes, allowing feed rates of up to 36 m/min, thus reducing non-productive time and simultaneously contributing to higher machining accuracy.

Robust high performance spindle

The high performance Hwacheon spindle means that you can rely on getting the best possible results, even in difficult cutting conditions and tough materials.

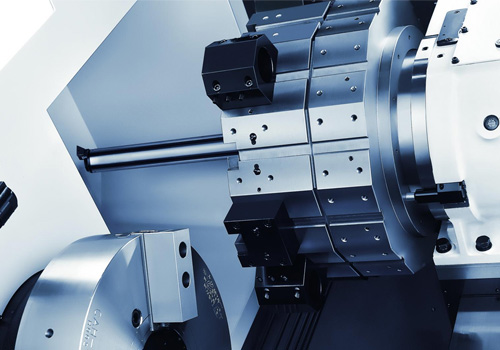

HI-TECH 200

-

Horizontal lathe with box guideways for Ø200 - 250 mm chucks (8 - 10 inch)

The Hi-TECH 200 owes its outstanding reliability and stability to its high-power drives and box guideways. The turret has an indexing time of just 0.15 s/station, rapid traverse speeds of 30 m/min and numerous optional features, making it suitable for reliable continuous operation and heavy duty cutting. In addition to this the Hi-TECH 200 is particularly easy to operate and service.

Solid monolithic flat bed design

The Hi-TECH 200 has box guideways on all axes, ensuring high rigidity, damping of vibrations and accuracy in difficult cutting conditions and during continuous operation.

HI-TECH 230

-

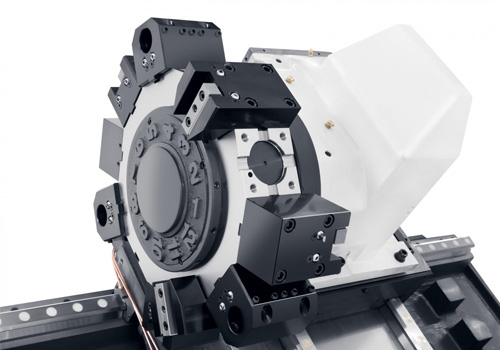

Horizontal lathe with box guideways for Ø200 - 250 mm - chuck, Y axis, sub

spindle

New standard for lathes with chuck sizes of 8-10 inches – reliability at all levels. The Hi-TECH 230 owes its particularly reliable machining performance to its exceptional rigidity and improved specifications in comparison with other 8 to 10 inch lathes with box guideways. In addition to this, it is also particularly easy to operate and to service. The model with the Y axis has a traverse path of up to ±60 mm – the largest in its class.

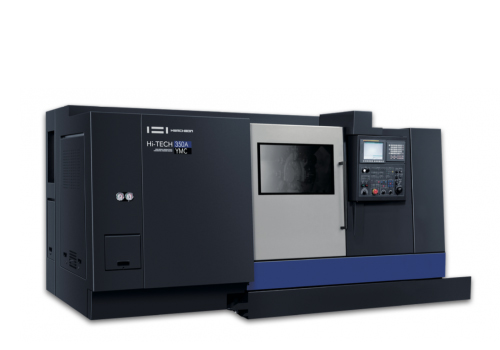

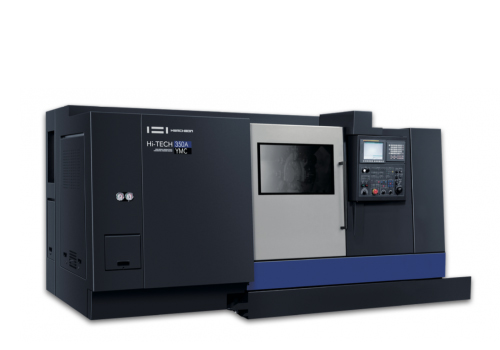

HI-TECH 350

-

Horizontal turning centre with box guideways for 8-10 inch chuck (Y-axis)

Comprehensive basic configuration - versatile: Whether used for straightforward or complex workpieces; the Hi-TECH 350 comes with a Y axis and driven tools as standard. With its high-power drive, broad box guideways and optional sub spindle, the Hi-TECH 350 is a reliable machine, which you can use to produce efficiently and flexibly. During heavy cutting work, the spindle delivers a consistently impressive torque at all speeds.

- High performance spindle: 5000 rpm (18.5/15 kW)

- High precision and rigidity, monolithic machine bed slanted at 45°

- Turret indexing time (1 Pos): 0.25 s

- Rapid traverse speed (X/Z): 20/24 m/min

- Optional sub spindle and driven tools

HI-TECH 450

-

Horizontal lathe with box guideways for Ø250 - 375 mm chucks

With its high-power drive and gears as standard, broad box guideways and many options, the Hi-TECH 450 is a reliable machine, which you can use to produce efficiently and flexibly. During difficult cutting tasks, the spindle consistently provides impressive torque at all speeds and levels.

Big jobs, small footprint

The Hi-TECH 450 is a highlight of Hwacheon technology. Where space is limited, the Hi-TECH 450 provides the highest turning diameter and turning length of today’s medium-sized lathes. A large number of options, such as a Y axis, sub spindle, steady rest carriage and much more, provide a high level of flexibility in the configuration of your machine. The machine can be precisely customised with the accessories you need for your production.

HI-TECH 550

-

Horizontal lathe with box guideways for Ø375 - 450 mm chucks

The Hi-TECH 550 is equipped with a particularly solid tool turret, guaranteeing maximum stability, accuracy and performance even during hard turning.

- High performance 30/22 kW spindle

- 15-18 inch chucks

- Turret indexing time (1 Pos): 0.2 s

- Extremely stable tail stock with a 120 mm diameter (MT#5)

- Direct-drive spindle

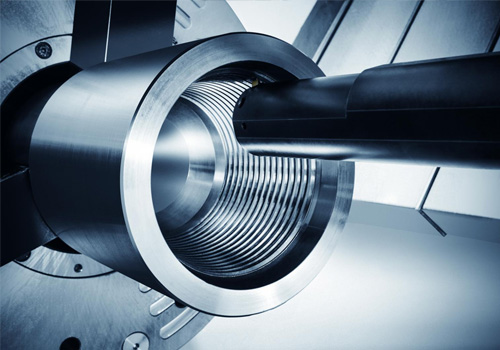

HI-TECH 550BB

-

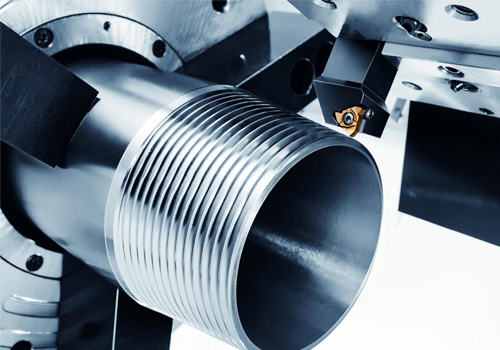

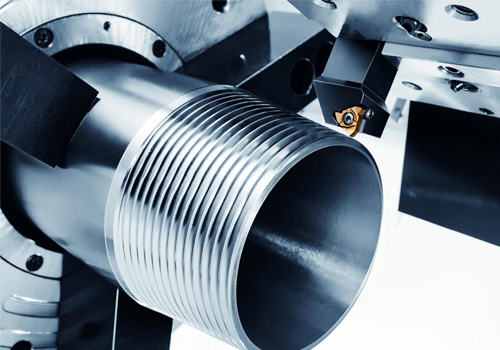

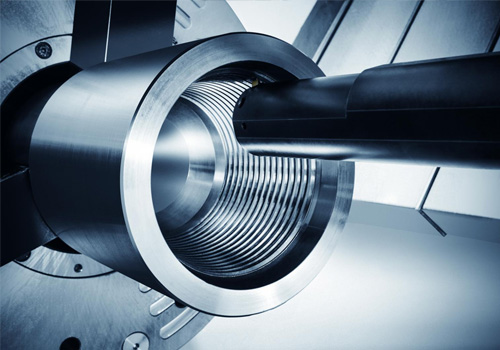

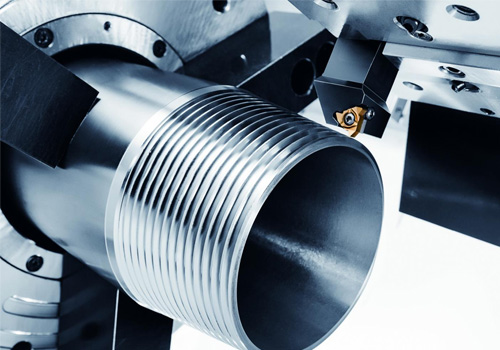

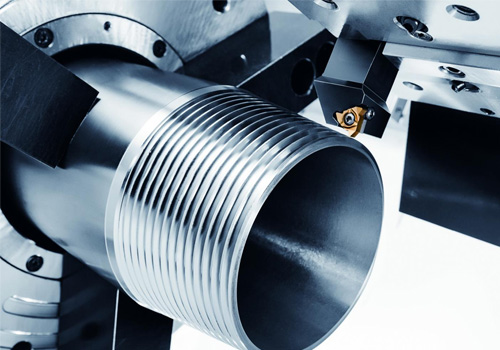

Horizontal lathe with BigBore spindle (180 mm) for tube machining

- Turning diameter over bed: 800 mm

- Max. turning length: 1,150 mm (long version: 2,150 mm)

- Optional pneumatic lathe chuck, diameter: 470 mm

- Inner diameter of spindle bearing: 240 mm

- Powerful spindle motor: 37/30 kW

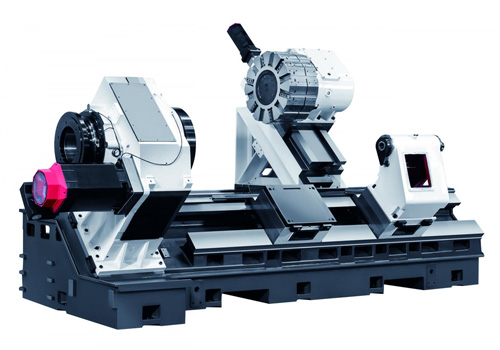

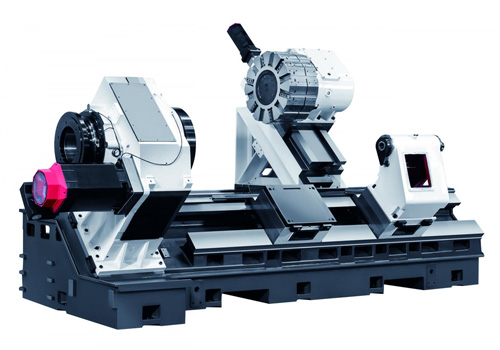

HI-TECH 700BB / 700BB+

-

Horizontal lathe with BigBore spindle (180 - 295 mm) for tube machining

- Turning diameter over bed: 900 mm

- Max. turning length: 2.050 mm

- Optional pneumatic chuck: Ø470 mm (BB+ Ø630 mm)

- Inner diameter of spindle bearing: Ø240 mm (BB+ Ø360 mm)

- Powerful spindle motor: 45/37 kW

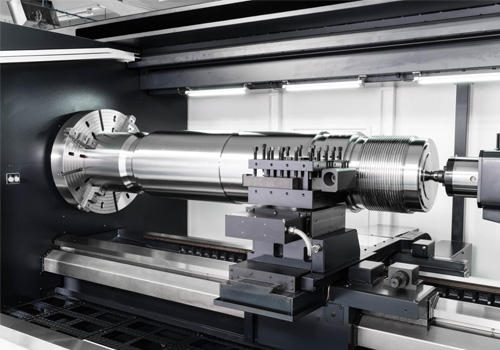

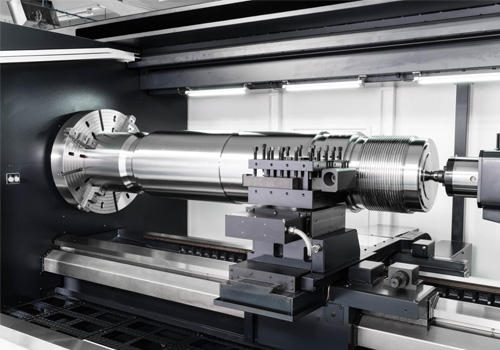

HI-TECH 850

-

Horizontal lathe with box guideways for Ø800 mm chucks

Horizontal turning centre ideally suited to large and hard workpieces: With the Hi-TECH 850 you will be able to master demanding machining tasks which require milling and turning operations. The large and stable tool turret and the monolithic machine bed with box guideways are designed for machining large workpieces.

