- Offer Profile

- The worldwide reputation of Mägerle flat and profile grinding machines is long established. With their equally high removal capacity and machining precision, they are recognised on the market as top-class machines. They demonstrate their performance and versatility daily in demanding applications in the turbine industry, the automotive and aircraft industry, the hydraulics industry and the energy sector, as well as machine tools and toolmaking. All industries that make the highest demands in respect of mechanical, ergonomic and operational qualities.

MÄGERLE Grinding Machines

MFP - Grinding Centers

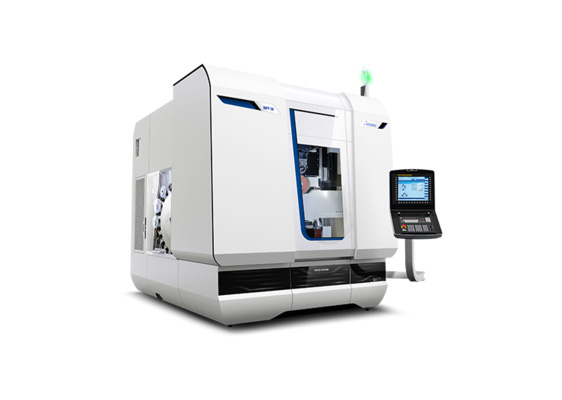

MFP 50

-

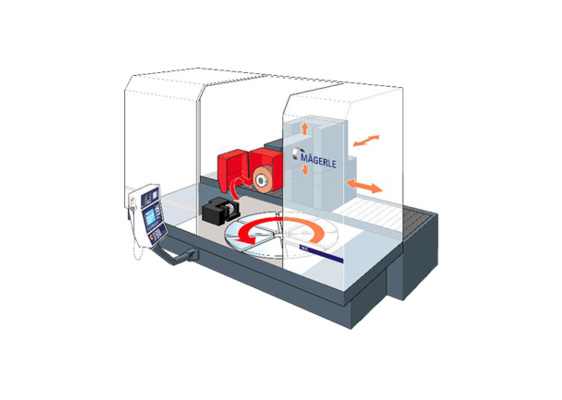

MFP 50 - 5-axes grinding centre with tool changer - The productive machine

Form when dealing with challenging workpieces. The high axis speed, minimal auxiliary times and quick tooling change make the MFP 50 one of the most productive machines of its kind.

Processes such as grinding, cutting and drilling can be achieved to absolute perfection in a single clamping. High productive benefit with simple operation are the result. The intelligent design principle takes production quality, safety and cost efficiency to a new level. The coolant nozzle, controllable via two axes, allows unrestricted freedom of movement and precise positioning of the coolant jet.

Spindle speeds of up to 10 000 revolutions per minute guarantee the highest machining precision.The grinding wheels are always mounted right at the front of the spindle, and the profile is changed through automatic positioning of the diamond rolls in the direction of the Z-axis. This allows a generous machining clearance, as collisions between wheel flange and workpiece are practically excluded.

In the MFP 50 the grinding wheel diameter is used to the maximum, resulting in significant cost savings.X-axis longitudinal stroke mm 500 Travel speed mm/min 0...20000 Y-axis vertical stroke mm 650 Travel speed mm/min 0...20000 Z-axis transverse stroke mm 650 Travel speed mm/min 0...20000 Grinding spindle drive - power max. kW 25 / 50 Rpm range max. rpm 0...10000 V-axis profile crushing device, roll width, max. mm 217 Tool changer positions - grinding wheels n/Pos 8 / 16 Tool changer positions - measuring probe, drill n/Pos 12 / 24 Tool length max. mm 200 Grinding wheel dimensions (Ø-external x W x Ø-bore) mm 300 x 60 x 76.2 Tool holding fixture HSKB-80 dividing device Swivel axes n / Axes 2 / 3 Grinding wheel peripheral speed m/s 35 - with key-operated switch switchable to m/s 50 - with additional flange monitoring switchable up to m/s 63

