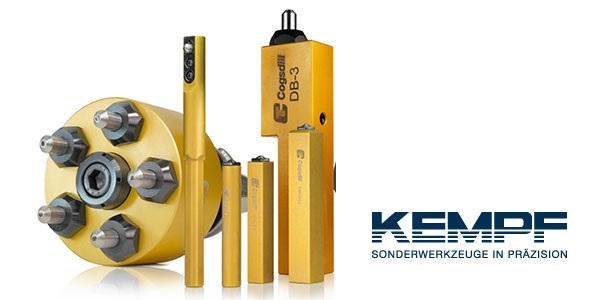

- Offer Profile

-

BURR-FREE - STRAIGHT OUT OF THE MACHINE

... with tool solutions by KEMPF! This statement is not just a promise to you, but rather our drive to offer you the best tool solutions that help you to achieve better productivity. With our large portfolio of deburring tools, for example, we can eliminate almost every manual deburring and automate the processes. For example, discover the unique & award-winning "Xebec Back-Burr Cutter & Path Deburring System" or even the patented "ExBurrDrill".

As a specialist for special tools, we are also able to offer the right tool for your application - quickly, cost-effectively and in the best KEMPF-quality. Convince yourself.

SPECIAL TOOLS

-

In order to meet the demands for increasingly complicated components with extremely tight tolerances, innovative special tools are required. As a specialist for special tools, our team of machinists and technicians develops individual special solutions for you and your application. Due to our many years of know-how in the field of cutting tools, we are able to design and construct special tools for the most difficult machining tasks. This allows us to offer you the right tooling solution for almost any machining process - quickly, cost-effectively and in the best KEMPF-quality.

Since holistic support is very important to us, we not only take care of product tests and measurements, but also offer repair and regrinding (or re-lasering) services. Everything from one source - just as it should be with a good partner.

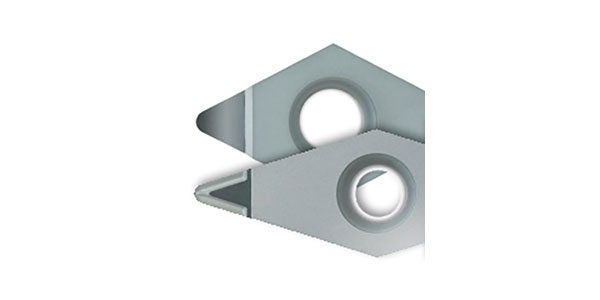

What we offer:- Tools with Diamond Tipping

- 3D lasered chip guides

- Lasered cutting edges for highest performance

DEBURRING TOOLS

-

Almost all machining processes produce unwanted burrs that must be removed. For the most diverse and unusual deburring operations, we offer you an extensive range of deburring tools that cover almost every application.

Also learn more about XEBEC Back-Bur Cutter & Path, for front and back deburring of edges on 3D curved surfaces, a system of deburring cutter & individually programmed NC data set.

IBEX DEBURRING SYSTEM

-

Features

IBEX SOFT, MEDIUM & HARD NEW!

- Tension compensation and pressure compensation with 10 mm each

- Even deburring result

- Shorter processing times

- Low programming effort

- Slim design

- Very high wear resistance, sealing against dirt

BURRAWAY

-

The features of the Burraway universal deburring tool are:

- Easy handling on all machines

- No need to change the direction of rotation

- Cost effective tools and spare knives

- Easy change and long service life of the knives

- Deburring thickness adjustable by spring tension

- Solutions for various applications can be realized

- Tools are available in inch (TYPE A, B, C) and in metric sizes (TYPE MA, MB, MC). The adjusting screws of the inch program are supplied with inch thread, those of the metric program with metric grub screws.

MICRO BURRAWAY

-

FEATURES OF THE MICRO-BURRAWAY

- designed for the smallest bores from 1.00 mm in diameter

- suitable for metric and inch bores

- suitable for all common tool holders

- easy handling due to two-part construction consisting of an cartridge (HSS blade) and base body