HI-TECH 850BB / 850BB+

-

Horizontal lathe with BigBore spindle (295 - 370 mm) for tube machining

- Turning diameter over bed: 1,050 mm

- Max. turning length: 2,650 mm (long version: 3,650 mm)

- Optional pneumatic chuck: Ø630 mm (BB+ Ø850mm)

- Inner diameter of spindle bearing: Ø360 mm (BB+ Ø440 mm)

- Powerful spindle motor: 45/37 kW

- Also available with driven tools: 11/7.5 kW

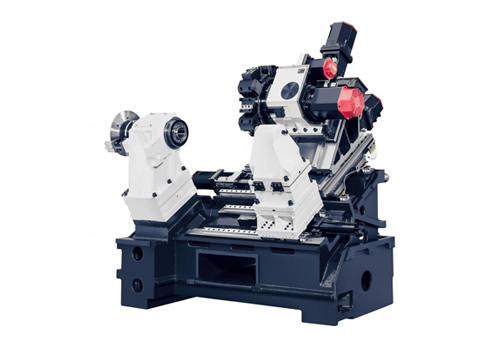

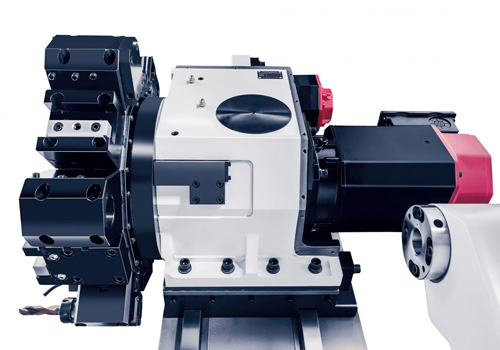

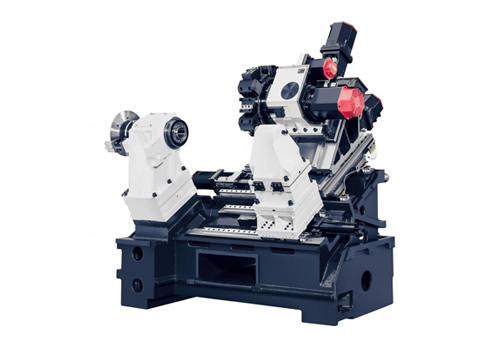

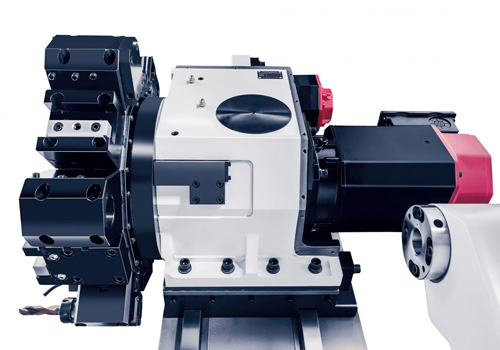

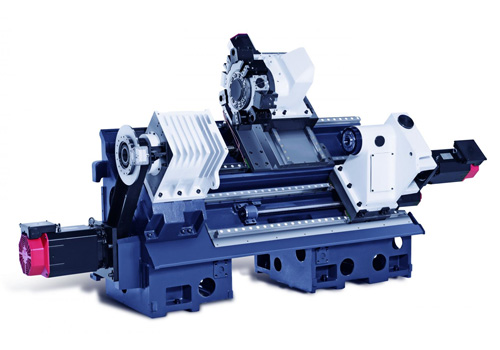

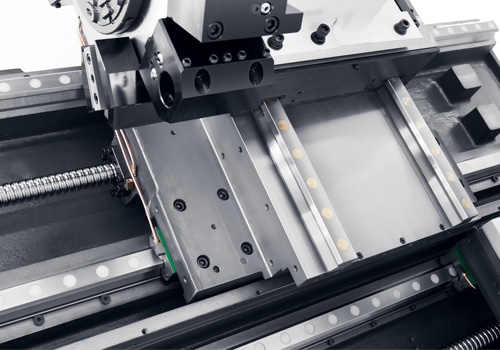

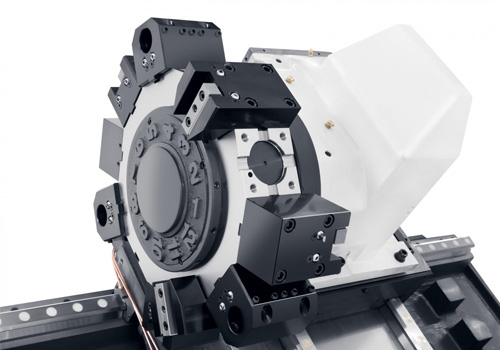

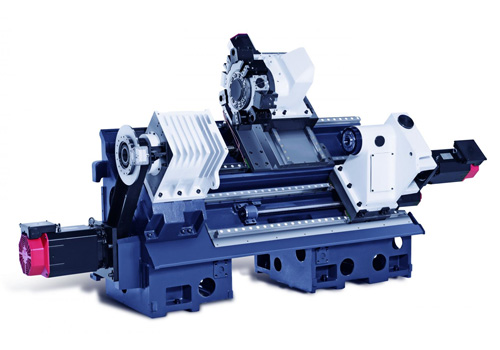

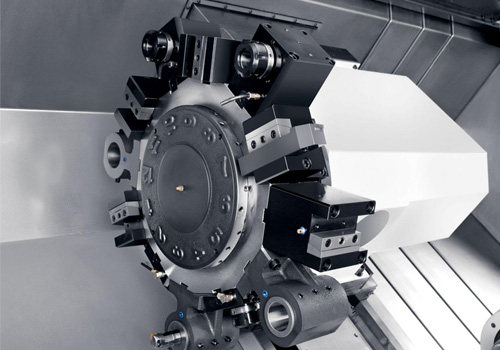

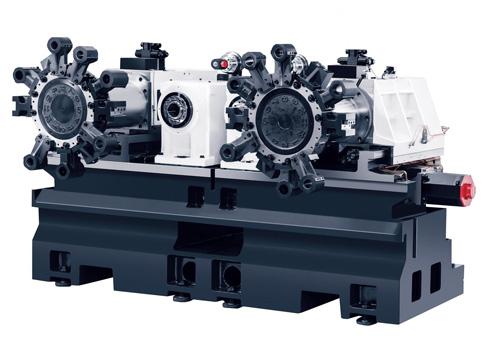

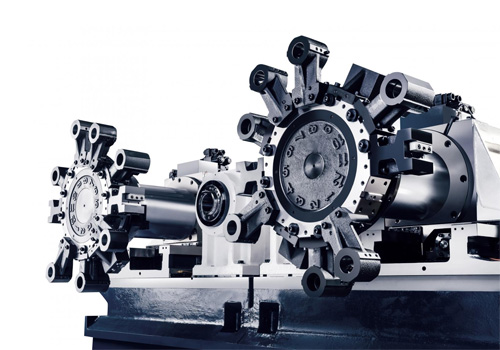

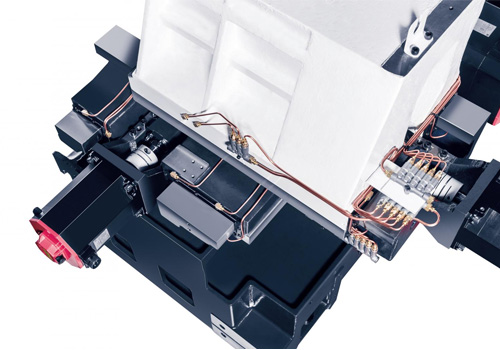

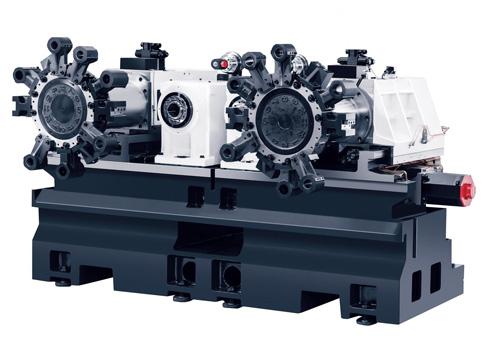

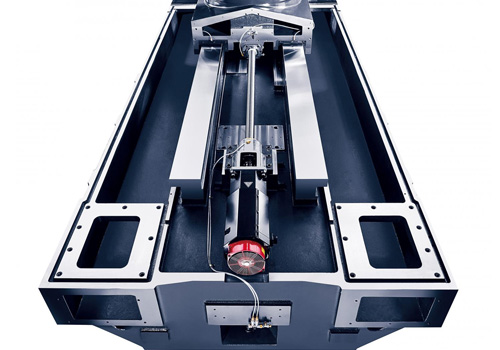

TTC-10

-

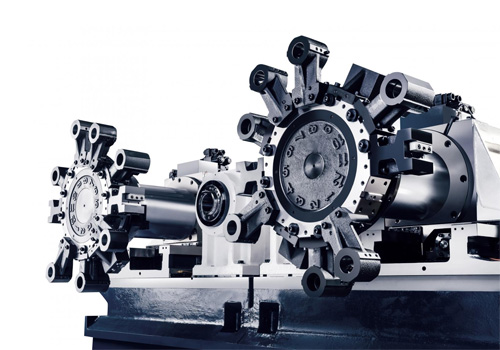

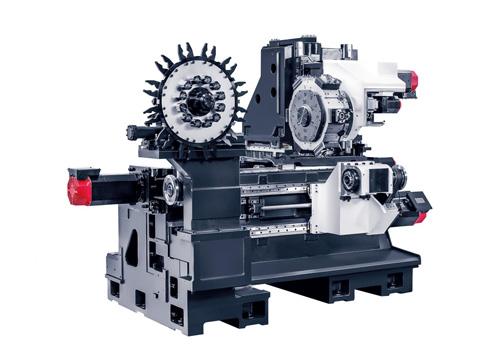

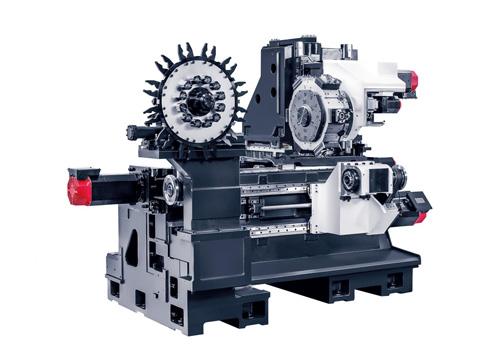

Twin spindle lathe (front) with box guideways for heavy duty cutting

The TTC-10 is a twin spindle lathe (front) with two 12-position turrets and two working spaces. It is used by companies all over the world to cut particularly tough and hard materials, such as alloys based on titanium and nickel, or hardened steel, and is ideally suited to automated operation by means of a portal loader.

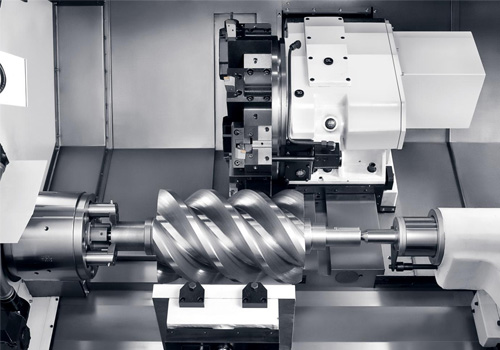

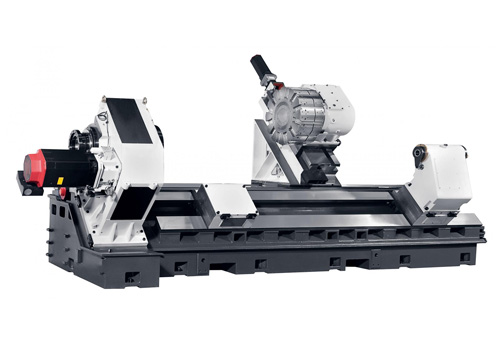

MEGA-72

-

HEAVY DUTY CNC LATHE

- High accuracy

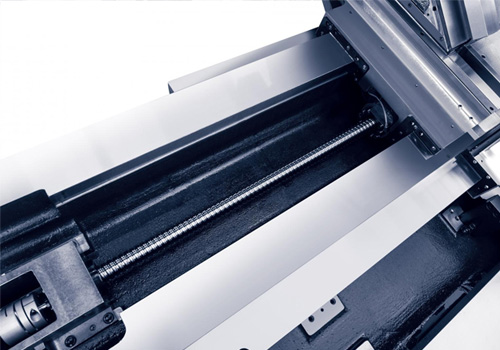

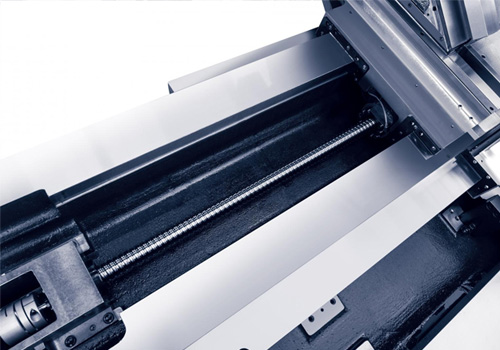

- Adoption of ball screw and servo motor

- Easy checking for spindle speeds by attachment of spindle position encoder

- Guarantee of repeatability ±5° by adoption of curvic toolpost

HEAVY DUTY CUTTING- Heavy duty cutting and precision turning by one piece fabricated bed & leg structure

