- Offer Profile

- STUDER – Know-how and capabilities

The name STUDER is synonymous with hardware, software, system integration and service in top Swiss quality. With a complete customized solution for every grinding task, the customer also benefits from our knowledge and expertise in relation to the grinding process. The STUDER logo has long been considered a seal of quality for first-class results worldwide. We will also ensure that The Art of Grinding remains closely associated with our name in the future.

STUDER high-precision cylindrical grinding

Conventional

- The conventional electrical and hydraulic Universal Cylindrical Grinding Machines are still favoured for many grinding tasks.

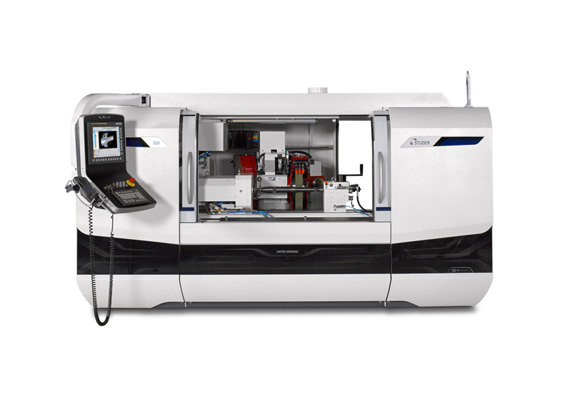

S20

-

The Compact for small precision components.

The S20 is designed for grinding medium-sized workpieces in individual and batch production. It is suitable for use in any industry where precise small components are manufactured. Operation is very simple and the machine can be reset very quickly.- Centre height 100 mm, distance between centres 400 or 650 mm

- Cross slide with wheelhead for external grinding with grinding wheel right and a mounting position for an internal grinding attachment

- Wheelhead can be manually swivelled to 15° and 30°

- Automatic grinding cycles for plunge and traverse grinding

- Machine table with swivel range of 15° and 30° depending on centre distance

- Partial enclosure

- Large range of accessories

S30

-

The Classical for medium-sized precision components.

The S30 is designed for grinding workpieces in individual and small batch production. It is suitable for use in any industry where precise medium-sized workpieces are manufactured. Operation is very simple and the machine can be reset very quickly.- Distance between centres 650 or 1000 mm

- Centre height 125 / 175 / 225 mm

- Swivelling turret wheelhead (for external and internal grinding)

- Automatic grinding cycles for plunge and traverse grinding

- Swivelling machine table

- Partial enclosure

- Granitan machine bed

- Large range of accessories

Universal

- The modular platform covers all the customer needs from the simple machine to the complex grinding systems.

S41

-

The Allrounder for complex grinding jobs

The S41 is a CNC universal cylindrical grinding machine of the latest generation. It boasts many technical features, such as the revolutionary StuderGuide® guideway system, high-precision axis drives with linear motors, extremely fast direct drive of the B-axis, an even larger selection of grinding head variants, and so on.- Centre height 225 / 275 mm

- Distance between centres 1000 / 1600mm

- Max. workpiece weight between centres 250 kg

- Speed of X- and Z-axis 0.001 – 20 000 mm/min

- StuderGuide® guide system with linear drive

- Turret wheelhead with direct drive and 0.00005° resolution, complete machining with up to four grinding wheels

- C axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan mineral-casting S103 machine base

- Very simple operation and programming thanks to StuderWIN

- StuderGRIND programming software for the creation of grinding and dressing programs directly on the machine control or on an external PC

- Reduced setup and resetting times with Studer Quick-Set

- Standardized interfaces for loader and peripheral devices

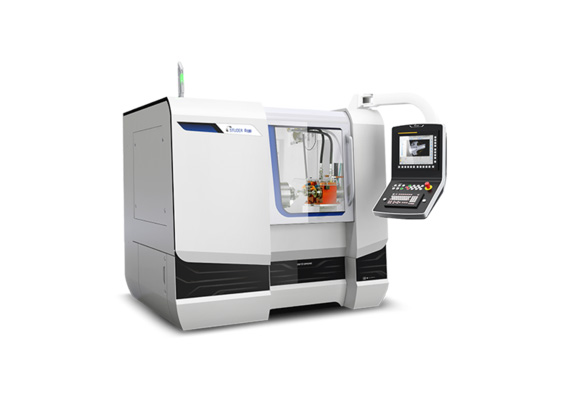

S21

-

The Greatest for small workpieces.