- simple functional principle of the burraway

- quick and easy change of the cartridge

BURR-OFF

-

FEATURES OF THE BURR-OFF DEBURRING TOOLS

- Easy handling on all machines

- change of direction of rotation not necessary

- inexpensive tool can be regrinded up to 4 times

- no metall shavings accumulation due to the open special construction

- from Ø 1,57mm up to Ø 5,56mm with a standard burr-off tool

- from Ø 5,56mm with 2 cutting edges standard

- Deburring force adjustable via adjusting screw

- Standard tools from Ø 1,57mm to Ø 16,28mm available from stock

ELLIPTI-BUR

-

FEATURES OF THE ELLIPTI-BUR DEBURRING TOOL

- Deburring of elliptical bore surfaces

- No need to change the direction of rotation

- Cost-effective tools and spare knives

- Easy change and long blade life

- Deburring thickness adjustable by spring tension

- Solutions can be realised for a wide range of applications

- Standard tools available for bore Ø 3.96 mm to Ø 25.4 mm

FLIP-CUT FACING & CHAMFERING

-

FEATURES OF THE FLIPCUT

- Precise chamfering and countersinking with one tool in one set-up

- The special cutting edge geometry ensures a forced folding back of the cutting edge

- The use of carbide-tipped cutting edges ensures a long tool life and economical machining

- Internal coolant supply ensures metall shavings removal and guarantees an optimum folding in and out of the carbide cutting edge

- Standard tools are available from Ø 7.0 mm to Ø 34.0 mm

- Standard cutting edges are available for back-side facing and front-side chamfering, as well as for back- and front-side chamfering

MICROLIMIT COUNTERSINK TOOLS

-

FEATURES OF THE MICROLIMIT COUNTERSINK TOOL

- Designed for the production of precise countersinks

- Cutting pressure is absorbed axially and radially via the plane bearing and the radial bearing

- Setting accuracy is 0.025 mm

- Long tool life

- Assembly of guiding pin, countersink and depth control adjustment (base body)

JB & CNF PRECISION CHAMFERING TOOLS

-

CHARACTERISTICS OF THE PRECISION CHAMFERING TOOL

- Infeed via overrun piece on the workpiece surface

- Constant and precise chamfering

- Guiding pin enables optimum support in the workpiece and extreme working depths (up to 10xD)

- Change of direction of rotation not necessary

- One basic tool covers workpiece Ø 4.0 mm - 25.0 mm, only the cutting edge and the guiding pin have to be adapted to the workpiece

- Chamfer size precisely adjustable via adjusting ring

- Guiding piece is mounted on bearings (prevents damage to the workpiece)

- Standard guiding pieces and cutting edges from Ø 4.75mm-Ø 19.05mm available

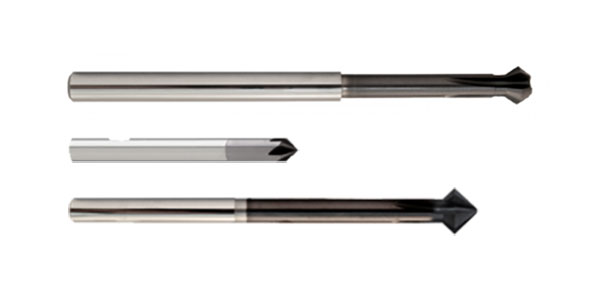

SOLID CARBIDE - DEBURRING CUTTERS

-

MINIMUM BURR WITH MAXIMUM FEED

When exit burrs must be avoided, the new solid carbide drill for minimum burr drilling has clear advantages. Thanks to its special tool geometry, burr formation at the hole exit is reduced to a minimum. Through the use of the new drill

- a downstream process for deburring becomes superfluous. This reduces process and

and, if necessary, set-up costs and reduces the machining time of the component. - In the case of very high demands on the burr-free nature of a component, process-reliable, downstream burr machining is made possible. The burr root of the

burr is minimized. The downstream deburring tool can shear off the burr root

the burr root with process reliability. The service life of the deburring tool is multiplied.

- a downstream process for deburring becomes superfluous. This reduces process and

WHEEL TYPE BRUSHES

-

FEATURES OF THE CERAMIC WHEEL TYPE BRUSH

- Self-sharpening cutting edges enable constant grinding performance

- Powerful grinding features and durable cutting edges

- Excellent surface finish and deburring results can be achieved

- Versatile use, e.g. on machining centres, special machines, drilling machines, robots, etc.

