- Offer Profile

-

SURFACE TREATMENT FROM THE WORLD MARKET LEADER

KNURLING - MARKING - BURNISHING - GEAR CUTTING

90 years of experience in knurling technology make it possible for us to produce tools in perfect precision,

in premium quality and for the most diverse requirements - for an outstanding appearance and first-class surface quality.

KNURLING TECHNOLOGY

-

WE ARE WORLD MARKET LEADER IN KNURLING TECHNOLOGY

90 years of experience in knurling technology makes it possible for us to manufacture tools with perfect precision and for the most diverse requirements – for outstanding optics and first-class surface quality.

REMIUM KNURLING TECHNOLOGY FOR HIGHEST DEMANDS

-

KNURLING TOOLS FOR PERFECT SURFACE FINISHING

The requirements placed on tools in the knurling technology sector are always a particular challenge in terms of quality, precision, stability and, above all, technological know-how. Since 2018, the high-end brand QUICK has belonged to Hommel+Keller Präzisionswerkzeuge GmbH. This is where design meets functionality and innovation meets experience.

FOR THE PERFECT PROFILE

The constantly increasing quality demands on the surface treatment means extraordinary requirements in knurling technology. Premium endproducts can only be met with first-class tools or even individual tool designs to make the difference in appearance and functionality compared to standard products tangible to the user. Individual product solutions lead to top products,

CUT KNURLING

-

THE SOLUTION FOR SPECIAL CHALLENGES

Knurling A major advantage lies in the processing of small diameters as well as thin-walled, soft or difficult to machine materials.

- Material removal under feed

- Machining of cylindrical workpieces

- exclusively in the axial direction

- For setting the tool in the middle

- Area of the workpiece is a puncture required.

CUT KNURLING QUICK C601 (LA/FL)

-

ADDED VALUES

- Developed for minimal installation space and maximum stability

- Designed for smallest workpiece diameters

- User-friendly handling

CUT KNURLING QUICK C602 (LA/KF)

-

ADDED VALUES

- Developed for minimal installation space and maximum stability

- Designed for smallest workpiece diameters

- Easy fine adjustment of the knurl holder

CUT KNURLING QUICK C611 (A1/FL) (A2/FL)

-

ADDED VALUES

- Adaptable, patented QUICK cooling unit

- Multifunctional: For use in front of and behind the rotation centre

- Flexible shank variation

- Head and shank fully exchangeable due to compatible interface

CUT KNURLING QUICK C612 (A1/KF) (A2/KF)

-

ADDED VALUES

- Adaptable, patented QUICK cooling unit

- Multifunctional: For use in front of and behind the rotation centre

- Flexible shank variation

- Head and shank fully exchangeable due to compatible interface

- Synchronised knurl holder for adjusting the working range

CUT KNURLING QUICK C621 (M/FL)

-

ADDED VALUES

- Designed for the largest possible working ranges

- Ideal for heavy-duty and roll turning lathes etc.

- Maximum stability due to solid construction

CUT KNURLING QUICK C622 (MI/KF) (MII/KF)

-

ADDED VALUES

- Designed for the largest possible working ranges

- Ideal for heavy-duty and roll turning lathes etc.

- Maximum stability due to solid construction

- Synchronised knurl holder for adjusting the working range

CUT KNURLING QUICK C693 (STR-A)

-

ADDED VALUES

- Knurl holders individually adjustable

- Maximum process stability

- All knurling processes can be used by conversion of the knurl holder jaws

- Suitable for very small installation spaces due to compact design

FORM KNURLING

-

CONVINCED BY THE VERSATILITY

Knurling is a chipless forming process which is suitable for machining cold-formable materials.

- All knurling shapes and profiles can be produced.

- Suitable for front and internal knurling

- Knurl up to the waistband possible

- The tool can be applied anywhere on the workpiece.