- High rigid headstock supported by cylinder & angular roller bearing

- Ball screw

- X-axis: ∅28 x 6 mm

- Z-axis: ∅45 x 12 mm (2000T/3000T)

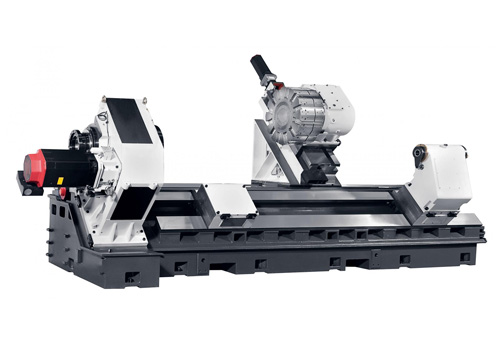

MEGA-110

-

HEAVY DUTY CNC LATHE

- High accuracy

- Utmost convenience

- Heavy duty cutting

- High stability

- Four bed sizes: 3, 4, 5 and 6 meters turning length

HEAVY DUTY CUTTING- Heavy duty cutting and precision turning by one piece fabricated bed & leg structure

- High rigid headstock

- Spindle through hole ∅155 mm : four point contacts with ball bearing, cylindrical roller bearing, angular bearing

- Spindle through hole ∅255 mm : three point contacts with taper roller bearing

- Spindle through hole ∅320 mm : three point contacts with taper roller bearing, double roller bearing

- Ball screw

- X-axis: ∅32 x 6 mm

- Z-axis: ∅50 x 12 mm (3000T/4000T), ∅62 x 12 mm (5000T),

- ∅80 x 12 mm (6000T)

- Guide way : Turcite

MEGA-130

-

HEAVY DUTY CNC LATHE

- High accuracy

- Utmost convenience

- Heavy duty cutting

- High stability

- Seven bed sizes: 3 to 10 meters turning length

HEAVY DUTY CUTTING- Heavy duty cutting and precision turning by one piece fabricated bed & leg structure

- High rigid headstock

- Spindle through hole ∅155 mm: four point contacts with ball bearing, cylindrical roller bearing, angular bearing

- Spindle through hole ∅255 mm: three point contacts with taper roller bearing

- Spindle through hole ∅320 mm: three point contacts with taper roller bearing, double roller bearing

- Ball screw

- X-axis: ∅32 x 6 mm

- Z-axis: ∅50 x 12 mm (3000T/4000T), ∅62 x 12 mm (5000T), ∅80 x 12 mm (6000T/7000T/8000T/10000T)

- Guide way : Turcite

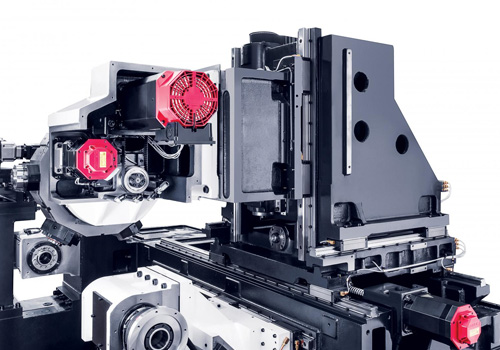

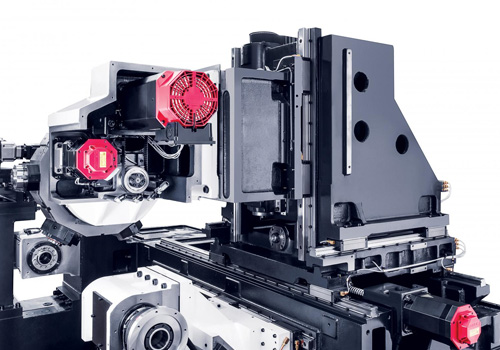

C1

-

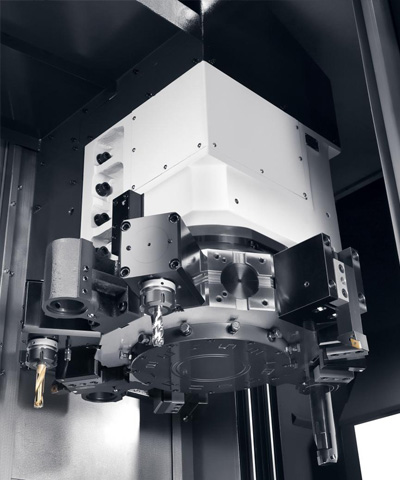

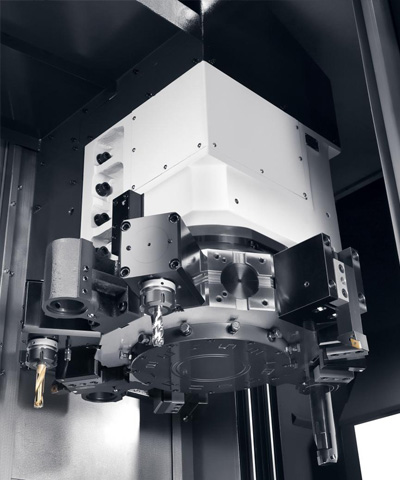

Horizontal turning centre for chuck sizes of Ø150 mm and tool magazine

Ideal for complex workpieces in small batches - for maximum flexibility. Thanks to its travelling column design, with its orthogonal X, Y and Z axes, the C1 unifies the machining characteristics of a lathe with the fabrication characteristics of a machining centre. This means that workpieces with complex contours can also be machined to an exceptional level of precision. At the same time, a sub spindle allows two machining steps to be carried out without clamping errors.

C2

-

Horizontal turning centre for chuck sizes of Ø200 mm and tool magazine

Ideal for complex workpieces in small batches - for maximum flexibility. Thanks to its travelling column design, with its orthogonal X, Y and Z axes, the C2 unifies the machining characteristics of a lathe with the fabrication characteristics of a machining centre. This means that workpieces with complex contours can also be machined to an exceptional level of precision. At the same time, a sub spindle allows two machining steps to be carried out without clamping errors

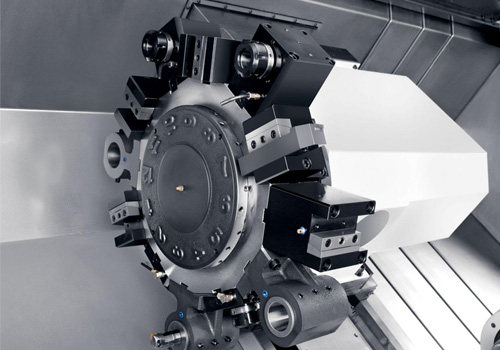

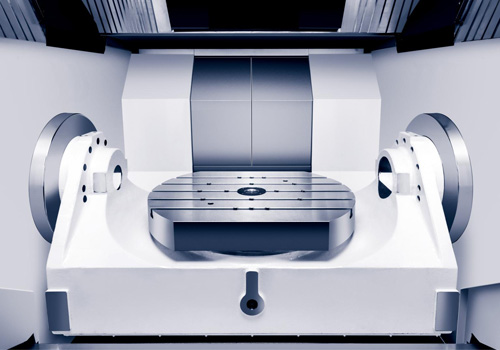

Vertical Turning Centers

- Hwacheon’s vertical turning centers are available in many different vertical CNC lathe lineups, ideal for your mid- to large-size applications.

VT-450

-

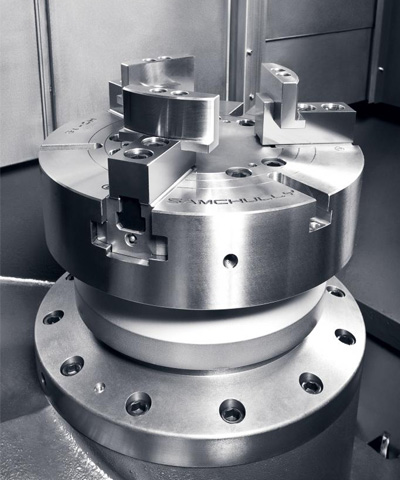

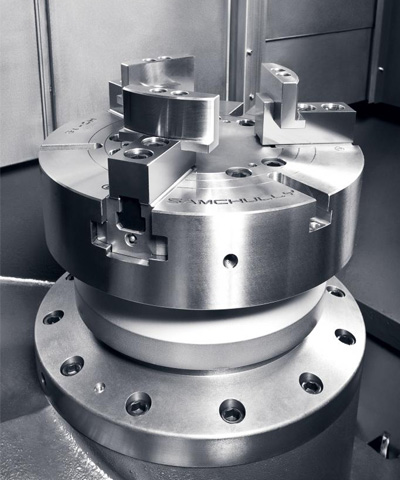

Vertical turning centre with Ø305 mm (12 inch) chuck

Safe, durable, efficient - a robust turning centre for continuous operation: For many well-known manufacturers, the VT-450 is the tool of choice for the machining of brake discs, brake drums, hubs and valve bodies. The single-piece cast machine bed limits thermal distortion extremely well, effectively absorbs undesirable vibrations and guarantees the highest levels of precision and surface finishes.

VT-650

-

Vertical turning centre with Ø450 mm (18 inch) chuck

Safe, durable, efficient - a robust turning centre for continuous operation: For many well-known manufacturers, the VT-650 is the tool of choice for the machining of brake discs, brake drums, hubs and valve bodies. The single-piece cast machine bed limits thermal distortion extremely well, effectively absorbs undesirable vibrations and guarantees the highest levels of precision and surface finishes.

VT-950

-

Vertical turning centre with box guideways for chuck sizes of Ø600 - 800 mm

Outstanding stability! Thanks to its heavy and monolithic cast Meehanite bed, the VT-950+ is extremely stable. Building on this solid foundation, these vertical lathes combine high performance main and feed drives, wide ball screws, 2-speed spindle drives and a robust travelling column. The VT-950+ and the larger VT-1150+ are thus currently among the most stable and high performance machines in this category.

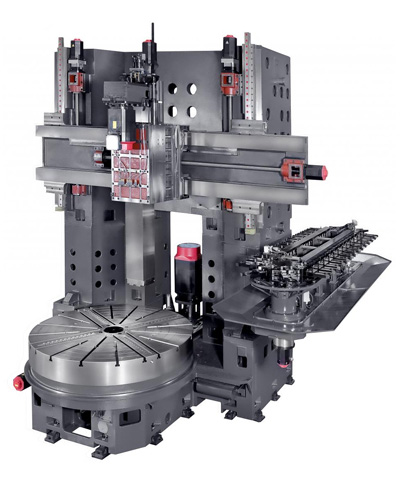

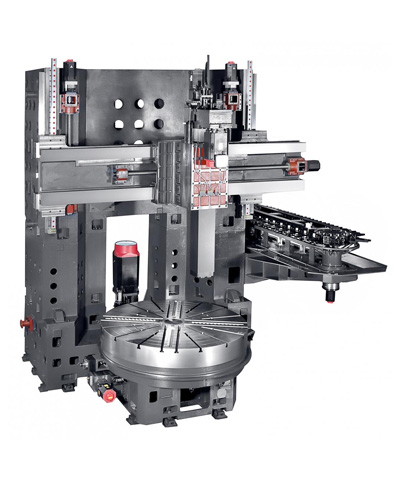

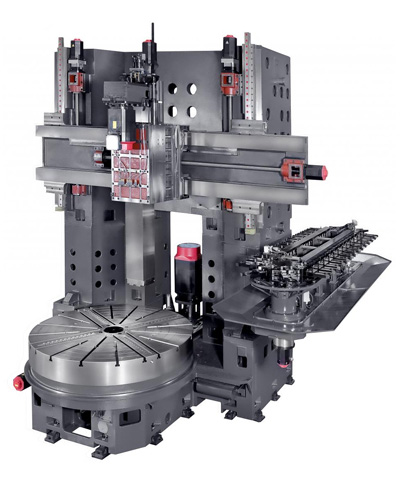

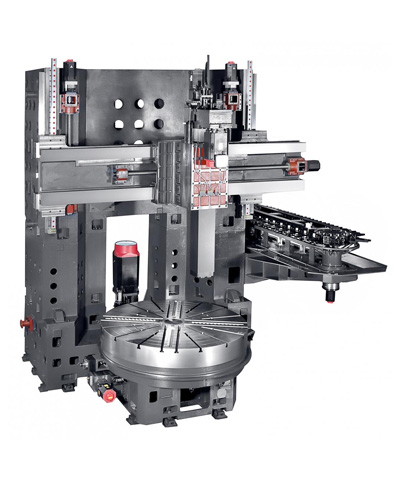

VT-1150+

-

Vertical turning centre with box guideways for chuck sizes of Ø800 - 1270 mm

Outstanding stability! Thanks to its heavy and monolithic cast Meehanite bed, the VT-1150+ is extremely stable. Building on this solid foundation, these vertical lathes combine high performance main and feed drives, wide ball screws, 2-speed spindle drives and a robust travelling column. The VT-950+ and the larger VT-1150+ are thus currently among the most stable and high performance machines in this category.