- Deburring and surface finishing in one operation

- The flexible fibre rods softly adapt to the shape of the workpiece

- The geometric shape of the workpiece is not changed

- Long tool life for significantly higher productivity and lower costs

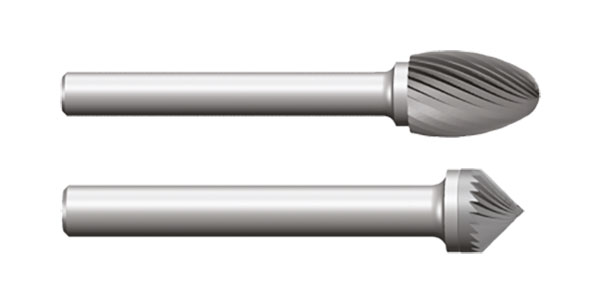

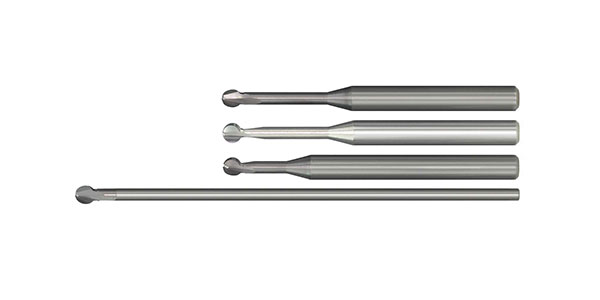

CARBIDE - ROTARY CUTTER

-

ROTARY CUTTER SERIES 40 TO 45

HM rotary cutters are especially suitable for use on robots and for manual use

in pneumatic or electric grinders.

All HM rotary cutters are available in different toothing variants. In the overviews only the

only the common variants Z1 and Z4 are listed.

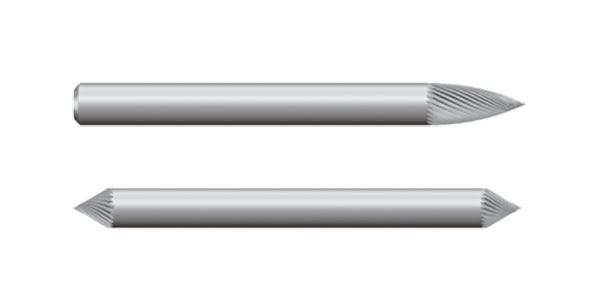

MINI - HM-ROTARY CUTTER SERIES 59

-

All MINI - carbide rotary cutters have a 3.0 mm

shank, are made of solid carbide and have an overall

have an overall length of 38 mm.

GMO DEBURRING TOOLS

-

FEATURES OF THE GMO DEBURRING TOOL

- deburring process in seconds

- deburring of smallest bores from Ø 0.8mm

- rotating tool with carbide blade

- clean and reliable deburring process

- easy handling, no special requirements necessary

- can be used on any machine, ideal for use on CNC machines

- deburring strength is adjustable by adjusting screws or 4 different springs

- Patented tool system

SURFACE BRUSHES

-

FEATURES OF THE Al2O3 HIGH PERFORMANCE CERAMIC

Ideal for deburring and rounding workpiece edges as well as for grinding, polishing & cleaning workpiece surfaces.- Self-sharpening cutting edges enable constant grinding performance

- Powerful grinding qualities and durable cutting edges

- Excellent surface finishes and deburring results can be achieved

- Versatile use, e.g. on machining centres, special machines, drilling machines, robots, etc.

- Deburring and surface finishing in one operation

- The flexible fiber rods carefully adapt to the shape of the workpiece

- The geometric shape of the workpiece is not changed

- Long tool life for significantly higher productivity and lower costs

MOUNTED POINTS WITH FIXED CERAMIC BODY

-

- This tool prevents clogging and scratches on the surface as it does not contain abrasive grains

- Ideal for improving the surface finish

- Suitable for any material, including aluminium and hardened steels

- Efficient removal of fine burrs with a burr root of less than 0.2 mm after machining

- The self-sharpening feature of the cutting edges at the fibre ends ensures very high grinding ability. The constantly working cutting edges ensure stable and continuous grinding performance

- Extreme edge and shape stability ensure long tool life and enable increasing productivity and lower costs

SHAVIV HAND DEBURRERS

-

SHAVIV HAND DEBURRING TOOL IN DIFFERENT VERSIONS

For manual deburring of components, available in different sets. Blades/countersinks, blade holders, handles and the tool sets are available on request.