The S21 is designed for grinding workpieces in individual, small batch and high volume production. It can be automated and is especially suitable for grinding high-precision workpieces like those required in the aerospace, precision mechanics and hydraulics/pneumatic industries.- Centre height 125 mm, distance between centres 400 mm

- Turret wheelhead swivelling manually or automatically

- High-resolution B-axis

- Frequency-controlled motor grinding spindle for external and internal grinding

- C axis for the workhead for form and thread grinding

- Workhead for universal use for live spindle grinding and for grinding between centres (option: workhead especially designed for grinding chuck components)

- Full enclosure with two sliding doors

- Granitan machine bed

- Large range of accessories

- Standardized interface for loader and peripheral devices

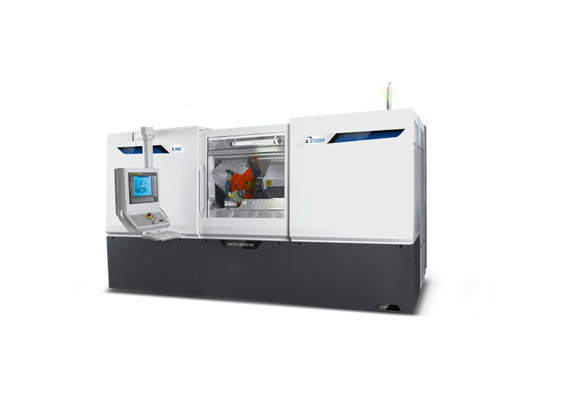

S31

-

The Versatile for big tasks.

The S31 is designed for grinding workpieces in individual, small batch and high volume production. It can be fitted with automation, and thanks to its universality, is especially suitable for use in the toolmaking and aerospace industries.- Centre height 175 mm, distance between centres 650 or 1000 mm

- Turret wheelhead swivelling manually or automatically

- High-resolution B-axis

- Frequency-controlled motor grinding spindle for external and internal grinding

- C axis for the workhead for form and thread grinding

- Several workhead variants are available for different grinding tasks

- Full enclosure with two sliding doors

- Granitan machine bed

- Large range of accessories

S33

-

The reasonably priced for individual requirements

The S33 is designed for grinding medium-sized workpieces in individual and batch production. It can be fitted with automation and is especially suitable for use in the toolmaking and precision engineering sectors. This is made possible by a new wheelhead with two motor spindles for external grinding and an internal grinding attachment. Three grinding wheels ensure that the workpiece can be machined even more individually and quickly - complete machining in a class of its own!- Distance between centres 650 or 1000 mm

- Fixed wheelhead adjustable to 0° or 30° for external grinding or turret wheelhead for external and internal grinding with Hirth manual swivel 2.5° or automatic swivel 1°

- Frequency converter with constant wheel speed for external grinding

- C-axis for the workhead for thread grinding

- Swivelling machine table for grinding cones

- Full enclosure with two sliding doors

- Granitan machine bed

- Standardized interface for loader and peripheral devices

- Large range of accessories

favoritCNC

-

The price hit for a large range of applications.

This CNC universal cylindrical grinding machine is designed for grinding medium-sized workpieces in individual and batch production. It can be easily retrofitted for other grinding tasks with various accessory kits such as in-process gauging, balancing system, contact detection and length positioning.- Distance between centres 650 mm / 1000 mm

- Centre height 175 mm

- Max. workpiece weight 80 kg

- Turret wheelhead with grinding wheel on the right and internal grinding attachment (optional) with manual swivel 2.5° Hirth

- External and internal grinding in a single clamping

- Granitan® S103 mineral-cast machine bed

- Extremely easy programming with STUDER Pictogramming

- StuderGRIND programming software (optional) for creating grinding and dressing programs on an external PC

ecoGrinder

-

The Simplified for complex demands.

This CNC universal cylindrical grinding machine is designed for grinding medium-sized workpieces in individual and serial production. With the various options, such as in-process gauging, balancing system, contact detection and length positioning, the machine can be adapted for other grinding applications at a later date.