VT-2000

-

Vertical turning centre for heavy duty cutting

High-torque main drive for heavy duty cutting- Table diameter: 2,032 mm (80 inch), manual

- Drive power: 75/60 kW with 49,836 Nm

Extremely rigid machine construction

- Monolithic construction

- Machine’s low centre of gravity results in high stability

- Box guideways

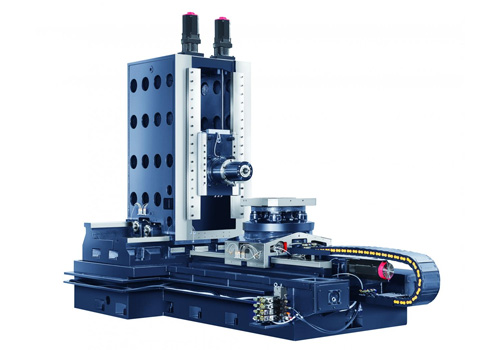

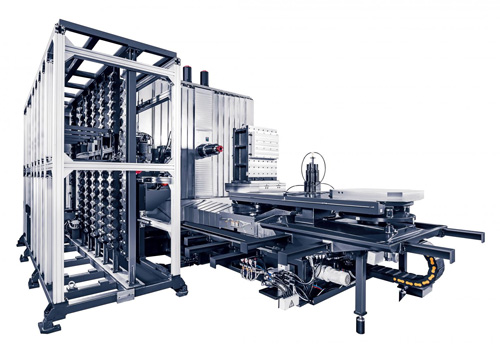

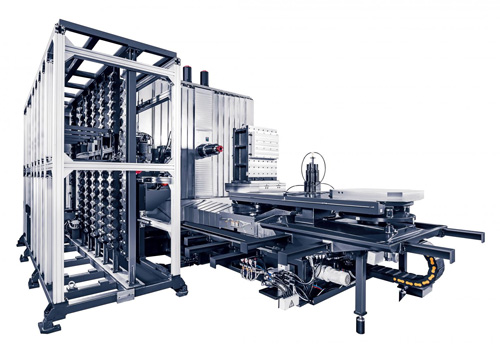

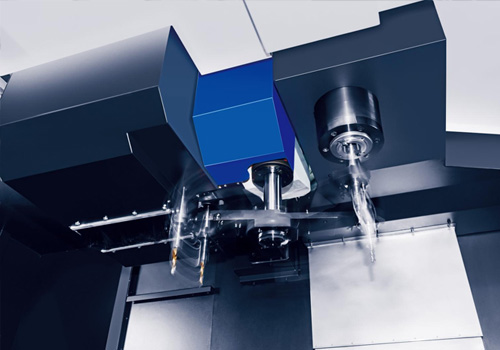

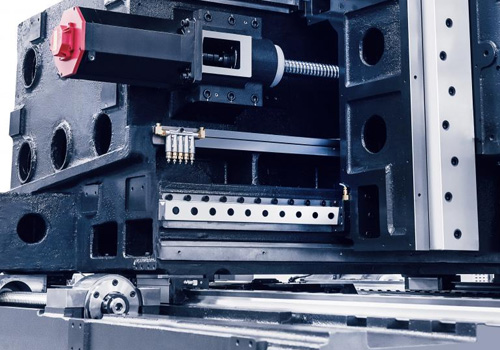

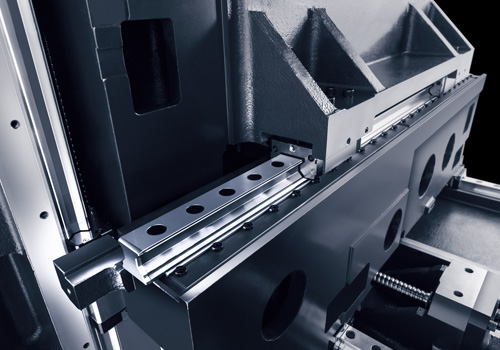

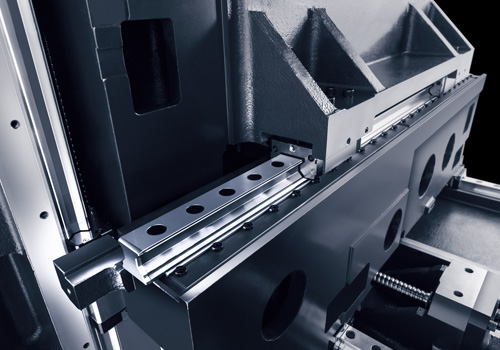

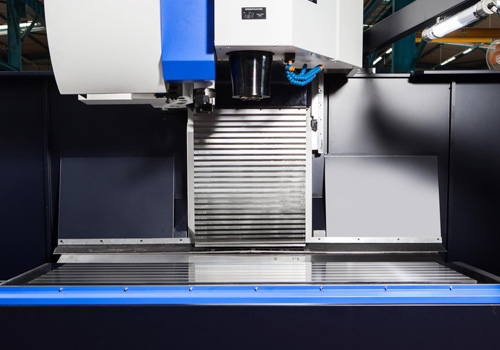

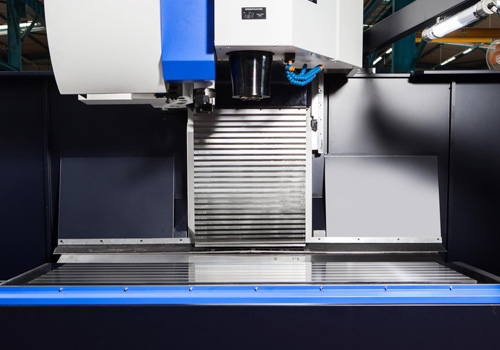

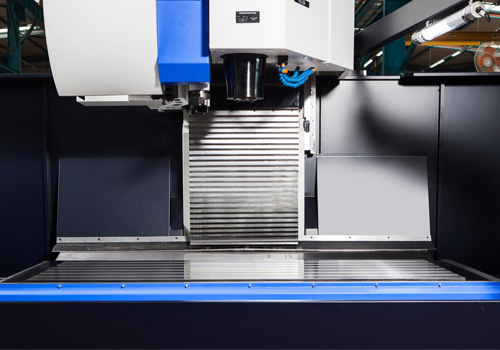

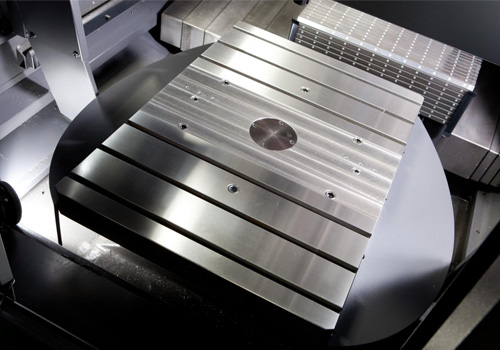

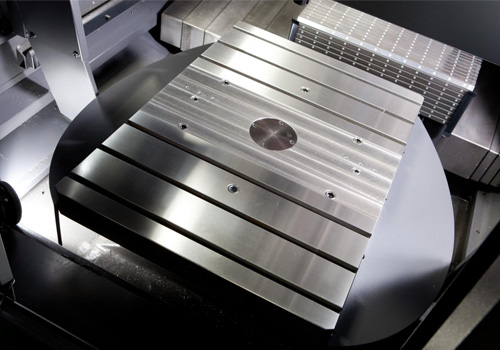

HORIZONTAL MACHINING CENTER

- High-performance spindles and accurate feed systems are the reasons why Hwacheon's horizontal machining centers are the best choice for the most demanding precision multiplex machining tasks. The horizontals are known to have a striking advantage due to their chip technology and their reduced machine footprintmakes them an ideal basis for establishing a factory automation system.

