MIKROSA

- Offer Profile

- The name MIKROSA is synonymous with centerless grinding machines in the premium range with the German seal of quality. Throughout our one hundred year-old company history we have developed ideas and innovations which now make extra fine grinding possible at the limit of the measurable range.

Product Portfolio

MIKROSA Grinding Machines

- This is what the MIKROSA brand represents:

- Technology - and market leader in centerless grinding

- Large application range: From small needles through to heavy railway axles

- Maximum precision with grinding accuracies in the 0.1 micrometer range

- Machines based on our modular system for individual, workpiece-oriented machine applications to suit customer requirements

- Precision plunge cut grinding in many variations and highly productive throughfeed grinding with optimum quality

- Standardised automation solutions

- Intelligent software solutions for optimum grinding results

- Inhouse technology centre for grinding tests (enabling optimum adaptation of processes and grinding technologies to customer requirements)

- More than 50 branches and service agents worldwide

- Commissioning and machine training on site

- HelpLine, remote service and field service for maintenance with system

- Inhouse measuring laboratory and test specialists guarantee highest quality and precision

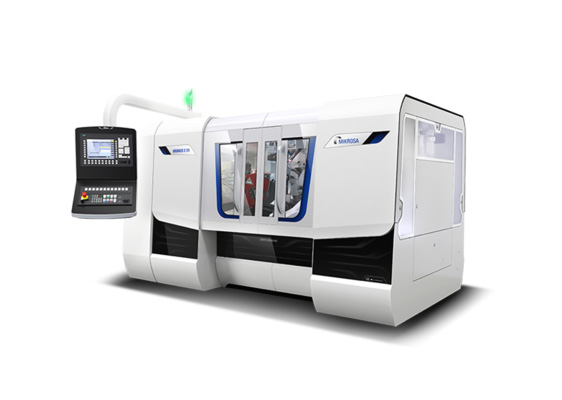

KRONOS S

- Precision and productivity - The KRONOS S is synonymous with leading accuracies in centerless grinding of small workpieces with plunge cut lengths up to 245 mm.

KRONOS S 125

-

High-precision and cost-effective

The KRONOS S 125 offers maximum precision for small workpieces. The compact, versatile centerless grinding machine combines speed with top quality.

Machine description:- Working range 0.5...30 mm, plunge length up to 120 mm

- Highest values in cycle time and cost effectiveness

- Short set-up and changeover times

- Thermally stable, vibration-damping GRANITAN® machine bed

- Cross-slide systems for grinding and regulating wheels

- Grinding spindles mounted on hybrid bearings for max. 120 m/s

- Exact reproducibility of grinding results, even in tolerance ranges of ±0.5 µm

- Designed for mass production

- Highest safety standard thanks to full enclosure

- Maintenance and service friendly SIEMENS Sinumeric 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- 15° inclined plunge cut grinding

- Plunge cut grinding in mass production

- Oscillation grinding

- Grinding of multiple operations in a single cycle

KRONOS S 250

-

High performance meets precision

The KRONOS S 250 is designed for plunge cut and throughfeed grinding of workpieces in the diameter range of 1.5 to 35 mm and with a plunge cut width up to 245 mm. The perfect machine for the mass production of small precision workpieces.

Machine description:- Working range 1.5...35 mm, plunge cut length up to 245 mm

- Highest values in cycle time and cost effectiveness

- Short set-up and changeover times

- Thermally stable, vibration-damping GRANITAN® machine bed

- Cross-slide systems for grinding and regulating wheels

- Grinding spindles mounted on hybrid bearings for max. 150 m/s

- Exact reproducibility of grinding results, even in tolerance ranges of ±0.5 µm

- Designed for mass production

- Highest safety standard thanks to full enclosure

- Maintenance and service friendly SIEMENS SINUMERIK 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- 6° inclined plunge cut grinding

- Plunge cut grinding in mass production

- Oscillation grinding

- Grinding of multiple operations in one cycle by offsetting the workpiece or grinding spindle

KRONOS M

- Flexibility and precision at the highest level - The KRONOS M offers the optimum adaptation to any grinding task with plunge cut lengths up to 395 mm.

KRONOS M 250

-

Modular and flexible

The KRONOS M 250 enables optimum adaptation to any grinding task. Thanks to its impressive system rigidity, the centerless precision grinding machine is the ideal solution for manufacturing workpieces of the highest quality.