FORM KNURLING QUICK F711

-

ADDED VALUES

- All common knurl profiles can be produced

- Single plus double roller system for maximum flexibility

- Firmly defined centre height

- Adjustment of alignment is possible

FORM KNURLING QUICK F712 (BO)

-

ADDED VALUES

- Knurling up to a shoulder

- All common knurl profiles can be produced

- Single plus double roller system for maximum flexibility

- Firmly defined centre height

- Adjustment of alignment is possible

FORM KNURLING QUICK F751

-

ADDED VALUES

- High process stability due to tangential machining

- Special design for Swiss-type lathes

- Eliminates double workplace allocation in the slide unit

- User-friendly handling

FORM KNURLING QUICK F761

-

ADDED VALUES

- High process stability due to tangential machining

- Knurl holders can be adjusted via synchronous spindle

- Force neutralisation due to tangential position

FORM KNURLING QUICK F791

-

ADDED VALUES

- Knurl holders individually adjustable

- Maximum process stability

- All knurling processes can be used by exchanging the knurl holder jaws

- Suitable for very small installation spaces due to compact design

- Force reduction due to three-point machining

FORM KNURLING QUICK F792

-

ADDED VALUES

- Knurl holders individually adjustable

- Maximum process stability

- All knurling processes can be used by exchanging the knurl holder jaws

- Suitable for very small installation spaces due to compact design

- Knurling up to a shoulder

ZEUS KNURLING TECHNOLOGY FOR DIVERSE APPLICATIONS

-

PERFECTION IN DESIGN AND FUNCTIONALITY

With knurling tools, our company is the global market leader. Our product range of zeus knurling technology offers tool solutions for a variety of applications. In addition to the standardized profiles, conical, convex, concave and special profiles are also possible.

FOR THE PERFECT PROFILE

The constantly increasing quality demands on surface treatment mean extraordinary requirements in knurling technology. Premium products can only be met with first-class tools or even individual tool designs in order to make the difference in appearance and functionality compared to standard products tangible to the user. Individual product solutions lead to top products. CUT KNURLING

-

THE SOLUTION FOR SPECIAL CHALLENGES

Cut knuling is a machining alternative. A major advantage lies in the processing of small diameters as well as thin-walled, soft or difficult to machine materials.

- Material removal under feed

- Machining cylindrical workpieces exclusively in the axial direction

- To set the tool in the central region of the workpiece a puncture is required

CUT KNURLING ZEUS SERIES 231

-

- Scaling and positioning aids

- Adjusting spindle for fine adjustment of the knurl profile

- Set screws in shank for clearance angle correction

- Coated carbide bearing bushes for improved antifrictional property

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

CUT KNURLING ZEUS SERIES 241

-

- Modular design: Tool can be used as righthand and lefthand version. Retooling by simply turning the cut knurling head

- Conversion to alternative full shank dimensions is possible

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

- Fine adjustment of centre height of the cut knurling head

- Fine adjustment of the clearance angle by means of synchronous adjustment spindle

- Coated carbide bearing bushes for improved antifrictional property

- Vertical height adjustment for use of shank size 20 mm on 25 mm (version 24120M250608A1)

CUT KNURLING ZEUS SERIES 291

-

- Easy and precise fine adjustment

- Modular exchangeable knurl holder jaws for conversion to a form knurling tool 191 / 192 (knurling up to a shoulder)

- Coated carbide bearing bushes for improved antifrictional property

FORM KNURLING

-

CONVINCED BY VERSATILITY

The form knurling is a non-cutting forming, which is suitable for the processing of cold formable materials.

- All form knurling shapes and profiles can be produced.

- Suitable for front and internal knurling

- Knurl up to the waistband possible

- The tool can be applied anywhere on the workpiece.