The machine bed made of solid Granitan® S103 forms the basis of the cylindrical grinding machine, which is equipped with high-quality components and can therefore guarantee exacting precision, performance and reliability for years. The open enclosure ensures an optimal view of the grinding process and easiest accessability.

Attention: This machine is not CE-compliant and is therefore only available on the Asian market.- Distance between centers 650 mm

- Centre height 175 mm

- Max. workpiece weight 80 kg

- Turret wheelhead with grinding wheel on the right and internal grinding unit (optional) with manual swivel 2.5° Hirth

- External and internal grinding possible in one setup

- Granitan® mineral-casting S103 machine base

- Extremely easy programming with Studer Pictogramming

- StuderGRIND programming software optionally available to create grinding and dressing programs on an external computer

Production

- For large serie production STUDER supplies tailored solutions with optimized grinding cycles and high machine availability.

S11

-

The super-productive machine for small workpieces.

The S11 is a production machine, which is precisely tailored to the desired process. Highly dynamic axis drives, high-quality STUDER guideway systems, short reaction times and optimized traverses form the basis of the S11. The high-speed grinding option (HSG) contributes to increasing productivity with its peripheral speed of up to 140 m/s.

With a mounting area of less than 1.8 m2, it is extremely compact and will fit in any workshop.

Precision is the result of perfect interaction between a large number of different factors. The basis is the Granitan® S103 machine base with its excellent damping characteristics and favorable thermal behavior. The modules are ideally suited to each other and produced with customary STUDER precision.- Distance between centres 200 mm

- Height of centres 125 mm

- Grinding wheel diameter 500 mm

- Grinding wheel arrangement 0° or 20°

- Right grinding wheel Ø 500 x 63 x 203 mm

- Full enclosure with new door concept for optimal accessibility

- Dual axis cover (telescopic and bellows)

- Granitan® S103 mineral casting machine base

- PCT touchscreen (Projective Capacitive Touch)

- Easy programming with the new operator interface

- StuderWINfocus on the Sinumeric 840D SL

- Simple and clear process visualization

- Software optimized for touchscreen

- In-process gauging software integrated into the machine control

- StuderWIN programming software for producing grinding and dressing programs on a PC

S12

-

The Efficient for the highest tolerances.

The basic concept of the S12 has been uncompromisingly tailored to precision. At the heart of the machine is a brand new drive/guide system based on linear motors with high-precision positioning (patent pending). The extremely rigid guide tables, supported on hydrostatic bearings, are magnetically prestressed. The infeed movement can be programmed in 10-nanometer steps.- Precision: Infeed movements in 10-nanometer steps thanks to hydrostatic guides and linear motor technology.

- Dynamics: Infeed speed 30 m/s, axis accelerations up to 3 m/s

- Flexibility: Different dressing concepts, internal grinding spindle on separate cross slide, automatic part handling.

- Distance between centres: 150 mm

- Centre height: 175 mm

- Grinding wheel diameter: 500 mm

- Arrangement of X-axis: 0° or 30°

- Cross slide X: Hydrostatics with linear motors or anti-friction guideways with ball-type linear drives

- Longitudinal slide Z: Hydrostatics with linear motors or guideways with patented surface structure and ball-type linear drives

- C axis for the workhead

- Internal grinding unit on a separate cross slide

- Simultaneous internal/external machining possible

- Application-specific workhead concepts (hydrostatic, motor spindle)

- Additional NC axis for profiling the grinding wheel

- Full enclosure with new door concept for optimal accessibility

- Granitan S103 mineral-cast machine base

- Large range of accessories

- Easy programming thanks to StuderWIN on Siemens 840D

- StuderGRIND programming software for generating grinding and dressing programs on a PC

- Standardized interfaces for loader and peripheral devices

S22

-

The production platform for your individual grinding solution

The S22 is a production platform. It focuses on medium-sized customer workpieces in large-scale production. The aim is to be able to machine any workpiece on the S22 with a wide range of technologies: conventional cylindrical grinding in the production environment, form and thread grinding, high speed grinding (HSG) with cutting speeds between 80 and 140 m/s, or heavy-duty applications with 160mm wide grinding wheels.- Grinding length max. 800 mm