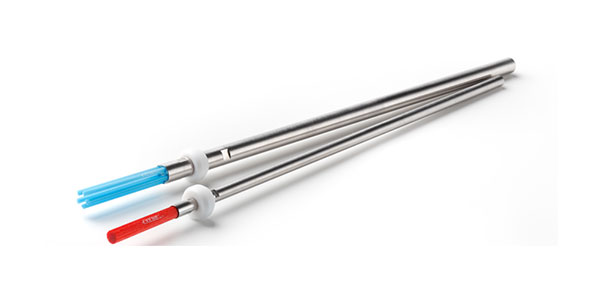

BACK BURR CUTTERS AND PATH

-

SPECIAL DEVELOPED DEBURRING CUTTER

- Micro-grain-HM: sharp cutting edge, with high wear resistance

- High-heat resistant AlTiCrN coating: wide range of applications from aluminum to difficult-to-machine materials such as Inconel or titanium

- Spiralized cutting edge: produces clean edges and prevents secondary burrs

- Faster machining due to the special geometry

NC-DATASET (PATH)

- Even edges due to constant stock removal over the contour

- Increase of tool life by shifting the cutter cutting point

CERAMIC BRUSH SURFACE END TYPE

-

For chamfering, deburring & descaling workpiece edges as well as for grinding, polishing & cleaning workpiece surfaces

The very easy handling ensures a considerable improvement of the surface finish and deburring quality in a very short time as well as a soft and vibration-free application. The "Ceramic Brush Surface End Type" is suitable for use on CNC machines and for working with the MMC system.

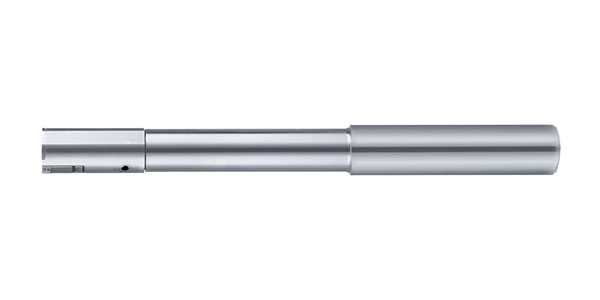

HSD - HIGH SPEED DEBURRING

-

FEATURES OF THE HSD DEBURRING TOOL

- Rotating tool with movable cutting edges

Pressure-controlled cutting edges fold into the cutting edge holder - Cutting force can be determined with oil, air or cooling water

- Deburring quality is influenced by the pressure of the medium (oil, air or coolant), the working feed and the spindle speed

- High feed rates and speeds are possible (conventional deburring tools are limited in deburring speed by the inertia of the spring elements)

- No measurable change of the workpiece surface in the main hole

- Patented tool system

- Rotating tool with movable cutting edges

CROSS-HOLE BRUSHES

-

FEATURES OF THE CERAMIC CROSS-HOLE BRUSHES

The "Ceramic Cross-Hole Brush" can be used to efficiently deburr bores.

The "Ceramic Cross-Hole Brush Extra Long" is particularly suitable for slotted holes.A special feature that distinguishes the extra long fibre rods from the standard fibre rods is a guiding ring made of plastic, which is located underneath the brush head. This guiding ring stabilises the brush and prevents the tool from staggering.

MOUNTED POINTS WITH FLEXIBLE SHANK

-

ADVANTAGES TO A DEBURRING CUTTER

- Automated processing (previously time-consuming manual processing and fluctuating quality)

- Higher and lasting deburring quality without secondary burr formation

- Shorter machining times on CNC machines

- The flexible shank ensures soft and flexible contact with the workpiece, counteracts a possible risk of breakage and allows sensitive deburring without chattering when used manually

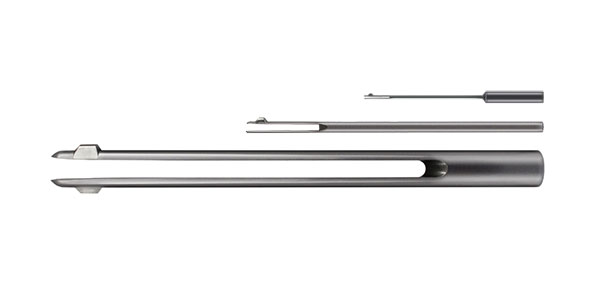

EXBURRDRILL - BURR MINIMAL DRILLING

-

MINIMUM BURR WITH MAXIMUM FEED

The new KEMPF solid carbide ExBurrDrill sets standards in the field of burr minimization - without compromising on feed.

We manufacture the KEMPF ExBurrDrill in special dimensions for your application

In order to achieve a burr-minimizing bore machining, we manufacture the KEMPF ExBurr Drill individually for your application. Taking into account the conditions on your component and the material, the tool geometry of the ExBurrDrill is designed in a parameterized manner.