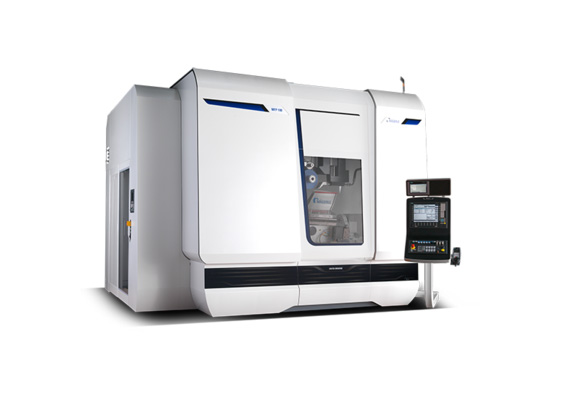

MFP 100

-

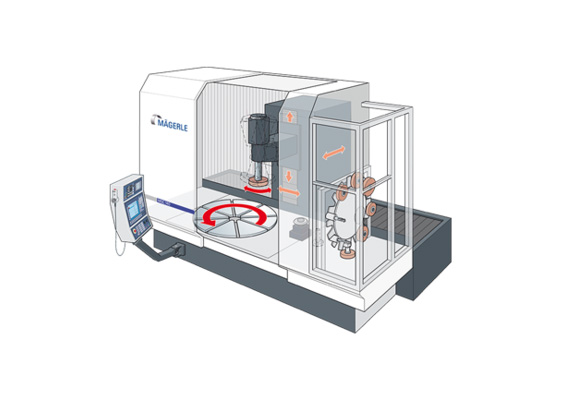

Mägerle MFP 100 - Universally usable, highly-productive grinding centre

With the MFP 100, Mägerle AG Maschinenfabrik has expanded the MFP series with a particularly flexible grinding centre. The new grinding centre is characterised by its high working speed, quick tool change and its expandable tool changer.

Variety in one clamping operation

Mägerle has specially designed the MFP 100 for those markets where multi-face machining of heavy and complex workpieces in just a single clamping operation is demanded. With 50 kW spindle power and a generously designed working area, the new Mägerle grinding centre is ideally suited for processing turbine guide and rotor blades as well as heat shields for use in the aviation and energy industry. The Mägerle MFP 100 is supplied with a dual-axis NC combination as standard. The grinding centre can also be optionally upgraded to a tri-axis system.

Short tool change cycles

The superior tool and lapping roll changer system is an outstanding feature of the MFP 100. The dual gripper changes grinding wheels and associated diamond contour rolls simultaneously - thus resulting in a noticeable reduction in downtime. The accelerated tool change cycles are accompanied by markedly increased axis dynamics. The overall increase in productivity achieved with the new MFP 100 grinding centre results in a significant reduction in unit costs.

Up to 60 tool stations

The MFP 100 tool changer is scalable. The standard version of the tool changer can be equipped with up to 30 tool holders. It can optionally be increased to up to 60 tool stations. The MFP 100 tool management system is also generously designed and can manage up to 500 different tools. In addition to 300 mm diameter grinding wheels and corresponding 160 mm diameter diamond contour rolls, it is possible to load the tool changer with tools such as drills, milling cutters, CBN wheels or measuring sensors.