- Centre height 175 / 225 mm

- Diameter of grinding wheel up to 610 mm

- Granitan® S103 mineral-cast machine bed

- Cross slide X: Pretensioned hydrostatics with linear motor or anti-friction guideways with ball-type linear drive

- Longitudinal slide Z: Hydrostatics with linear motor or guideway with patented surface structure and ball-type linear drive

- C axis for the workhead

- Application-specific workhead concepts

- Additional NC axis for profiling the grinding wheel (diamond roll)

- Full enclosure with movable front panels for optimal accessibility

- Integrated loading unit or handling cells for loading and unloading from the left, right or from above

- Large range of accessories

- Easy programming with StuderWIN on Fanuc 310i -A

- StuderGRIND programming software for creating grinding and dressing programs

- Standardized interfaces for loader and peripheral devices

Combination

- For rational hard/fine machining STUDER offers a combination machine for an optimized processing.

S242

-

The Flexible Machine for grinding and turning operations.

The S242 combined machine tool ideally combines the technologies of cylindrical grinding and hard turning. Thanks to its design concept, it can easily cope with both processes. Consequently, it enables highly efficient hard fine machining of shafts and chucking components with a high manufacturing quality, production reliability and the desired surface quality in a single clamping. It is interesting not only for high-volume production but also for small batch sizes and single parts.- Distance between centres 400/800/1000 mm

- Swing diameter 180 mm

- Synchronous tailstock with selectable axial clamping pressure for workpiece drive definable for each workpiece in the workpiece program

- Multiple in-process gauging. Indivudual workpiece positions and diameters are stored in the workpiece program.

- Machine bed with inclined design (machining plane 45°) made from GRANITAN®

- Standardized interfaces for loader and peripheral devices

- Automated part handling system (option)

- Easy programming thanks to StuderWIN

- Full enclosure with sliding door

- The modular kit system enables customer-specific designs

- Large range of accessories

Internal

S110

-

The practical for your specific grinding task

The S110, a different very compact machine concept. The workpiece is moved on the cross-slide, while the grinding spindles are mounted in a fixed position to the base of the machine. This guarantees stability, offers good accessibility for set-up or workpiece change, and is easily automatable. The spindle set-up, with up to 3 HF grinding spindles in a linear arrangement, can be optimally designed to meet customer requirements. The ideal machine for chuck applications for individual components up to small-batch production. A cost-effective solution for high-precision automated grinding can be achieved with the optional, fully integrated automatic loading and unloading system.- Up to three HF grinding spindles in a linear arrangement

- Large selection of internal and external spindles (external wheel up to Ø 300mm)

- C axis for the workhead for form and thread grinding

- Manual A axis for precise thread grinding

- Compact and user-friendly

- Various dressing options

- Full enclosure with sliding door

- Integrated or autonomous loading systems

- Measuring probe

- SimCT offline simulation software

- Dovetailed work table for simple positioning of the grinding spindles (option)

- CNC-controlled Y-axis (vertical)

- Wide range of clamping devices and accessories

- Standardized interface for loader and peripheral devices

S120

-

The robust one for long workpieces.

The S120 is based on the same machine concept as the S110, but is designed for larger and longer workpieces. The spindle set-up, with up to 3 HF grinding spindles in a linear arrangement, can be optimally designed to meet customer requirements. The ideal grinding machine for internal, face, thread and taper grinding on long workpieces up to approx. 650mm in length, e.g. for the machining of the ends of machine spindles.- Up to three HF grinding spindles in a linear arrangement

- Large selection of internal and external spindles

- C axis for the workhead for form and thread grinding

- Manual A axis for precise thread grinding

- Various dressing options

- Full enclosure with sliding door

- Integrated or autonomous loading systems

- Measuring probe

- SimCT offline simulation software

- Large range of accessories

- Standardized interface for loader and peripheral devices

S131

-

The universal machine for diverse applications in internal grinding.