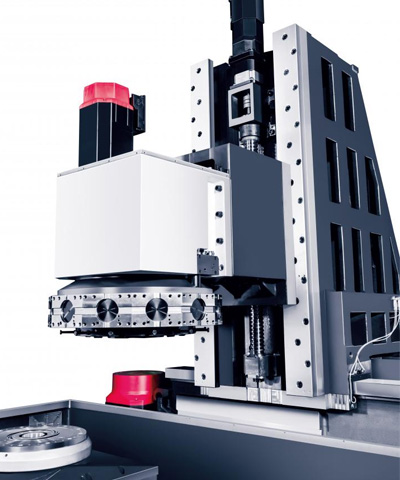

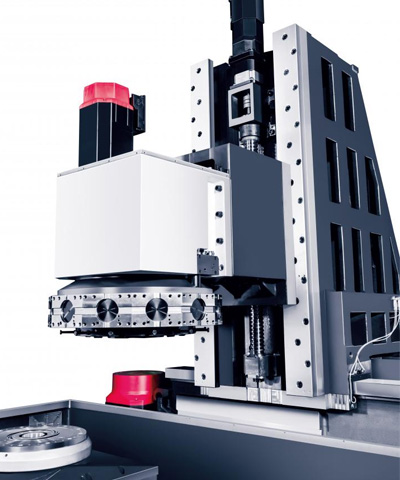

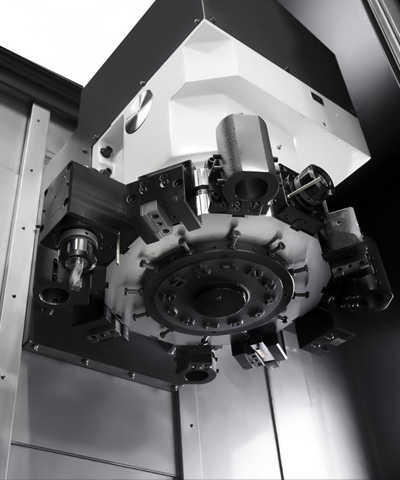

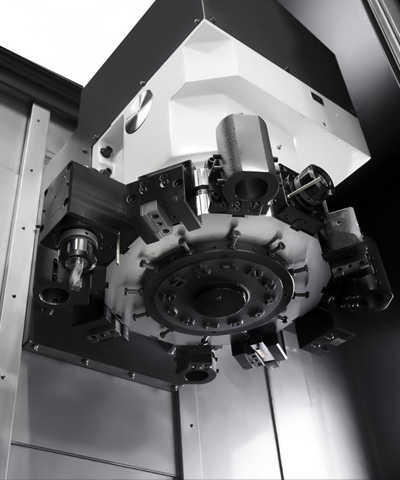

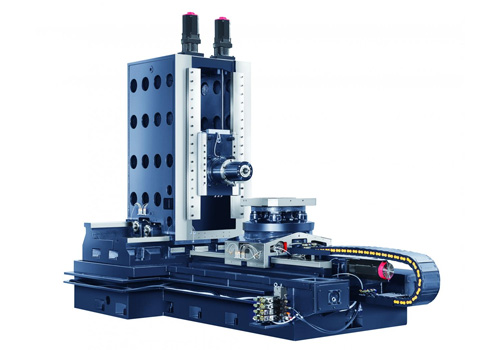

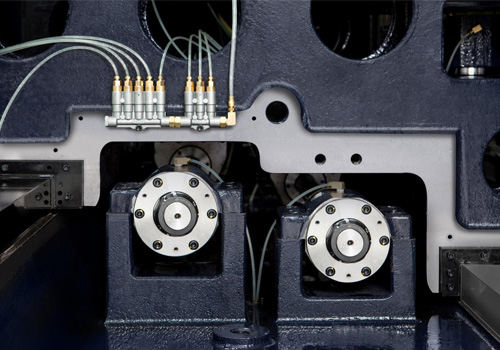

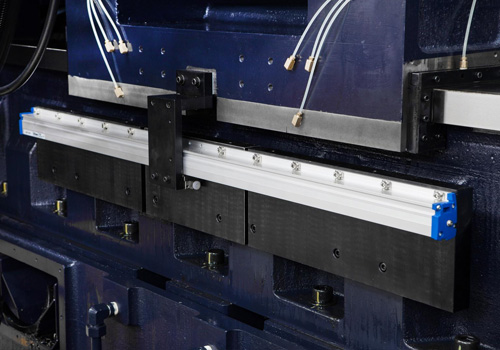

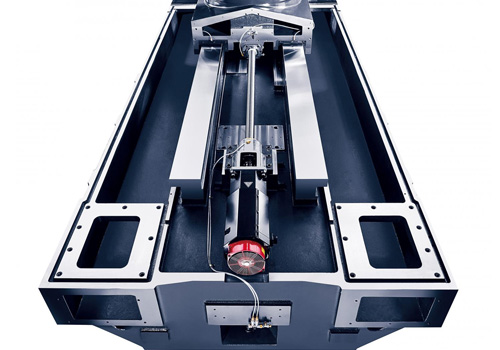

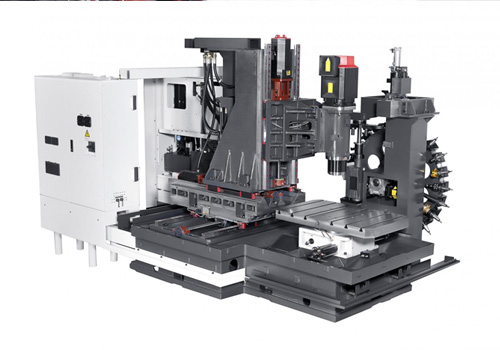

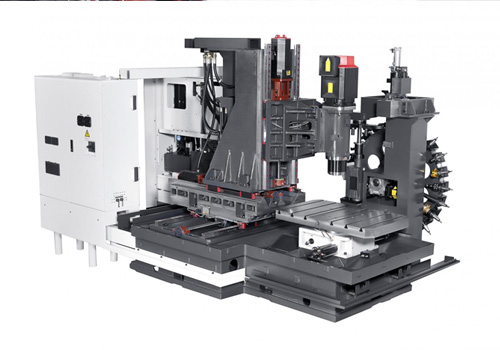

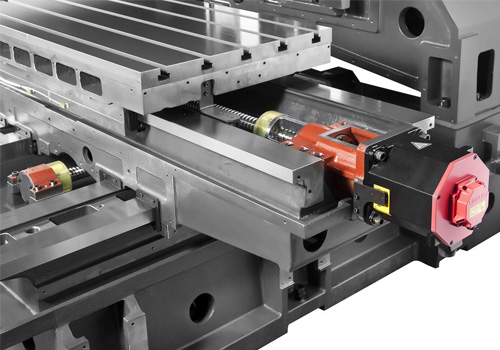

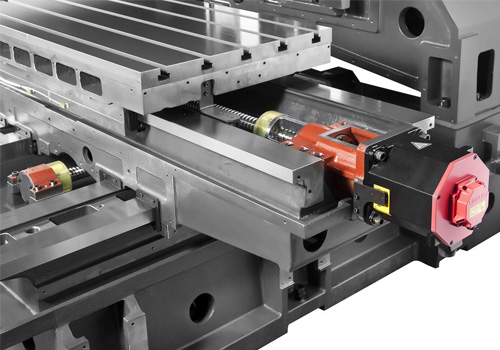

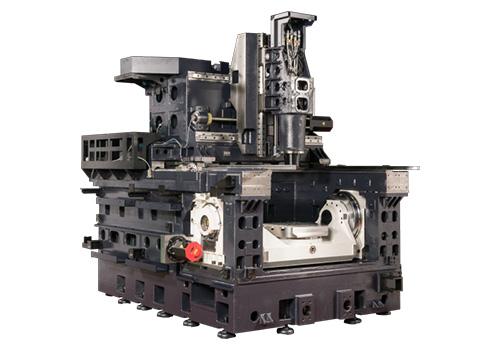

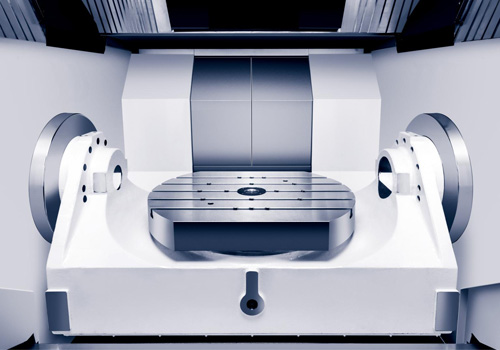

H6

-

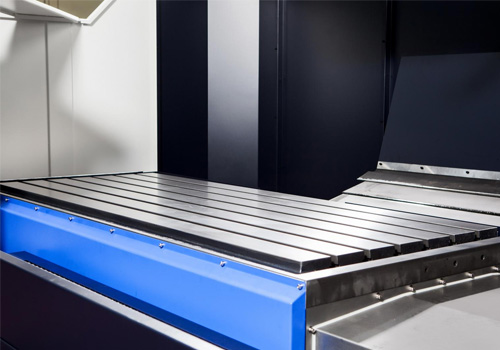

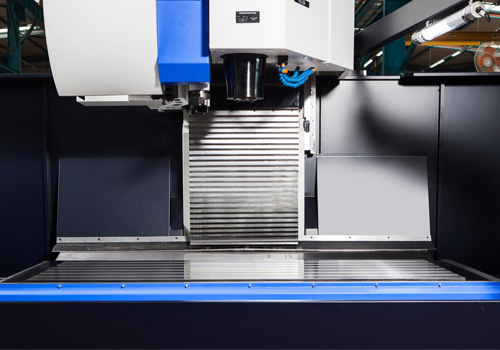

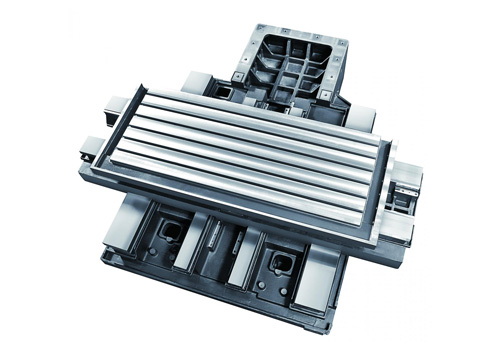

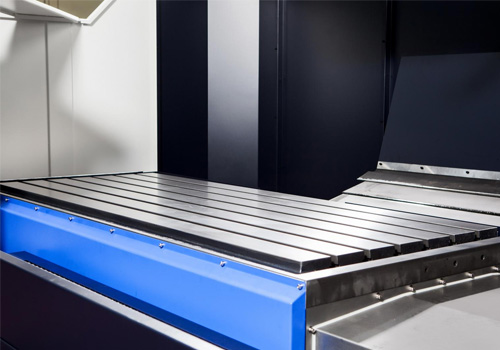

Horizontal machining centres with 630 mm pallet size, gear spindle and box

guideways on all axes

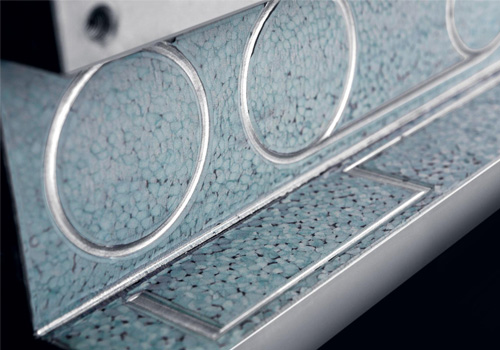

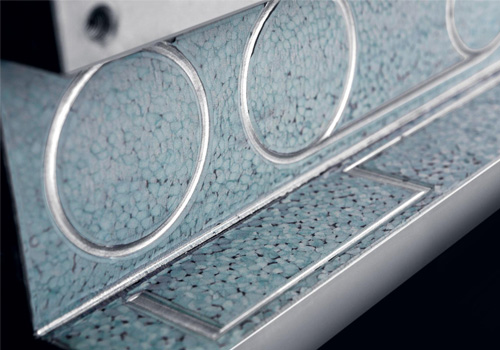

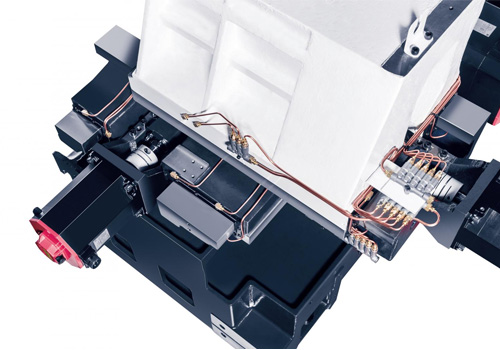

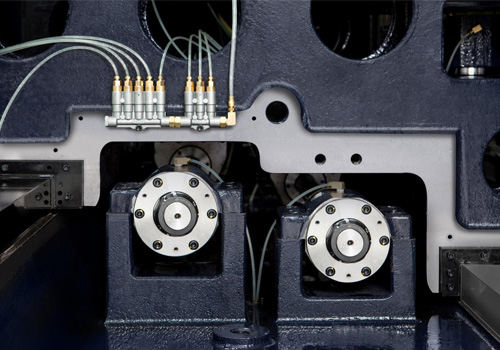

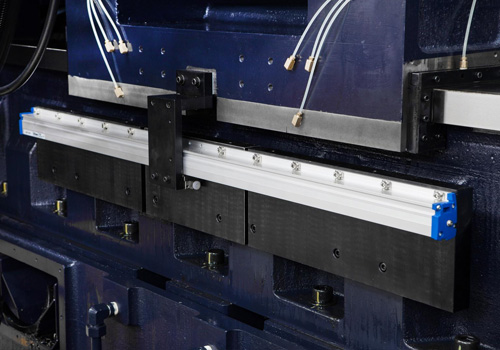

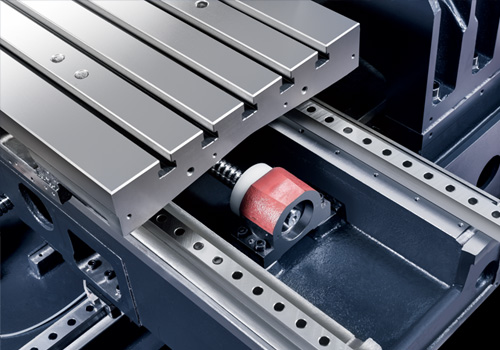

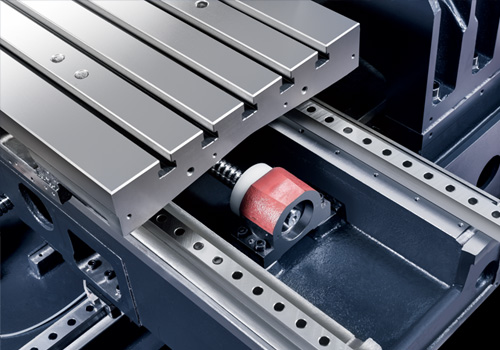

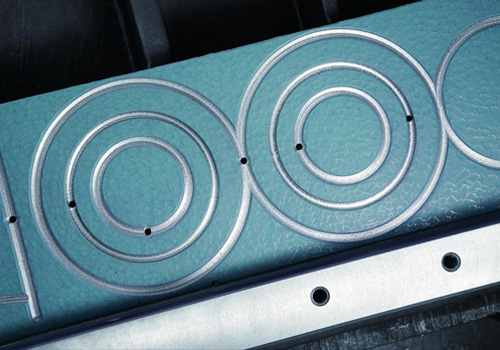

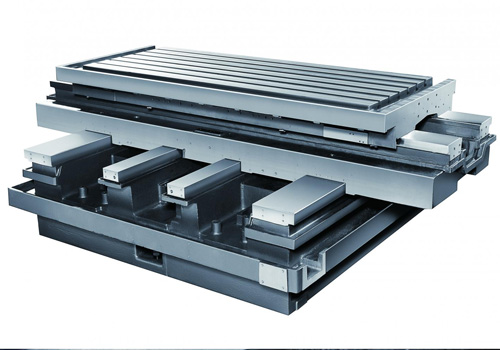

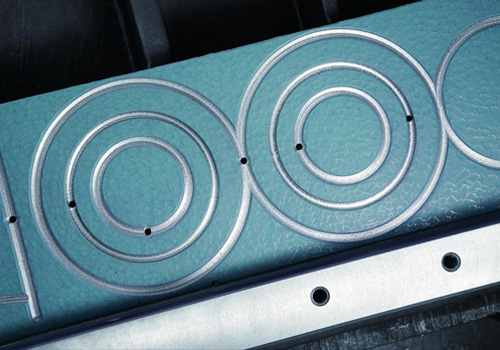

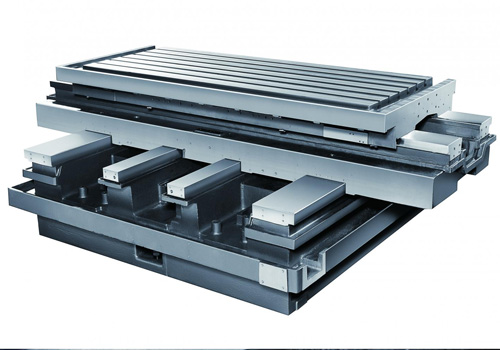

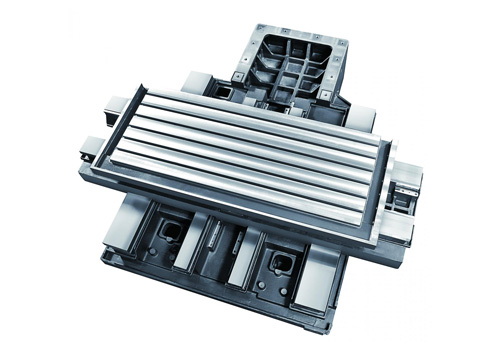

Stable and high-power roughing - precise and dynamic smoothing! The generously proportioned box guideways and the twin drives on the X and Y axes permit accuracy and high cutting rates. The charging of the box guideways with compressed air results in a very low break loose torque and guarantees uniformity of movement. The high drive torque on the gear spindle and the unique Hwacheon oil jet cooling system provide stable high performance cutting and the highest quality machining, even over longer machining times.- All axes have very wide box guideways