Compact and ergonomic

In spite of its performance characteristics, the MFP 100's compact design is sure to impress. With a width of 4.6 m width and a depth of 4 m, the footprint for a grinding machine of this category is incredibly small. The NC table can be conveniently loaded from above and from the front, manually, with a crane or with a robot. The simple access opening on the rear for scheduled and preventive maintenance supports the outstanding ergonomic design of the new Mägerle grinding centre.X-axis longitudinal stroke mm 1000 Travel speed mm/min 0...40000 Y-axis vertical stroke mm 900 Travel speed mm/min 0...30000 Z-axis transverse stroke mm 750 Travel speed mm/min 0...30000 Grinding spindle drive - power max. kW 50 Rpm range max. min-1 0...10000 V-axis profile crushing device, roll width, max. mm 100 Tool changer positions - grinding wheels n/Pos 30 / 60 Grinding wheel dimensions (Ø-external x W x Ø-bore) mm 300 x 100 x 76,2 Tool holding fixture HSKB-80 dividing device HSK-B80 Indexer swivel axes n / Axes 2 / 3 Grinding wheel peripheral speed m/s 35 /50 / 63 Overhead dresser roll for CD / IPD / HSD 2 quick-clamping spindles HSK-B80 integrated swivel single side dresser roll Measuring system wiht feeler Controll - Siemens Sinumerik 840D SL

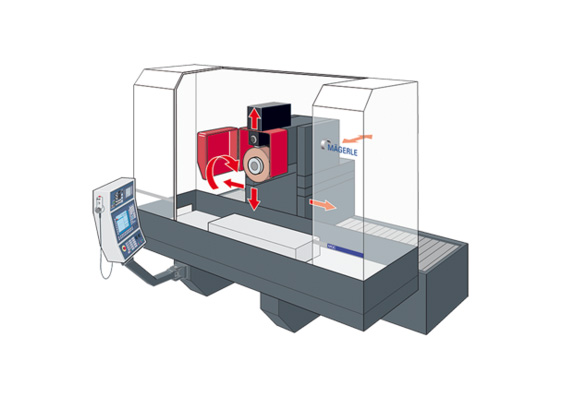

MFP - Surface and profile grinding machine

MFP

-

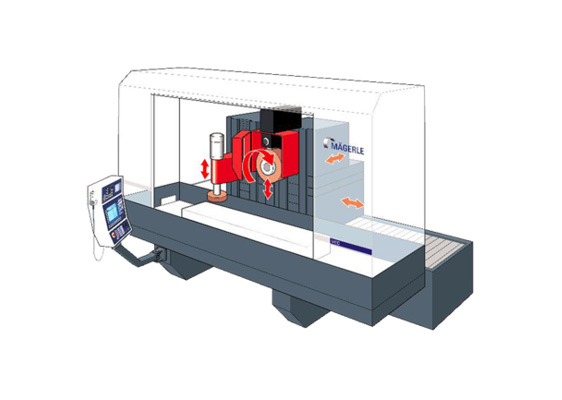

Mägerle MFP series – The long-distance machine

With the MFP series, Mägerle comprehensively covers the requirements for flat and profile grinding machines. These machines specialise in creep feed grinding as well as profile and flat grinding operations using the pendulum method. They demonstrate their full performance potential in applications where workpieces must be produced in large batches and with high stock removal volumes in the customary high Mägerle precision. Thanks to their robust construction, the machines in the MFP series also master these requirements in hard 24/7 continuous operation. The Mägerle MFP series has a modular design. Table lengths and vertical strokes across a large range can be freely combined with different additional axes and special components. This flexible modular system enables diverse machine configurations, which are precisely geared to the specific user requirementsX-axis longitudinal stroke mm 800 ... 2600 Travel speed mm/min 0...30000 Y-axis vertical stroke mm 450 ... 750 Travel speed mm/min 0...10000* Z-axis transverse stroke mm 350 ... 900 Travel speed mm/min 0...10000* V-axis profile crushing device, roll width, max. mm 167 ...307 Roll diameter max. mm 160 Roll drive AC drive max. rpm 6000 Grinding spindle drive - power kW 25/50/75/115** Rpm range rpm 5000 (8000) Grinding wheel peripheral speed m/s 35 - with key-operated switch switchable to m/s 50 - with additional flange monitoring switchable up to m/s 63 Grinding wheels - diameter mm 400 ... 600 Grinding wheels - width mm 160 ... 300 * optionally m/min 20 ** max. spindle power is dependent on size

MGC - Workpiece carrier

MGC-FT

-

Mägerle MGC with stationary workpiece carrier – The heavy worker

The MGC grinding centre with stationary table is designed for the high-precision processing of large and heavy workpieces. With a broad range of different table sizes and vertical strokes, this machine meets the highest requirements in respect of load bearing capacity. Like all models in the MGC series, this grinding centre is also based on the proven modular concept. Thanks to its variety of configurations with one or several spindles in a horizontal or vertical arrangement as well as a multitude of additional components, the MGC with fixed console is also one of the front-runners in its category with regard to flexibility.

