DIATEC

- Offer Profile

- DIATEC Diamond technology Llc. is a leading manufacturer of high-precision diamond tools. We would be delighted to offer you any information

Product Portfolio

Monocrystalline

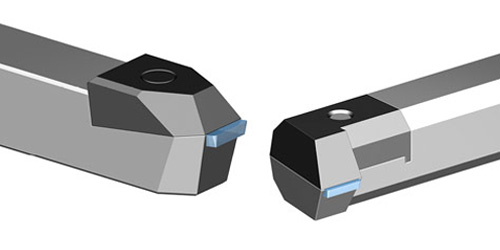

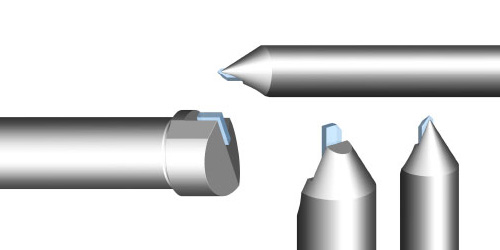

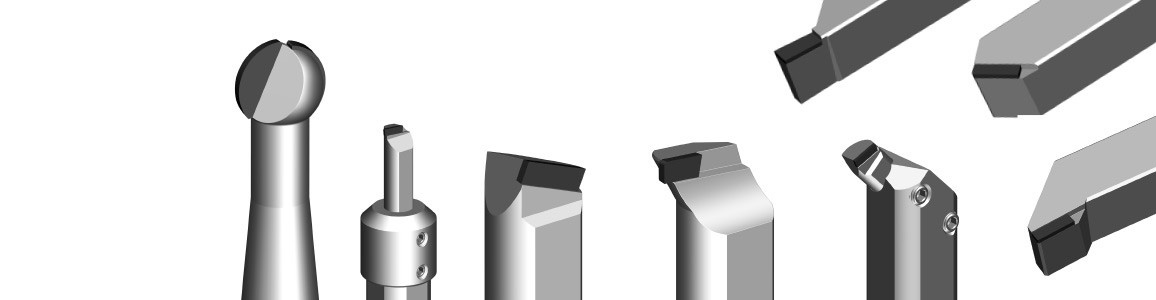

Turning tools - monocrystalline

Standart diamond turning tools for polish turning

Diamond turning tools for the optical industry

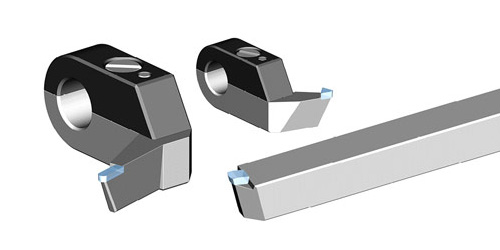

Fly cutting tools for the optical industry

Turning diamonds for manufacturing weeding rings

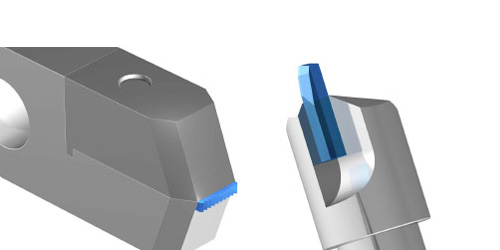

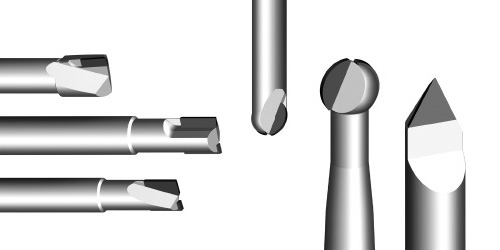

Standart diamond milling tools - monocrystalline

Standart outils de fraisage

Standart diamond milling tools for the watchmaking industry

Special designs

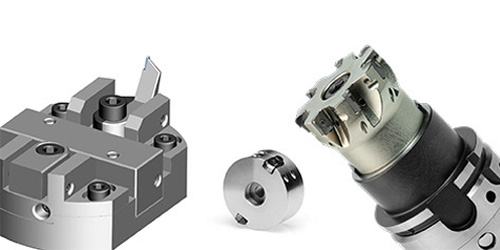

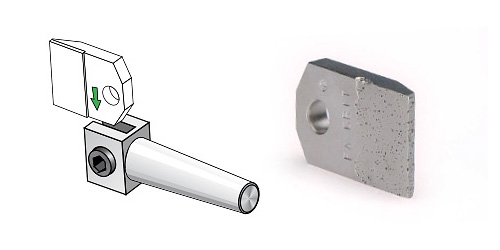

Tool holders

Milling heads

CVP-PCD-CBN

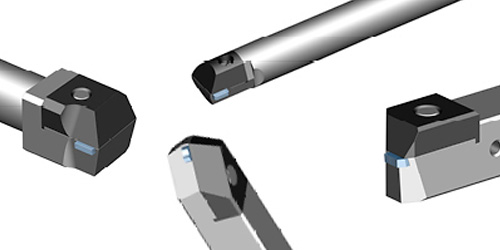

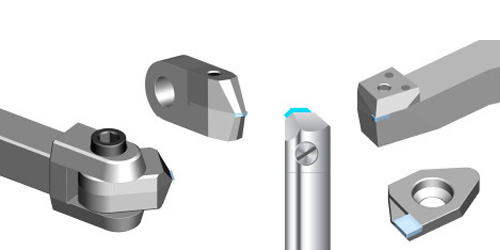

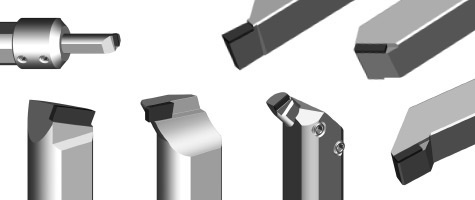

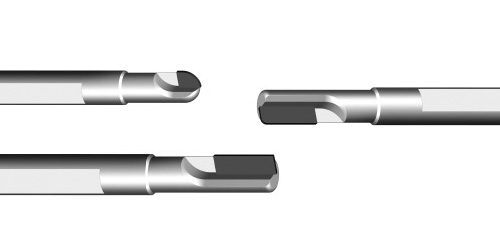

Turning tools - PCD, CVD, CBN