PCD- & CBN-TOOLS

When it comes to tools for metalworking, KEMPF is exactly the right partner for you. Absolutely reliable, with almost 50 years of experience and a comprehensive program of high-quality tools. We look forward to your inquiry.

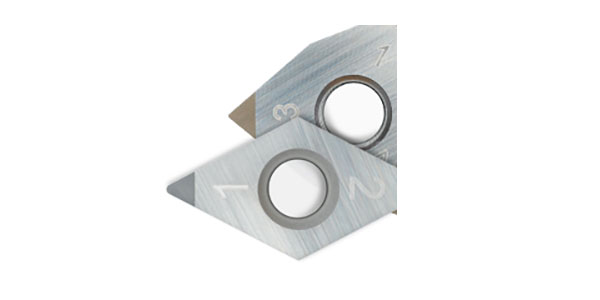

PCD-INDEXABLE INSERTS

- Materials containing titanium, hardened materials or superalloys are usually difficult to machine. PCD and CBN tools are designed precisely for these applications, as the extremely hard cutting materials can also cope with these metals. Whether in turning with our tipped inserts or in demanding drilling operations - we offer high-precision and durable tool solutions for this.

CBN-INDEXABLE INSERTS

Materials containing titanium, hardened materials or superalloys are usually difficult to machine. PCD and CBN tools are designed precisely for these applications, as the extremely hard cutting materials can also cope with these metals. Whether in turning with our tipped inserts or in demanding drilling operations - we offer high-precision and durable tool solutions for this.

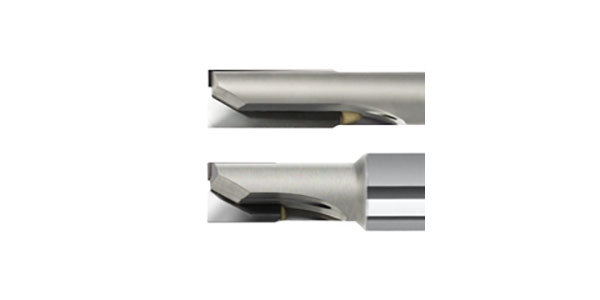

PCD SHANK CUTTERS

-

Materials containing titanium, hardened materials or superalloys are usually difficult to machine. PCD and CBN tools are designed precisely for these applications, as the extremely hard cutting materials can also cope with these metals. Whether in turning with our tipped inserts or in demanding drilling operations - we offer high-precision and durable tool solutions for this.

PCD DRILLS

DIAMOND TIPPED TOOLS

-

No matter which diamond cutting material is used - the advantage is obvious, in their hardness diamond cutting materials are far superior to all other cutting materials such as cutting ceramics, carbide and HSS. They are particularly suitable for the efficient and process-reliable machining of non-ferrous metals.

SOLID CARBIDE & HIGH PERFORMANCE DRILLS

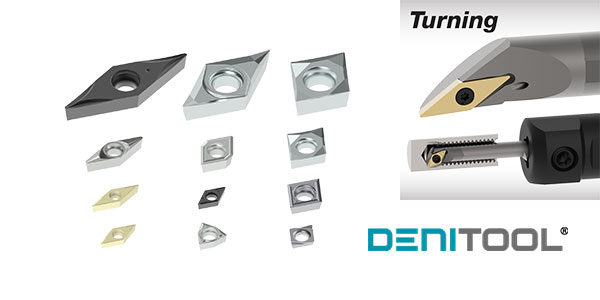

Even standard applications require first-class tools to achieve precise and consistent results. In our extensive range of drills and milling cutters, you are guaranteed to find the right tool for contour milling, high-speed drilling, finishing and roughing.TURNING & GROOVING TOOLS

Our turning and grooving systems are perfectly matched to each other and thus enable you to achieve precise and high-quality results with short machining times. With standardized indexable inserts and matching copy holders, coated inserts for difficult-to-machine materials or with special grooving blades with matching holders, we also have the right tool solution for your problem.

TURNING & GROOVING TOOLS DENITOOL

AUTOMATIC TURNING TOOLS & -BLANKS

MINI TURNING AND GROOVING SYSTEMS INTERNAL MACHINING

BURNISHING TOOLS

In order to compact surfaces, they must be rolled or flattened. Depending on the application, large surfaces or only very small bores have to be machined. We offer the right tool for each variant.