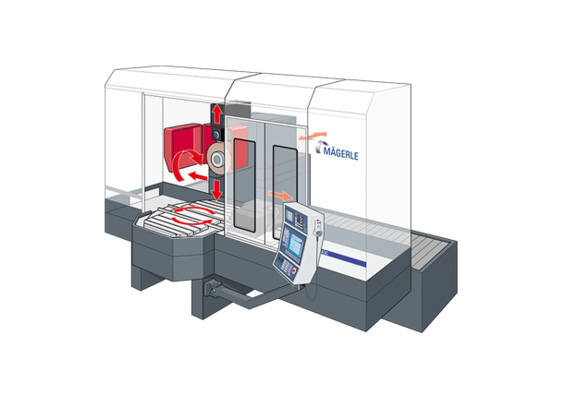

MGC-ST

-

Mägerle MGC with swivelling table – The open solution

Like its sister systems in the MFP series, the Mägerle Grinding Center delivers superb results for creep feed grinding with high removal capacities as well as for profile and flat grinding. In its swivelling table version, the MGC is also designed with the maximum ejection capacity. The 180° swivelling table allows loading and unloading of workpieces while machining is in operation. Non-productive times for workpiece change are thus largely eliminated. This results in maximum productivity for small and large batches, as well as in special applications. The MGC with swivelling table, in conjunction with the automatic loading and unloading system, frees up additional reserves. The openly accessible swivelling table also provides the ideal interface.

MGC-RH

-

Mägerle MGC with rotary table – The specialist

With table diameters of up to 2.5 metres and a maximum load bearing capacity of 12 tons, the MGC rotary table grinding centre is unequalled throughout the world. Well-known companies in the power turbine industry rely on this powerful concept. This grinding centre is unrivalled particularly when it comes to machining turbine blades with Hirth gears and Curvic couplings of the highest quality. The direct-drive rotary table mounted on hydrostatic bearings ensures the necessary precision, with a positioning accuracy of less than three angular seconds.

MGC-RV

-

Mägerle MGC with vertical spindle and rotary table – The versatile machine

Versatility with the highest production quality level is the outstanding strength of this vertical grinding machine. It demonstrates its capabilities particularly in the manufacture of bearing rings, where optimum runout characteristics are required for maximum smooth running. Equipped with rotary table and fully automatic tool changer, this vertical grinding machine can master other functions in addition to grinding. Whether turning, milling, drilling, reaming or boring, this system delivers the same impressive results. The vertically arranged spindle swivelling in the range of ± 50° offers plenty of space for machining a wide variety of workpieces. An interchangeable spindle measuring probe guarantees that each individual workpiece is machined in a single clamping with consistently high perfection.

MGC - Special Class

MGC-SPEZ

-

Mägerle special grinding centres – Special Class

The standardised Mägerle modular concept can be freely configured to provide individual solutions. Grinding centres which are completely tailored to specific customer requirements are developed within the scope of a proven product range. Single and multiple spindle systems with a horizontal or vertical arrangement can be combined as desired with stationary workpiece carriers, swivelling table or rotary table, in any dimensions. The result in all cases is a made-to-measure tool which fulfils the high requirements on manufacturing quality in the automotive, aviation and hydraulic sectors, in turbine construction and mechanical engineering, as well as in the roller bearing and tool industry, with optimal cost effectiveness.