- Twin drives on the X & Y axes

- Spindles manufactured by Hwacheon:

8,000 rpm (35/22 kW and 1654 Nm), 2-speed drive

12,000 rpm (30/25 kW and 420 Nm), motor spindle

H8

-

Horizontal machining centres with 800 mm pallet size, gear spindle and box

guideways on all axes

Stable and high-power roughing - precise and dynamic smoothing! The H6 is the optimal solution if high rigidity is required for the machining of your workpieces. The generously proportioned box guideways and the twin drives on the X and Y axes permit accuracy and high cutting rates. The charging of the box guideways with compressed air results in a very low break loose torque and guarantees uniformity of movement. The high drive torque on the gear spindle and the unique Hwacheon oil jet cooling system provide stable high performance cutting and the highest quality machining, even over longer machining times. The zero backlash pre-loaded worm drive on the B axis, combined with a rotary encoder which regulates directly, guarantee that your requirements for accuracy will be met. The solid and extremely stiff structure of the machine bed and machine stand - designed and sized by means of FEM - is an additional factor contributing to the high machining quality of finished workpieces. Combined with the exclusive Hwacheon software components, you will simultaneously achieve greater efficiency, higher productivity and process safety.- All axes with box guideways

- Hwacheon spindles:

Gear spindle: 8,000 rpm (35/22 kW and 1654 Nm)

Motor spindle: 12,000 rpm (30/25 kW and 420 Nm)

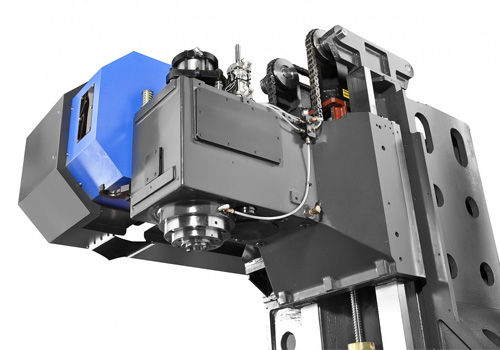

A600

-

Horizontal machining centre for flexible production

Rigid machine structure

The extremely rigid box-in-a-box design and modest footprint of the A600 are ideal for demanding machining tasks, automation and incorporation into a production line.

High performance spindle

Due to the integration of the motor into the spindle, vibrations, noise and losses of performance at high speeds are reduced to a minimum. The spindle oil is delivered directly to the spindle bearing in order to ensure optimum lubrication. In order to minimise the thermal expansion of the spindle, temperature controlled oil continuously flows around the spindle cover. In order to obtain the highest possible degree of precision, the temperature of the spindle and the expansion of the spindle are compensated for on the control side in real time.

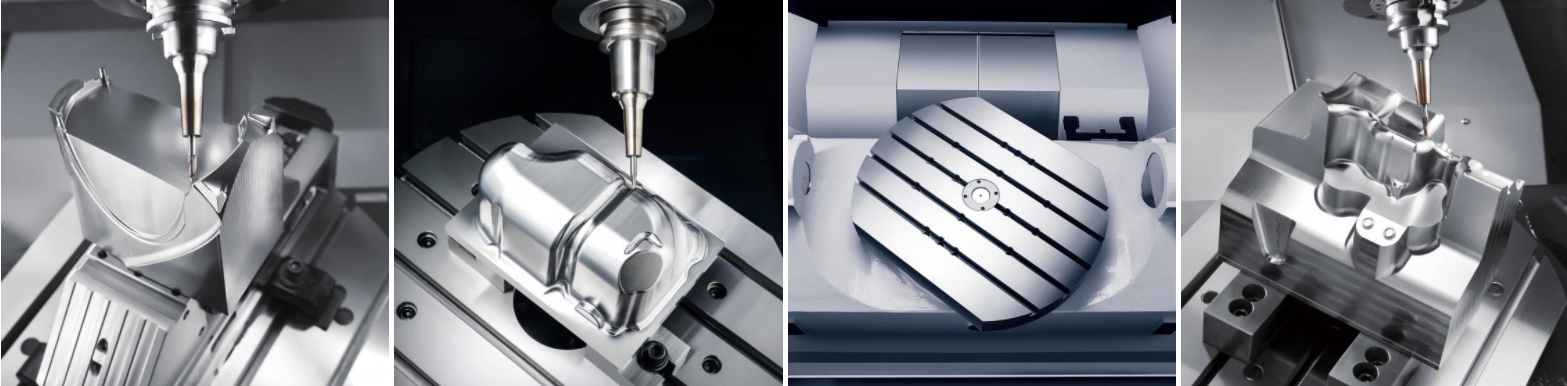

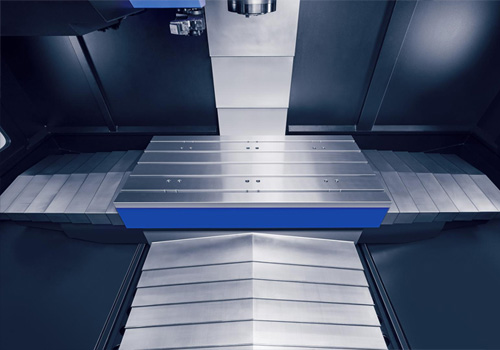

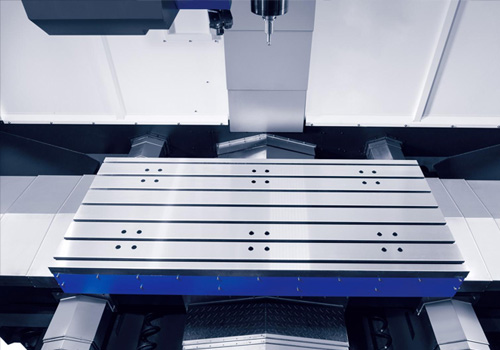

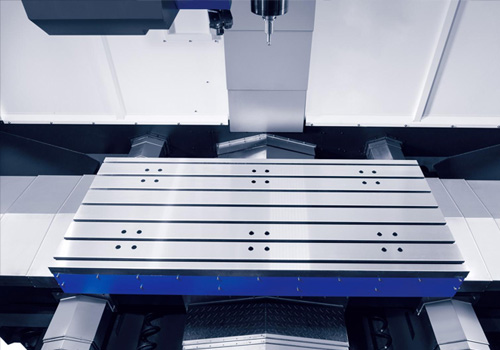

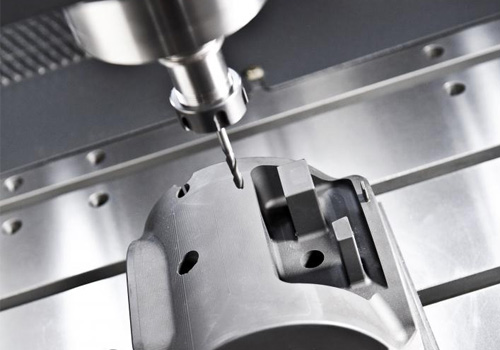

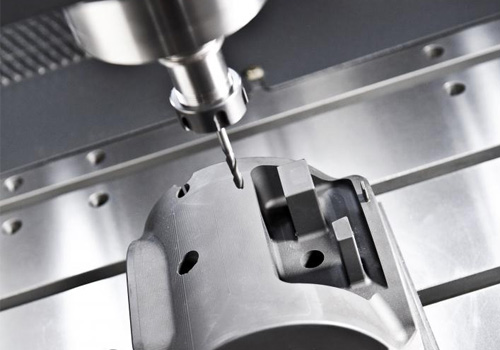

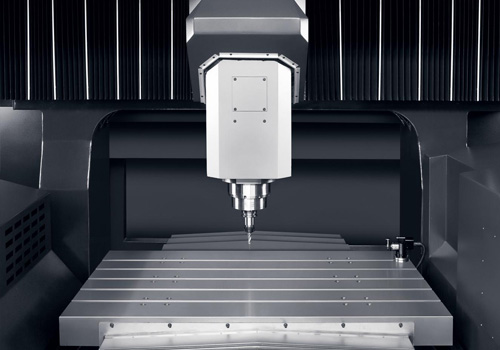

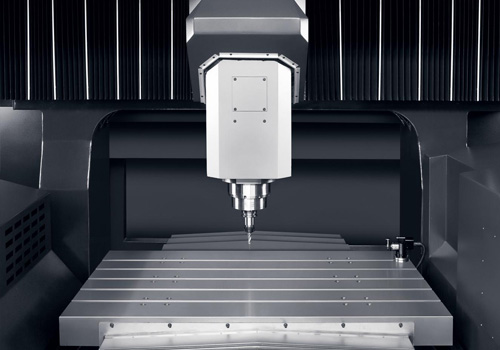

VERTICAL MACHINING CENTER

- Hwacheon offers a wide range of vertical maching centers, designed for sophisticated die and mold and precision part production. As a result of the combination of high quality machine components and modern machining software, we set new standards.

VESTA-660

-

Vertical machining centre with linear guideways and X traverse path 660 mm

Vertical machining centre for multi-purpose areas of application: The VESTA-660 stands on a heavy cast iron base with and has a cross table design. It is equipped with dynamic linear guideways on all axes. It is characterised by its high-level basic configuration and additional configuration options.