Shank type tools for internal machining

Custom products in PCD and CVD

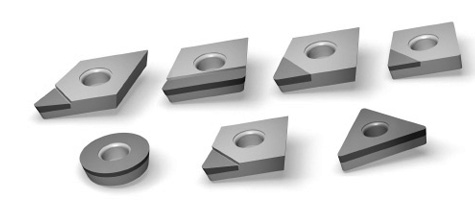

Indexable inserts in MCD, CVD, PCD, CBN

PCD and CVD diamond milling tools

Standard

CVD diamond milling tools

Dressing tools

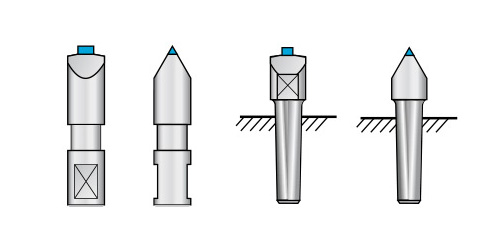

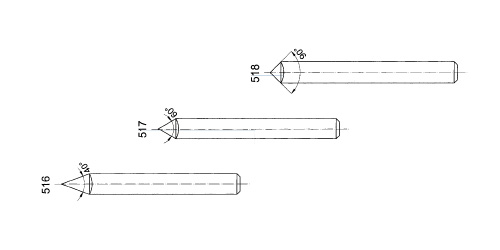

Single point diamond dressers

Single point throw-away diamond dressers

Single point diamond dressers

Shaping tools

Conical centered dressing diamonds

Cluster type dressers

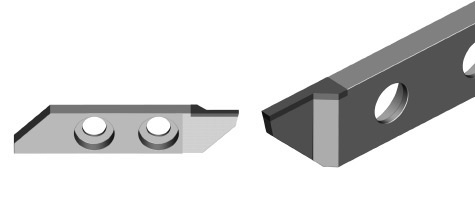

Multigrain diamonds - diamond inserts

Diamond dressing plates

Multipoint indexable crown

Diamond grit impregnated dressers

PCD/MCD dressers / Hand dressers

PCD/MCD dressers

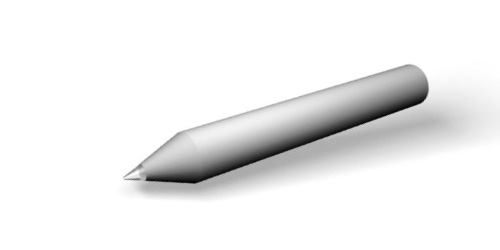

Hand dressers

Solid carbide

Solide carbide tools

-

By "carbide tools" we mean they are made of sintered tungsten carbide.

They are characterised by their resistance to wear and high level of hardness (especially at elevated temperatures). They are therefore used extensively in tools and parts for chip removal, chipless shaping and in applications involving abradant wear.