FORM KNURLING ZEUS SERIES 130

-

- Centre height must be adjusted

- Set screws in shank for clearance angle correction

- Carbide pins

FORM KNURLING ZEUS SERIES 131

-

- All holders equipped with ClickPin system – for fast retooling of the knurling wheels

- Set screws in shank for clearance angle correction

- Carbide pin

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

FORM KNURLING ZEUS SERIES 132

-

- Knurling wheel fixed by means of carbide collar studs

- Set screws in shank for clearance angle correction

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

FORM KNURLING ZEUS SERIES 141

-

- Shank size 20 x 20 mm and 25 x 25 mm with ClickPin system – for fast retooling of the knurling wheels

- Modular design: Tool can be used as righthand and lefthand version

- Knurling head with flexible centring

- Set screws in shank for clearance angle correction

- Carbide pins

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

FORM KNURLING ZEUS SERIES 142

-

- Knurling wheels fixed by means of carbide collar studs

- Modular design: Tool can be used as righthand and lefthand version. Retooling by simply turning the knurling head

- Knurling head with flexible centring

- Set screws in shank for clearance angle correction

FORM KNURLING ZEUS SERIES 161

-

- Knurl holder is easily adjustable to workpiece diameter by means of synchronous spindle

- Set screws in shank for clearance angle correction

- Carbide pins with surface secured by set screw

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

FORM KNURLING ZEUS SERIES 162

-

- Knurling wheels fixed by means of carbide collar studs

- Knurl holder is easily adjustable to workpiece diameter by means of synchronous spindle

- Set screws in shank for clearance angle correction

- Modular shank design: Shank size 10 x 10 mm optionally adaptable

FORM KNURLING ZEUS SERIES 191

-

- Easy and precise fine adjustment

- Modular exchangeable knurl holder jaws for conversion to knurling up to a shoulder (192) or a cut knurling tool (291)

- Carbide pins

FORM KNURLING ZEUS SERIES 192

-

- Easy and precise fine adjustment

- Modular exchangeable knurl holder jaws for conversion to a form knurling tool (191) or a cut knurling tool (291)

- Carbide collar studs

ZEUS MARKING TECHNOLOGY

-

FAST - FASTER- THE FASTEST:

MARKING WITHIN ONE SECOND ONLYThe fast, cost-effective and flexible alternative to laser marking, needle embossing or engraving, integrated into the processing process.

IN MODERN TIMES

-

nowadays, the most modern production technologies with components and system components are absolutely essential for the marking of workpieces. Immediate traceability, batch separation and tracking as well as complete manufacturing documentation are indispensable requirements.

The Zeus marking tool is a multi-talent when marking on surface - whether oblique or spherical surface, frontally or up to the collar

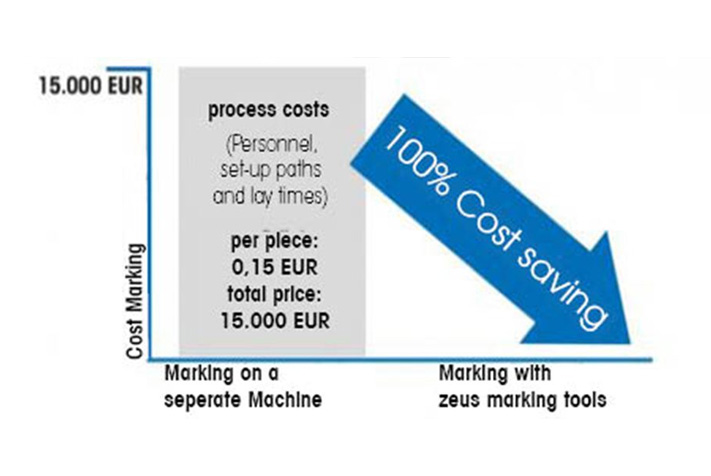

COST SAVING ZEUS MARKING TOOLS

-

THE ZEUS MARKING ADVANTAGES THAT CONVINCE:

- FAST

The processing times are significantly shorter compared to other marking techniques such as laser marking, needle embossing etc. - COST-EFFECTIVE

Complete machining on one machine significantly reduces set-up, travel and lay times - FLEXIBLE

Can be used on all conventional and CNC turning and milling centers. - INDIVIDUAL AND PRECISE

The scrolls or segments can be personalized, are easily interchangeable and provide the full precision and sharpness of the characters.