VESTA-1000+

-

Vertical machining centre with linear guideways and X traverse path 1,000 mm

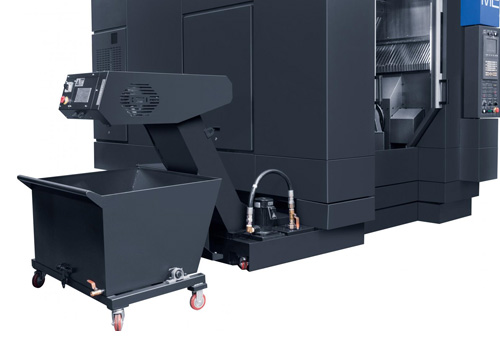

The VESTA-1000+ stands on a grey cast iron bed with a cross table design and is equipped with dynamic linear guideways on all axes. It is characterised by its versatility in different areas of application and its range of configuration options.- Tool magazine with 30 positions

- Faster tool changes

- Siemens 828D, Fanuc 0i or Heidenhain iTNC 620

- Oil-cooled 12,000 rpm (18.5 kW) Hwacheon spindles

- Side or rear-mounted swarf conveyor

VESTA-1300

-

Vertical machining centre with linear guideways and X traverse path 1,000 mm

The VESTA-1000+ stands on a grey cast iron bed with a cross table design and is equipped with dynamic linear guideways on all axes. It is characterised by its versatility in different areas of application and its range of configuration options.- Tool magazine with 30 positions

- Faster tool changes

- Siemens 828D, Fanuc 0i or Heidenhain iTNC 620

- Oil-cooled 12,000 rpm (18.5 kW) Hwacheon spindles

- Side or rear-mounted swarf conveyo

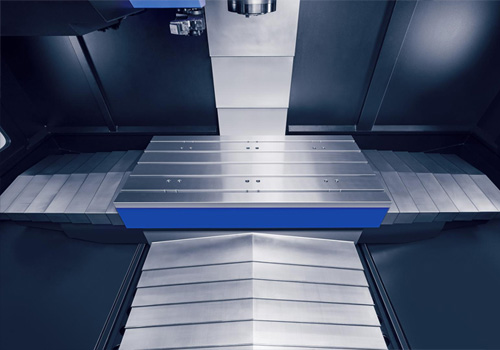

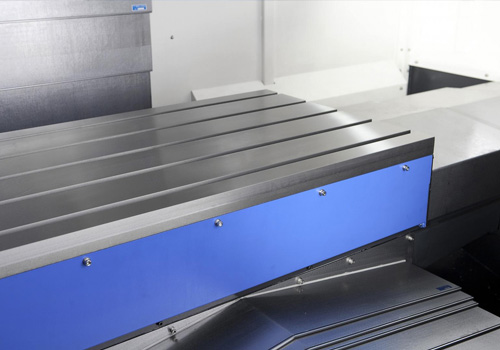

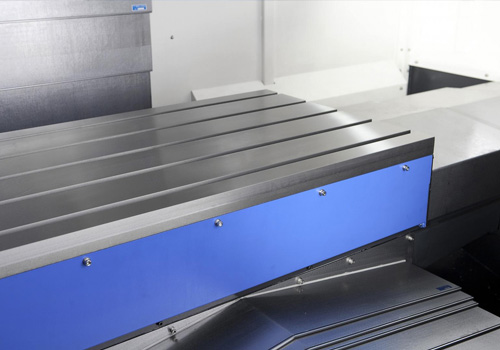

VESTA-2000

-

Vertical machining centre with linear guideways, and X traverse path 2,000 mm

Large working space with 2,000 x 850 mm table for workpieces of up to 1,800 kg: The VESTA-2000 a new build size in HWACHEON’s VESTA series. The traverse paths of 2,000 x 850 mm and the cross table, which is mounted on four guideways of the same clamping area, and a maximum table load of 1,800 kg permit the machining of a broad spectrum of parts.- Tool magazine with 30 positions

- 4 spiral conveyors in working space

- Faster tool changes

- Siemens 828D, Fanuc 0i or Heidenhain iTNC 620

- Hwacheon spindles of 8,000, 10,000 or 12,000 rpm

VESTA-610D

-

Vertical Machining Center with Dual Table (650 x 450 mm)

Hard Machining Results Every Time VESTA-610B is the answer.

The dual table in VESTA-610D guarantees heigh level of productivity. The rotating switching mechanism is equipped with hydraulic clamps. While a work piece is being machined on one side of the table, loading and unloading can be performed on the other table side parallel during the machining operation.

VESTA-850B

-

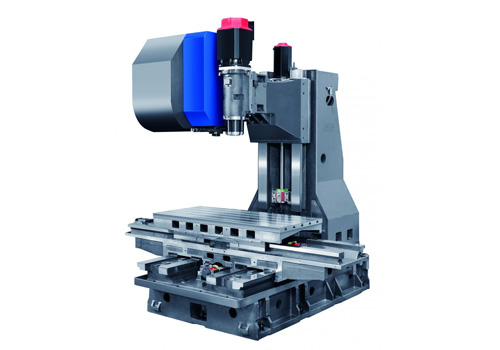

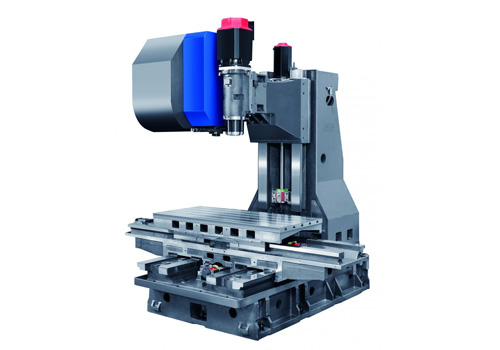

Vertical machining centre with box guideways, gear spindle, and X traverse

path 850 mm

The VESTA-850B - ideal for particularly ductile materials and high cutting rates. Thanks to its broad box guideways and solid cast iron body, the VESTA-850B has ideal stability and damping characteristics, which make the best use of the extraordinarily high torque of the two-stage gear spindle. With four box guideways on the Y axis, workpieces with a weight of up to 800 kg can be cut with ease.

VESTA-1050B

-

HIGH RIGID BOX WAY VERTICAL MACHINING CENTER

Hard Machining Results Every Time VESTA-1050B is the answer.

Hwacheon's vertical machining center employ highly tough, highly rigid box way design on all axes for ultimate precision . These machines can be configured with a wide choice of spindle models to satisfy your production needs.- 8,000 rpm or 6,000 rpm high-speed spindles to choose from

- Feed(X/Y/Z): 1,050/600/600 mm

- Gear-driven high-torque spindle: 2-speed shifting

- Box way design for all axes

VESTA-1300B

-

HIGH RIGID BOX WAY VERTICAL MACHINING CENTER

Hard Machining Results Every Time VESTA-1300B is the answer.

Hwacheon's vertical machining center employ highly tough, highly rigid box way design on all axes for ultimate precision . These machines can be configured with a wide choice of spindle models to satisfy your production needs.- 6,000, 8000, 10000, 12000 rpm high-speed spindles to choose from

- Feed(X/Y/Z) 1,300/670/650 mm

- Gear-driven high-torque spindle: 2-speed shifting

- Box way design for all axes

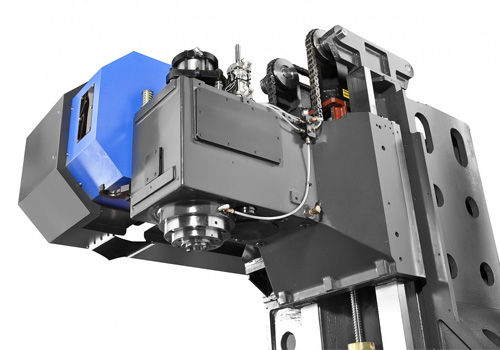

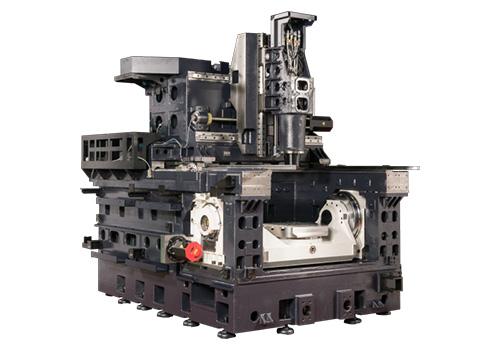

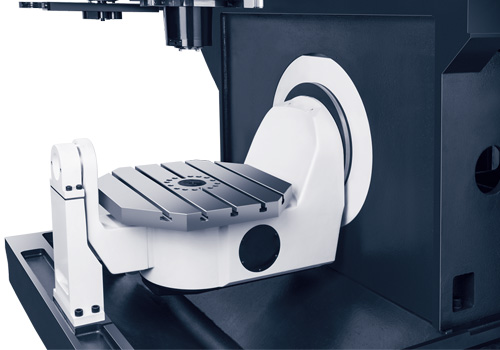

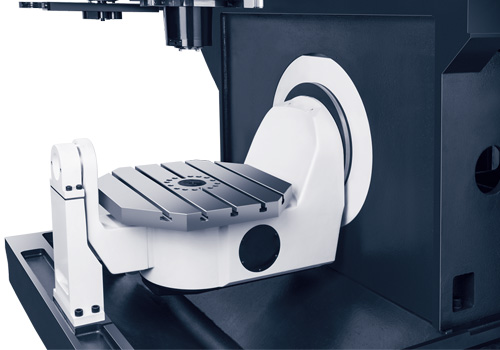

M2-5AX

-

5-axis machining centre with Ø500 mm rotary table

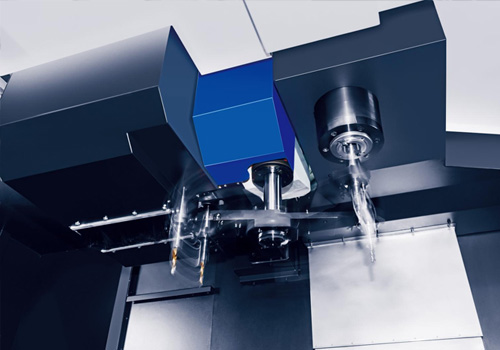

The M2 sets new standards for tool, die and mould making applications and precision parts. Like no other machine in this segment, this machine stands out for its great weight, its twin drives and its extremely stable guideways. The M2 thus fulfils all the requirements for dynamic cutting with excellent surface finishes and accuracy of contour.- Standard: 20,000 rpm with 22 kW / 118 Nm

- Optionally: 32,000 rpm with 18.5 kW / 6 Nm

M3-5AX

-

5-axis machining centre with Ø700 mm rotary table (800 kg)

For applications in tool, die and mould making, from precision components to heavy duty cutting, the M3 sets a new standard. Like no other machine in this segment, this machine stands out with its great weight, twin drives and extremely stable guideways. The M3 thus fulfils all the requirements of heavy duty cutting and is also suited to high cutting rates.- Standard: 20,000 rpm with 22 kW / 118 Nm

- Optionally: 24,000 U/min with 37 kW / 221 Nm

- Optionally: 14,000 rpm with 37 kW / 303 Nm (High-Torque)

M4-5AX

-

5-axis machining centre with Ø800 x 630 mm table (1,2 tons)

For applications in tool, die and mould making, from precision components to heavy duty cutting, the M4 sets a new standard. Like no other machine in this segment, this machine stands out with its great weight, twin drives and extremely stable guideways. The M4 thus fulfils all the requirements of heavy duty cutting and is also suited to high cutting rates.- Standard: 12,000 rpm with 30 kW / 420 Nm

- Optionally: 8,000 rpm with 55 kW / 1,009 Nm (High-Torque)

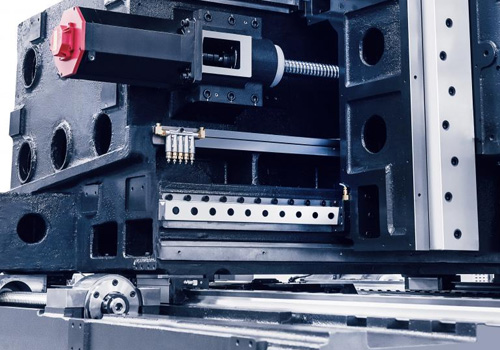

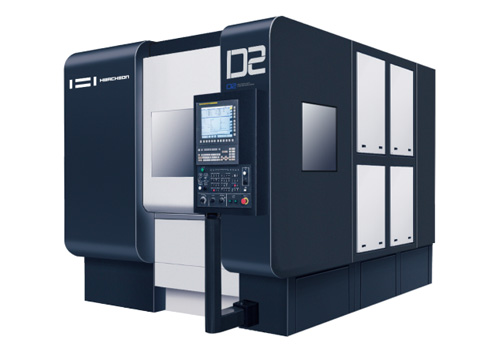

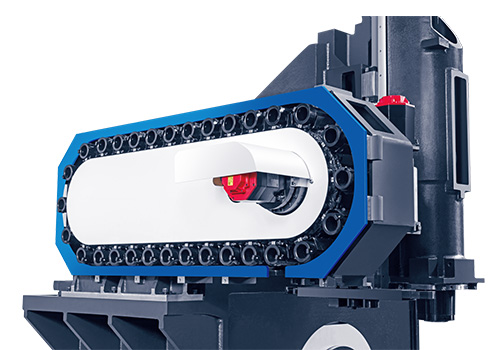

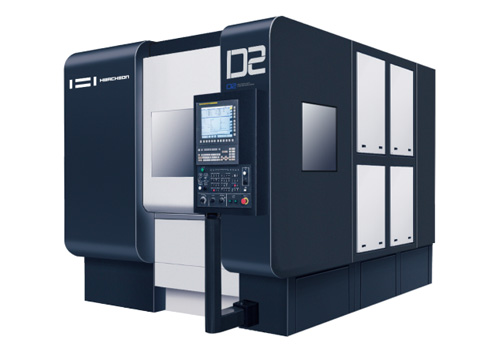

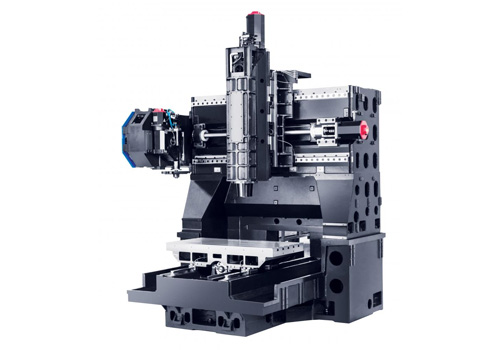

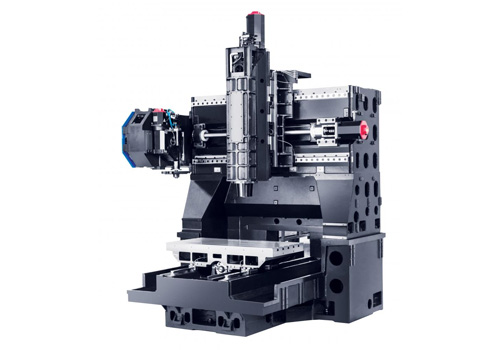

D2-5AX

-

Universal 5-axis machining centre with Ø600 mm - rotary table

The compact D2-5AX is designed for use in workshops, education, laboratories and for tool, jig, die and mould making. The D2-5AX has 5 axes as standard, of which 4 can be controlled simultaneously.