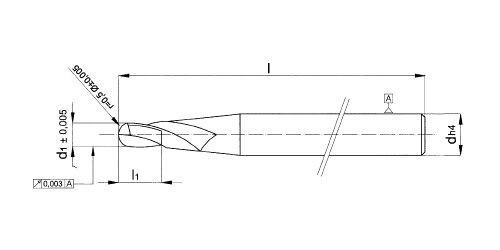

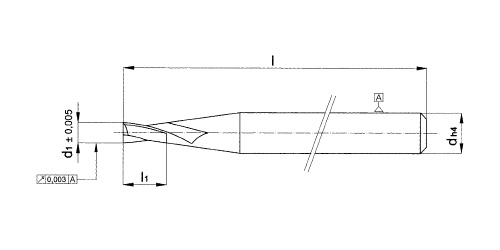

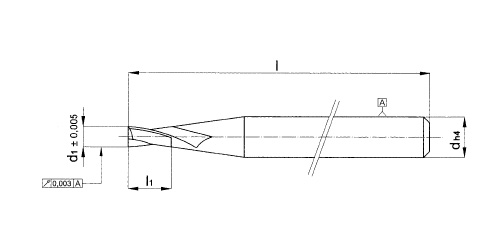

Solid carbide micro-radius cutters

Carbide micro-end mill cutters

Carbide micro-end mill cutters short version

Gravers

Technology

Introductionto the world of ultra-hard cutting materials

Cutting material groups

Selecting a cutting material: Description - Properties - Suitability

Cutting edge and selecting cutting edge geometry

General cutting data for milling turning

Selecting cutting data when turning

Selecting cutting data when milling

Flank wear of diamond cutting materials

Wiper geometries for high-performance chip removal

Chip breakers: geometries and cutting data

Production & Quality

Production

-

Manufacturing

Rough diamond cutting in Antwerp

Working with trained specialists, we have built up a diamond cutting facility using saws in the worldwide centre of the diamond trade.

YAG laser diamond cutting

Internal profiles and radii are shaped in advance using YAG laser cutters.

Diamond welding in a high vacuum

Diamonds can only be welded in a high vacuum kiln – a special process that we have put into practice with a high-tech system.

Cutting edges polished as smooth as glass

Our grinding machines which we developed and built ourselves are distinguished by their quiet running. Using them, we can achieve the finest, absolutely notch-free cutting edges.

Profiles and radii in the tight tolerance range

We are able to guarantee the tightest tolerances thanks to the precision grinding machines we have developed ourselves.

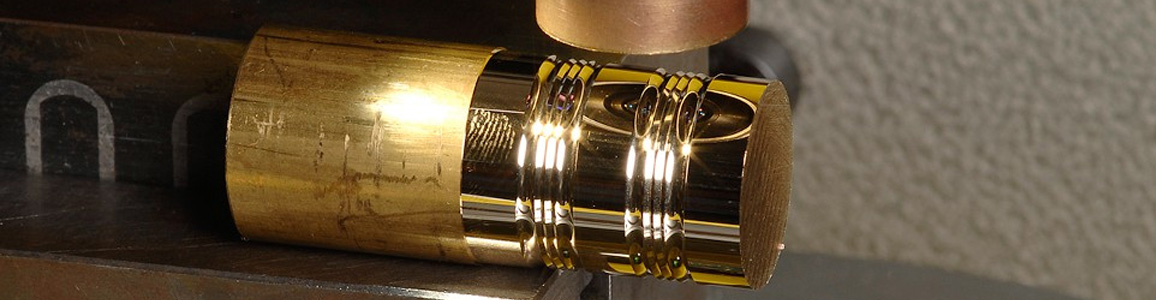

Manufacture of toolholders

We manufacture toolholders on modern CNC lathes and milling machines in our subsidiary company SDI GmbH.

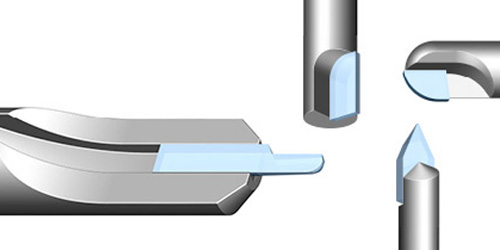

Fitting diamonds

The diamonds used in machining tools are pressed into a bed of silver solder and fixed with a clamping arrangement. Only a precision-machined fitting perfectly matching the dimensions of the stone and the perfect mounting of the diamond in the bed of solder guarantee the vibration-free operation of the tool. Diamond holders are ground smooth on a surface grinding machine.

Quality

-

What can the customer expect of us?

Support in the development of appropriate tools

Most of these diamond tools are manufactured according to customer specifications using technical drawings. If the customer does not have a drawing, we would be pleased to produce a manufacturing drawing based on a sketch free of charge. We use Unigraphics CAD software to do this. We can use this to present tools in a 3D animation.

Selection of diamonds

We used only homogeneously crystallized rough diamonds.

Sufficient “sharpening reserve” in the holder

Frequent sharpening can only be guaranteed if most of the diamond is in the holder.

Profiles and radii in tight tolerance range thanks to in-house developed grinding machines

Thanks to precision grinding machines developed in-house

Cutting edges polished to a mirror finish

Thanks to the grinding machines we developed ourselves with optimal quiet running, we are able to achieve the finest, absolutely notch-free cutting edges.

Sharpening service

Valuable diamond tools have to be sharpened. The Meyco and Wirz sharpening service offers the following:

Examination of damaged tool cutting edges under the microscope

Preparing a quotation on request

Sharpening diamond cutting edges

Checking the fitting and holder

Practical testing in a lathe or milling machine

Checking all cutting angles and recording on file