- FAST

REVOLVING MARKING

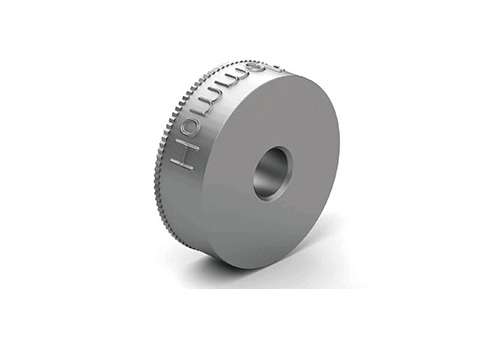

REVOLVING MARKING MARKING ROLL N° 40

-

Benefits

- Easy handling

- Fast and economical

- Suitable for series production

- Marking rolls can be easily exchanged

- All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Features

- The design of marking roll n° 40 is dependent on the workpiece diameter

- A drive provides for perfect revolving application of the marking.

- The lateral drives can be removed after marking

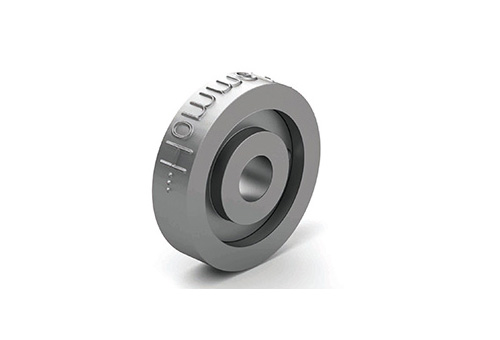

REVOLVING MARKING MARKING ROLL N° 40-K

-

Benefits

- Easy handling

- Fast and economical

- Suitable for series production

- Marking rolls can be easily exchanged

- All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Features

- The design of marking roll n° 40-K is dependent on the pitch circle / marking diameter

- A drive provides for perfect revolving application of the marking

REVOLVING MARKING ZEUS SERIES 130/131

-

- Centre height must be adjusted (series 130)

- Top edge of shank = centre height (series 131)

- Set screws in shank for correcting alignment

- Carbide pin

REVOLVING MARKING ZEUS SERIES 311/312

-

- Top edge of shank = centre height

- Set screws in shank for correcting alignment

- Carbide bolts (series 311)

- Carbide pin (series 312)

EXAMPLES OF APPLICATIONS FOR TOOL N° 311:

- Marking on flat faces

When applying the marking to a flat face, the calculated position of the pitch circle diameter must be taken into account - Marking conical surfaces

You must match the pitch circle diameter of the marking roll to the desired position on the workpiece

EXAMPLES OF APPLICATIONS FOR TOOL N° 312:- Marking conical surfaces

You must match the pitch circle diameter of the marking roll to the desired position on the workpiece

SPRING-RETURN MARKING

SPRING-RETURN MARKING MARKING ROLL N° 41

-

Benefits

- Especially versatile since it is independent of theworkpiece diameter

- Marking is possible at high speed

- Change in reading direction is possible (see operating manual)

Features

- n The design of marking roll n° 41 is independent of the workpiece diameter

- Three driving points guarantee a perfect impression. They may be placed to the side of the characters

- Full depth and definition are accomplished in one go All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Application

- Precise positioning of characters on workpiece circumference

- Centre height corresponds to the first marking point

- Marking positions can be set as desired

SPRING-RETURN MARKING MARKING ROLL N° 41

-

Benefits

- n Especially versatile since it is independent of the workpiece diameter

- Marking is possible at high speed

Features

- The design of marking roll n° 41 is independent of the workpiece diameter

- Three driving points guarantee a perfect impression. They may be placed to the side of the characters