Machine description:- Working range 1.5...100 mm, plunge cut length up to 245 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- High system rigidity thanks to regulating spindles supported on both sides and rigidly designed slide systems

- Overhung grinding spindles

- Grinding spindles mounted on hydrodynamic bearings (optional)

- Designed for mass production

- High cost effectiveness thanks to reduced cycle times

- Optionally extendable if application requirements change

- Highest safety standard thanks to full housing

- Maintenance and service friendly SIEMENS SINUMERIK 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- Plunge cut grinding in mass production

- Surface grinding (grinding spindles mounted on hydrodynamic bearings)

KRONOS M 400

-

Flexible and individual

The KRONOS M 400 combines precision and highest productivity in a single machine. Its modular design enables optimum adaptation to the respective grinding task, whether in throughfeed or plunge cut grinding.

Machine description:- Working range 1.5...100 mm, plunge cut length up to 395 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- High system rigidity thanks to grinding and regulating spindles supported on both sides and rigidly designed slide systems

- Grinding spindles mounted on hydrodynamic bearings for max. 63 m/s (optional)

- Designed for mass production

- High cost effectiveness thanks to reduced cycle times

- Optionally extendable if application requirements change

- Highest safety standard thanks to full enclosure

- Maintenance and service friendly SIEMENS SINUMERIK 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- Plunge cut grinding in mass production

KRONOS L

- Precision for large workpieces - The KRONOS L was specially designed for the processing of large, heavy workpieces and stands out due to short set-up times.

KRONOS L 550

-

Strong for medium-sized workpieces

The KRONOS L 550 is perfect for the machining of medium-sized to large workpieces. The centerless grinding machine combines highest grinding quality with impressive productivity.

Machine description:- Working range 5...250 mm, plunge length up to 545 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- Slide systems for grinding and regulating wheel side

- Short set-up times thanks to modular dressing system

- Designed for mass production

- User-specific software for all centerless grinding requirements

- Highest safety standard thanks to full enclosure

- Maintenance and service friendly SIEMENS SINUMERIK 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- Plunge cut grinding in mass production

KRONOS L 660

-

Strong and dynamic

The KRONOS L 660 offers high performance for machining large workpieces. The centerless grinding machine combines cost-cutting production advantages with the highest grinding quality.

Machine description:- Working range 5...250 mm, plunge length up to 655 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- Slide systems for grinding and regulating wheel side

- CBN-capable up to 120 m/s

- Hydrodynamic grinding and regulating spindles

- Short set-up times thanks to modular dressing system

- Designed for mass production

- User-specific software for all centerless grinding requirements

- Highest safety standard thanks to full enclosure

- Maintenance and service friendly SIEMENS SINUMERIK 840D sl control system

Possible technologies:- Plunge cut grinding

- Throughfeed grinding

- Plunge cut grinding in mass production

Special Machines

- Tailor-made grinding solutions - Our speical machines are the experts for special grinding tasks. As always with MIKROSA, the custumer application defines the solution.

KRONOS K

-

Purpuse-build for taper rollers

The KRONOS K is the optimum solution for external grinding of taper rollers in throughfeed grinding operations. Based on the KRONOS M 400, an infeed screw adapted to the workpiece dimensions is used instead of the regulating wheel.

Machine description:- Special grinding machine for taper rollers

- Working range 4.5.. 35 mm, grinding wheel width of 400 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- Regulating wheel is replaced by infeed screw, which is aligned to the workpiece dimensions

- High system rigidity as infeed screw and grinding spindle are supported on both sides

- Modular dressing system

- SIEMENS SINUMERIK 840D sl control system

Possible technologies:- External grinding in throughfeed grinding operations

KRONOS dual

-

Between centers and centerless

Through the combination of centerless grinding and grinding between centers, the KRONOS dual preserves the workpiece center during centerless grinding. The perfect solution for machining workpieces that must retain a reference to the centring device after centerless grinding.

Machine description:- Combination of centerless grinding and grinding between centers

- Working range 15... 100 mm, plunge cut length up to 630 mm

- Thermally stable, vibration-damping GRANITAN® machine bed

- Shorter machining times thanks to higher stock removal rates

- Preservation of workpiece center

- Much shorter machining times with higher grinding accuracy in comparison with pure grinding between centers

- Max. regulating wheel lowering of 30 mm

- Complete machine concept based on the proven KRONOS L 660

- SIEMENS SINUMERIK 840D sl control system