Optionally all 5 axes can also be controlled simultaneously. The stability, high accuracy and high drive power of the D2-5AX derive from its heavy machine bed of 10 tonnes, spindles made by Hwacheon and the use of high quality components. Thanks to its ergonomic construction, high rapid traverse speed, and its ease of automation, the D2-5AX is ideal for high productivity applications, whether for small or large numbers of units.- Rapid acceleration: 0.7 G

- Faster tool changes: 1.8 s

- The right spindle for every area of application: 12k, 14k (High-Torque), 20k or 24k rpm

- Hydraulically clamped B and C axes with a direct position measuring system

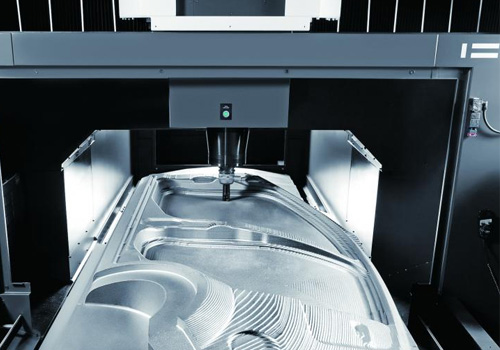

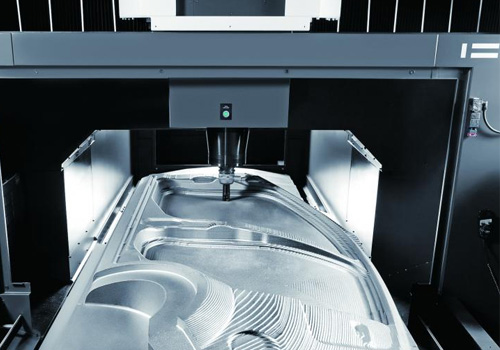

SIRIUS-UM

-

HSC machining centre for tool, die and mould making with a table size of 850

x 500 mm

The HSC machining centres in the SIRIUS series (UM/UL+/UX) have been Hwacheon’s most successful tool, die and mould-making machines for almost 20 years.

As a home-grown market leader in this segment, the name Hwacheon is a byword for the highest precision, reliability and efficiency.- Standard: 20,000 rpm with a drive power of 18.5/11 kW und 60/17.5 Nm (10 min / const.)

- Optionally: 20,000 rpm with a drive power of 22/18.5 kW and 118/80 Nm (15 min / const.)

- Optionally: 32,000 rpm with a drive power of 18.5/13 kW and 4.1/5.9 Nm

(1 min / const.)

Request

SIRIUS-UL+

-

HSC machining centre for tool, die and mould making with a table size of

1,200 x 600 mm

This is the perfect tool, die and mould-making solution you have always been looking for. SIRIUS-UL+ is a vertical tool, die and mould-making machine which leads world-wide in terms of performance - it offers your business a total production solution all in one place, from tool selection to the final product.

SIRIUS-UX

-

HSC machining centre for tool, die and mould making with a table size of

1,650 x 750 mm

The HSC machining centres in the SIRIUS series (UM/UL+/UX) have been Hwacheon’s most successful tool, die and mould-making machines for almost 20 years. As a home-grown market leader in this segment, the name Hwacheon is a byword for the highest precision, reliability and efficiency.- Standard: 12,000 rpm with a drive power of 30/25 kW and 350/239 Nm (10 min / const.)

- Optionally: 15,000 rpm with a drive power of 30/25 kW und 263/191 Nm (10 min / const.)

SIRIUS-850

-

Vertical machining centre with box guideways and a table size of 2,150 x 850

mm (max. 4 t)

The SIRIUS-850 is a vertical machining centre with a cross table design. The Y axis is equipped with four very wide hand-scraped box guideways, which have been designed for heavy workpieces. The high-torque oil-cooled HWACHEON spindles (8,000 or 12,000 rpm, 420 Nm, 30 kW) allow for optimum surface finishes with maximum precision even when operated for long periods at high cutting rates.

SIRIUS-1050

-

Vertical machining centre with box guideways and a table size of 2,500 x 850

mm (max. 5 t)

The SIRIUS-1050 is a vertical machining centre with a cross table design. The Y-axis is equipped with four wide hand-scraped box guideways, which have been designed for heavy workpieces. The high-torque oil-cooled HWACHEON spindles (8,000 or 12,000 rpm, 420 Nm, 30 kW) allow for optimum surface finishes with maximum precision even when operated for long periods at high cutting rates.

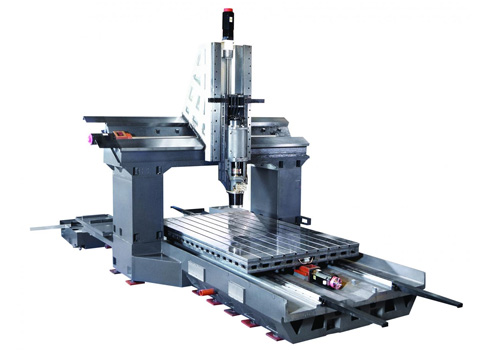

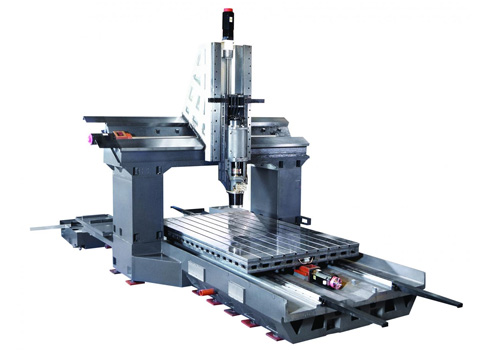

SIRIUS-1350

-

Portal milling machine for Die & Mold with 2.800 x 1.250 mm table size and box

guide ways.

Features:- Box guide ways

- Bridge / Portal type

- 3 axis

- Fanuc 31i

- Heidenhain TNC 640

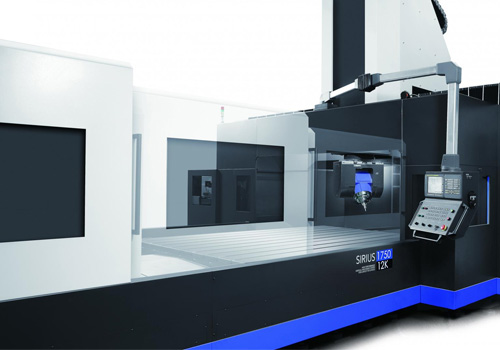

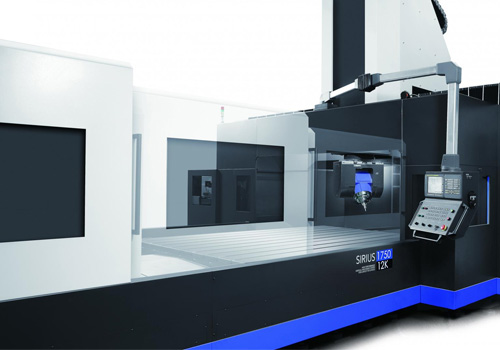

SIRIUS-1750

-

Portal milling machine for tool, die and mould making with a table size of

3,200 x 1,750 mm

The SIRIUS-1750 has a large work table which can cope with workpieces of 3,200 x 1,750 mm (10 tonnes). For even bigger workpieces, the table can be extended to a size of 4,200 x 1,750 mm (15 tonnes).

The table and the work spindle which are positioned under the gantry are mounted on high-quality linear guideways.- Standard: 12,000 rpm with a drive power of 30/25 kW (30 min/const.) and a torque of 420/239 Nm (10 min/const.)

- Optionally: 15,000 rpm with a drive power of 30/25 kW (30 min/const.) and a torque of 262/191 Nm (10 min/const.)

SIRIUS-2500

-

Portal milling machine for tool, die and mould making with a table size of

3,300 x 2,000 mm

The SIRIUS-2500 has a large work table which covers workpieces of 3,300 x 2,000 mm (10 tonnes). For even bigger workpieces, the table can be extended to a size of 4,200 x 2,000 mm (15 tonnes).

The table and the work spindle which are positioned under the gantry are mounted on high-quality linear guideways.- Standard: 8,000 rpm with a drive power of 30/25 kW (30 min/const.) and a torque of 420/239 Nm (10 min/const.)

- Optionally: 12,000 rpm with a drive power of 30/25 kW (30 min/const.) and a torque of 420/239 Nm (10 min/const.)

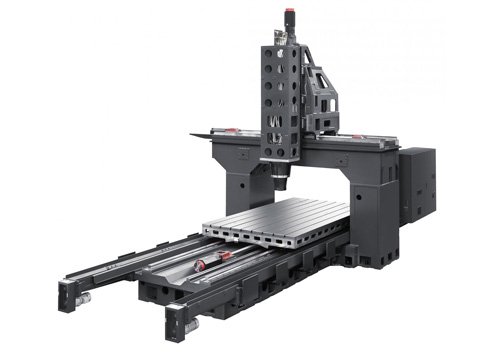

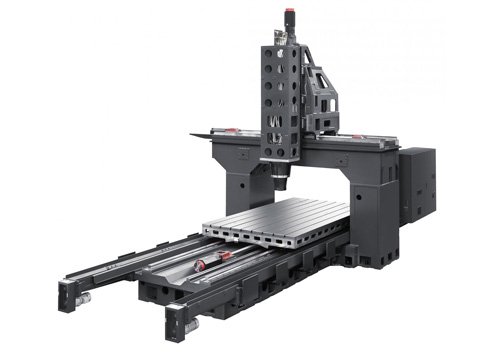

HIREX-4000

-

HIGH EFFICIENCY COLUMN TRAVERSE MACHINING CENTER

Multi-Tasking- High-efficiency with long stroke table (X-axis: 4,000 mm)

- Same effect as 2 machines with Partition (Opt.)

HIGH SPEED- Rapid Traverse (X/Y/Z): 30/36/36 m/min

- Spindle Speed: 10,000 rpm

- Tool to Tool: 1.7 s

HIT-360D

-

Compact tapping centre with rotatable double table

The innovative HiT-360D machining centre sets new standards in the efficient production of medium to large batches. A high-speed spindle with a direct spindle connection enables high productivity and stable tapping, even for small taps.

An easily rotated double table ensures that set-up and the removal of finished pieces do not affect main time. Rapid tool changing and high traverse speeds of up to 60 m/min make the machining centre a real hit in terms of efficiency.

HIT-400 / 400L

-

Compact Highspeed Machining Center (Tapping-Center)

The innovative HiT-400 and HiT-400L machining centres set new standards in the efficient production of medium to large batches. A high-speed spindle with a direct spindle connection enables high productivity and stable tapping, even for small taps.

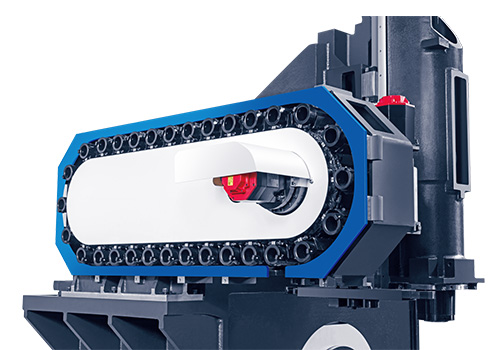

HIM-G1

-

Vertical machining centre for machining graphite

Dry machining graphite- Dry process graphite machining

- Compact machine design

- High speed & high precision machining process

- Excellent dust collection

HIM-G2+

-

Vertical machining centre for machining graphite

Dry machining graphite- High-precision machining centre

- Small and highly efficient dust extraction mechanism

- Low space requirement

- Machine construction calculated with FEM

- Linear guideways on all axes

- Oil-chilled spindle

- Good accessibility and easy to clean