- Full depth and definition are accomplished in one go

- All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Application

- Precise positioning of characters on workpiece circumference

- Centre height corresponds to first marking point

- Marking positions can be set as desired

- No problem to mark workpieces all the way to the collar

SPRING-RETURN MARKING MARKING SEGMENT N° 42

-

Benefits

- Especially versatile, since it is independent of the workpiece diameter

- Exchangeable segments enable fast, flexible, and eco- nomical adaptation of the text for different applications

- Marking is possible at high speed

- Change in reading direction is possible (see operating manual)

- Exchangeable segment mount unit for faster switching to a different text

Features

- The design of marking segment n° 42 is independent of the workpiece diameter

Three driving points guarantee a perfect impression. They may be placed to the side of the characters - Marking without driving points is generally possible

- Segments can be exchanged individually

- Full depth and definition are accomplished in one go. All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Application

- Precise positioning of characters on workpiece circumference

- Centre height corresponds to first marking point

- Marking positions can be set as desired

SPRING-RETURN MARKING MARKING SEGMENT N° 43

-

Benefits

- Especially versatile, since it is independent of the workpiece diameter

- Exchangeable segments enable fast, flexible, and eco- nomical adaptation of the text for different applications

- Marking is possible at high speed

- Reading direction can be changed by turning the T-shaped segments

- No problem to mark workpieces all the way to the collar

- Exchangeable segment mount unit for faster switching to a different text

Features

- The design of marking segment n° 43 is independent of the workpiece diameter

- Three driving points guarantee a perfect impression.

- They may be placed to the side of the characters

- Marking without driving points is generally possible

- Segments can be exchanged individually

- Full depth and definition are accomplished in one go

- All characters can be used as the drive, including logos, backslash, asterisks, number signs, etc.

Application

- Precise positioning of characters on workpiece circumference

- Centre height corresponds to first marking point

- Marking positions can be set as desired

SPRING-RETURN MARKING ZEUS SERIES 421

-

- Modular design: Tool can be used as right-hand and left-hand version

- Modular shank design: shank size 16 x 16 mm, adaptable

- Top edge of shank = centre height

- Set screws in shank for correcting alignment

- Hardened pin

- Right spring (pre-mounted) for spindle direction (CW)

SET CONSISTING OF:

- 1 x base shank (solid shank version) tool 421-16M

- 1 x shank adapter 20 x 20 mm

- 1 x shank adapter 25 x 25 mm

- 1 x spring, left (for changing the direction of rotation)

- In high-quality case

SPRING-RETURN MARKING ZEUS SERIES 422

-

- Modular shank design: shank size 8 x 8 mm, adaptable

- Top edge of shank = centre height

- Set screws in shank for correcting alignment

- Possible to mark workpieces up to a shoulder ( for 15 x 7 x 6 mm marking roll )

- Hardened pin

- Right spring (pre-mounted) for spindle direction M3 (CW)

SET CONSISTING OF:

- 1 x base shank (solid shank version) tool 422-08R

- 1 x shank adapter 10 x 10 mm

- 1 x shank adapter 12 x 12 mm

- 1 x shank adapter 16 x 16 mm

- In high-quality case

SPRING-RETURN MARKING ZEUS SERIES 431

-

- Modular design: Tool can be used as right-hand and left-hand version

- Modular shank design: shank size 16 x 16 mm, adaptable

- Top edge of shank = centre height

- Set screws in shank for correcting alignment

- Hardened pin

- Right spring (pre-mounted) for spindle direction (CW)

SET CONSISTING OF:

- 1 x base shank (solid shank version) tool 431-16M

- 1 x shank adapter 20 x 20 mm

- 1 x shank adapter 25 x 25 mm

- 1 x spring, left (for changing the direction of rotation)