The S131 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

The workpiece length is 300 mm (11.8"), the maximum internal grinding length is 175 mm (6.9") and the external length is 125 mm (4.9"). The S131 is the ideal machine for grinding flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S131 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.- Swing diameter above the table 250 mm (9.8")

- Max. workpiece length 300 mm (11.8")

- Internal grinding length 175 mm (6.9")

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

S141

-

The universal machine for short and long workpieces

The S141 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

Three sizes are available for workpiece lengths of 300 mm, 700 mm and 1300 mm (11.8", 27.5" and 51.1"). For all models the maximum internal grinding length is 250 mm (9.8") and the external length is 150 mm (5.9"). The S141 is the ideal machine for grinding spindle shafts, spindle housings, rotor shafts, axes or flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S141 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.- Swing diameter above the table 400 mm (15.7")

- Max. workpiece length 300 / 700 / 1300 mm (11.8" / 27.5" / 51.1")

- Internal grinding length 250 mm (9.8")

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

S151

-

The universal machine for workpieces with a large diameter.

The S151 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

Two sizes are available for workpiece lengths 700 mm and 1300 mm (27.5" and 51.1"). For both models the maximum internal grinding length is 380 mm (14.9") and the external length is 150 mm (5.9"). The S151 is the ideal machine for grinding spindle shafts, spindle housings, rotor shafts, axes or flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S151 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.- Swing diameter above the table 550 mm (21.7")

- Max. workpiece length 700 / 1300 mm (27.5" / 51.1")

- Internal grinding length 380 mm (14.9")

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

CT730

-

The variable for extremely hard materials.

The CT730 is a very flexible internal cylindrical grinding machine with B-axis. It is especially designed for grinding small to medium-sized workpieces in very hard materials such as Tungsten carbide, ceramic or sapphire. The up to four HF grinding spindles in a linear arrangement (for internal or external machining), can be optimally configured to meet the customer requirements and adapted to suit the respective grinding application.- Up to four HF grinding spindles in a linear arrangement

- Work table with dovetail guide for simple positioning of the grinding spindles

- Large selection of internal and external spindles

- B-axis with automatic swiveling range of +60° / -91°

- C axis for the workhead for form and thread grinding

- CNC-controlled Y-axis (vertical)

- Full enclosure with sliding door

- Measuring probe

- SimCT offline simulation software

- Wide range of clamping devices and accessories

- Standardized interface for peripheral devices

CT750

-

The high-performance machine for radius grinding up to 90°

The CT750 radius grinding machine for the manufacture of small to medium-sized workpieces, particularly for very hard materials such as tungsten carbide, ceramic or sapphire, is equipped with a two-spindle turret. The CNC-controlled B-axis enables grinding of cones and radii up to 90° in polished surface quality using an oscillating grinding wheel. The number of radii that can be ground is not limited.- Spindle turret for two grinding spindles

- B-axis with automatic swivelling range of +60° / -91°

- C axis for the workhead for form and thread grinding

- Full enclosure with sliding door

- Measuring probe

- SimCT offline simulation software

- Wide range of clamping devices and accessories

- Standardized interface for peripheral devices

CT930

-

The productive for B-axis applications.

The CT930 is a very flexible internal cylindrical grinding machine with B-axis which is especially suitable for grinding complex, medium-sized workpieces in a single clamping. The up to three HF grinding spindles in a linear arrangement (for internal or external machining) can be adapted to suit the respective grinding application.- Up to three HF grinding spindles in a linear arrangement

- Large selection of internal and external spindles

- B-axis with automatic swiveling range of +60° / -91°

- C axis for the workhead for form and thread grinding

- CNC-controlled Y-axis (vertical)

- Full enclosure with sliding door

- Measuring probe

- Various dressing options

- Operator interface with HMI-SimCT simulation software

- Wide range of clamping devices and accessories

- Standardized interface for loader and peripheral devices

CT960

-

The allrounder for complex grinding jobs.

The CT960 is a high-end universal internal cylindrical grinding machine with a B-axis swiveling to 91° and a four-spindle turret. It is suitable for both general grinding tasks and particularly for grinding complex workpieces in toolmaking. The optimal stability and rigidity of the machine enable finish-grinding of workpieces in polished surface quality.- Spindle turret for 4 grinding spindles (four internal spindles or three internal and one external spindle)

- B-axis with automatic swiveling range of +60° / -91°

- C axis for the workhead for form and thread grinding

- Full enclosure with sliding door

- Measuring probe

- Various dressing options

- Manual A axis for precise thread grinding

- Operator interface with HMI-SimCT simulation software

- Wide range of clamping devices and accessories

- Standardised interface for loader and peripheral devices