- 1 x start and end segment

- In high-quality case

SPRING-RETURN MARKING ZEUS SERIES 432

-

- Modular shank design: shank size 8 x 8 mm and 16 x 16 mm, adaptable

- Top edge of shank = centre height

- Set screws in shank for correcting alignment

- Hardened pin

- Right spring (pre-mounted) for spindle direction (CW)

SET CONSISTING OF:

- 1 x base shank (solid shank version) tool 432-08R

- 1 x shank adapter 10 x 10 mm

- 1 x shank adapter 12 x 12 mm

- 1 x shank adapter 16 x 16 mm

- 1 x start and end segment

- In high-quality case

- 1 x base shank (solid shank version) tool 432-16R

- 1 x shank adapter 20 x 20 mm

- 1 x shank adapter 25 x 25 mm

- 1 x start and end segment

- In high-quality case

ENGRAVING TECHNOLOGY

ENGRAVING TECHNOLOGY EMBOSSING DRUMS

-

- Embossing and printing of various materials, such as leather and textiles

- Marking optionally with raised or recessed lettering

ENGRAVING TECHNOLOGY HAND STAMPS

-

- Marking of various materials for identification, numbering or decoration

- Your individual logos and symbols are manufactured exactly to your specifications

ENGRAVING TECHNOLOGY MACHINE STAMPS

-

- Embossing of all types of materials

- Shank end suitable for journal, groove or square holder

- Production is based on your requirements and drawings

ENGRAVING TECHNOLOGY ROLLS

- Marking optionally with raised or recessed lettering

ENGRAVING TECHNOLOGY SPECIAL ENGRAVING

- For marking of complex surfaces we will be glad to develop an individual solution. Based on your data and drawings we will

develop and deliver the right tool, also for exceptionally complex applications

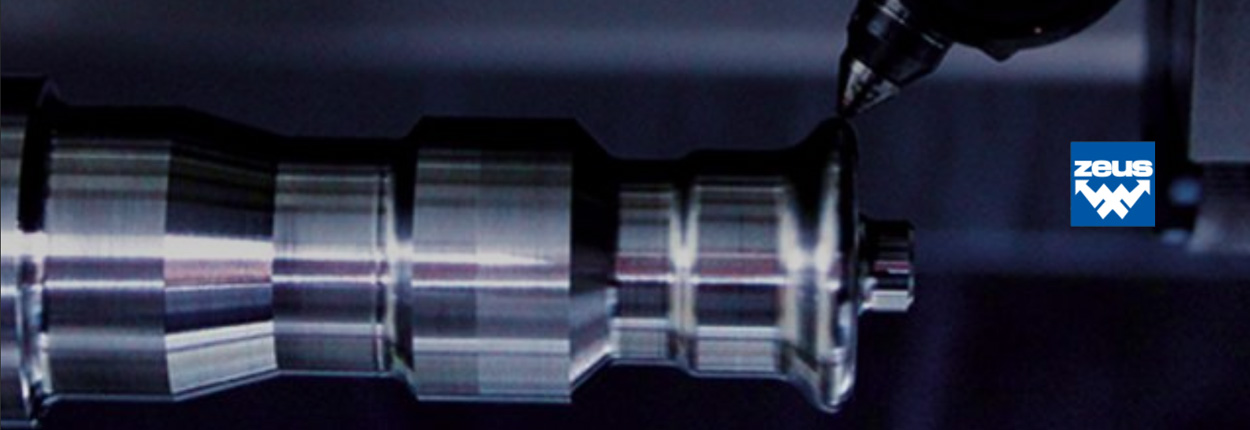

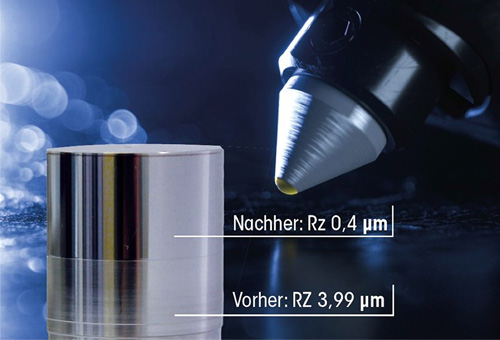

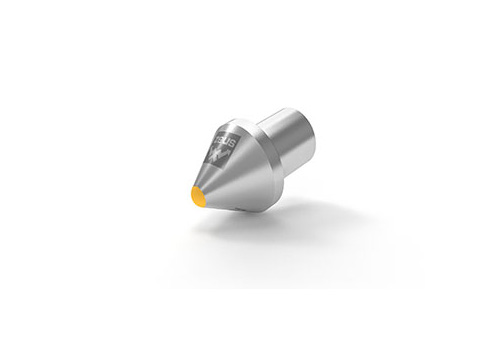

ZEUS BURNISHING TECHNOLOGY

-

PERFECTION IN DESIGN AND FUNCTIONALITY

The fast, cost-effective and flexible alternative to grinding, polishing or honing, integrated into the machining process.

THE SURFACE ALLROUNDER

-

The zeus diamond burnishing tool is an all-rounder in the burnishing of surfaces - whether cylindrical, conical, convex, concave or plan surfaces.THE ZEUS BURNISHING ADVANTAGES THAT CONVINCE

- HIGHEST SURFACE QUALITY (RZ < 1ꞍM)

- BURNISHING THE HARDEST MATERIALS (UP TO 65 HRC)

- TOP SURFACE QUALITY

The cold deformation densifies and solidifies the surface. It is thus more resistant to wear and corrosion. - FASTER & COST-EFFECTIVE

The zeus burnishing tool integrates the burnishing of a component into the machining process on a machine. It can replace subsequent processing steps such as grinding, polishing, superfinishing, honing or hardening. - FLEXIBLE

The zeus burnishing tool integrates the burnishing of a component into the machining process on a machine. It can replace subsequent processing steps such as grinding, polishing, superfinishing, honing or hardening. - COMPACT DESIGN

can be used on machines with limited work space.

BURNISHING TOOLS DIAMOND TIP

BURNISHING TOOLS ZEUS SET 510

-

- Fixed tool head

- Can be adjusted up to ±10° thanks to integrated setting options in the shaft

- To burnish ripples with cylindrical surfaces – limited cones and radii

RECOMMENDATIONS:- Burnishing speed up to 200 m/min

- Feed rate up to 0.2 mm/U

- Workpiece measurement of 0.01 mm (~Rz 10) and 0.02 mm (~Rz 20)

- It is recommended to use a cooling lubricant

BURNISHING TOOLS ZEUS SET 520

-

- Tool head is variably adjustable

- Tool with universal application

- Swivel range ±90°

- Thanks to the adjustability of the tool head, it is possible to burnish plane surfaces, conical, convex and concave geometries

- Application up to a shoulder

RECOMMENDATIONS:- Burnishing speed up to 200 m/min

- Feed rate up to 0.2 mm/U

- Workpiece measurement from 0.01 mm (~Rz 10) and 0.02 mm (~Rz 20)

- It is recommended to use a cooling lubricant

GEAR CUTTING TOOLS

-

INNOVATIVE – POWERFUL – PROCESS ENHANCED

HOBit stands for performance and reliability in the area of gearing. Know-how, years of experience of our employees and

state-of-the-art technology form the basis for the highest quality and outstanding service.

HOB - BORE TYPE

-

Customized for your machining task. Contact us!

DISC CUTTER

- Available in diverse sizes for your individual machining requirements. Ask us!

HOB - SHANK TYPE

- Especially manufactured according to your individaul requirements. We will be pleased to inform you of the possibilities.

SHAPER CUTTER AND POWER SKIVING CUTTER

- On request, according to your specifiations.